Yamaha 6hp Outboard Parts Diagram Overview

In the world of marine propulsion systems, comprehending the intricate components of small engines is essential for maintenance and repair. Each element plays a crucial role in ensuring optimal performance and reliability on the water. This guide aims to provide a detailed look at the various components that contribute to the functionality of these power units.

By familiarizing oneself with the key elements, enthusiasts and operators can enhance their understanding of how each piece interacts within the system. This knowledge not only aids in troubleshooting but also empowers users to undertake effective maintenance practices, ensuring longevity and efficiency.

In this exploration, we will delve into the various sections of the propulsion system, highlighting the function and significance of each component. Whether for casual outings or serious boating endeavors, knowing how these pieces work together can greatly enhance the experience and performance of any marine vessel.

Understanding Yamaha 6hp Outboard Components

This section aims to explore the various elements that contribute to the functionality of a compact marine engine. By comprehending how each component interacts, users can enhance their knowledge for maintenance, repair, or optimization purposes. Each part plays a vital role in ensuring smooth operation and reliability on the water.

Key Elements of the Engine

- Fuel System: Responsible for delivering the right amount of fuel to the engine. It typically includes a fuel tank, lines, and a carburetor.

- Ignition System: Essential for starting the engine, this system ignites the fuel-air mixture to produce power.

- Cooling Mechanism: Prevents overheating by circulating water around the engine components.

- Exhaust System: Facilitates the expulsion of gases produced during combustion, ensuring efficiency and safety.

