Understanding John Deere Front Quick Hitch Parts Diagram

In the realm of agricultural machinery, the efficient connection of implements is crucial for optimal performance. A comprehensive overview of these connection elements enhances the user’s ability to maintain and utilize their equipment effectively. Grasping the intricate relationships between various components can lead to improved functionality and productivity.

Within this section, we will explore the essential elements involved in the assembly and attachment of implements to tractors. By examining the layout and interrelations of these components, users can gain insights that facilitate smoother operations and reduce the risk of malfunctions. Knowledge of these details is paramount for any operator looking to maximize the utility of their machinery.

Delving into the specifics allows for a clearer understanding of how each piece interacts within the larger system. This exploration not only aids in identifying necessary replacements but also enhances overall maintenance practices, ensuring that equipment remains in peak condition for all agricultural tasks.

Understanding John Deere Quick Hitch Systems

Quick attachment systems enhance the versatility of agricultural machinery, allowing for seamless integration of various implements. These innovations simplify the process of switching tools, increasing efficiency in farming operations. Understanding the components and mechanics behind these systems is crucial for optimal performance.

Key Features of Attachment Mechanisms

Modern attachment systems offer several features designed for user convenience. Quick connect mechanisms ensure a secure fit, while adjustable components provide flexibility for different implements. Safety locks prevent accidental disengagement, contributing to safer operation in the field.

Maintenance and Troubleshooting

Regular maintenance is essential for ensuring the longevity of attachment systems. Inspecting for wear and tear, lubricating moving parts, and ensuring proper alignment can prevent costly repairs. If issues arise, understanding the basic troubleshooting steps can save time and enhance productivity.

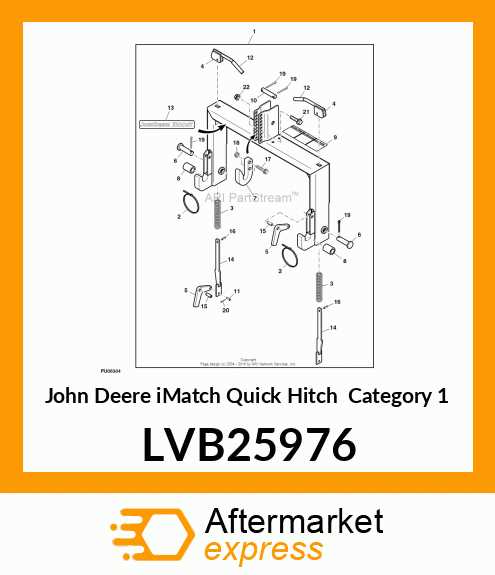

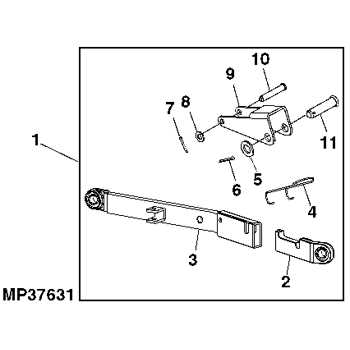

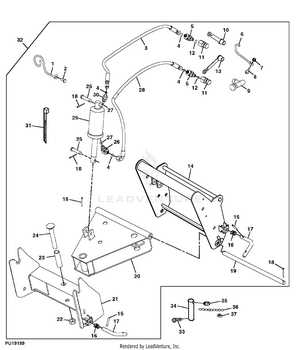

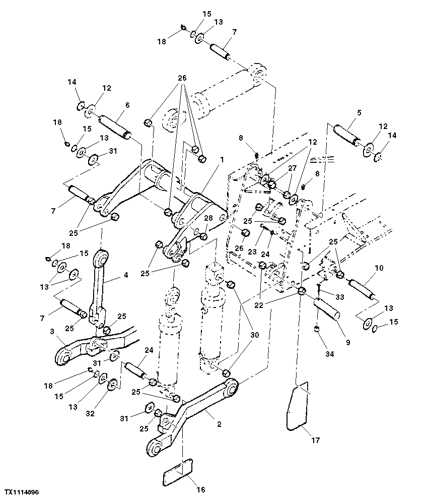

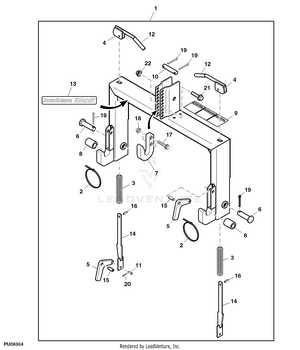

Components of Front Quick Hitch

This section delves into the essential elements that constitute an attachment mechanism used for tractors. Understanding these components is crucial for optimizing functionality and enhancing the versatility of agricultural equipment.

Key Elements

The primary components include a robust frame designed for stability, along with connectors that facilitate seamless engagement with various implements. Additionally, hydraulic systems play a vital role in enabling smooth operation and adjustments.

