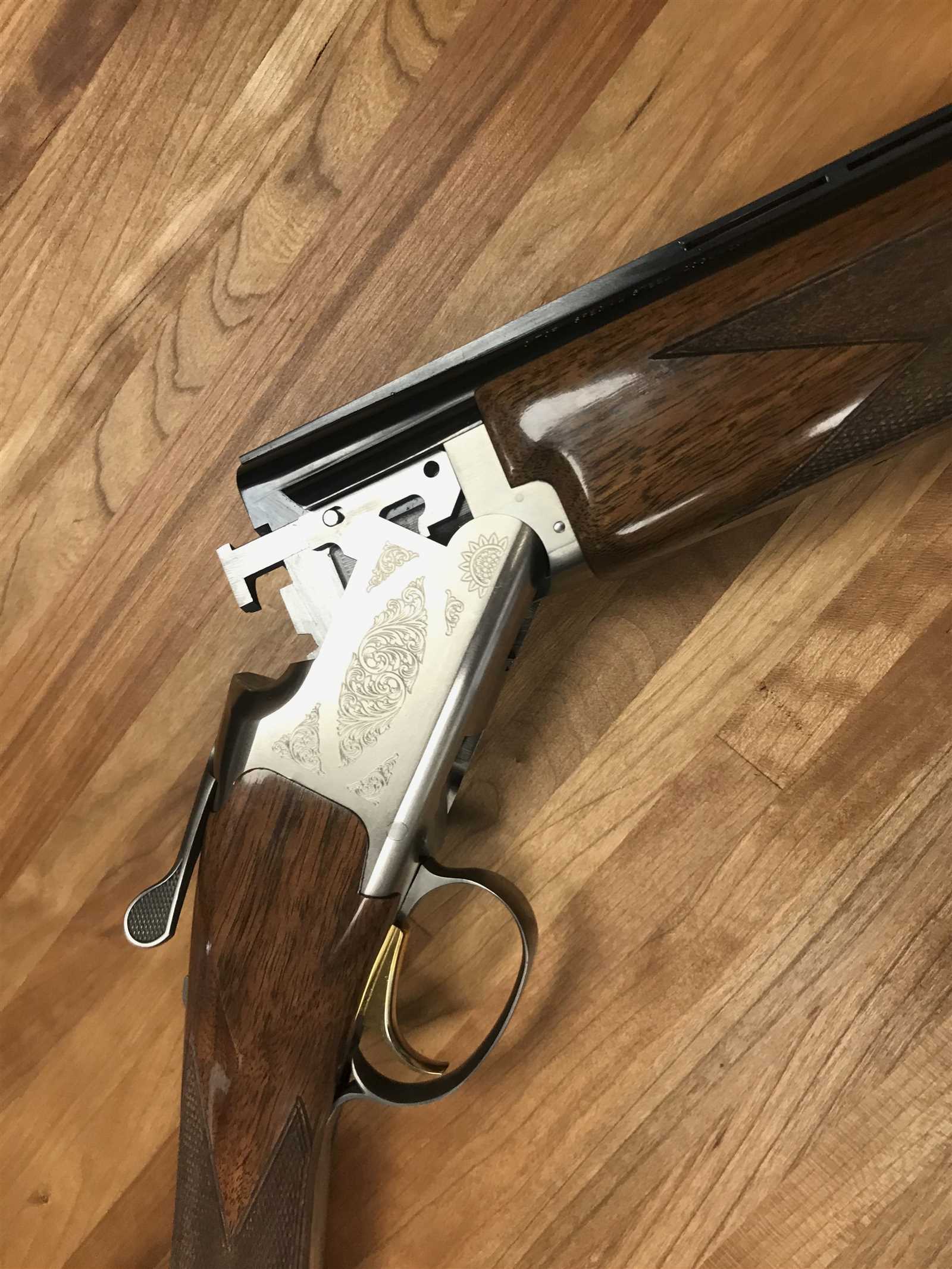

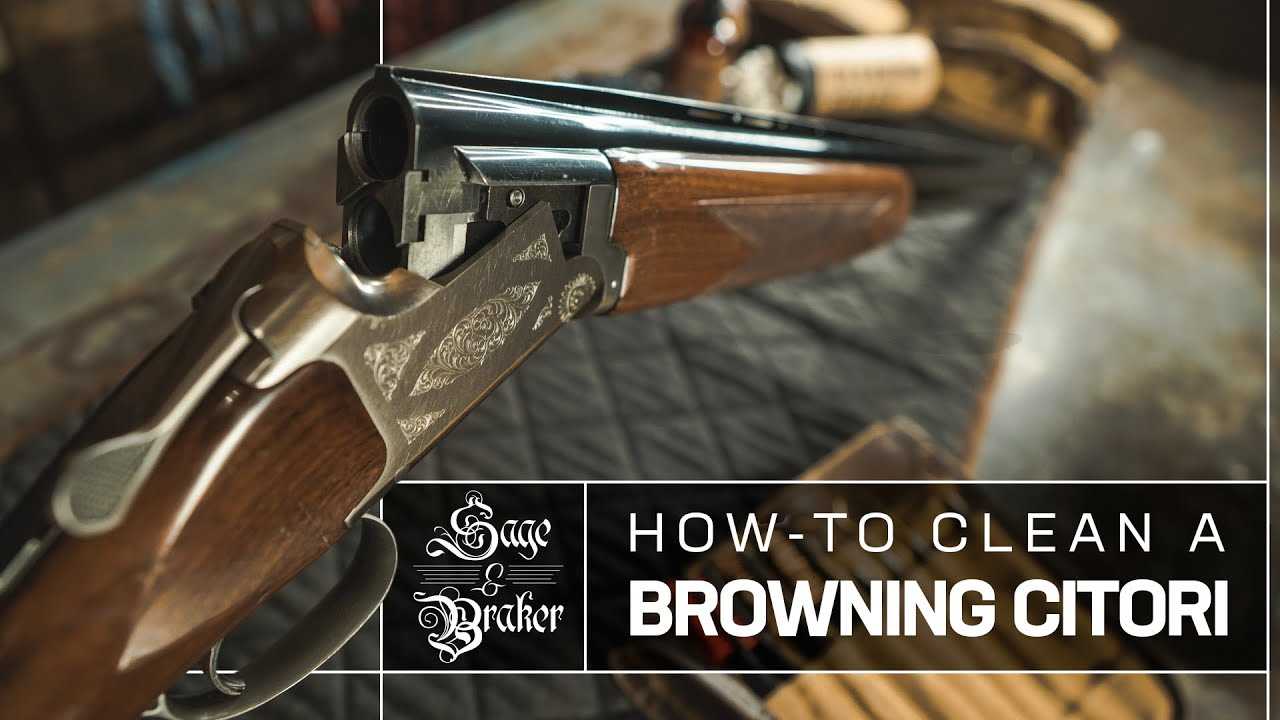

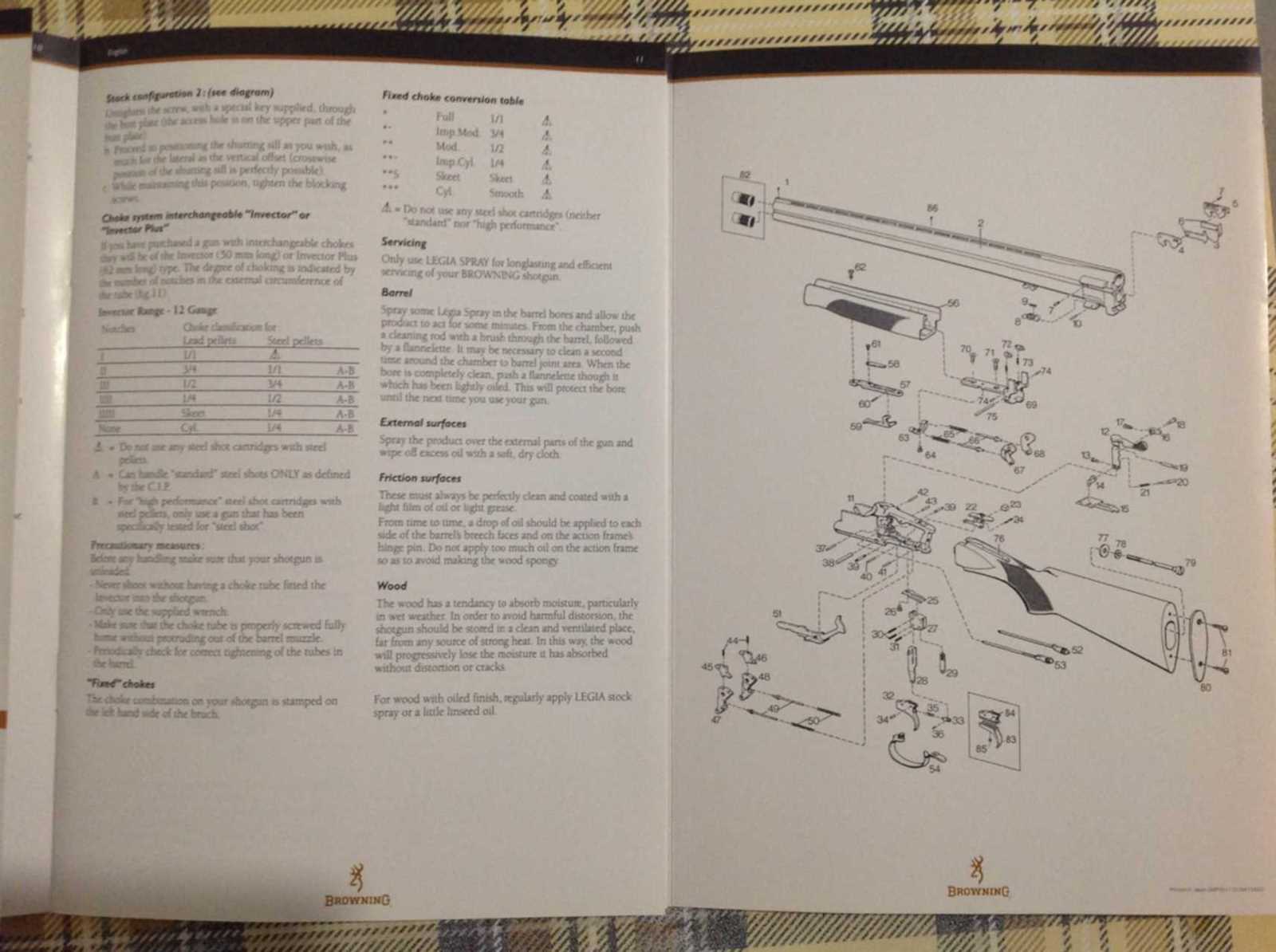

Browning Citori Parts Diagram Overview

In the world of firearms, understanding the intricate elements that contribute to the functionality of a shotgun is essential for enthusiasts and professionals alike. Each component plays a crucial role in ensuring reliable performance and accuracy. This section delves into the various sections of a shotgun, offering a comprehensive look at its inner workings.

Familiarity with the individual elements not only enhances one’s appreciation of the weapon but also aids in maintenance and troubleshooting. From the firing mechanism to the stock, each piece is designed to work harmoniously, providing the shooter with a seamless experience. A thorough grasp of these components enables users to make informed decisions regarding modifications or repairs.

As we explore this topic, it becomes evident that a systematic understanding of the layout and functions of these components is paramount. Whether you’re a seasoned shooter or a newcomer to the sport, this knowledge will empower you to engage with your firearm more effectively and safely.

