Comprehensive Guide to Ryobi Jigsaw Parts Diagram

When it comes to maintaining and repairing power tools, having a clear understanding of their inner workings is essential. A well-structured representation of tool elements not only facilitates identification but also aids in troubleshooting common issues. Knowing how each component interacts can enhance efficiency and prolong the lifespan of your equipment.

Visual aids play a crucial role in this process, offering insights into the layout and functionality of individual parts. Whether you’re a seasoned craftsman or a weekend warrior, familiarizing yourself with these illustrations can empower you to undertake repairs confidently. The ability to pinpoint the right pieces makes a significant difference when it comes to restoration and upkeep.

Moreover, comprehending the arrangement of essential elements fosters a deeper appreciation for the craftsmanship behind your tools. This knowledge not only enhances your repair skills but also enriches your overall experience, transforming maintenance from a daunting task into a manageable one. Embracing this approach ensures that your tools remain in optimal condition, ready for any project that comes your way.

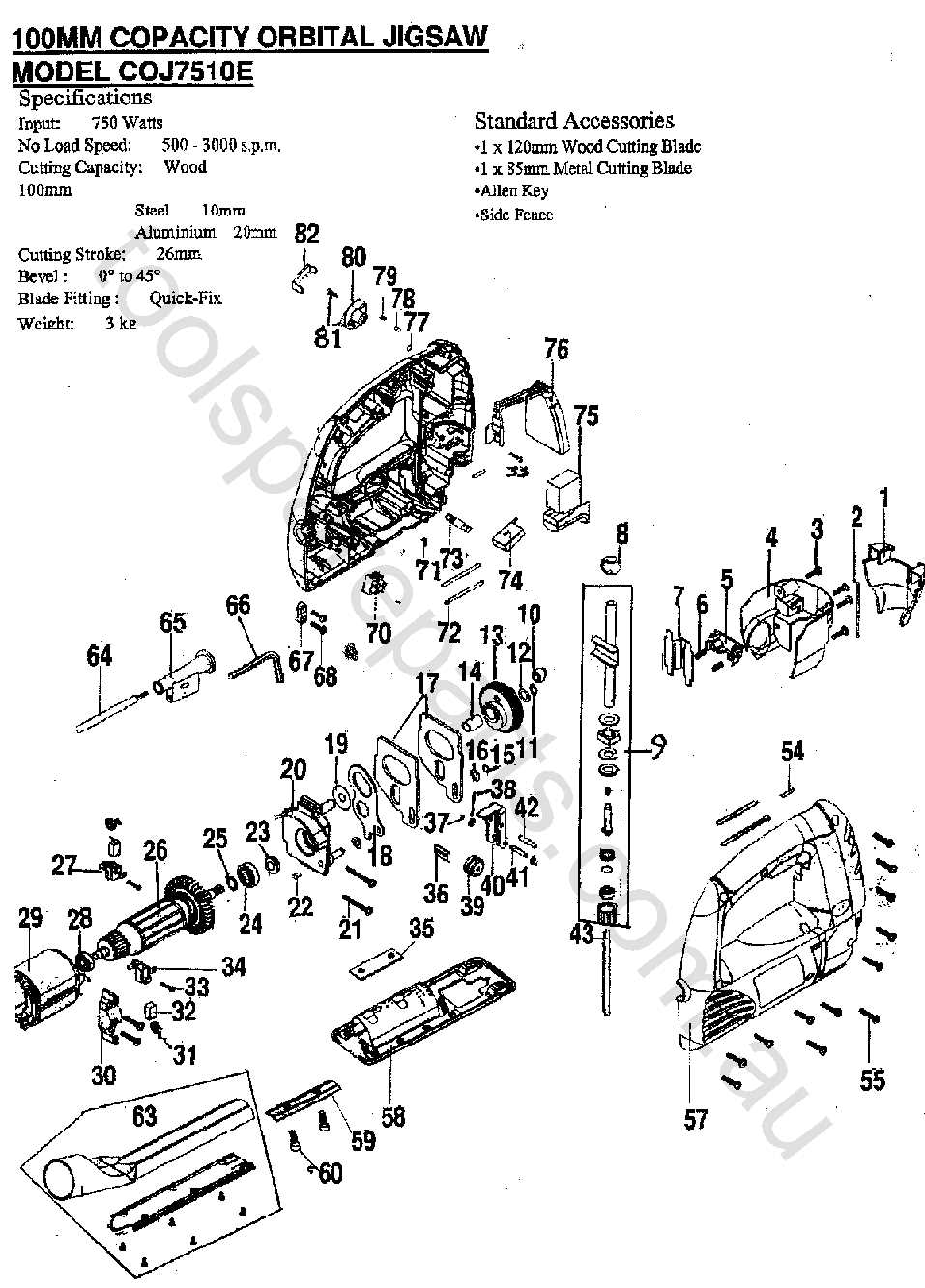

Understanding Ryobi Jigsaw Components

Grasping the various elements of a cutting tool can enhance both its usage and maintenance. Each component plays a vital role in ensuring smooth operation and achieving precise results. Familiarity with these individual parts not only aids in troubleshooting but also fosters a deeper appreciation for the craftsmanship involved in tool design.

Key Elements of the Tool