Supporting Features

Among the supporting features are safety latches, which ensure secure attachment during operation. Furthermore, adjustable linkages allow for compatibility with different tool designs, making the setup adaptable to diverse tasks.

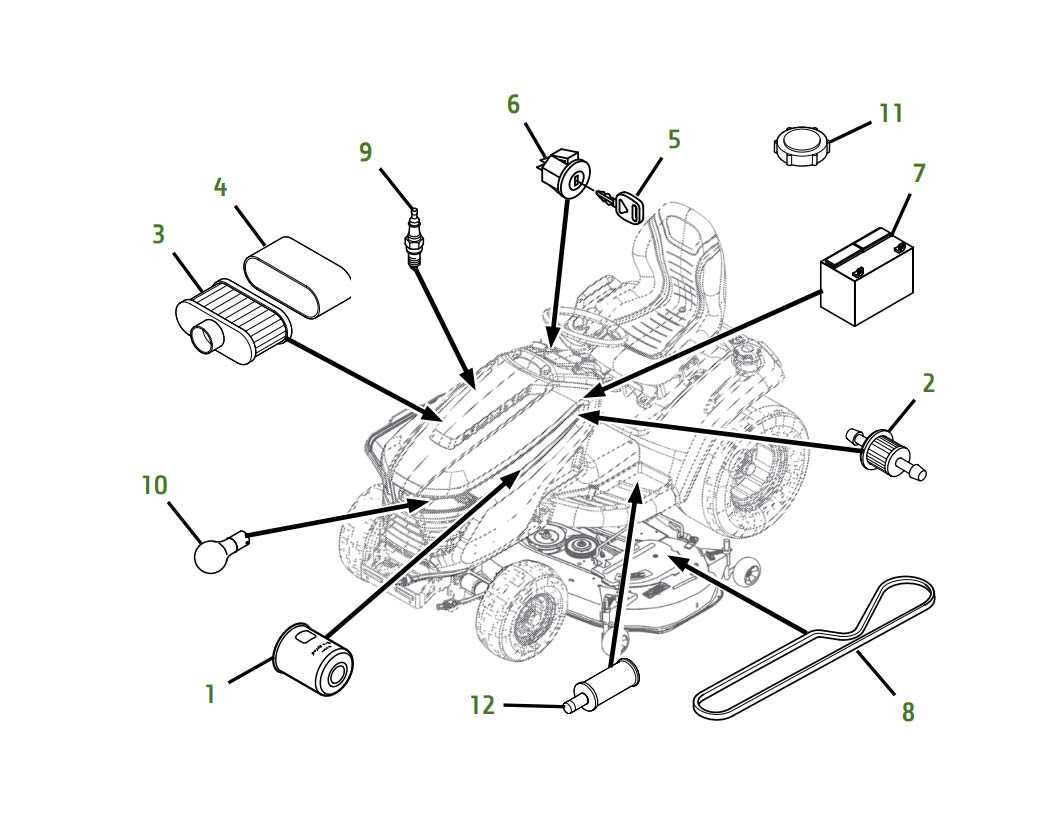

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and assembly. These illustrations serve as guides, showing how various elements interact within a larger system. Mastering the interpretation of these visuals can streamline repairs and enhance overall functionality.

Key Elements to Identify

- Labels: Look for annotations that provide names or numbers for each component.

- Symbols: Familiarize yourself with common icons that represent specific functions or parts.

- Connections: Observe lines or arrows indicating how components are linked or interact.

Steps to Analyze

- Start by scanning the entire illustration for a general overview.

- Focus on individual sections to understand the roles of specific components.

- Refer to the accompanying legend or key for detailed explanations of symbols.

- Cross-reference with the actual items if possible, to solidify understanding.

Benefits of Using Quick Hitch

The integration of versatile coupling systems significantly enhances operational efficiency in agricultural practices. These systems allow for swift attachment and detachment of implements, streamlining workflow and saving valuable time during tasks.

Increased Efficiency

Utilizing these advanced connection methods minimizes downtime between equipment changes. Operators can transition from one tool to another with minimal effort, facilitating a more productive work environment.

Improved Versatility

These systems enable the use of a wider variety of implements, allowing operators to tackle diverse tasks with ease. This adaptability is essential for maximizing the utility of machinery across various farming activities.

| Benefit | Description |

|---|---|

| Time-Saving | Quick attachment and release reduce operational delays. |

| Ease of Use | Simplifies the process of changing implements for operators. |

| Enhanced Productivity | Allows for more tasks to be completed in less time. |

| Flexibility | Supports a wide range of attachments for various jobs. |

Common Issues with Quick Hitch Parts

When working with attachment systems, users often encounter several challenges that can impact functionality and efficiency. Understanding these common problems can aid in better maintenance and performance.

Frequent Problems

- Worn or damaged connectors can lead to improper fitting.

- Rust and corrosion may impede movement and functionality.

- Misalignment of components affects the overall performance.

