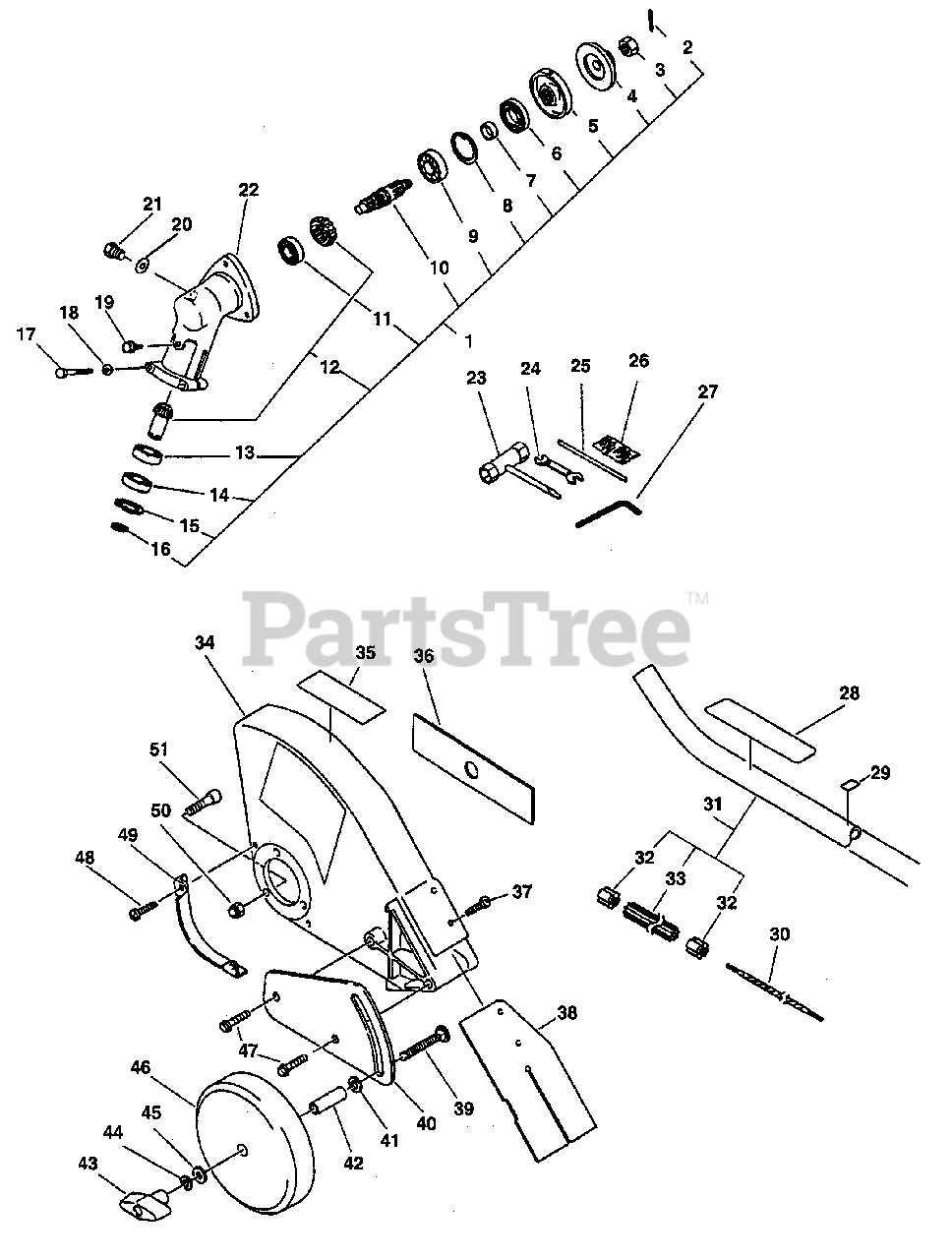

SRM-2100 Parts Diagram Overview

When it comes to understanding the internal structure of any mechanical system, having a clear view of its essential elements is critical. This section will walk you through the vital connections and mechanical pieces that ensure smooth operation and functionality. By examining these individual components, you’ll gain a better understanding of how they all work together to achieve seamless performance.