Among the essential components, the motor stands out as the powerhouse, driving the entire mechanism. Additionally, the cutting blade, designed for specific materials, is crucial for achieving desired finishes. The base plate, often adjustable, contributes to stability and precision during operation.

Importance of Maintenance

Regular upkeep of these components is imperative for longevity and efficiency. Cleaning the blade and ensuring it is securely attached can prevent accidents and enhance performance. Lubrication of moving parts can also reduce wear and tear, ensuring the tool remains in optimal condition for years to come.

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of tools and equipment. These illustrations provide users with an organized view of each element, making it easier to identify, locate, and understand the function of various pieces. This clarity enhances the efficiency of both novice and experienced individuals when working on machinery.

Facilitating Repairs

Having access to these visual guides simplifies the process of troubleshooting and fixing devices. When individuals can quickly pinpoint where specific elements are located, they can save time and reduce frustration. Furthermore, these images help in ensuring that the right parts are acquired when replacements are needed.

Enhancing Understanding

Beyond practical repair applications, these visuals also contribute to a deeper comprehension of how different components interact within a system. This knowledge is invaluable for anyone looking to improve their skills or expand their expertise in mechanical work.

| Benefit | Description |

|---|---|

| Time Efficiency | Reduces the time spent on locating and identifying components. |

| Accuracy in Repairs | Helps ensure the correct components are used during maintenance. |

| Skill Development | Enhances understanding of the device’s operation and parts interaction. |