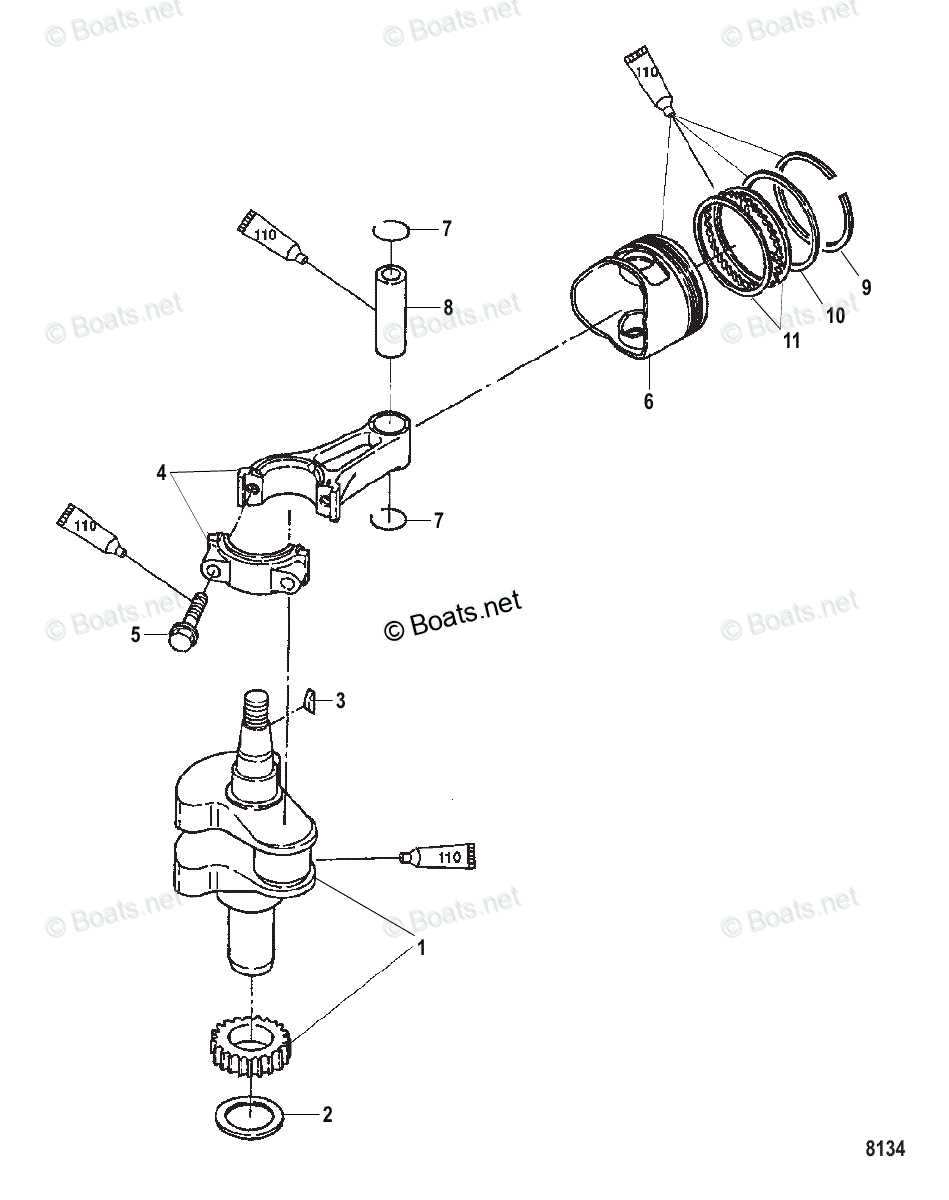

Mechanical Components

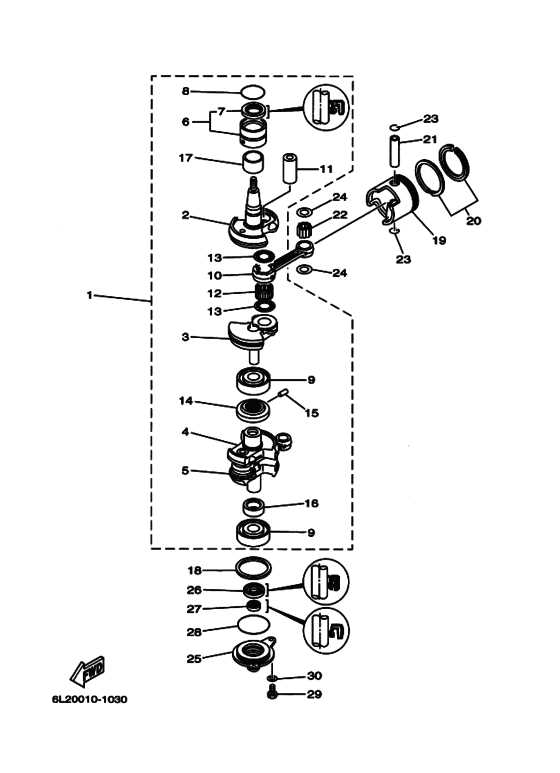

- Crankshaft: Converts the linear motion of the pistons into rotational motion to drive the propeller.

- Pistons: Move up and down within the cylinders, creating the power necessary for propulsion.

- Cylinder Head: Houses the combustion chamber and includes valves that control the intake and exhaust processes.

- Gearbox: Adjusts the speed and torque transmitted to the propeller, allowing for versatile navigation.

Understanding these components provides a solid foundation for anyone interested in marine engines, enabling effective troubleshooting and informed decision-making during maintenance activities.

Exploring Key Features of Yamaha Engines

Marine engines are known for their remarkable efficiency, reliability, and performance, making them essential for a variety of watercraft. Understanding the distinctive characteristics of these power units can significantly enhance the experience of operating boats and other water vessels. This section delves into some of the pivotal features that define these engines and contribute to their popularity among enthusiasts and professionals alike.

One notable aspect of these engines is their innovative design, which emphasizes lightweight construction and compact dimensions. This allows for easier handling and improved maneuverability, especially in smaller vessels. Furthermore, advanced engineering techniques have been employed to ensure that these units deliver consistent power while minimizing fuel consumption.

Another key feature is the incorporation of cutting-edge technology that enhances performance and reliability. From electronic fuel injection systems to advanced cooling mechanisms, each component is crafted to optimize functionality and prolong the lifespan of the engine.

| Feature | Description |

|---|---|

| Lightweight Design | Facilitates easy handling and improved maneuverability. |

| Fuel Efficiency | Delivers maximum power while consuming minimal fuel. |

| Advanced Cooling Systems | Ensures optimal operating temperatures for enhanced performance. |

| Durability | Built with high-quality materials to withstand harsh marine environments. |

In conclusion, these engines exemplify a harmonious blend of performance, efficiency, and durability. Their innovative features not only elevate the boating experience but also establish a standard in the marine industry.

Essential Parts for Maintenance and Repair

Ensuring the longevity and efficiency of your marine engine requires a thorough understanding of its critical components. Regular maintenance and timely repairs are essential for optimal performance. Familiarity with the fundamental elements involved in operation can significantly enhance the reliability and durability of the machinery.

Fuel System: This includes components such as the fuel tank, fuel filter, and fuel lines. Regular inspection and replacement of these elements can prevent fuel contamination and ensure a smooth operation.

Ignition System: Key to the engine’s starting process, the ignition system comprises spark plugs, coils, and wiring. Maintaining these components is vital for reliable ignition and overall performance.

