John Deere GX335 Parts Overview

The intricate world of lawn machinery encompasses a variety of elements that work in harmony to ensure optimal performance. Grasping the layout and function of these components is crucial for both maintenance and repair tasks. This section aims to provide clarity on the essential parts, helping users navigate the complexities of their equipment effectively.

By familiarizing oneself with the various components, operators can enhance the longevity and efficiency of their machines. Knowledge of each element’s role and arrangement not only simplifies troubleshooting but also empowers users to make informed decisions regarding upgrades and replacements. This exploration serves as a valuable resource for anyone looking to deepen their understanding of lawn equipment mechanics.

This section provides a comprehensive overview of a specific model designed for various outdoor tasks. Understanding the structure and components of this machine is essential for efficient operation and maintenance. The following outlines key aspects that contribute to its functionality.

- Introduction to the Model: An overview of the machine’s purpose and its significance in landscaping and gardening.

- Key Features: A detailed look at the standout features that enhance usability and performance.

- Engine Specifications: Information on the engine type, horsepower, and fuel efficiency.

- Transmission System: An explanation of the transmission mechanism and its impact on driving experience.

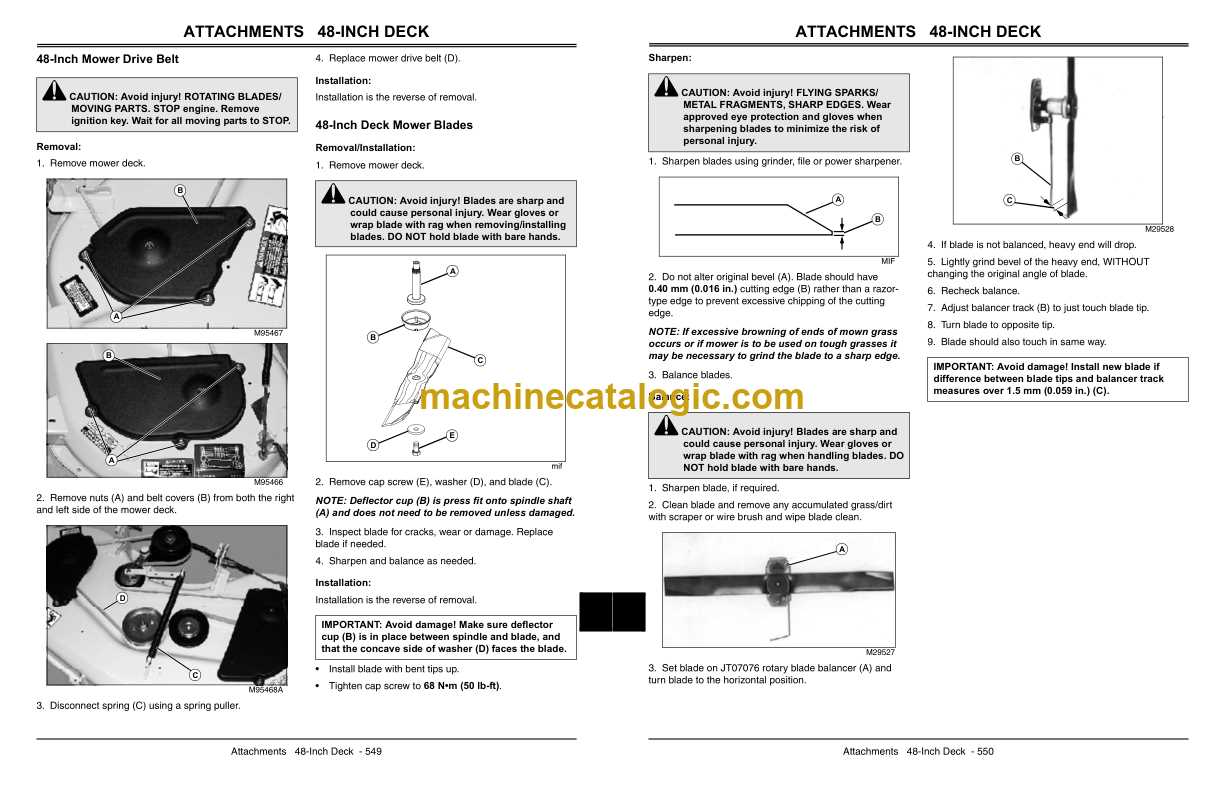

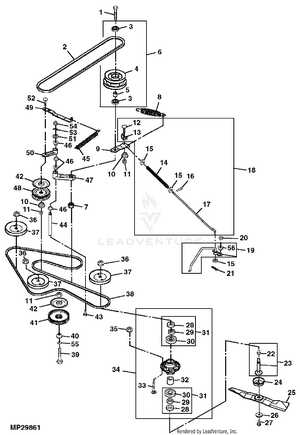

- Deck Configuration: Insights into the mowing deck and its adjustable settings for optimal cutting.