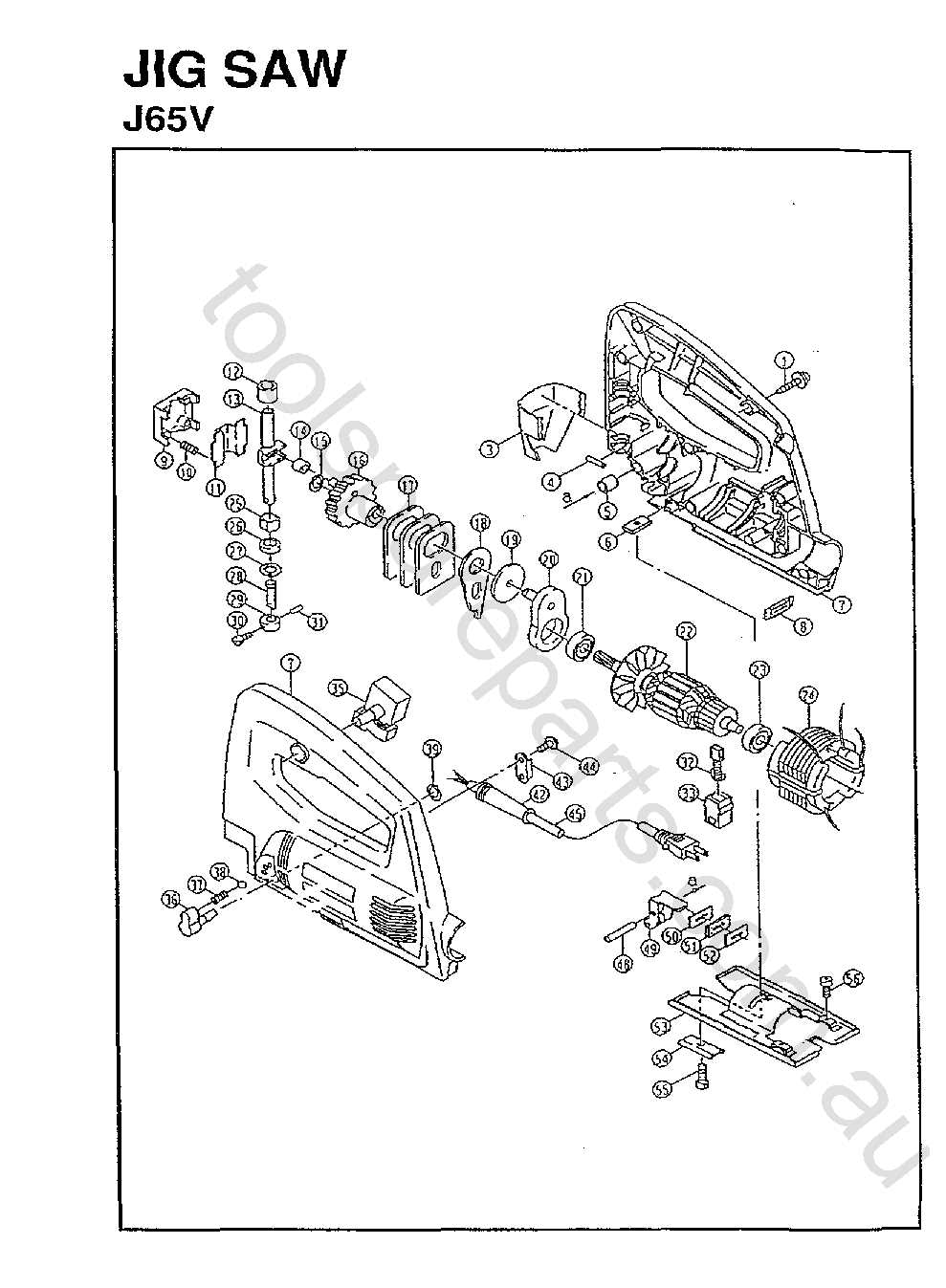

Identifying Key Jigsaw Parts

Understanding the essential components of a cutting tool is crucial for effective operation and maintenance. Each segment plays a vital role in ensuring that the device functions smoothly and efficiently, making it important to familiarize oneself with their characteristics and purposes.

| Component | Description |

|---|---|

| Base Plate | The flat surface that rests against the material being cut, providing stability and support. |

| Blade | The sharp element responsible for making cuts; available in various styles for different materials. |

| Handle | The part that the user grips, designed for comfort and control during operation. |

| Trigger | The mechanism that initiates the cutting action, allowing for speed regulation. |

| Dust Blower | A feature that clears debris from the cutting line, enhancing visibility and precision. |

By recognizing these vital elements, users can better appreciate how to operate and maintain their cutting tools, ensuring optimal performance in various projects.

Common Issues with Ryobi Jigsaws

Power tools often encounter a range of challenges during operation, affecting their performance and usability. Understanding these common problems can help users diagnose issues quickly and efficiently, ensuring that the equipment remains functional and reliable.

Performance Problems

One frequent concern involves the tool’s cutting ability. Users may notice that the blade does not move smoothly, leading to uneven cuts or stalling during operation. This issue can often be attributed to dull blades or incorrect installation. Regular maintenance and timely replacement of blades are essential to prevent this from occurring.

Electrical and Power Issues

Another prevalent problem is related to the electrical system. Users might experience difficulties with the device failing to start or sudden loss of power while in use. Such issues may arise from faulty cords, connections, or internal components. Ensuring all connections are secure and inspecting the power source can help mitigate these disruptions.