In the following sections, we will explore the main assemblies and individual elements that make up the core of this system. From the internal workings to the external features, every part plays an important role in maintaining reliability and efficiency. These details will help you identify the function and importance of each piece, making it easier to approach maintenance or troubleshooting tasks.

Understanding the SRM-2100 Components Layout

The arrangement of key elements in this equipment plays a crucial role in ensuring its efficient operation. By recognizing how the various sections are positioned, users can gain a deeper understanding of its overall functionality. This knowledge helps with maintenance and identifying potential issues without the need for professional assistance.

Key Functional Areas

Each section is organized to perform specific tasks that contribute to the machine’s performance. For example, power-related modules and control systems are strategically placed for ease of access. Learning the purpose and location of these areas allows for quicker problem-solving and routine check-ups.

Navigation and Maintenance

Familiarity with the internal setup makes navigation during troubleshooting more intuitive. Knowing where essential components are located enables effective maintenance, reducing downtime and enhancing the reliability of the equipment. Regular checks on acc

Exploring Key Mechanical Parts of SRM-2100

This section delves into the essential components that make up the core of this machine’s functionality. Understanding how various elements work together is crucial for maintaining smooth operation and ensuring long-lasting performance. Each element is designed to fulfill a specific role, contributing to the overall efficiency and durability.

Drive Mechanism

The driving system is the powerhouse behind the device, transforming energy into movement. Its components work in harmony to ensure reliable motion, providing the necessary force to complete tasks efficiently. Proper alignment and maintenance of these elements ensure consistent operation and prevent wear.

Cutting Assembly

The cutting assembly is responsible for precision and sharpness in performance. Built for durability, it includes elements designed to withstand heavy use while delivering clean and accurate results. Regular inspection and care of these components extend the lifespan of the equipment and maintain high-quality performance.