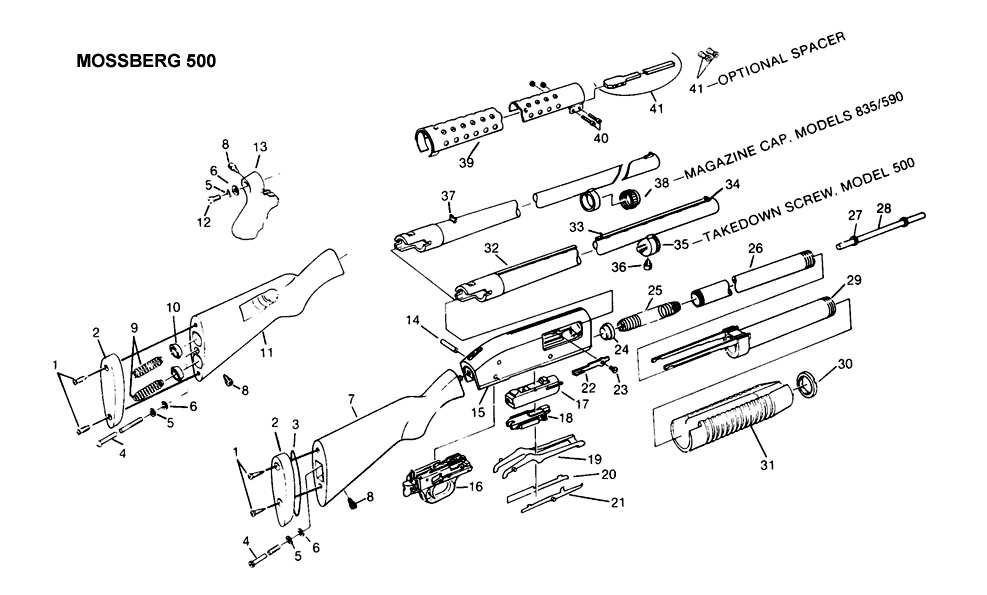

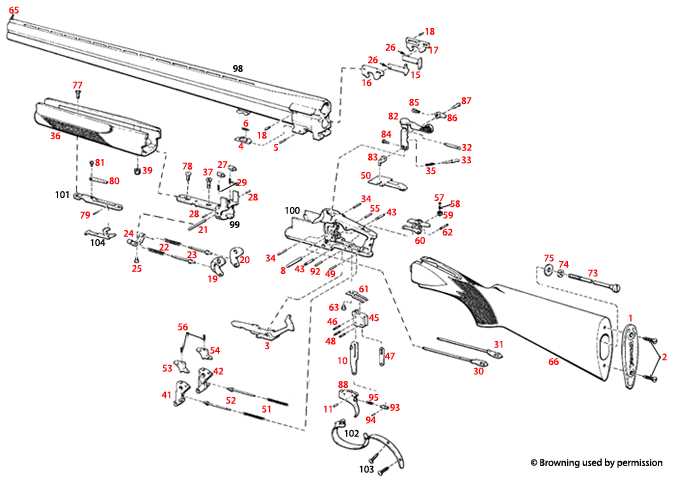

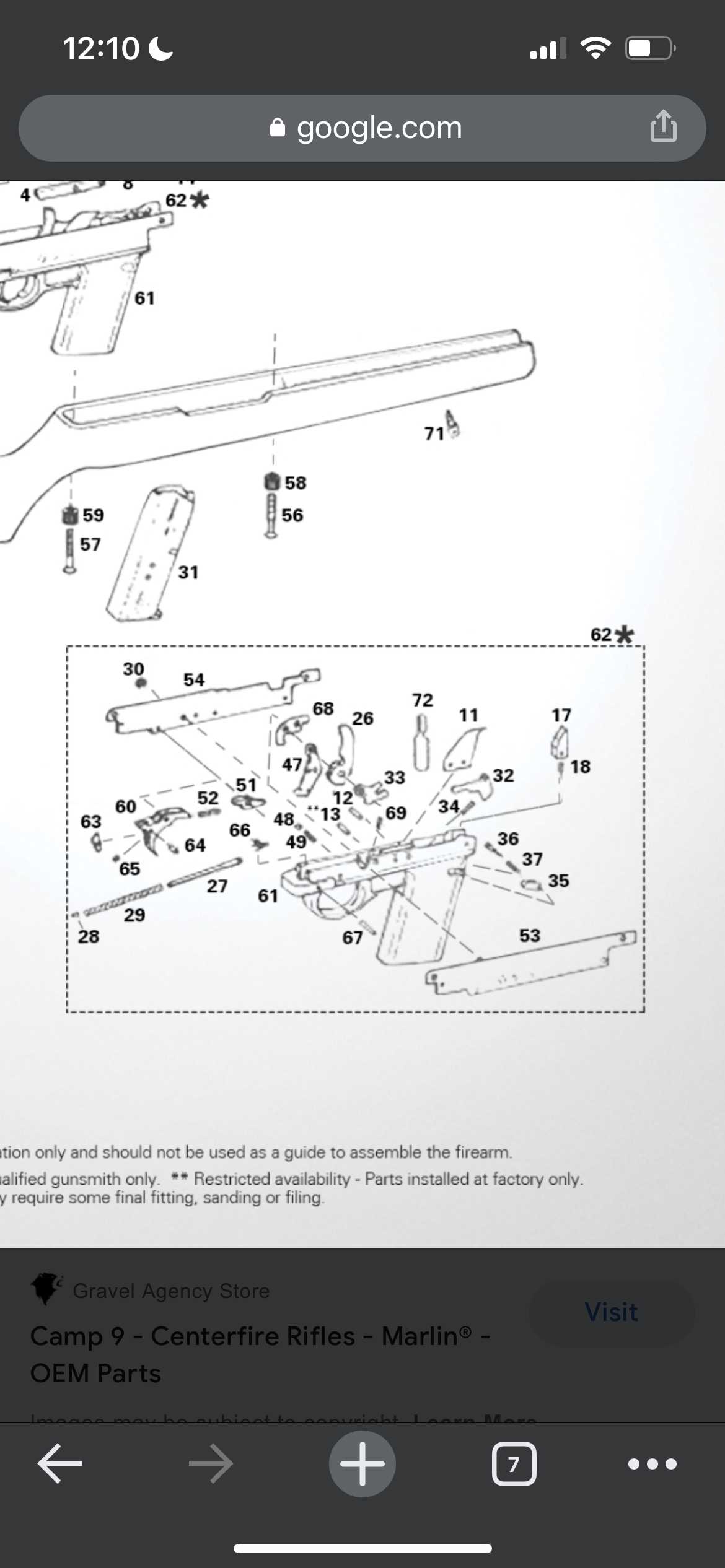

Components Overview

This section provides a comprehensive look at the various components that make up a particular firearm. Understanding the individual elements is essential for both maintenance and enhancement of the weapon’s performance. Each component plays a vital role, contributing to the overall functionality and reliability of the firearm.