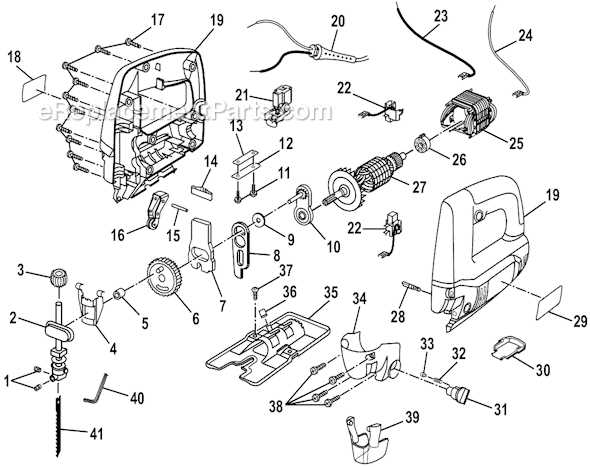

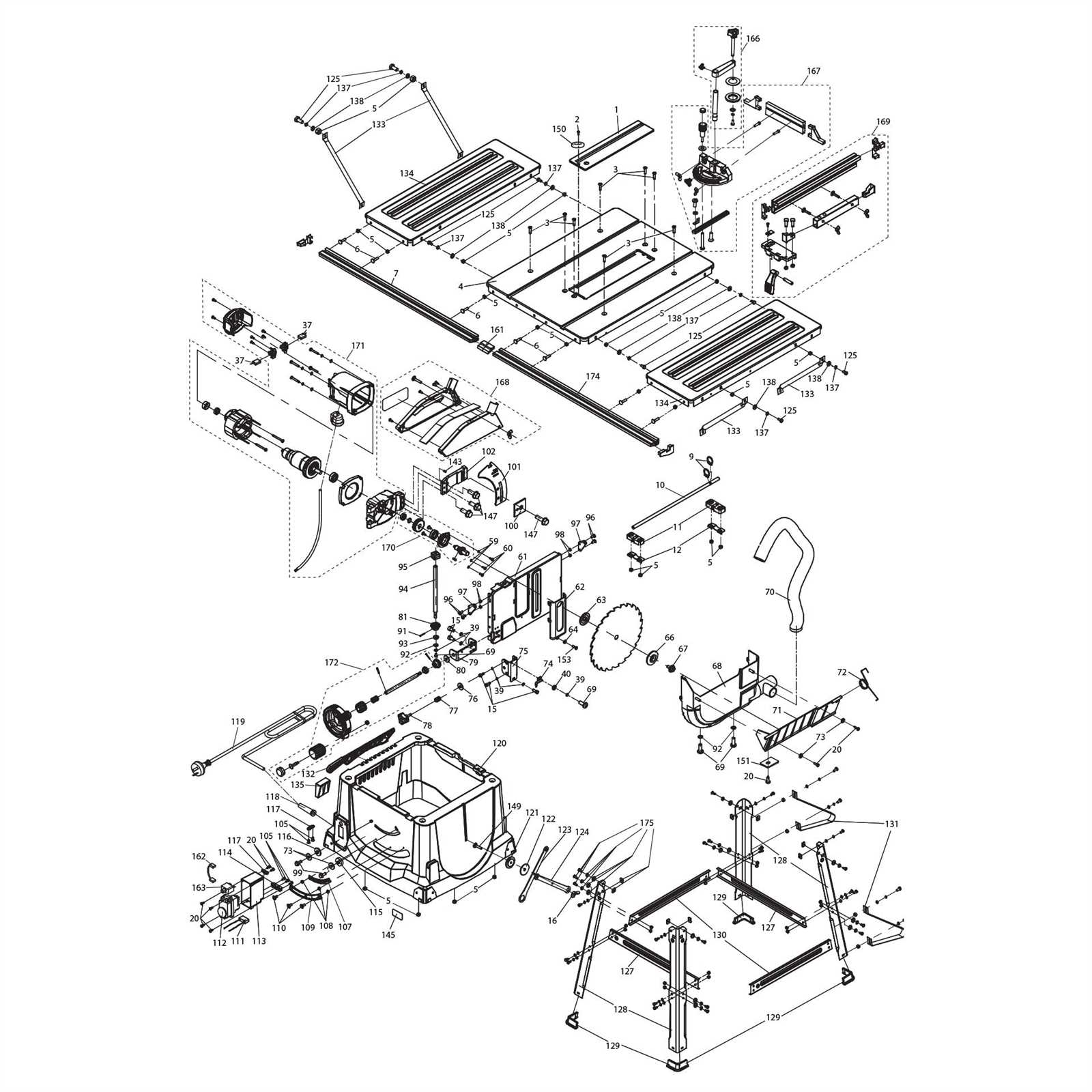

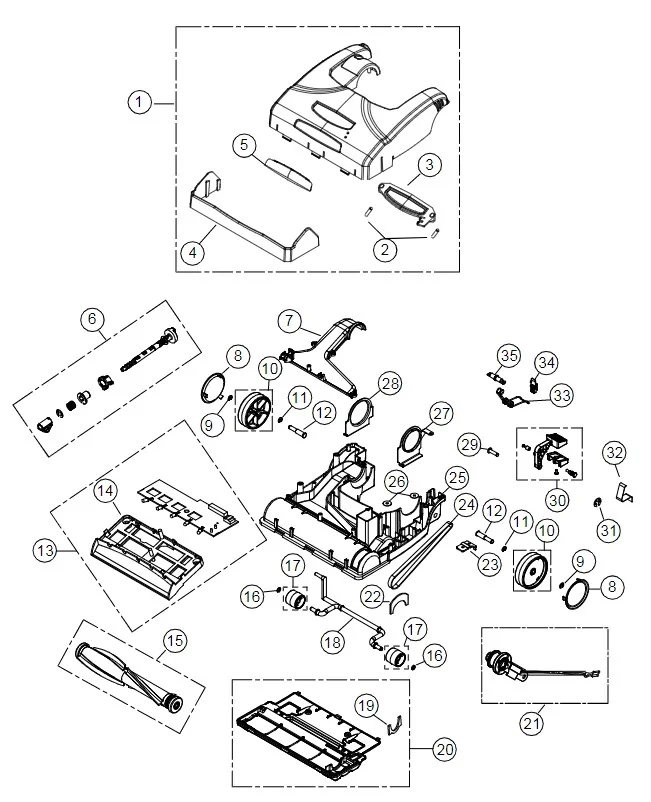

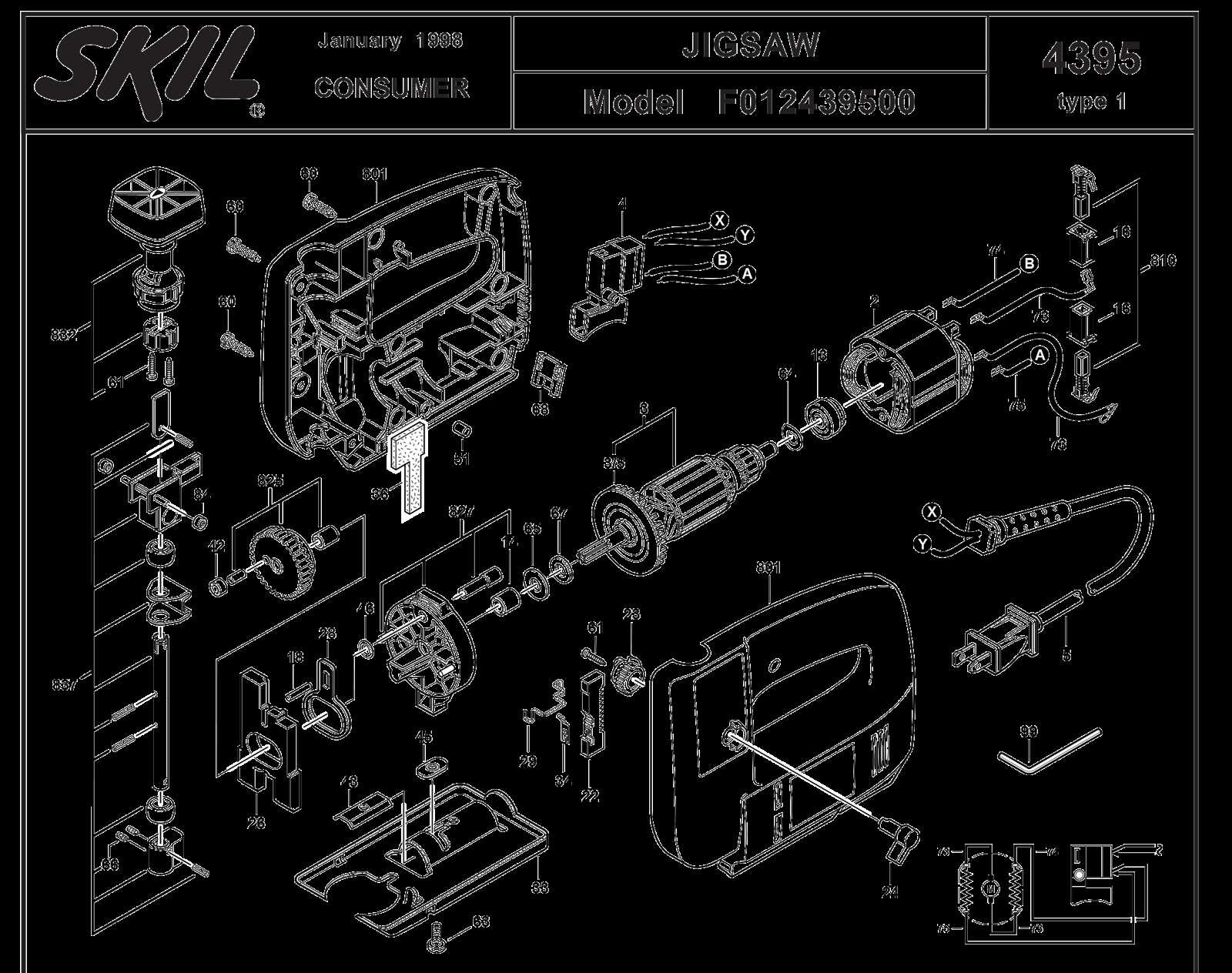

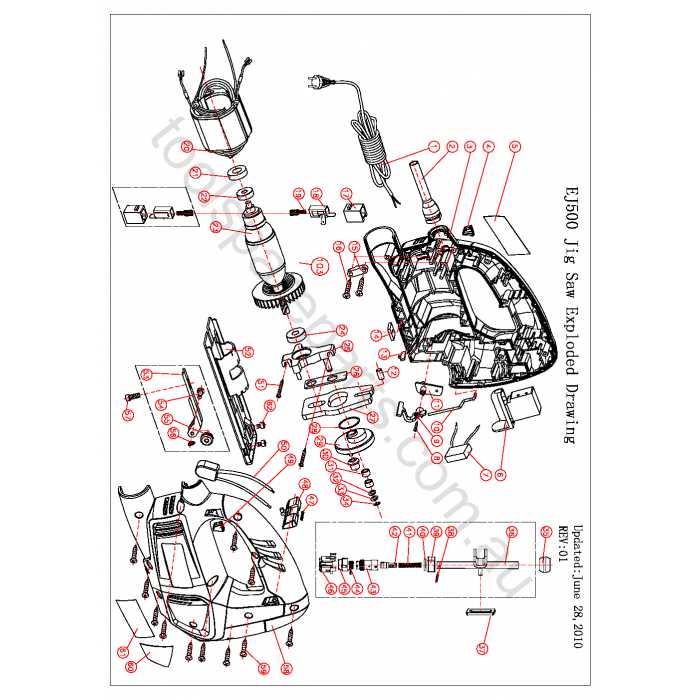

How to Read a Parts Diagram

Understanding an assembly illustration is crucial for anyone looking to maintain or repair equipment. These visual representations provide a clear overview of the various components and their relationships within the device. By familiarizing yourself with the layout, you can identify specific elements and grasp how they function together.

Start by examining the legend or key, which typically explains the symbols and notations used in the illustration. This will help you decode the meaning behind each part and ensure you are interpreting the image correctly. Next, pay attention to the organization of components; they are usually arranged in a logical sequence, often reflecting the assembly order. This can guide you in both disassembling and reassembling the equipment efficiently.