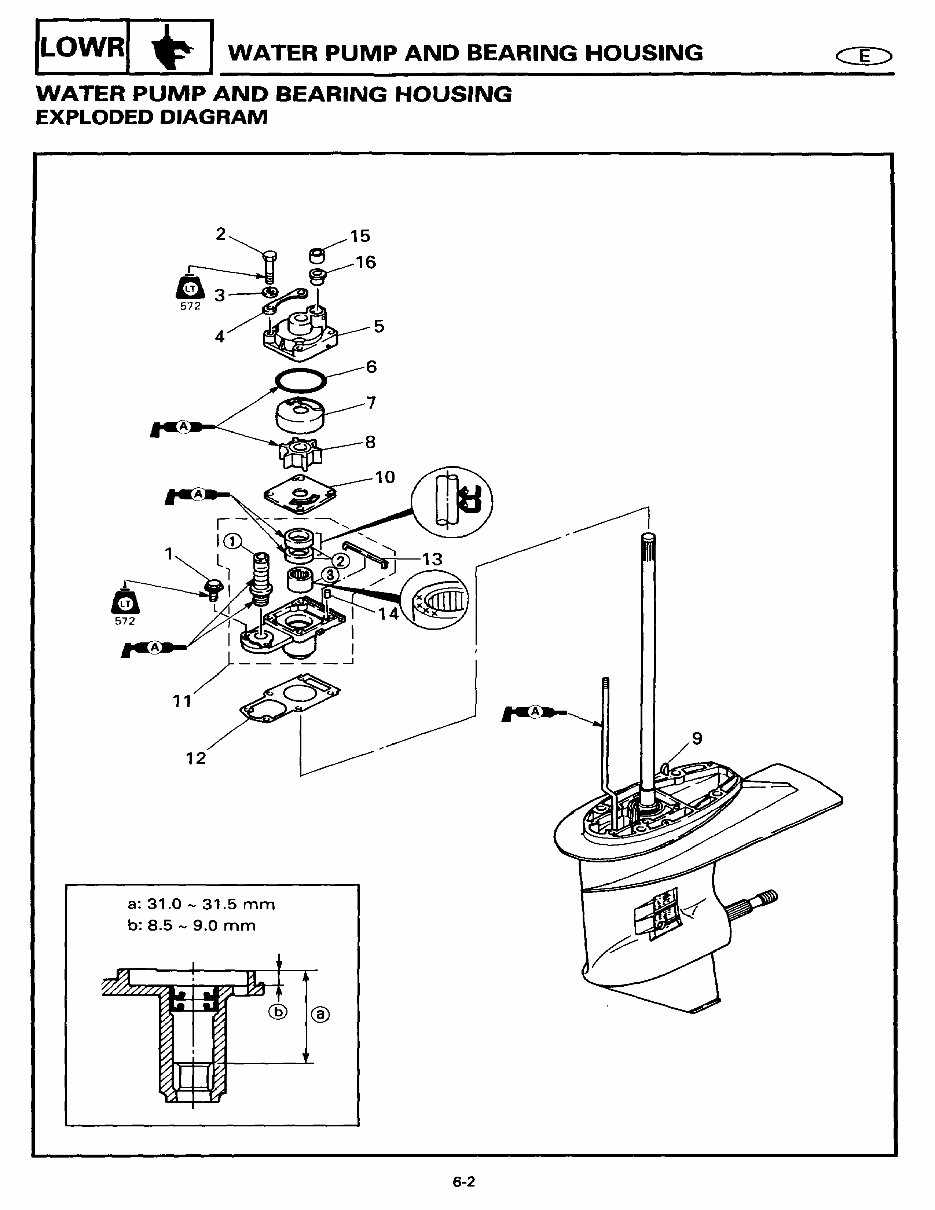

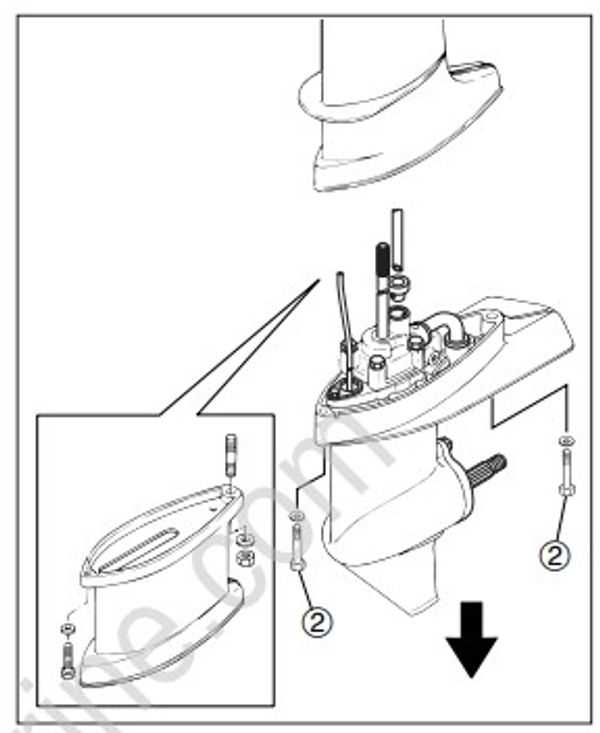

Cooling System: Overheating can lead to severe damage. Essential elements in this system include the water pump, thermostat, and cooling passages. Regular checks and replacements can prevent overheating issues.

Lubrication System: Adequate lubrication minimizes friction and wear on moving parts. Important components include the oil pump, oil filter, and various seals. Regular oil changes and system checks are crucial for engine health.