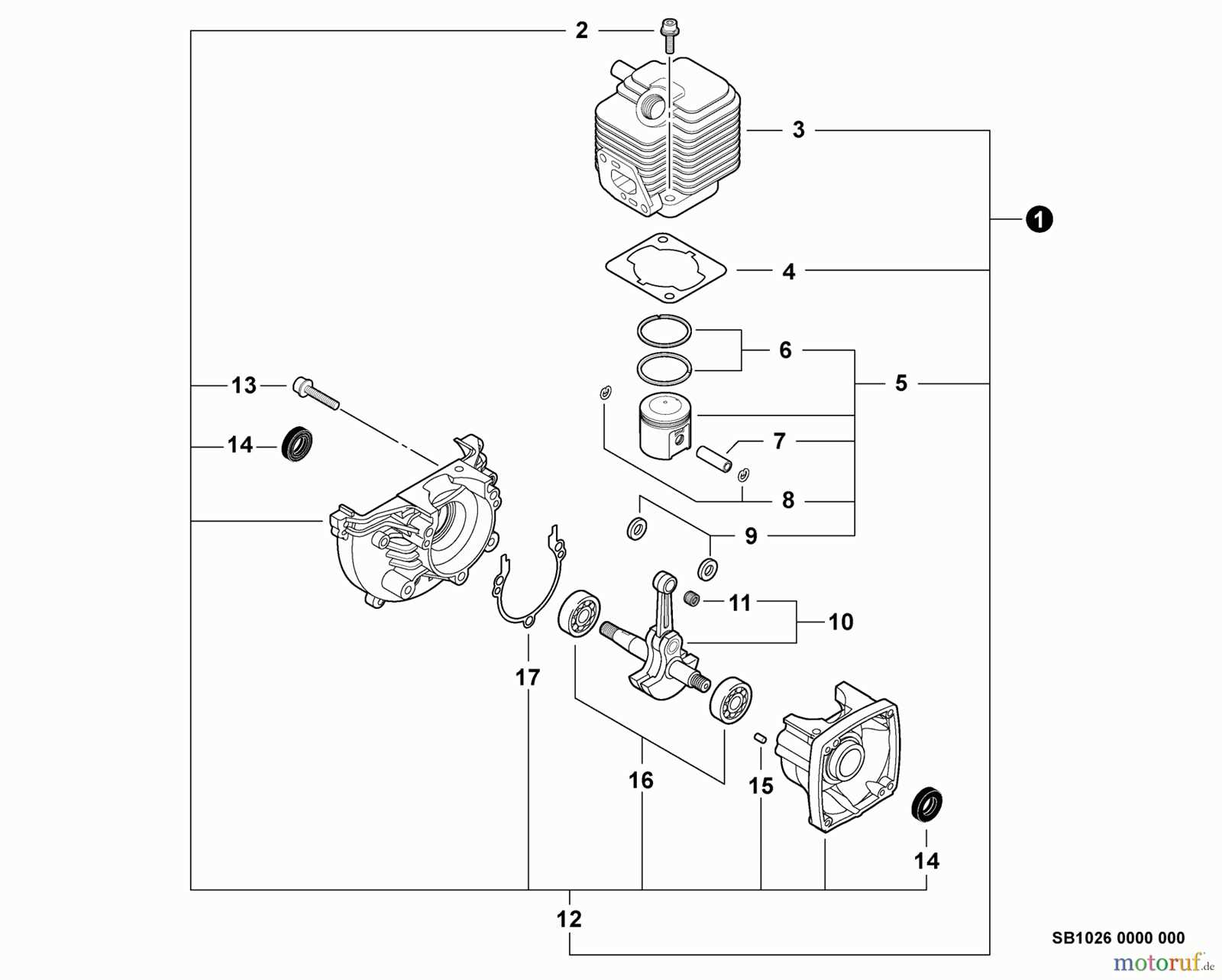

Detailed Overview of the SRM-2100 Engine Assembly

The following section provides a comprehensive examination of the key components responsible for the functionality and efficiency of the engine assembly. It delves into the internal mechanisms that ensure smooth operation, detailing the crucial segments that contribute to the overall performance of the system.

- Cylinder and Piston Mechanism: This part controls the core movements within the engine, driving the operational cycle by converting pressure into motion.

- Carburetor System: A vital element responsible for blending air and fuel to maintain optimal combustion. It ensures the proper ratio is met for efficient operation.

- Ignition Unit: Essential for sparking the combustion process, this system triggers the necessary reaction to start the engine’s power cycle.

- Exhaust Pathway: This section is designed to expel gases safely, reducing harmful emissions and

SRM-2100 Fuel System Diagram and Functions

The internal combustion process relies on a carefully designed fuel delivery network, ensuring the efficient flow of energy. This setup is essential for optimal engine performance, regulating how the mixture of air and fuel is introduced into the combustion chamber. Each component within this structure plays a crucial role in managing the movement and distribution of fuel, contributing to the overall efficiency and reliability of the equipment.

The fuel delivery mechanism typically includes several key elements, each responsible for a specific task. The flow of liquid fuel begins from the storage container and is directed through a series of passageways that ensure proper pressurization and filtration before reaching the engine. These elements work in unison to maintain a steady supply of clean fuel, free from contaminants, ensuring that the combustion process occurs smoothly.

A proper balance between air intake and fuel injection is vital.

Electrical Components in SRM-2100: A Breakdown

Understanding the essential electrical elements within the system is key to ensuring optimal performance. These components work together to power and regulate the machine, ensuring smooth operation across various functions. Knowing how each piece fits into the larger system can help with both maintenance and troubleshooting.

Power Supply and Distribution

The primary source of energy is crucial for the entire operation. It delivers the necessary current to all connected elements. Proper wiring and stable connections are vital for efficient power distribution, preventing potential disruptions or failures during operation.

Control Systems

The control section manages the regulation of power, ensuring that each part receives the correct amount of energy. These systems include circuits and other key elements that monitor performance, enabling the equipment to function reliably and safely under various conditions.

