The fuel system is responsible for delivering the necessary energy to the engine, ensuring smooth and efficient operation. It involves several interconnected components that work together to maintain proper fuel flow and pressure throughout the engine’s operation. Understanding these connections can help in identifying issues and maintaining optimal performance.

The fuel system connections begin at the tank, where the pump draws fuel and sends it through the lines. Along the way, the fuel is filtered before reaching the injectors. The injectors then deliver the precise amount needed for combustion, ensuring efficiency and power. Each connection is vital for maintaining the balance and flow within the system.

The ignition mechanism is a critical component responsible for initiating the engine’s combustion process. It operates by generating the necessary electrical current to spark the engine, ensuring smooth and efficient operation. This system is integral to the overall functionality of any motorized equipment, playing a key role in starting and maintaining engine performance.

The primary elements of this system include the spark plugs, coils, and control module. Each part works in harmony to ensure the correct timing and intensity of the spark, which is essential for the engine to function. These components interact with the engine’s overall electrical system to deliver optimal ignition and performance.

Problems within this system can result in misfires, difficulty starting, or engine stalling. Regular inspection and maintenance of the ignition elements can prevent these issues, ensuring consistent and reliable performance. Proper care and timely replacements of the necessary components are key to avoiding major breakdowns.

The cooling mechanism in a motor is essential for maintaining optimal performance by regulating heat produced during operation. This system is composed of various components that work together to ensure the engine runs smoothly, preventing overheating and extending its lifespan.

Key elements within this structure collaborate to circulate fluids, dissipate heat, and ensure temperature stability. Below is an overview of the main components involved:

- Pump: Responsible for driving the coolant through the entire system, ensuring steady circulation.

- Heat Exchanger: A critical part that helps lower the temperature of the fluid before it returns to the engine.

- Thermostatic Valve: Controls the flow of liquid, opening or closing depending on the current temperature.

- Pipes and Hoses: Transport the coolant between the various elements of the system, ensuring proper flow and efficiency.

- Coolant Reservoir: Holds the fluid that circulates through the system, providing a steady supply for continuous cooling.

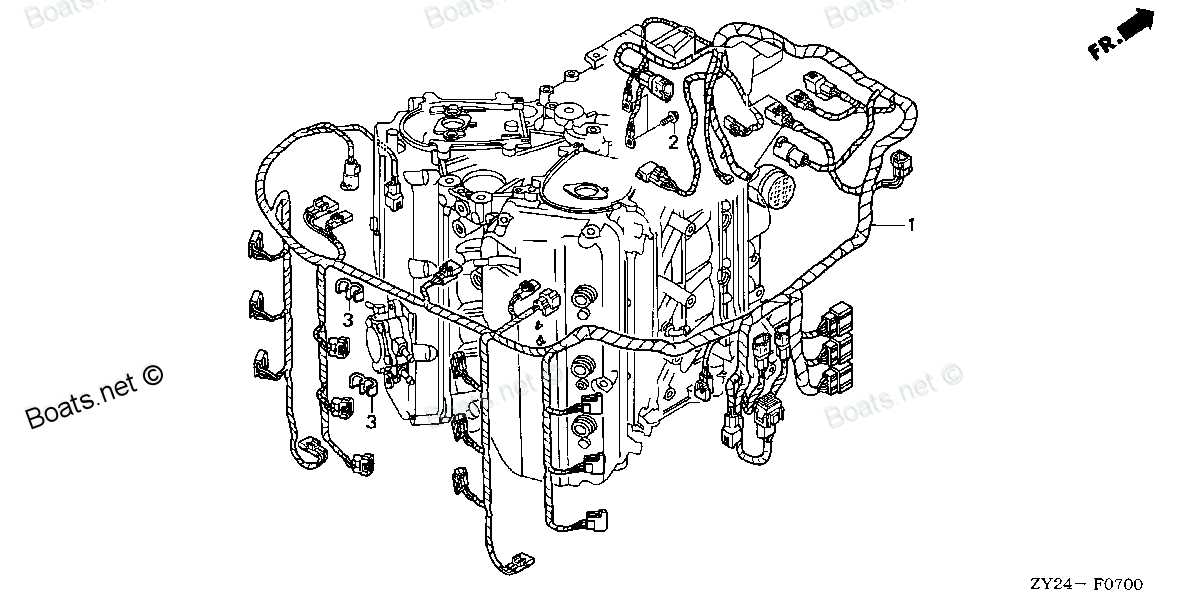

Electrical Components Overview

The functionality of marine engines heavily relies on various electrical elements that ensure smooth operation and efficient performance. Understanding these components is crucial for maintenance and troubleshooting. Each part plays a vital role in the overall system, contributing to the effective management of energy and communication within the engine.

Key Electrical Elements

Among the essential components are the ignition systems, which facilitate the starting process and ensure optimal combustion. Additionally, the wiring harness connects different parts, allowing for effective communication and power distribution. Proper management of these systems is vital for preventing malfunctions and ensuring longevity.

Importance of Regular Maintenance

Routine checks and maintenance of the electrical components can significantly enhance performance and reliability. Regular inspections help identify wear and tear, enabling timely repairs that prevent costly breakdowns. Maintaining these systems ensures that the engine operates efficiently, providing a better experience on the water.

Propeller Assembly and Functions

The assembly responsible for propulsion plays a crucial role in the overall functionality of marine vessels. It converts rotational energy from the engine into thrust, enabling movement through water. Understanding its components and operation is essential for effective maintenance and performance enhancement.

- Components of the Assembly:

- Blades: The primary elements that interact with water to generate thrust.