Look for numbered items, as these often correspond to a list that provides detailed descriptions, including part numbers and specifications. This information is invaluable when sourcing replacements or performing upgrades. Additionally, be aware of any notes or warnings included in the illustration, as they may highlight important safety considerations or installation tips.

Finally, practice is key. The more you work with these visuals, the more adept you will become at navigating them. This skill will not only save you time during repairs but also enhance your overall understanding of how the equipment operates.

Maintenance Tips for Jigsaw Longevity

Proper upkeep of your cutting tool is essential for ensuring its durability and optimal performance. By following a few simple guidelines, you can extend the life of your equipment and maintain its efficiency. Here are some key maintenance practices to consider:

- Regular Cleaning: Keep the tool free from dust and debris. Use a soft brush or compressed air to remove particles that can affect its operation.

- Inspect Blades: Check cutting edges for wear and replace them when they become dull. Sharp blades enhance cutting efficiency and reduce strain on the motor.

- Lubrication: Apply appropriate lubricant to moving parts to minimize friction. This helps prevent overheating and prolongs the life of the mechanism.

- Check Power Cords: Inspect electrical cords for any signs of damage. Frayed wires can pose safety risks and should be replaced immediately.

Implementing these practices can greatly improve the lifespan of your equipment, ensuring it remains a reliable companion for your projects.

Where to Find Replacement Parts

When it comes to maintaining and restoring your tools, locating suitable components can make all the difference. Whether you’re looking to enhance functionality or replace worn-out elements, knowing where to source these items is essential for keeping your equipment in optimal condition.

Official Retailers

One of the most reliable sources for acquiring necessary components is through authorized retailers. These outlets often provide a comprehensive selection of genuine items, ensuring compatibility and quality. Check their websites or visit local stores for assistance and inventory availability.

Online Marketplaces

In the digital age, various online platforms offer a vast array of components for your tools. Websites specializing in home improvement and equipment often feature user-friendly search functions, allowing you to find exactly what you need. Be sure to read reviews and confirm seller reliability before making a purchase.

Remember: Always verify the specifications and compatibility of the components you intend to buy to ensure a successful replacement. Investing time in research can save you money and hassle in the long run.

Tools Needed for Jigsaw Repairs

When it comes to maintaining and fixing power cutting devices, having the right instruments at your disposal is crucial. The process can be streamlined and made more efficient with a well-selected toolkit. Knowing what tools to gather before starting repairs can save both time and effort, ensuring that tasks are completed effectively.

Essential items typically include a screwdriver set for removing screws and accessing internal components. A wrench is also necessary for loosening and tightening nuts and bolts, ensuring all parts are securely fastened. Additionally, a pair of pliers can assist in gripping and manipulating smaller pieces during the repair process.

For those working on electronic aspects, a multimeter is invaluable for diagnosing electrical issues. Furthermore, a cleaning brush will help remove dust and debris from the motor and other sensitive areas, which can enhance performance and prolong the tool’s lifespan. Having a reliable workbench or surface to conduct repairs is also essential, providing a stable environment for detailed work.

Lastly, it’s advisable to keep a set of replacement blades on hand. These can often wear out over time and having them readily available will facilitate smoother operations in future tasks. Equipped with these essential tools, anyone can tackle repairs with confidence and efficiency.

Comparing Different Ryobi Models

This section delves into the various offerings from the brand, focusing on the distinct features and specifications that set them apart. By examining the differences, users can make informed decisions based on their individual needs and preferences.

When evaluating the models, consider the following aspects:

- Power Source: Different variants may operate on either battery or corded power, affecting portability and runtime.

- Cutting Capacity: Each model has varying depths and angles for cutting, impacting versatility in different projects.

- Speed Settings: Adjustable speed options allow for greater control depending on the material being worked with.

- Weight: Heavier tools might provide stability, while lighter options enhance maneuverability.

Additionally, consider the following features:

- Ergonomics: Comfort during extended use can significantly affect performance.

- Blade Change Mechanism: Quick-change systems can save time and improve efficiency.

- Dust Management: Integrated systems for dust extraction can create a cleaner workspace.

Understanding these elements will assist users in selecting the right tool for their specific tasks, ensuring optimal performance and satisfaction.