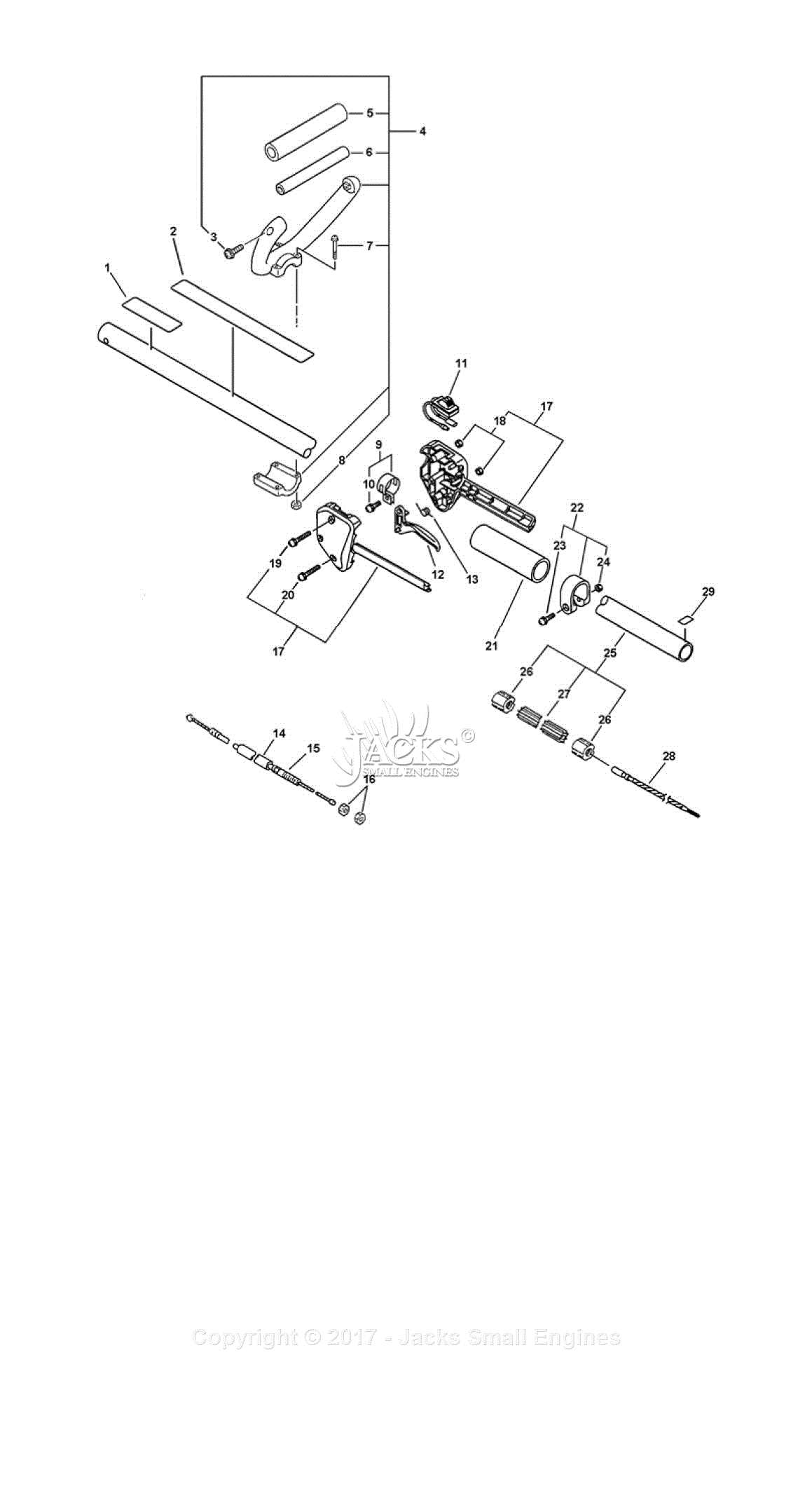

Understanding the SRM-2100 Throttle and Control Mechanisms

The throttle and control systems in any machinery play a crucial role in regulating performance and responsiveness. In this context, it is essential to examine how these components interact to ensure efficient operation. The effective management of speed and power is achieved through a well-designed mechanism that allows for precise adjustments, thereby enhancing the overall user experience.

Components of the Throttle Mechanism

- Throttle Body: Responsible for controlling the air intake, directly affecting engine performance.

- Control Linkage: Connects the throttle control to the throttle body, facilitating smooth operation.