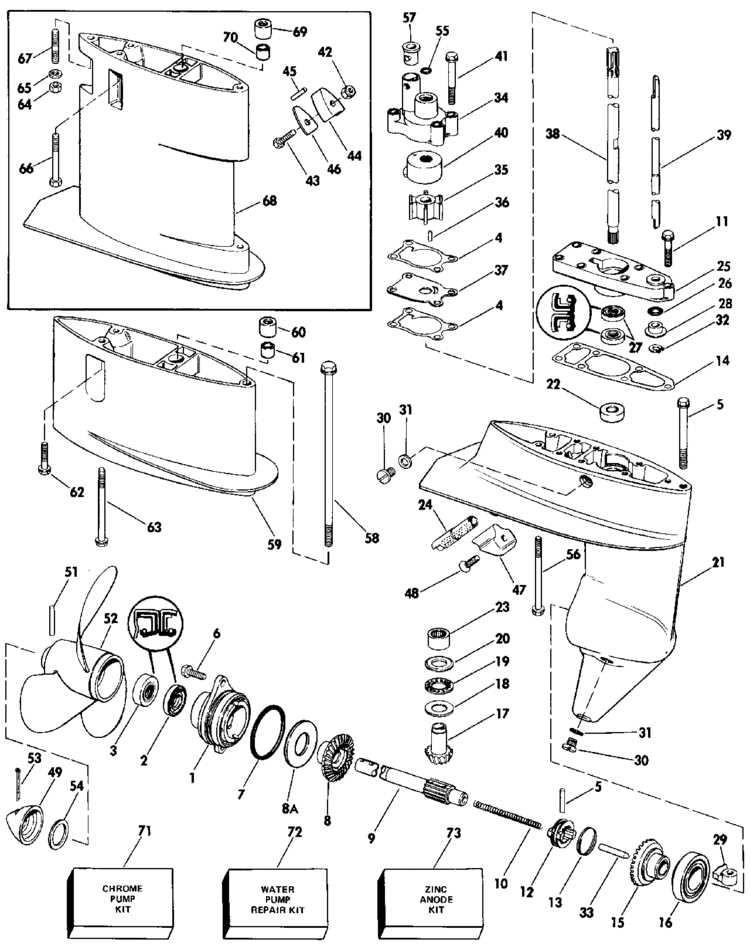

Propulsion Components: These consist of the propeller, drive shaft, and lower unit. Ensuring these elements are in good condition is critical for efficient movement and maneuverability on the water.

Understanding and maintaining these essential components can help prevent unexpected failures and ensure a safe, enjoyable experience on the water.

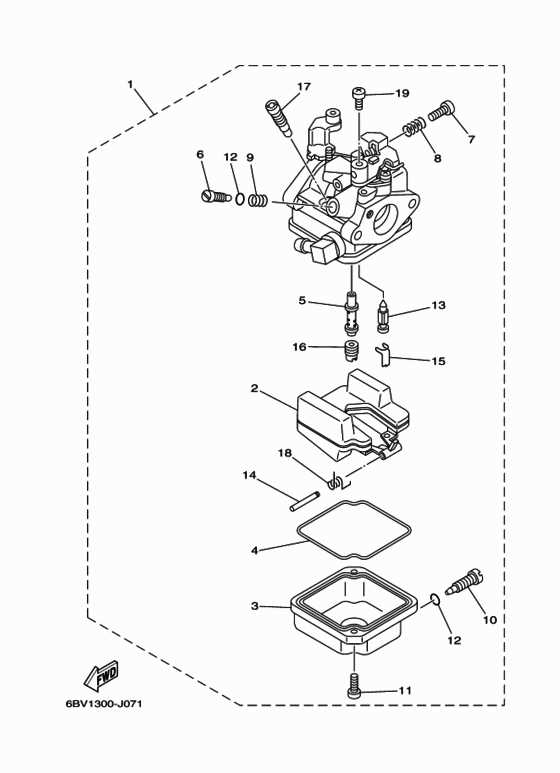

Overview of Fuel System Components

The fuel system plays a crucial role in ensuring optimal performance and efficiency of marine engines. It is responsible for delivering the appropriate amount of fuel to the combustion chamber, allowing for smooth operation and effective power generation. Understanding the various elements of this system is essential for maintenance and troubleshooting.

Key Elements of the Fuel System

The primary components of the fuel system include the fuel tank, fuel pump, fuel filter, and carburetor. Each part has a specific function that contributes to the overall functionality of the engine. The fuel tank stores the fuel, while the fuel pump ensures a steady supply by moving the fuel from the tank to the engine. The fuel filter removes impurities, preventing damage to the engine, and the carburetor mixes the fuel with air in the correct ratio for combustion.

Importance of Maintenance

Regular maintenance of the fuel system is vital to prevent issues such as clogging or fuel leaks. Inspecting components for wear and tear, ensuring proper fuel flow, and replacing filters as needed can significantly enhance the longevity and performance of the engine. By paying attention to these elements, users can enjoy reliable operation and avoid costly repairs.

Cooling System and Its Importance

The cooling mechanism is a crucial aspect of any marine propulsion unit, ensuring optimal performance and longevity. This system prevents overheating by circulating a coolant, which absorbs excess heat generated during operation. Without an effective cooling system, the engine could face severe damage, leading to costly repairs and decreased reliability.