DIY Repairs vs. Professional Help

When faced with a malfunctioning tool, one must decide whether to tackle the repairs independently or seek assistance from an expert. Both approaches have their merits, and understanding the nuances can help individuals make an informed choice based on their skills, the complexity of the issue, and available resources.

Advantages of DIY Repairs

Taking on repairs yourself can be rewarding. It often leads to cost savings and a sense of accomplishment. Additionally, handling repairs allows you to learn more about your equipment, fostering greater familiarity and confidence for future projects.

When to Seek Professional Help

In some cases, enlisting a professional is the more prudent option. Complex issues, lack of time, or insufficient expertise can make it challenging to achieve satisfactory results. Professionals have the training and experience to diagnose and resolve problems efficiently, often with guaranteed results.

| Criteria | DIY Repairs | Professional Help |

|---|---|---|

| Cost | Generally lower | Typically higher |

| Time | Variable; may take longer | Often quicker |

| Skill Level | Requires some knowledge | Expertise available |

| Tools Required | May need to purchase or rent | Professional tools provided |

Frequently Asked Questions About Jigsaws

This section addresses common inquiries regarding a versatile cutting tool often used in various woodworking projects. Understanding its functionalities, maintenance, and operational techniques can enhance the user experience and improve the quality of results.

What types of materials can be cut with this tool? This tool is suitable for a wide range of materials, including wood, plastic, and metal, depending on the blade type and settings.

How do I choose the right blade? Selecting the appropriate blade is crucial. Consider the thickness and type of material, as well as the desired finish–finer blades are better for intricate cuts, while thicker blades are ideal for heavier materials.

What safety precautions should I take? Always wear safety glasses to protect your eyes from debris. Ensure the workpiece is secure, and keep hands clear of the cutting area to avoid accidents.

How can I maintain my tool for optimal performance? Regularly check the blade for wear and replace it when necessary. Keep the base clean and lubricate moving parts to ensure smooth operation.

Is there a difference between corded and cordless models? Yes, corded models typically offer more power and continuous operation, while cordless versions provide greater mobility and convenience for outdoor tasks.

Understanding Warranty and Service Options

When investing in power tools, it’s essential to be informed about the coverage and support available to ensure your equipment remains functional over time. Knowing the specifics of warranty conditions and service choices can help you make the most of your purchase.

Typically, warranties provide assurance regarding the quality and durability of the product. These agreements often cover manufacturing defects and may extend for a specified period. Here are some key points to consider:

- Duration: Check the length of the warranty and what it encompasses.

- Conditions: Understand what is required to keep the warranty valid, such as regular maintenance or specific usage guidelines.

- Exclusions: Familiarize yourself with situations that may void the warranty, such as unauthorized repairs or modifications.

In addition to warranties, knowing the service options available can enhance your experience with the tool. Consider the following:

- Authorized Service Centers: Locate nearby facilities that can perform repairs and maintenance in line with warranty conditions.

- Customer Support: Take advantage of customer service resources for troubleshooting and guidance.

- Replacement Parts: Ensure access to genuine components for repairs to maintain performance and reliability.

By understanding these aspects, you can ensure that your investment is protected and that you have access to the necessary support for long-term use.

Tips for Choosing the Right Blade

Selecting the appropriate cutting tool is crucial for achieving precise and efficient results in your projects. The right blade can significantly impact the quality of your cuts, the materials you can work with, and the overall performance of your equipment. Here are some essential considerations to help you make an informed choice.

Understand the Material

Different materials require specific blade types to ensure optimal performance. Consider the following:

- Wood: Look for blades designed for woodcutting, which usually have fewer teeth and wider gaps.

- Metal: Opt for blades made from high-speed steel or bi-metal, featuring finer teeth for smoother cuts.

- Plastic: Choose blades that have a design suitable for plastic to avoid melting during the cut.

Blade Tooth Configuration

The arrangement and number of teeth on a blade influence the cutting speed and finish:

- Fewer Teeth: Blades with fewer teeth cut faster but may leave a rough finish, ideal for quick cuts.

- More Teeth: Blades with more teeth provide smoother cuts and are better for detailed work, although they cut slower.