Stihl 045 Parts Diagram Overview

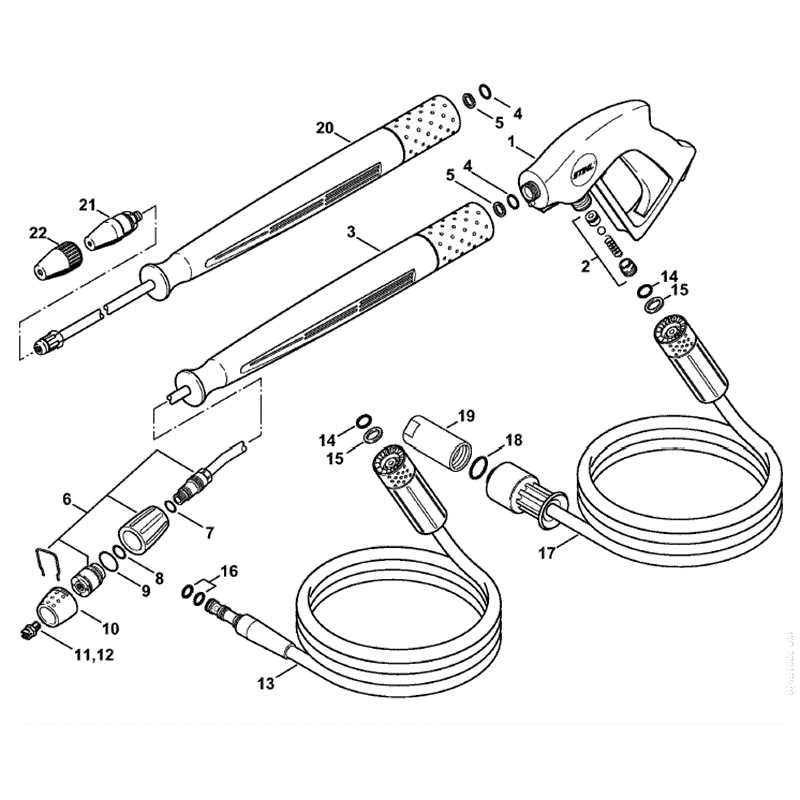

In the realm of outdoor power equipment, comprehending the arrangement and functionality of various elements is essential for effective maintenance and repair. A detailed illustration that showcases each component’s position can greatly assist users in identifying parts and understanding their roles within the system. This knowledge not only enhances the user experience but also promotes longevity and efficiency.

Recognizing how each element interacts with others is crucial for troubleshooting and ensuring optimal performance. Whether it involves replacing a worn-out piece or assembling a new unit, a clear visualization serves as a valuable guide. By familiarizing oneself with the structure and design, users can approach repairs with confidence and precision.

Additionally, having access to accurate representations enables enthusiasts and professionals alike to streamline their workflow. With the right resources at hand, individuals can efficiently diagnose issues, facilitate repairs, and optimize the functionality of their machinery. This section aims to provide insights into the intricate layout of components, empowering users to engage effectively with their equipment.

Visual representations of components play a crucial role in comprehending complex machinery. These illustrations provide users with a clear overview of how various elements fit together, enhancing maintenance and repair efforts. By utilizing these resources, individuals can ensure the longevity and efficient operation of their equipment.

Benefits of Visual Component Representations

- Enhanced Clarity: Visuals eliminate ambiguity, allowing users to identify and locate each element swiftly.

- Streamlined Repairs: Quick reference aids in troubleshooting and facilitates efficient replacement of faulty components.

- Informed Decision-Making: Knowledge of individual parts empowers users to make better purchasing choices for replacements or upgrades.

Applications in Maintenance and Upgrades

- Regular inspections can be conducted more effectively with clear visual guidance.

- Upgrading or customizing machinery becomes less daunting when users understand the relationship between components.

- Educational tools for training new users can leverage these visuals to impart knowledge swiftly.

Key Components of Stihl 045

Understanding the essential elements of a chainsaw can greatly enhance its maintenance and performance. Each component plays a vital role in ensuring the efficiency and reliability of the tool, allowing users to achieve optimal results during their tasks. This section explores the significant parts that contribute to the functionality of this powerful machine.

Engine Assembly

The engine assembly is the heart of the tool, providing the necessary power to drive the cutting chain. Comprised of various components such as the cylinder, piston, and crankshaft, this assembly converts fuel into mechanical energy. Regular maintenance of the engine is crucial for maintaining peak performance, ensuring longevity and preventing breakdowns.

Bar and Chain System

The bar and chain system is responsible for the cutting action. The guide bar serves as the support for the chain, which is equipped with sharp teeth designed to slice through wood. Proper tensioning and lubrication of this system are essential for smooth operation and to reduce wear on both the chain and the bar, enhancing overall efficiency during cutting tasks.