Key Elements

The essential components include the receiver, barrels, and stock, which collectively ensure the firearm operates efficiently. The receiver houses the trigger mechanism and is crucial for the firing process. The barrels are responsible for directing the projectile, while the stock provides stability and support during handling.

Accessory Components

Additional elements such as the trigger guard, safety mechanisms, and sighting systems enhance the user’s experience. These accessories not only improve safety but also allow for customization according to personal preferences and shooting styles.

Understanding Shotgun Mechanisms

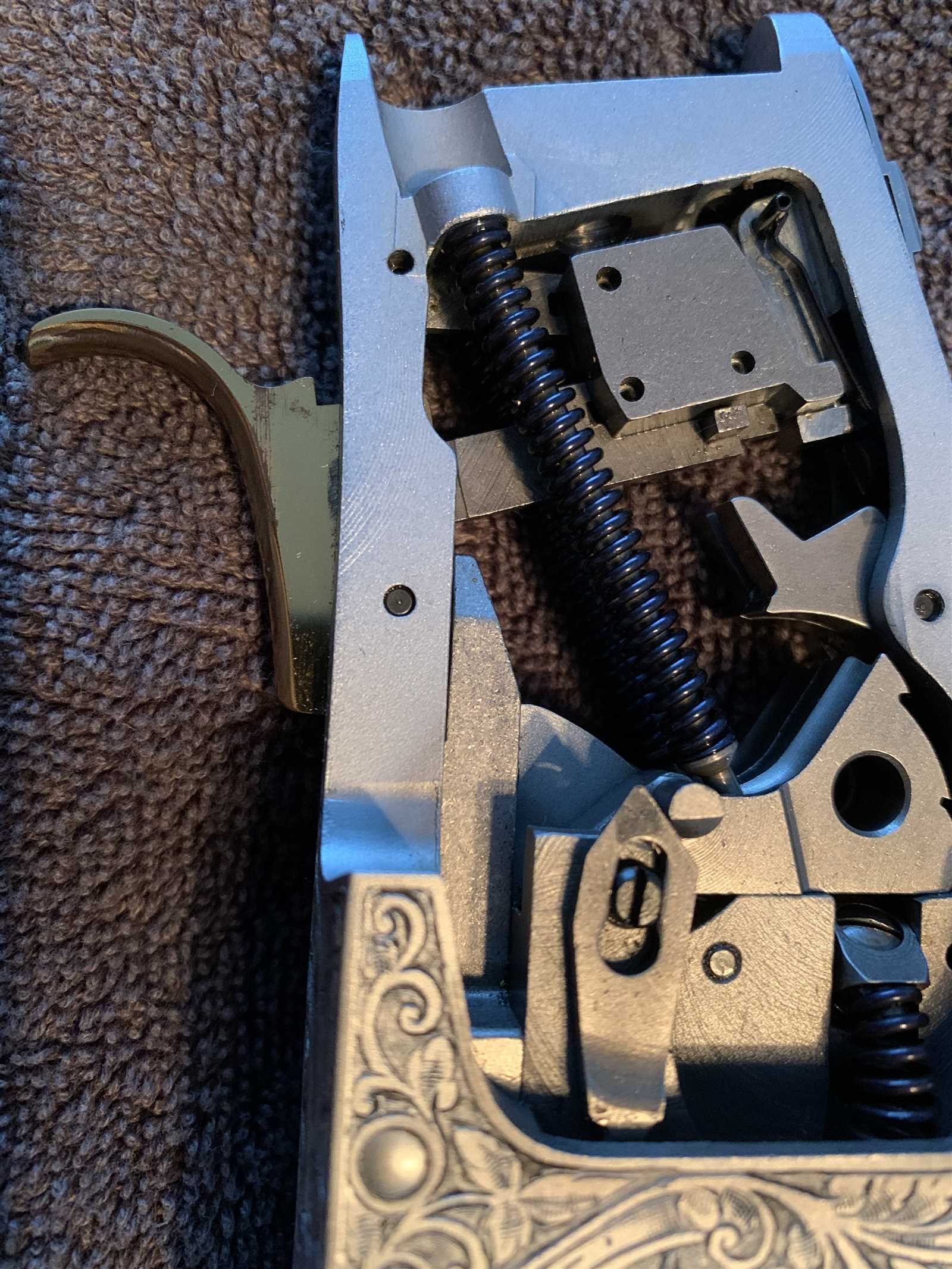

The operation of a shotgun involves intricate systems that work together to deliver consistent performance. These mechanisms are designed to ensure reliable firing, efficient cycling of shells, and effective ejection of spent casings. A comprehensive understanding of these systems is essential for anyone looking to maintain or troubleshoot a shotgun effectively.