- Actuator: Engages and disengages the throttle based on input, ensuring accurate speed management.

Control System Functionality

This system relies on a series of interconnected components that work together seamlessly. Each part contributes to the overall functionality, ensuring that operators can maintain optimal performance levels. Key functions include:

- Speed Regulation: Adjusting the throttle allows for variations in speed based on operational requirements.

- Power Distribution: Effective control mechanisms distribute power efficiently to different parts of the system.

- Response Time: A well-designed throttle system minimizes lag between input and output, enhancing overall responsiveness.

Understanding these elements is vital for ensuring the smooth operation of any machinery. Regular maintenance and awareness of how these systems function can significantly improve performance and longevity.

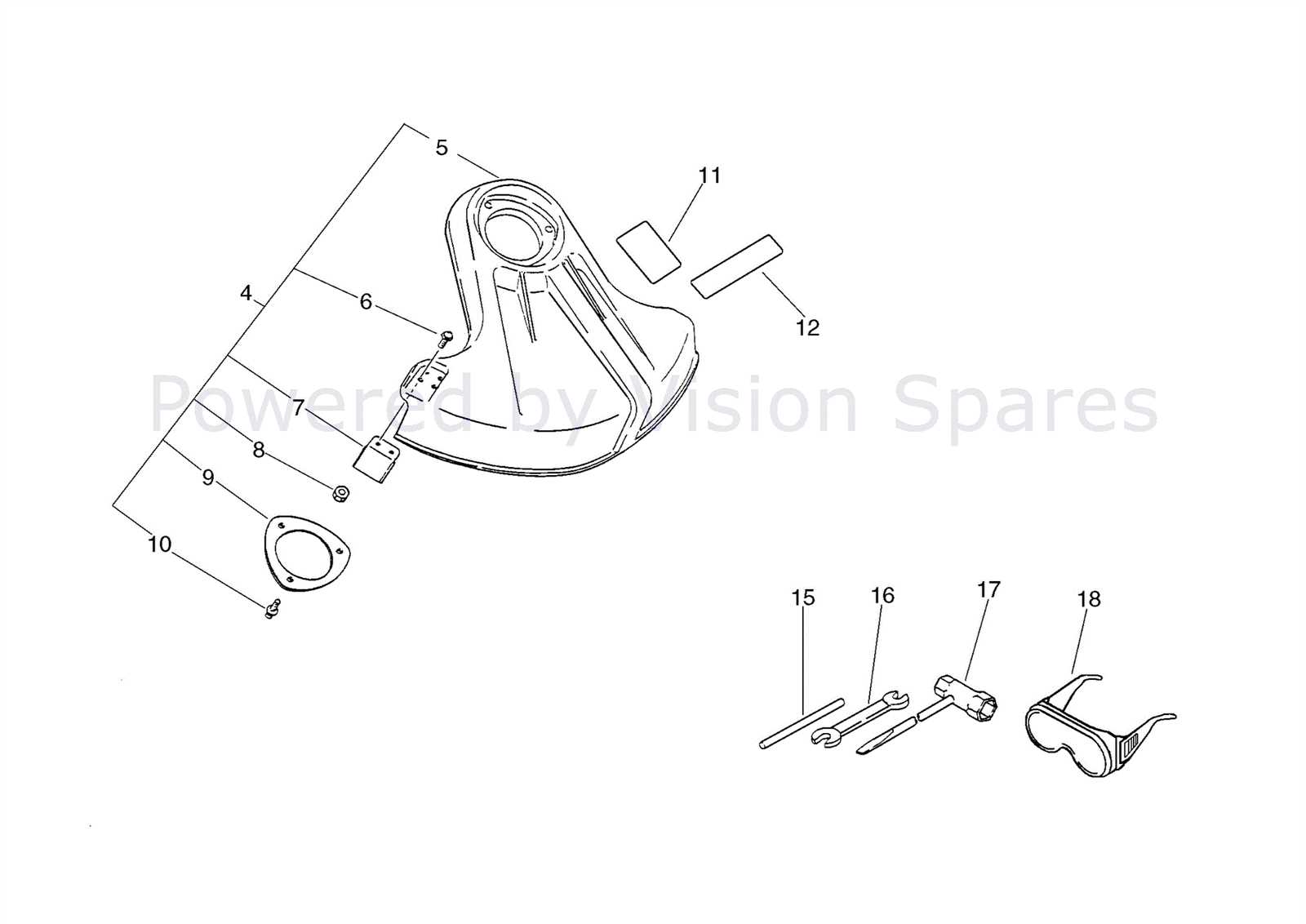

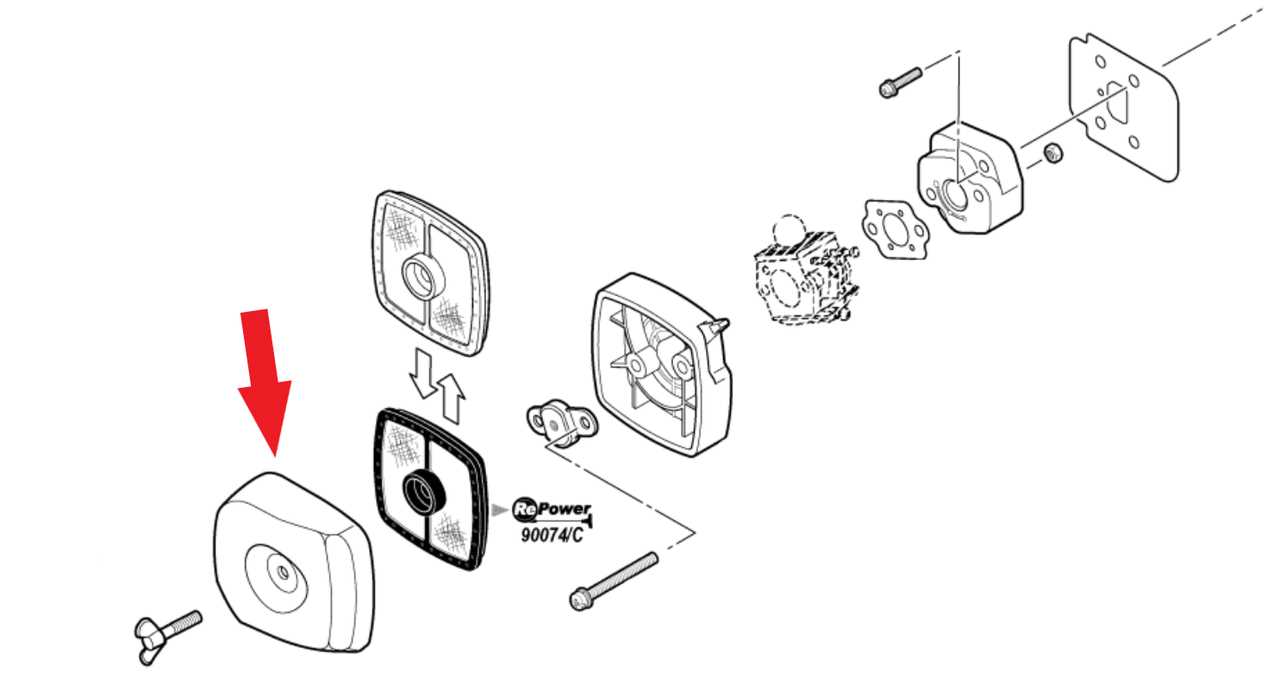

Air Filtration System in SRM-2100: An Overview

The air filtration mechanism is a crucial component designed to maintain optimal air quality within the equipment. This system works to capture and eliminate airborne impurities, ensuring that the internal environment remains clean and efficient for operational tasks.

This filtration setup plays a vital role in enhancing performance and longevity by preventing the ingress of dust and particulates. Its design incorporates multiple layers that effectively filter out contaminants while allowing necessary airflow.

Component Description Primary Filter This element captures larger particles, preventing them from entering the internal systems. Secondary Filter Designed to trap smaller particles that may have bypassed the primary filter. Pre-Filter An initial line of defense that enhances the lifespan of the main filtration components. Filter Housing Encases the filtration elements, ensuring secure installation and easy maintenance access. Regular maintenance and timely replacement of these components are essential to ensure the system operates efficiently, thereby enhancing the overall functionality of the equipment.