- Loose bolts and fasteners can result in instability during operation.

Maintenance Tips

- Regularly inspect all components for wear and damage.

- Clean and lubricate joints to prevent rust build-up.

- Tighten all fasteners to ensure secure connections.

- Store equipment in a dry place to minimize exposure to moisture.

Maintenance Tips for Quick Hitch

Proper upkeep of attachment systems is essential for optimal performance and longevity. Regular maintenance ensures that all components function smoothly and reduces the risk of unexpected failures.

Regular Inspections

- Check for wear and tear on all connectors.

- Inspect for rust or corrosion on metal surfaces.

- Ensure all moving parts are lubricated adequately.

Cleaning Practices

- Remove dirt and debris after each use.

- Use a pressure washer for thorough cleaning, if needed.

- Dry all components to prevent moisture buildup.

Comparing Different Quick Hitch Models

This section explores various models designed for easy attachment and detachment of implements, highlighting their unique features and functionalities.

- Model A: Known for its robust construction and compatibility with a wide range of equipment.

- Model B: Features a lightweight design, making it ideal for smaller tractors while maintaining strength.

- Model C: Offers advanced quick-release mechanisms, allowing for rapid implement changes without hassle.

- Model D: Prioritizes ease of use with ergonomic adjustments, suited for frequent operation.

Each model presents distinct advantages tailored to different user needs, allowing for efficient farming or landscaping tasks.

Installation Guide for Quick Hitch Parts

This section provides a comprehensive overview for the assembly of essential components designed to enhance your equipment’s efficiency. Understanding the proper techniques and tools required is crucial for achieving optimal performance and longevity.

Step 1: Begin by organizing all necessary components in a clean workspace. Ensure you have the correct tools, such as wrenches and sockets, readily available to facilitate a smooth installation process.

Step 2: Carefully align each piece according to the provided specifications. Pay close attention to the orientation of each element, as incorrect positioning may lead to operational issues.

Step 3: Secure all connections firmly, but avoid over-tightening to prevent damage. Utilizing a torque wrench can help maintain the appropriate tension on bolts and screws.

Step 4: After assembly, conduct a thorough inspection to confirm that all components are securely fastened and properly aligned. This step is vital to ensure safe and efficient operation.

Step 5: Finally, perform a test run to check for any irregularities in operation. Make necessary adjustments based on your observations to achieve the best results.

Finding Genuine John Deere Parts

Ensuring the authenticity of components is crucial for maintaining equipment performance and longevity. Genuine items provide reliability and compatibility, ultimately enhancing your machinery’s efficiency.

Why Choose Authentic Components?

- Quality Assurance

- Perfect Fit

- Manufacturer Support

How to Identify Genuine Components

- Check Packaging: Look for branding and official seals.

- Verify Serial Numbers: Match with manufacturer records.

- Consult Authorized Dealers: Purchase from trusted sources.

Upgrading Your Quick Hitch System

Enhancing your attachment system can significantly improve efficiency and functionality. By selecting the right components, you can ensure seamless compatibility and increased performance.

Consider the following aspects when upgrading:

- Compatibility: Ensure new attachments match existing equipment.

- Strength: Opt for durable materials that withstand heavy usage.

- Ease of Use: Look for designs that simplify the connection process.

Additionally, explore the benefits of:

- Improved versatility with multiple attachments.

- Enhanced safety features to prevent accidents.

- Increased lifting capacity for more demanding tasks.

Ultimately, investing in an upgraded system can lead to greater productivity and satisfaction in your operations.

Safety Considerations When Using Quick Hitches

Ensuring safety while operating equipment is paramount, especially when utilizing attachment mechanisms. Proper understanding and adherence to safety guidelines can prevent accidents and injuries, promoting a secure working environment.

Before engaging any implement, it is crucial to inspect the connection for wear or damage. This assessment helps to identify potential issues that could compromise safety during operation.

Always follow the manufacturer’s instructions regarding weight limits and compatibility of attachments. Overloading or using incompatible equipment can lead to equipment failure, posing risks to the operator and bystanders.

Additionally, ensure that all safety features, such as pins and locking mechanisms, are properly engaged before use. This precaution minimizes the chances of accidental detachment during operation.

Training and awareness are vital. Operators should be well-versed in safe practices and emergency procedures to effectively respond to unexpected situations.

Frequently Asked Questions About Quick Hitches

This section addresses common inquiries related to attachment systems used for tractors and other agricultural machinery. Understanding these components can enhance efficiency and ease of use for operators.

What are the main benefits of using an attachment system?

Utilizing an efficient connection mechanism allows for quick changes between various implements, thereby saving time and increasing productivity. Additionally, these systems are designed to provide enhanced stability and security while in operation.

How do I maintain my attachment system?

Regular inspections and proper lubrication are essential for longevity. Ensure all components are free of dirt and debris, and check for signs of wear or damage. Proper maintenance will help prevent costly repairs and ensure optimal performance.