At the heart of any shotgun lies the firing mechanism, which initiates the shot. This mechanism typically includes components such as hammers, firing pins, and triggers. Each part plays a crucial role in the timing and execution of the shot, ensuring that when the trigger is pulled, the firing pin strikes the primer of the cartridge, igniting the propellant.

Another vital aspect is the action, which refers to how the firearm loads and ejects shells. Shotguns can be classified into several categories based on their action type, including break-action, pump-action, and semi-automatic. Each type has its unique operation method, impacting reloading speed and ease of use.

Below is a simplified overview of different shotgun action types:

| Action Type | Description | Advantages |

|---|---|---|

| Break-Action | Opens at the hinge to load and unload shells. | Simple design, easy to maintain. |

| Pump-Action | Requires manual operation of a sliding fore-end to chamber a shell. | Fast cycling, reliable under various conditions. |

| Semi-Automatic | Automatically chambers a new shell after firing. | Quick follow-up shots, minimal manual effort. |

Understanding these mechanisms helps in making informed decisions about usage, maintenance, and repair. This knowledge enhances both safety and performance, ensuring that enthusiasts can fully appreciate the craftsmanship involved in these remarkable firearms.

Importance of Proper Maintenance

Key reasons for prioritizing maintenance include:

| Reason | Description |

|---|---|

| Performance Enhancement | Routine checks and cleaning ensure that all components operate smoothly, leading to improved efficiency. |

| Safety Assurance | Regular inspections can uncover potential safety hazards, reducing the risk of accidents and injuries. |

| Cost-Effectiveness | Timely maintenance prevents costly repairs and replacements by addressing minor issues early on. |

| Increased Lifespan | Proper care extends the life of the machinery, maximizing the investment made in the equipment. |

Implementing a consistent maintenance strategy fosters reliability and confidence in the operation, ultimately contributing to a more enjoyable experience.

Common Issues and Solutions

In the realm of firearm maintenance, understanding prevalent challenges and their resolutions is crucial for ensuring optimal performance and longevity. Users often encounter a variety of mechanical or operational issues that may affect functionality. By identifying these common problems and applying effective solutions, enthusiasts can maintain their equipment in peak condition.

Operational Malfunctions

One of the most frequent complications involves failures in operation, such as misfires or inconsistent firing. This may stem from issues like improper loading, insufficient lubrication, or debris accumulation within the mechanism. Regular cleaning and proper handling techniques can mitigate these risks. If the issue persists, a thorough inspection may be necessary to identify worn components that require replacement.

Accuracy Problems

Another common concern relates to accuracy, which can be influenced by several factors including sight misalignment, environmental conditions, or ammunition quality. To enhance precision, users should ensure that sights are correctly calibrated and consider experimenting with different ammunition brands. Additionally, practicing regularly can significantly improve shooting skills and overall accuracy.

Replacing Worn Components Safely

Ensuring the longevity and optimal performance of your firearm requires careful attention to its individual elements. When components exhibit signs of wear, timely replacement is essential to maintain functionality and safety. This section provides guidance on how to replace these critical pieces effectively and securely.

Steps for Safe Component Replacement

- Identify Worn Parts

- Gather Necessary Tools

- Ensure a Clean Work Area

- Follow the Manufacturer’s Guidelines

- Perform a Thorough Inspection After Replacement

Safety Precautions

- Always wear protective gear, including safety glasses and gloves.

- Make sure the firearm is unloaded before starting any work.

- Use appropriate tools designed for the specific components.

- Keep a well-organized workspace to avoid losing small pieces.

- Consult a professional if you encounter difficulties during the replacement process.

By adhering to these guidelines, you can ensure that worn components are replaced efficiently, contributing to the safe operation of your firearm.