Proper temperature regulation is vital for maintaining the efficiency of the engine. An overheated engine can lead to a decrease in power output and performance, while running at an optimal temperature allows for smoother operation and better fuel efficiency. Additionally, maintaining appropriate temperatures helps prolong the lifespan of internal components.

Routine maintenance of the cooling system is essential for preventing issues that could arise from neglect. This includes checking for blockages, inspecting hoses and connections, and ensuring that the coolant is at the proper level. Regular maintenance not only enhances performance but also provides peace of mind to the operator.

In summary, the cooling system plays a fundamental role in ensuring the engine operates efficiently and reliably. By understanding its significance and committing to regular upkeep, users can enhance the overall performance and durability of their marine engines.

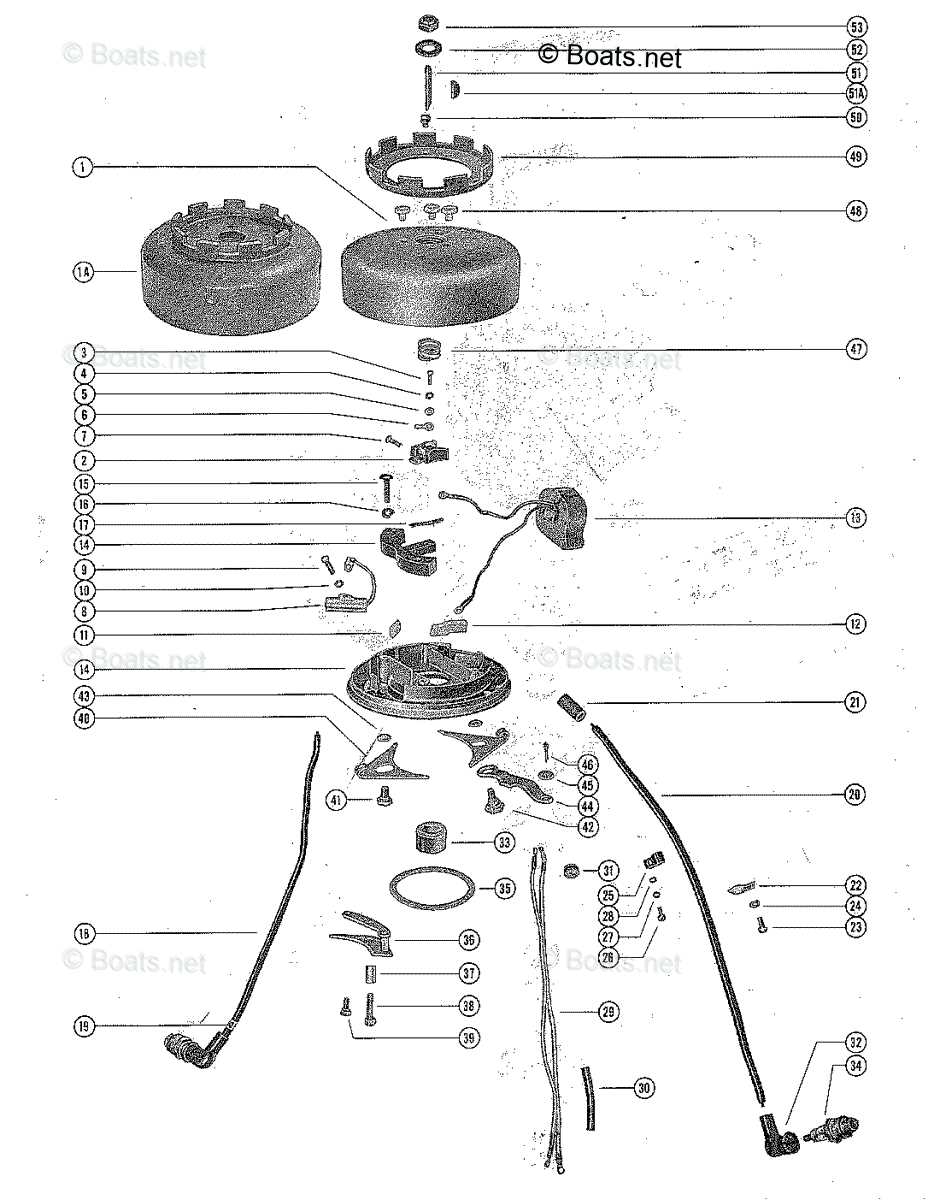

Electrical Parts and Their Functions

Understanding the various components responsible for the electrical systems in marine engines is essential for optimal performance and reliability. These elements play crucial roles in ensuring the engine operates smoothly, providing power for ignition, navigation, and control functions.

Key Components

- Battery: Supplies the necessary power to start the engine and operate electrical accessories.

- Ignition Coil: Converts battery voltage into a higher voltage to create a spark for ignition.

- Voltage Regulator: Maintains a consistent voltage level to protect electrical components from fluctuations.