- Wheel Assembly: Description of the wheel sizes, types, and their role in maneuverability.

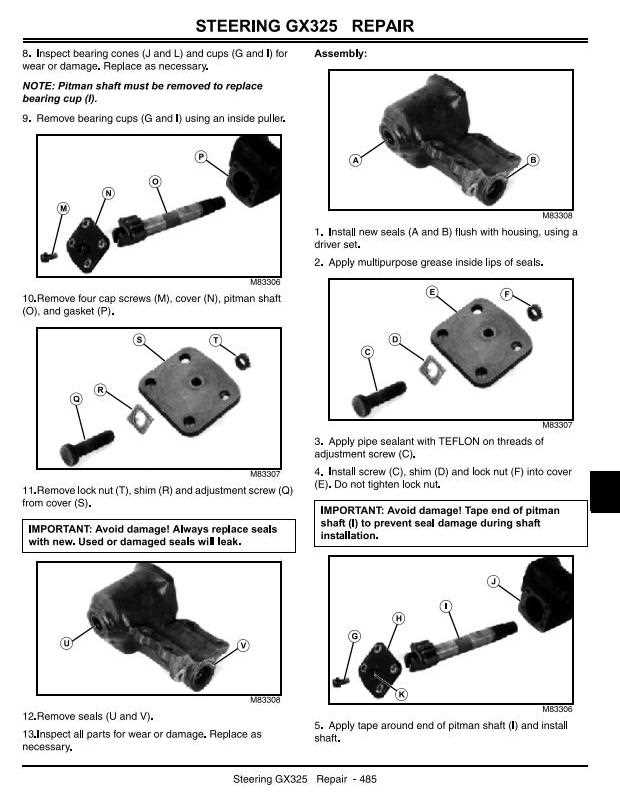

- Steering Mechanism: Overview of the steering system and its importance in navigation.

- Electrical Components: Summary of the electrical system and its functionality for efficient operation.

- Maintenance Tips: Guidelines on regular upkeep and troubleshooting common issues.

- Safety Features: Highlighting safety measures integrated into the design for user protection.