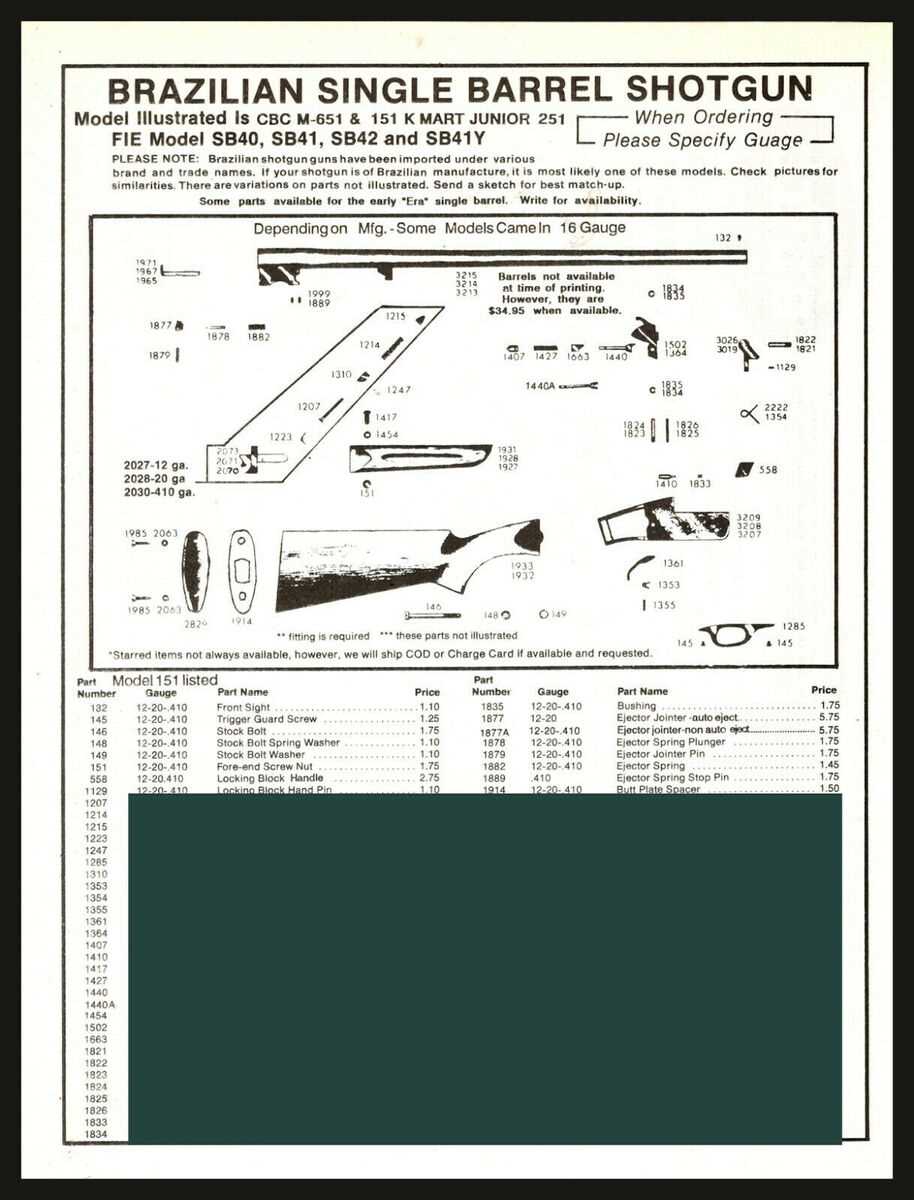

Identifying Parts by Serial Number

Understanding the unique identifiers of a firearm is essential for maintenance and replacement purposes. Each unit typically carries a serial number that serves as a key reference point for locating and identifying specific components. This numerical sequence can reveal valuable information about the item’s manufacturing details, model specifications, and even production date, ensuring the correct elements are selected during repairs or upgrades.

To begin the identification process, locate the serial number, which is often engraved or stamped on the receiver or frame. Once identified, consulting the manufacturer’s documentation or official resources can provide insights into the corresponding components associated with that specific number. It’s crucial to reference official manuals or online databases that detail the various models and their features based on serial number ranges.

Moreover, enthusiasts and professionals alike can benefit from joining forums or communities focused on similar units. Members often share insights and personal experiences regarding component compatibility, helping others navigate the intricacies of identification and replacement. In conclusion, leveraging the serial number not only simplifies the process of finding the correct components but also enhances the overall experience of owning and maintaining a firearm.

Tools Required for Disassembly

To successfully take apart a firearm, it’s essential to gather the right instruments. Having the appropriate tools not only facilitates the process but also ensures that the components remain intact and undamaged. Understanding the specific requirements for disassembly can make the task more efficient and less daunting.

Essential tools for this procedure include a combination of screwdrivers, wrenches, and punches. A set of precision screwdrivers is crucial for loosening screws without stripping them, while adjustable wrenches can help tackle any nuts or bolts. Additionally, punches are useful for removing pins and other fasteners that may hold parts together.

It’s also advisable to have a cleaning cloth and a container for small parts at hand. Keeping your workspace organized can prevent the loss of critical components during disassembly. Lastly, a protective mat can provide a safe surface to work on and help avoid scratches or damage to the firearm’s finish.