- Starter Motor: Engages the engine when starting, providing the initial rotation needed to ignite the fuel.

- Wiring Harness: Connects all electrical components, facilitating the flow of electricity throughout the system.

Functions of Electrical Components

- Power Management: Efficiently regulates the electrical supply to prevent overload and ensure longevity.

- Signal Transmission: Facilitates communication between various sensors and the control unit for real-time monitoring.

- Safety Features: Integrates protective measures such as fuses and circuit breakers to avoid damage from electrical faults.

- Lighting: Powers navigation and safety lights, enhancing visibility during operation.

- Control Systems: Enables the operator to manage engine functions effectively, improving overall control and responsiveness.

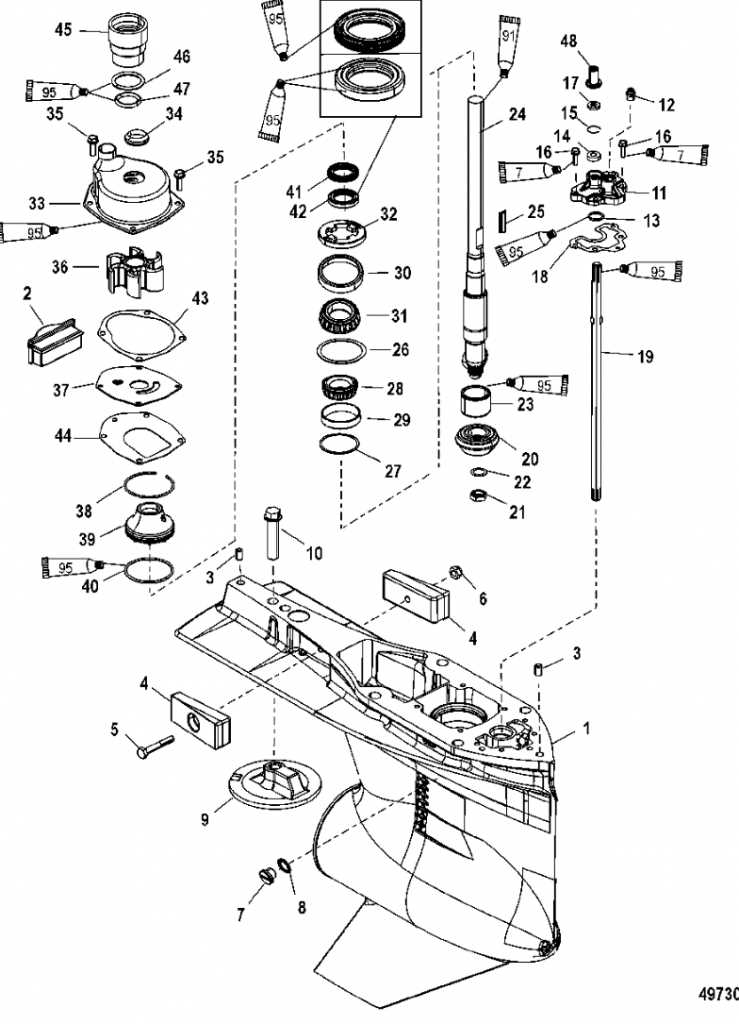

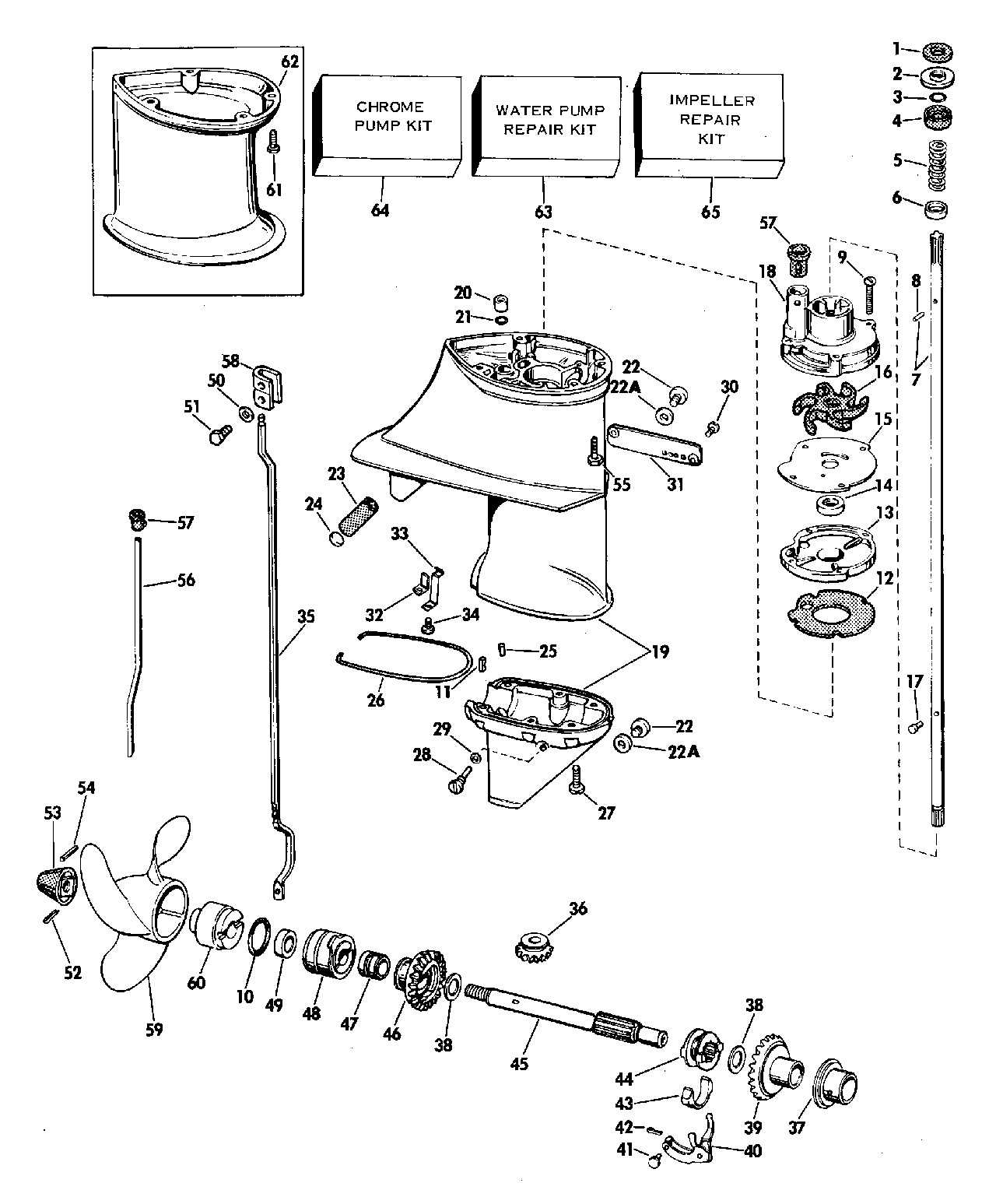

Identifying Propulsion System Elements

Understanding the components that contribute to the propulsion system is essential for effective maintenance and optimal performance. Each element plays a specific role in ensuring smooth operation and efficiency, and recognizing them can significantly aid in troubleshooting and repairs.

Main Components

- Propeller: The key element responsible for generating thrust by converting engine power into movement.

- Shaft: Connects the engine to the propeller, transmitting rotational force.

- Gearbox: Facilitates the change in speed and torque, allowing for efficient power transfer to the propeller.

- Coupling: Connects the shaft to the engine, ensuring a secure fit and efficient power transfer.

Additional Elements

- Control Cables: Enable the operator to adjust throttle and gear settings from the helm.

- Fuel System: Supplies the engine with the necessary fuel for operation, impacting overall performance.

- Cooling System: Maintains optimal operating temperatures, preventing overheating and ensuring longevity.

Recognizing these components helps in assessing the system’s health and performance. Regular inspections and understanding their functions can prevent potential issues and enhance the overall experience.

Importance of Safety Equipment