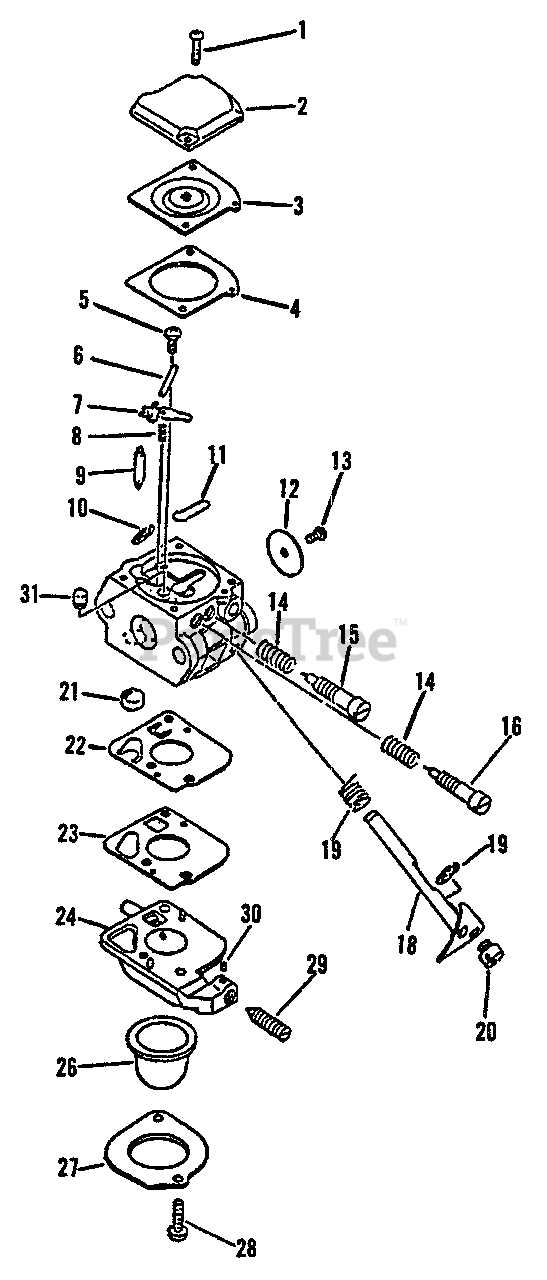

SRM-2100 Carburetor Parts and Functions

The component responsible for mixing fuel and air in an optimal ratio plays a vital role in the overall performance of a combustion engine. Understanding its different elements and their respective roles is essential for effective maintenance and troubleshooting.

Below is an overview of the key elements that contribute to the functionality of this assembly:

- Fuel Inlet: This entry point allows the flow of fuel into the system, ensuring a steady supply for combustion.

- Float Chamber: Maintains a constant fuel level, enabling proper mixing with air for combustion.

- Needle Valve: Regulates the amount of fuel entering the float chamber, playing a crucial role in maintaining the correct fuel level.

- Venturi Tube: This narrowing section creates a vacuum that draws fuel into the air stream, facilitating the mixing process.

- Throttle Valve: Controls the amount of air-fuel mixture entering the engine, influencing speed and power output.

- Choke Valve: Assists in starting the engine by enriching the air-fuel mixture during cold starts.

Each of these components interacts seamlessly to ensure that the engine operates efficiently, providing the necessary power for various tasks. Regular inspection and cleaning of these elements can prevent performance issues and prolong the lifespan of the equipment.

Exhaust System in SRM-2100: Key Elements

The exhaust mechanism plays a critical role in ensuring optimal performance and efficiency in small engines. This system facilitates the expulsion of combustion byproducts, contributing to cleaner operation and reduced emissions. Understanding its essential components helps users maintain and troubleshoot issues effectively.

Main Components

- Exhaust Muffler: This element reduces noise generated during operation and helps in the control of exhaust flow.

- Exhaust Pipe: A conduit that directs exhaust gases away from the engine and disperses them into the atmosphere.