Step-by-Step Disassembly Guide

This section aims to provide a clear and concise methodology for disassembling a specific type of firearm. By following these steps, you can ensure a thorough understanding of its components and their arrangement.

Preparation

- Gather necessary tools: screwdrivers, punches, and a clean workspace.

- Ensure the firearm is unloaded and clear of any ammunition.

- Review the manufacturer’s instructions for safety precautions.

Disassembly Steps

- Begin by removing the stock from the main body.

- Detach the forearm by unscrewing the retaining screws.

- Carefully take out the trigger mechanism, noting the arrangement of springs and pins.

- Remove the barrel assembly by unscrewing the connecting parts.

- Finally, inspect and clean each component for maintenance.

Reassembly Tips for Beginners

Putting together your firearm after maintenance or repairs can seem daunting, but with the right approach, it can become a straightforward task. This section offers valuable guidance to help novices navigate the reassembly process smoothly and efficiently.

Here are some essential tips to keep in mind:

- Organize Components: Lay out all the parts in a clean, well-lit area. Group similar items together to avoid confusion.

- Refer to Resources: Use diagrams or manuals that illustrate the assembly process. Visual aids can be invaluable for understanding how parts fit together.

- Take Your Time: Don’t rush through the reassembly. Patience is key to ensuring everything is properly aligned and secured.

- Work Methodically: Follow a systematic approach. Start with the main assembly and gradually add components, checking each step as you go.

- Double-Check Alignment: Ensure that all parts are aligned correctly before tightening screws or fasteners. Misalignment can lead to operational issues.

By following these simple guidelines, beginners can build confidence and proficiency in reassembling their firearm, ensuring safe and effective operation.

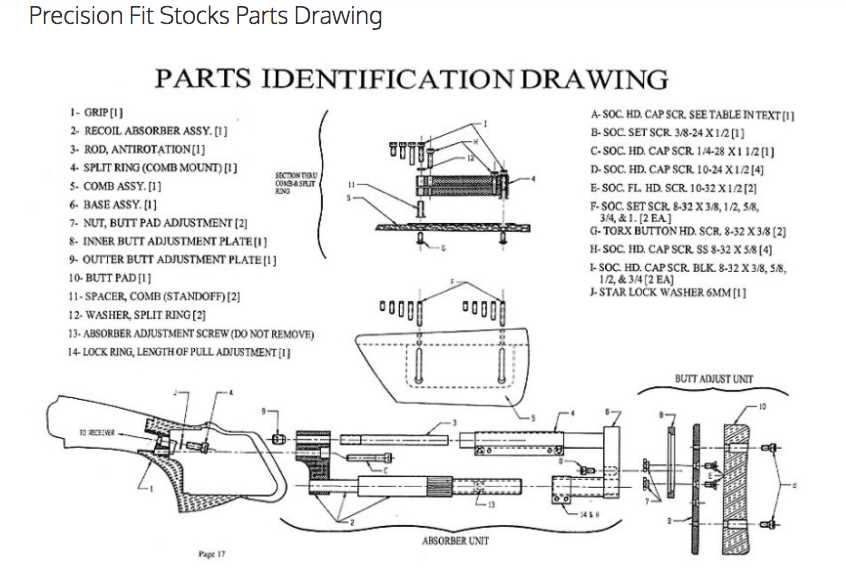

Customizing Your Browning Citori

Enhancing your firearm can significantly improve both its aesthetic appeal and functionality. Personalizing various components allows enthusiasts to tailor their experience, ensuring that each shot aligns with their preferences and style. Whether you’re aiming for a unique look or improved performance, customization opens a world of possibilities.

Popular Customization Options

There are several avenues for customization, ranging from visual upgrades to functional enhancements. Here are some popular options:

| Customization Type | Description |

|---|---|

| Stock Modifications | Adjusting length, shape, or material for better fit and comfort. |

| Finish Options | Applying different coatings or engravings for a personalized look. |

| Trigger Adjustments | Tuning for improved responsiveness and feel. |

Considerations for Customization

When personalizing your firearm, it’s essential to consider factors such as legality, warranty implications, and the impact on resale value. Always ensure that modifications adhere to local regulations and maintain the integrity of the firearm.

Resources for Parts and Repairs

Finding reliable sources for components and maintenance is crucial for ensuring the longevity and performance of your equipment. Whether you need replacements or professional assistance, various resources are available to meet your needs.

Online Retailers

- Specialized websites offering a wide range of components.

- Marketplace platforms where users can buy or sell individual items.

- Manufacturer’s official sites providing authentic parts.

Repair Services

- Local workshops specializing in equipment restoration.

- Authorized service centers with trained technicians.

- Online forums where enthusiasts share DIY repair tips.