Ensuring a safe experience while navigating on water is paramount. Having the right safety gear not only protects individuals but also enhances overall enjoyment and confidence during outings. Whether one is fishing, recreational boating, or exploring, prioritizing safety is essential.

Proper safety equipment can significantly reduce risks and prevent accidents. Some key items to consider include:

- Life Jackets: Essential for all passengers, these should fit well and be easily accessible.

- First Aid Kits: A well-stocked kit can address minor injuries and emergencies.

- Flare Guns: Useful for signaling distress and ensuring visibility in case of an emergency.

- Fire Extinguishers: A critical component for fire safety, especially on fuel-powered vessels.

- Communication Devices: Having a reliable means to communicate can be lifesaving.

Investing in quality safety gear is not just a legal requirement in many regions but also a responsible choice. Regular checks and maintenance of equipment ensure readiness in unexpected situations. By adopting a proactive approach to safety, individuals can enjoy their time on the water with peace of mind.

Common Issues with Outboard Motors

Watercraft propulsion systems can experience various challenges that impact their performance and reliability. Understanding these frequent problems can help in maintaining and troubleshooting the motor, ensuring optimal operation during outings.

Fuel Problems: Inadequate fuel supply or contamination can lead to engine stalling or poor performance. Regular checks on fuel quality and cleanliness of fuel lines are essential to prevent these issues.

Electrical Failures: Issues with wiring, connections, or battery performance may hinder the ignition system. Ensuring that electrical components are in good condition can help avert starting difficulties.

Overheating: Insufficient cooling can cause engines to overheat, often due to blockages in water intake or a malfunctioning pump. Monitoring cooling systems and ensuring unobstructed water flow is critical to avoid damage.

Propeller Damage: Dents or bends in the propeller can negatively affect thrust and efficiency. Regular inspections for physical damage and alignment can help maintain optimal functionality.