- Gaskets and Seals: Essential for preventing leaks, these components ensure a secure connection between various parts of the system.

Functionality

The exhaust assembly operates by channeling gases produced during combustion. As the engine runs, these gases pass through the muffler and pipe, where noise reduction occurs before being released into the environment. Regular inspection of the exhaust system is crucial for maintaining engine health and performance.

SRM-2100 Ignition System Parts and Operations

The ignition mechanism is a crucial component of any engine, playing a vital role in initiating combustion and ensuring optimal performance. Understanding the various elements involved in this system is essential for effective maintenance and troubleshooting. This section delves into the individual components that contribute to the functionality of the ignition mechanism, as well as their specific operations.

Component Function Ignition Coil Transforms low voltage from the battery into high voltage needed for spark generation. Spark Plug Delivers the electric spark to ignite the air-fuel mixture in the combustion chamber. Ignition Module Controls the timing and delivery of the spark based on engine conditions. Starter Motor Engages the engine to initiate the combustion process when starting. Flywheel Stores rotational energy and helps maintain engine speed during combustion cycles. Each of these components works in harmony to ensure efficient ignition, impacting the overall performance and reliability of the engine. Regular inspection and maintenance of these elements are essential for preventing operational issues and enhancing longevity.

Vibration Dampening Mechanism in SRM-2100

The vibration dampening system plays a crucial role in enhancing the performance and longevity of machinery. By effectively reducing oscillations and vibrations generated during operation, this mechanism contributes to improved stability and comfort. It achieves this by utilizing a combination of materials and design features that absorb and dissipate energy, preventing it from transferring to other components.

This innovative mechanism often incorporates various elements such as isolators, dampers, and flexible couplings. Isolators are designed to minimize the transmission of vibrations, while dampers convert kinetic energy into thermal energy, thereby reducing motion. Flexible couplings further enhance this effect by allowing for slight misalignments and absorbing shocks, ensuring smooth operation even under varying conditions.

Regular maintenance and monitoring of the vibration dampening system are essential to ensure optimal functionality. Over time, wear and tear can affect its performance, leading to increased vibrations and potential damage to the machinery. By addressing these issues promptly, operators can maintain efficiency and prevent costly repairs.

SRM-2100 Starter Assembly: A Complete Guide

The starter assembly plays a crucial role in initiating the engine’s operation, providing the necessary force to turn over the motor. Understanding its components and functionality can enhance maintenance and troubleshooting processes. This guide delves into the various elements of the starter mechanism, ensuring optimal performance and longevity.

Key Components of the Starter Mechanism

- Starter Motor: The primary unit that engages the engine, converting electrical energy into mechanical motion.

- Drive Gear: This component connects the starter motor to the flywheel, enabling the motor to spin and start the engine.

- Solenoid: Acts as a switch, allowing current to flow to the starter motor when the ignition is activated.

- Battery Connection: Supplies the necessary power for the starter assembly to function effectively.

Maintenance Tips

- Regularly check electrical connections for corrosion and ensure they are secure.

- Inspect the starter motor for signs of wear or damage, which may hinder performance.

- Keep the drive gear clean and lubricated to prevent jamming during operation.

- Test the solenoid to ensure it activates properly when the ignition is engaged.

Maintenance Tips for SRM-2100 Components

Proper upkeep of essential components is crucial for ensuring optimal performance and longevity. Regular attention to these elements can prevent unexpected failures and extend the lifespan of the equipment. This section provides valuable insights into effective maintenance practices tailored for specific elements.

Regular Inspection

Conducting routine checks can help identify wear and tear before they lead to significant issues. Look for signs of damage, such as cracks, corrosion, or looseness. Ensuring all connections are secure is vital for reliable operation.

Cleaning and Lubrication

Keep components free from debris and contaminants. Use appropriate cleaning agents and tools to maintain hygiene. Additionally, apply suitable lubricants to moving parts to reduce friction and prevent premature wear.

Component Inspection Frequency Maintenance Action Drive Mechanism Monthly Check for alignment and lubrication Cooling System Quarterly Clean filters and check fluid levels Electrical Connections Biannually Inspect for corrosion and secure all connections