How to Read Parts Diagrams

Understanding visual schematics for machinery can enhance your ability to identify components and facilitate repairs. These illustrations provide a clear overview of how different elements interact within a system, making it easier to recognize the parts you need for maintenance or replacement.

When approaching these visuals, consider the following key points:

- Familiarize Yourself with Symbols: Each symbol or number corresponds to a specific element. Understanding these representations is crucial for navigating the schematic effectively.

- Identify Groupings: Components are often grouped by function or location. Pay attention to how elements are clustered, as this can provide insight into their roles within the machinery.

- Use the Legend: Many illustrations include a legend that explains the symbols used. Always refer to this section to clarify any uncertainties regarding the components.

- Follow the Flow: Observe the flow of the schematic. This will help you understand how components interact and the sequence of operations.

- Take Notes: As you analyze the illustration, jot down any important information or questions that arise. This will aid your understanding and assist you when seeking specific parts.

By applying these strategies, you can effectively interpret visual representations and make informed decisions about maintenance and repairs.

Identifying Replacement Parts Easily

Finding suitable components for your equipment can be a straightforward process with the right approach. Understanding how to navigate through available resources and utilizing visual references can significantly enhance your ability to identify the necessary items quickly.

Here are some effective strategies for streamlining the identification of essential components:

- Refer to the User Manual: The manual typically includes illustrations and descriptions that can help you understand the assembly and the specific items required for replacement.

- Utilize Online Resources: Many websites offer detailed visuals and descriptions of various components, enabling you to cross-reference your needs with available options.

- Join Online Forums: Engaging with communities that focus on similar equipment can provide insights and shared experiences that might assist you in identifying the right items.

- Consult with Professionals: Seeking advice from experts in repair shops can offer you additional clarity on component identification and compatibility.

By implementing these methods, you can enhance your efficiency in locating the correct components, ensuring your equipment remains operational and effective.

Maintenance Tips for Stihl 045

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. Adopting a consistent maintenance routine can prevent potential issues, enhance efficiency, and save you time and money in the long run. Below are some key strategies to keep your machine in top condition.

Routine Cleaning

Keeping the exterior and internal components clean is vital. After each use, wipe down the machine to remove dirt, debris, and sap. Regularly check and clear the air filter to ensure proper airflow, which is crucial for optimal functioning. A clean engine will run smoother and reduce wear on parts.

Check and Replace Components

Periodically inspect the various components for signs of wear and tear. Look for frayed wires, worn belts, or damaged hoses. Replacing these elements promptly can prevent further damage. Additionally, ensure that the blades are sharp and in good condition; dull blades can strain the motor and reduce cutting efficiency.

Signs of Wear and Tear

Understanding the indicators of deterioration is crucial for maintaining the efficiency and longevity of your equipment. Regular inspection can help identify issues before they escalate into more significant problems. Awareness of these signs not only prolongs the life of your machinery but also ensures safety during operation.

Common Indicators

Several visual and functional cues can signal that your machinery requires attention. Here are some of the most frequent signs of wear and tear:

| Indicator | Description |

|---|---|

| Unusual Noises | Sounds such as grinding, rattling, or squeaking may suggest that components are not functioning smoothly. |

| Decreased Performance | A noticeable drop in efficiency or power output can indicate that parts are worn or damaged. |

| Visual Damage | Cracks, chips, or other visible defects on surfaces can be a clear sign that components have been compromised. |

| Vibrations | Excessive shaking or vibrations during operation may point to loose or damaged components. |

| Leaks | Fluid leaks around joints or seals can indicate that gaskets or O-rings need to be replaced. |

Preventive Measures

Taking proactive steps can mitigate the effects of wear and tear. Regular maintenance checks, timely replacements, and proper usage can help maintain the functionality of your equipment. Adopting these practices ensures a longer lifespan and reduces the likelihood of unexpected failures.

Where to Find Authentic Parts

When maintaining equipment, sourcing high-quality components is crucial for optimal performance and longevity. Authentic components ensure compatibility and reliability, enhancing the overall functionality of your machinery. Understanding where to find these genuine items can save time and prevent future issues.

Authorized Dealers

Visiting authorized dealers is one of the most reliable ways to obtain genuine components. These retailers are officially recognized and offer a range of original items tailored for various machinery models. Their knowledgeable staff can assist in identifying the correct components and provide valuable insights on installation and maintenance.

Online Marketplaces

Reputable online marketplaces can also be a valuable resource. Look for sellers with positive reviews and a history of offering authentic products. Many platforms allow you to filter search results to display only genuine items, making it easier to find what you need. Always verify the seller’s credibility and check for warranty information before making a purchase.