Corrosion: Exposure to water can lead to rust and corrosion, impacting various metal components. Applying protective coatings and performing routine maintenance can mitigate this issue.

Being aware of these common challenges allows for proactive measures and timely interventions, enhancing the longevity and reliability of marine propulsion systems.

Resources for Parts Replacement

Finding reliable sources for component replacement is crucial for maintaining the efficiency and longevity of your marine engine. Whether you are looking to repair a malfunctioning element or upgrade your existing setup, a variety of options are available to help you acquire the necessary items.

- Manufacturer Websites: Official sites often provide detailed information about available components, including specifications and compatibility details.

- Authorized Dealers: Local retailers or online distributors that are recognized by the manufacturer can offer genuine items and expert assistance.

- Marine Supply Stores: Specialty shops focused on marine equipment frequently stock a range of components, tools, and accessories.

- Online Marketplaces: Platforms such as eBay or Amazon can be useful for finding both new and used items at competitive prices, although verification of the seller’s reputation is recommended.

- Forums and Community Groups: Online communities dedicated to marine activities can provide valuable insights, recommendations, and sometimes even direct sales of components from fellow enthusiasts.

When sourcing replacements, consider factors such as warranty, return policies, and customer reviews to ensure you make informed decisions.

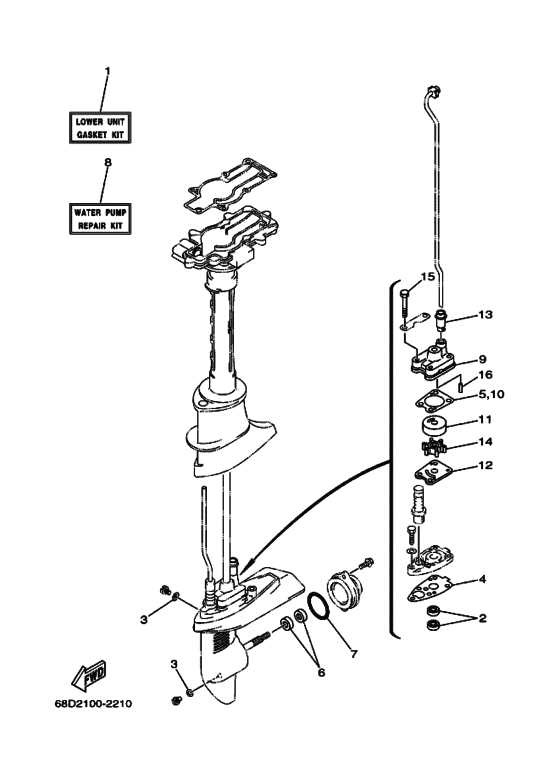

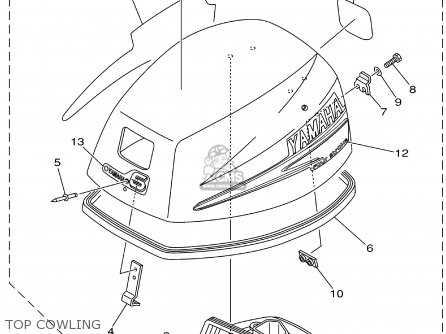

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair tasks. These visual aids provide a detailed view of individual elements and their interconnections, helping users identify and source the necessary components efficiently.

Identifying Key Elements

When examining a schematic, focus on the following aspects:

- Labels: Each component is usually marked with a specific identifier, making it easier to reference in manuals or when ordering.

- Numbers: Numerical annotations often indicate the quantity or sequence of items within the assembly.

- Lines and Arrows: These illustrate connections and flow, highlighting how components interact within the system.

Using the Information Effectively

Once familiar with the key elements, utilize the schematic for:

- Ordering Replacement Items: Match the labels and numbers with those in supplier catalogs to ensure accuracy.

- Identifying Assembly Locations: Understand where each component fits within the overall configuration, simplifying installation or repairs.

- Troubleshooting: Use the visual aid to pinpoint potential issues by tracing connections and relationships between parts.

Tips for Efficient Outboard Operation

Maximizing the performance of a marine propulsion system involves several best practices that ensure optimal fuel efficiency and longevity of the equipment. By adopting effective techniques, operators can enhance their experience on the water while minimizing unnecessary wear and tear on their vessels.

Regular Maintenance

Routine upkeep is essential to keeping a propulsion unit functioning smoothly. This includes checking fluid levels, inspecting for wear, and ensuring all components are in good condition. Regular maintenance not only extends the lifespan of the equipment but also improves its overall efficiency.

Optimal Fuel Management

Using high-quality fuel and adhering to recommended octane ratings can significantly affect performance. Additionally, monitoring fuel consumption and making adjustments to operating speed can lead to better mileage and reduced costs over time.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Check fluid levels | Before each use | Prevents overheating and damage |

| Inspect spark plugs | Every 50 hours | Ensures smooth ignition |

| Clean fuel filter | Every season | Improves fuel flow and performance |

| Examine propeller | Monthly | Identifies damage and increases efficiency |