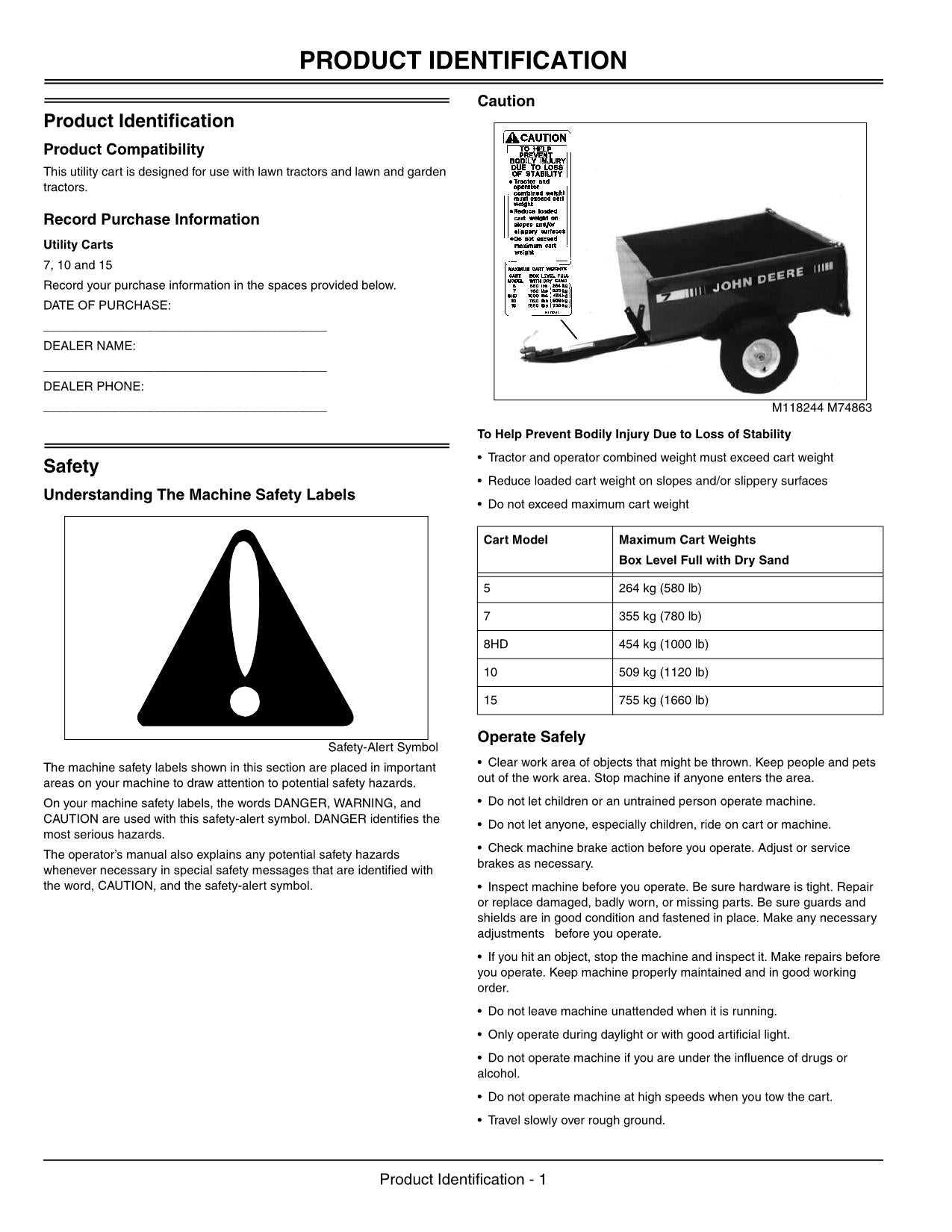

- Accessories and Attachments: Discussion of additional tools and accessories that enhance performance.