- Hub: Connects the blades to the drive shaft and transmits power.

- Spacers and Adapters: Assist in aligning and securing the assembly to the engine.

- Shear Pin: A safety feature that protects the assembly from damage during excessive stress.

Each component is designed to work harmoniously, ensuring efficient propulsion while minimizing drag. Regular inspections and timely replacements are vital to maintain optimal performance.

- Functions of the Assembly:

- Thrust Generation: Converts engine power into forward motion.

- Speed Control: Adjusts the pitch and angle to modify speed and handling.

- Fuel Efficiency: Designed to maximize propulsion while minimizing fuel consumption.

- Vibration Dampening: Reduces engine vibrations, contributing to a smoother ride.

Understanding the assembly’s design and functions helps boat operators make informed decisions regarding upgrades and repairs, ultimately enhancing the vessel’s performance and longevity.

Hydraulic Steering: Parts Involved

The hydraulic steering system plays a vital role in ensuring smooth maneuverability and control in watercraft. Understanding the components that make up this system can enhance maintenance and troubleshooting efforts.

- Steering Wheel: The primary control used by the operator to direct the vessel.

- Hydraulic Pump: Converts mechanical energy into hydraulic pressure to assist in steering.

- Steering Cylinder: This component receives hydraulic fluid from the pump and converts it into linear motion.

- Hydraulic Fluid: The medium that transfers power through the system, facilitating movement.

- Hoses and Fittings: Essential for connecting various components, allowing fluid to flow throughout the system.

- Reservoir: Stores hydraulic fluid and ensures a steady supply to the system.

Each element works in harmony to provide efficient steering capabilities, making it crucial to keep them in optimal condition for reliable performance.

Maintenance Tips for the Honda BF225

Regular upkeep is essential for ensuring the longevity and optimal performance of your marine engine. By following a structured maintenance routine, you can prevent potential issues and enhance the overall reliability of your watercraft.

Here are some vital maintenance suggestions:

- Inspect the Engine Oil: Check the oil level frequently and replace it as needed to ensure proper lubrication.

- Clean the Fuel System: Regularly examine and clean the fuel filter to prevent clogs that can affect performance.

- Examine the Cooling System: Ensure that the cooling system is functioning correctly to prevent overheating. Clean the cooling passages as necessary.

- Check the Battery: Maintain the battery by checking connections, cleaning terminals, and ensuring it is fully charged.

- Inspect Propeller and Shaft: Regularly examine the propeller and shaft for damage or debris that may hinder performance.

- Test Safety Equipment: Ensure all safety gear is in good condition and easily accessible in case of an emergency.

By adhering to these maintenance practices, you can significantly extend the lifespan of your marine engine and ensure a safer experience on the water.

Replacing Wearable Components

In any mechanical system, certain elements experience regular wear and tear due to continuous use. These components are essential for the overall functionality and performance of the machinery. Timely replacement of these parts is crucial to maintain efficiency and prevent further damage.

Identifying Worn Components: Regular inspections can help identify which elements need attention. Look for signs such as unusual noises, leaks, or decreased performance, which may indicate that specific components are wearing out. Addressing these issues early can save time and reduce repair costs in the long run.

Replacement Process: When replacing worn elements, ensure you have the right tools and replacement items on hand. Follow the manufacturer’s guidelines for proper installation techniques. Take your time during this process to ensure that everything is securely fitted and aligned correctly. After installation, it’s advisable to conduct a thorough test to confirm that the system operates smoothly.

Common Issues and Solutions

In the realm of marine engines, various challenges may arise during operation. Identifying these issues and understanding how to address them is crucial for maintaining optimal performance. Below are some frequent problems encountered and their corresponding solutions.

-

Engine Won’t Start:

This can be caused by several factors, including insufficient fuel, a faulty battery, or electrical issues. To resolve this:

- Check fuel levels and quality.

- Inspect the battery connections and charge if necessary.

- Examine wiring for any signs of damage.

-

Overheating:

Excessive heat can lead to severe damage. Common causes include blocked cooling passages or low coolant levels. To address overheating:

- Ensure the cooling system is free from debris.

- Check and top up coolant levels as needed.

- Inspect the water pump for proper function.

-

Rough Idling:

Rough running at idle can indicate fuel delivery problems or air leaks. Solutions include:

- Clean or replace the fuel filter.

- Inspect gaskets for air leaks and replace as necessary.

- Adjust idle speed settings for optimal performance.

-

Fuel Consumption Issues:

Excessive fuel usage can be a sign of inefficient combustion or other underlying problems. To improve fuel efficiency:

- Ensure the spark plugs are clean and functioning.

- Regularly check and replace the fuel filter.

- Keep the engine properly tuned for peak performance.

Where to Find OEM Parts

Finding original equipment manufacturer components can greatly enhance the performance and longevity of your machine. These high-quality items are designed specifically to fit and function with your equipment, ensuring optimal operation.

Authorized Dealers: Visiting authorized dealers is one of the most reliable ways to source genuine components. These dealers are certified and have direct access to the manufacturer’s inventory, guaranteeing that you receive authentic items.

Online Retailers: Numerous online platforms specialize in selling OEM components. Websites dedicated to marine equipment or those affiliated with manufacturers often provide a wide selection, making it easier to find the specific items you need.

Local Repair Shops: Many local repair shops maintain a stock of original items for various brands. Consulting with a trusted technician can lead you to reliable sources and recommendations for obtaining the right components.

Manufacturer’s Website: The official website of the brand often features a dedicated section for ordering genuine components. This is a convenient option to ensure you are getting authentic products straight from the source.