Tools Needed for Repairs

Having the right equipment is essential for effectively addressing any maintenance tasks or troubleshooting issues with your machinery. Whether you’re conducting routine checks or performing more complex repairs, the following tools will ensure you can work efficiently and safely.

- Screwdrivers: A variety of screwdrivers, including flathead and Phillips, are necessary for loosening and tightening screws throughout the assembly.

- Wrenches: Both adjustable and fixed wrenches are crucial for handling nuts and bolts, allowing for precise adjustments and secure fittings.

- Pliers: Needle-nose and standard pliers can help with gripping, twisting, and cutting wires or small components.

- Torque Wrench: This tool ensures that bolts and screws are tightened to the manufacturer’s specified torque, preventing damage from over-tightening.

- Cleaning Supplies: Brushes, cloths, and degreasers are essential for maintaining cleanliness and ensuring that parts operate smoothly.

- Replacement Parts: Always keep a selection of common components on hand to replace worn or damaged items quickly.

- Safety Gear: Gloves, goggles, and masks are important for personal protection during maintenance tasks.

Equipping yourself with these tools not only streamlines the repair process but also enhances your ability to perform tasks safely and effectively. Being prepared will allow you to tackle any challenges that arise with confidence.

Benefits of Using Original Parts

Utilizing components that are specifically designed for a particular model offers numerous advantages. These elements are crafted to meet precise specifications, ensuring compatibility and optimal performance. This approach not only enhances the functionality of the equipment but also contributes to its longevity.

Here are some key benefits of opting for authentic components:

| Benefit | Description |

|---|---|

| Quality Assurance | Original components undergo rigorous testing to guarantee high standards and reliability, reducing the risk of failure. |

| Perfect Fit | These components are designed to seamlessly integrate with your equipment, minimizing the likelihood of issues during installation and operation. |

| Enhanced Performance | Using genuine parts ensures that your equipment operates at peak efficiency, providing better power and efficiency. |

| Longer Lifespan | Authentic components are made from superior materials, leading to increased durability and a longer operational life for your equipment. |

| Warranty Protection | Many manufacturers offer warranties on their products, which may be voided if non-original components are used. |

Comparing Aftermarket vs. OEM Parts

When maintaining or repairing machinery, the choice between original equipment manufacturer (OEM) components and aftermarket alternatives can significantly impact performance and longevity. Each option presents unique benefits and considerations that can affect the decision-making process for users seeking reliability and efficiency.

Understanding OEM Components

Original equipment manufacturer components are made by the same company that produced the equipment. These items are specifically designed to meet the exact specifications of the original assembly, ensuring compatibility and quality. Using OEM components often results in optimal performance and may be backed by a warranty, providing peace of mind to the user.

The Benefits of Aftermarket Alternatives

Aftermarket alternatives, on the other hand, are produced by third-party manufacturers. These components may offer cost savings and a wider variety of options, catering to diverse needs and preferences. However, the quality can vary significantly, and some users may experience compatibility issues or reduced performance. Careful research and consideration are essential when opting for these alternatives.

Common Repair Procedures Explained

Maintaining outdoor power equipment is essential for ensuring optimal performance and longevity. Understanding the common repair techniques can help users address issues effectively and enhance the tool’s efficiency. This section outlines several prevalent procedures that are typically required during maintenance and repair tasks.

-

Cleaning the Air Filter:

A clogged air filter can impede airflow and affect performance. Regularly cleaning or replacing the filter is crucial. Follow these steps:

- Remove the air filter cover.

- Take out the filter and inspect it for damage.

- If reusable, clean it with warm, soapy water and allow it to dry completely.

- Reinstall the filter and cover securely.

-

Sharpening the Blade:

Keeping the cutting blade sharp ensures efficient cutting and reduces strain on the engine. Here’s how to sharpen it:

- Disconnect the spark plug for safety.

- Remove the blade carefully.

- Use a sharpening tool to grind the cutting edge evenly.

- Reattach the blade, ensuring it is secured properly.

-

Replacing the Fuel Filter:

A dirty fuel filter can cause starting issues and performance decline. Follow these steps for replacement:

- Locate the fuel filter within the fuel tank or fuel line.

- Remove the old filter and discard it properly.

- Install the new filter, ensuring the correct orientation.

-

Checking the Spark Plug:

The spark plug is vital for ignition. Regular inspection is necessary. To check it:

- Remove the spark plug wire and the plug itself.

- Inspect the plug for wear or carbon buildup.

- Clean it with a wire brush or replace it if necessary.

- Reinstall the plug and reconnect the wire securely.

By familiarizing oneself with these procedures, users can effectively troubleshoot and maintain their outdoor equipment, ensuring it operates efficiently and reliably throughout its lifespan.