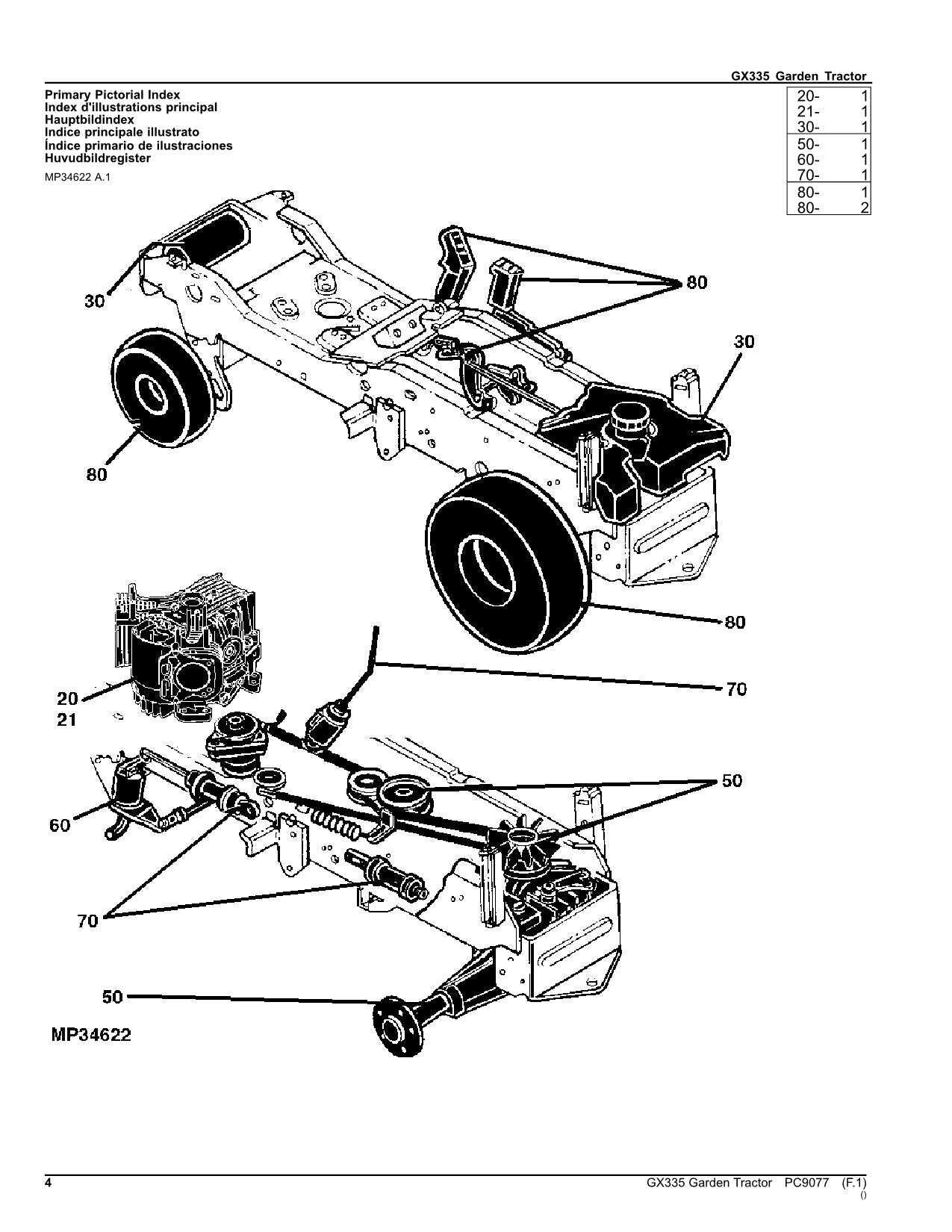

Key Components of GX335

The efficiency and performance of a compact lawn tractor depend on its essential elements. Understanding these fundamental parts allows users to maximize functionality and ensure the longevity of their equipment. This section will explore the vital components that contribute to the overall operation of this particular model.

One of the main features includes the powerful engine, which is responsible for driving the machine and providing the necessary torque for various tasks. Additionally, the cutting deck is crucial for achieving a precise and clean cut, featuring sharp blades that can tackle different grass types. The transmission system also plays a significant role, enabling smooth movement and speed adjustments to suit different terrains.

Moreover, the frame serves as the backbone of the unit, supporting all components and ensuring stability during operation. Other important parts include the steering mechanism, which allows for easy maneuverability, and the wheel assembly, designed for optimal traction and control. By familiarizing oneself with these critical elements, operators can maintain their equipment effectively and address any issues that may arise during use.

Importance of Parts Diagrams

Visual representations of components are crucial for understanding the assembly and functionality of machinery. They provide a clear overview of how each element fits together, facilitating maintenance and repair processes.

Accurate identification of components is essential for efficient troubleshooting. When users can easily locate the necessary elements within a schematic, they can swiftly address issues and ensure optimal performance.

Additionally, these visual aids serve as a valuable reference during reassembly, preventing errors and minimizing the risk of damage. By having access to a comprehensive overview, users can ensure that all necessary components are in place, thereby enhancing the longevity and efficiency of the equipment.

Understanding Engine Parts Layout

The arrangement of engine components is crucial for optimal performance and reliability. A well-organized configuration ensures that each part functions harmoniously, contributing to the overall efficiency of the machine. This section aims to provide insights into how various elements are positioned and their significance in maintaining effective operation.

Familiarity with the layout aids in diagnosing issues and performing maintenance tasks efficiently. Below is a simplified representation of the essential components typically found within an engine assembly, illustrating their typical arrangement:

| Component | Function |

|---|---|

| Cylinder | Houses the combustion process. |

| Piston | Transfers energy from combustion to mechanical motion. |

| Crankshaft | Converts linear motion into rotational motion. |

| Valves | Regulate the flow of air and fuel into the combustion chamber. |

| Camshaft | Controls the opening and closing of valves. |

| Fuel Injector | Delivers fuel into the combustion chamber. |

| Cooling System | Prevents overheating and maintains optimal temperature. |

Transmission System Breakdown

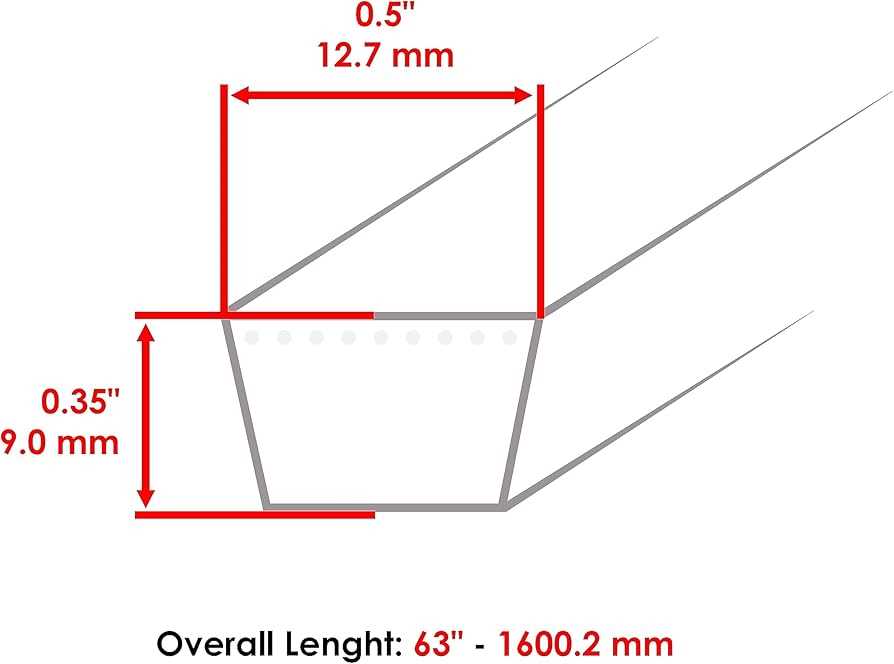

The transmission system is a crucial component in the operation of various machinery, responsible for transferring power from the engine to the wheels. Understanding the intricacies of this system is essential for efficient maintenance and repair.

This section will explore the key elements of the transmission system, highlighting its various components and their functions. A thorough comprehension of these elements can lead to improved performance and longevity of the equipment.

- Transmission Case: The outer housing that protects the internal components and contains the fluid.

- Gear Set: A collection of gears that facilitate the changing of speed and torque, ensuring the machinery operates smoothly under different conditions.

- Torque Converter: A device that transfers power from the engine to the transmission, allowing for a smooth transition of power.

- Clutch Assembly: Responsible for engaging and disengaging the engine from the transmission, enabling smooth gear shifts.

- Fluid Pump: Circulates transmission fluid to lubricate components and maintain optimal operating temperatures.

By focusing on these critical elements, operators can ensure their machinery runs efficiently and effectively, minimizing the risk of breakdowns and enhancing overall performance.

Hydraulic Components Explained

Hydraulic systems play a crucial role in the operation of various machinery by converting fluid power into mechanical energy. Understanding the individual components that make up these systems is essential for effective maintenance and repair.

Key Elements of Hydraulic Systems

- Hydraulic Pump: This device generates fluid flow and pressure, enabling the system to perform work.

- Actuators: These components convert hydraulic energy into mechanical motion, such as cylinders or motors.

- Valves: Used to control the flow and direction of hydraulic fluid within the system, ensuring efficient operation.

- Reservoir: A storage tank that holds hydraulic fluid, allowing for proper circulation and cooling of the system.

- Hoses and Fittings: Essential for connecting various components, ensuring secure fluid transfer and preventing leaks.

Maintenance Considerations

Regular maintenance of hydraulic components is vital for optimal performance. Key practices include:

- Checking fluid levels and quality regularly.

- Inspecting hoses for wear or damage.

- Testing pumps and actuators for proper functionality.

- Cleaning filters to prevent contamination.

By understanding these components and their functions, operators can ensure the longevity and reliability of their hydraulic systems.

Electrical System Overview

The electrical system in modern machinery plays a crucial role in ensuring optimal performance and reliability. This system integrates various components that work together to provide power, control, and communication across different functionalities. Understanding its structure and operation is essential for effective maintenance and troubleshooting.

Key Components

This system consists of several integral elements that contribute to its overall functionality. The primary components include the battery, alternator, wiring harness, and various sensors. Each part has a specific role, contributing to the machine’s efficiency and operational capabilities.

Electrical Circuit Configuration

Electrical circuits in machinery are designed to facilitate smooth power distribution and control signals. A basic understanding of how these circuits are arranged can aid in identifying potential issues and performing effective repairs.

| Component | Function |

|---|---|

| Battery | Stores electrical energy for starting and powering electrical devices. |

| Alternator | Generates electricity to recharge the battery and power electrical systems while the engine runs. |

| Wiring Harness | Distributes electrical power and signals between components. |

| Sensors | Monitor various system parameters and relay information to the control unit. |

Maintenance Parts and Accessories

Ensuring optimal performance of your equipment requires the right components and supplementary items. Regular upkeep not only enhances functionality but also prolongs the lifespan of machinery. This section covers essential elements that contribute to effective maintenance, ensuring your tools operate smoothly and efficiently.

Essential Components

Various elements play a crucial role in maintaining efficiency. Regularly checking and replacing worn-out components is vital for preventing malfunctions. Key items include filters, belts, and fluids, all of which should be selected based on the manufacturer’s recommendations to ensure compatibility and effectiveness.

Additional Tools and Supplies

Alongside primary components, certain accessories can significantly improve the maintenance process. Tools like wrenches, screwdrivers, and cleaning supplies are indispensable for performing routine checks and repairs. Investing in high-quality implements not only simplifies tasks but also ensures safety and reliability.

Identifying Common Wear Items

In any machinery, certain components experience regular degradation due to constant use and environmental factors. Recognizing these items is crucial for maintaining optimal performance and prolonging the lifespan of the equipment. By understanding which parts typically wear out, operators can proactively replace them and avoid potential breakdowns.

Key Components to Monitor

Several elements are prone to wear and should be regularly checked. These components often include belts, blades, and filters. Monitoring their condition can significantly enhance efficiency and prevent costly repairs.

Maintenance and Replacement Schedule

Implementing a routine maintenance schedule can help in tracking the state of wear items. Frequent inspections allow for timely replacements, reducing the risk of unexpected failures. Below is a table summarizing the typical wear items and their recommended inspection intervals:

| Component | Recommended Inspection Interval |

|---|---|

| Belts | Every 50 hours of use |

| Blades | Every 25 hours of use |

| Filters | Every 100 hours of use |

Ordering Replacement Parts

When it comes to maintaining equipment, sourcing quality components is essential for optimal performance. Whether you are repairing a lawn tractor or other machinery, knowing how to procure the right items can save time and ensure durability.

Here are some key steps to follow when placing an order for new components:

- Identify the Required Component:

Before making a purchase, it is crucial to determine the exact item needed for replacement. Consult the user manual or service guides to find the specifications.

- Find a Reliable Supplier:

Look for reputable retailers or online platforms that specialize in machinery components. Consider checking reviews and ratings to gauge their reliability.

- Check Compatibility:

Ensure that the item you intend to purchase is compatible with your equipment model. Cross-reference with manufacturer specifications to avoid any mismatches.

- Compare Prices:

Take the time to compare prices from different sources. This will help you find the best deal without compromising quality.

- Review Return Policies:

Before finalizing your order, review the return and exchange policies of the supplier. This will provide peace of mind in case the wrong item is received.

Following these guidelines can streamline the process of obtaining essential components, ensuring that your equipment remains in peak condition for years to come.

Tips for DIY Repairs

Engaging in self-repairs can be a rewarding experience that saves time and money. Understanding the fundamentals of maintenance can empower you to tackle various tasks with confidence. Here are some helpful strategies to ensure successful outcomes during your repair endeavors.

Before commencing any work, it’s essential to gather the necessary tools and materials. Organizing your workspace will not only streamline the process but also enhance safety. Familiarize yourself with the equipment to avoid potential pitfalls.

| Tip | Description |

|---|---|

| Research | Take time to study manuals or guides related to your equipment. Understanding its components will aid in identifying issues. |

| Safety First | Always prioritize safety by wearing appropriate gear and ensuring the work area is free from hazards. |

| Take Notes | Documenting the steps you take can help you remember the process for future reference and assist others who may need similar repairs. |

| Ask for Help | Don’t hesitate to seek advice from experienced individuals or online communities. Sharing knowledge can lead to better outcomes. |

| Test Thoroughly | After completing repairs, ensure to test the equipment thoroughly to confirm that it operates as intended. |

Resources for Parts Information

Finding reliable information regarding components and their specifications is crucial for effective maintenance and repair of machinery. Various resources are available that provide insights into the necessary elements required for equipment upkeep. These resources can range from official manuals to online platforms where users share their experiences and recommendations.

Official Manuals and Documentation

Manufacturers often publish comprehensive guides that detail the specifications and installation procedures for their equipment. These documents serve as a primary source of information for understanding the various elements of machinery.

Online Communities and Forums

Engaging with online communities can be an excellent way to gather insights from other users. These platforms often feature discussions on troubleshooting and maintenance, making them valuable for anyone seeking advice or information on specific components.

| Resource Type | Description | Benefits |

|---|---|---|

| Official Manuals | Documentation provided by the manufacturer | Detailed specifications and installation instructions |

| Online Forums | Discussion platforms for user experiences | Practical advice and shared knowledge |

| Retailer Websites | Online stores selling machinery components | Availability of various components and prices |