Understanding the ZF Marine Transmission Parts Diagram

Understanding the intricate workings of advanced power systems is essential for optimizing performance and ensuring reliability. This section provides a comprehensive look at various elements that contribute to the overall functionality of these mechanisms, highlighting their significance in enhancing efficiency.

Exploring these crucial components offers valuable insights into their design and interrelations. Each element plays a vital role in the seamless operation of the entire system, ensuring that energy is effectively transferred and utilized.

By delving into the specifics, one can appreciate the engineering behind these components and their ultimate impact on performance. A thorough grasp of these aspects not only aids in maintenance but also informs decisions regarding upgrades and replacements.

Understanding ZF Marine Transmission Systems

Exploring the complexities of ZF systems reveals the intricate mechanisms that enable efficient power distribution in various vessels. These sophisticated assemblies play a crucial role in ensuring optimal performance and reliability in challenging environments. By examining their components and functions, one can appreciate the engineering behind seamless operation.

The core of these systems lies in their ability to manage torque and speed variations effectively. This adaptability is vital for maintaining stability and responsiveness in watercraft. The following table outlines the essential elements involved in these assemblies and their respective functions:

| Component | Function |

|---|---|

| Gearbox | Adjusts rotational speed and torque to suit operational needs. |

| Clutch | Engages and disengages the power flow between the engine and drive system. |

| Propeller Shaft | Transfers rotational energy from the gearbox to the propeller. |

| Control Mechanism | Allows the operator to manage speed and direction with precision. |

Understanding the interplay between these components is essential for troubleshooting and optimizing performance. Proper maintenance and knowledge of each element’s role can greatly enhance the efficiency and lifespan of the entire assembly.

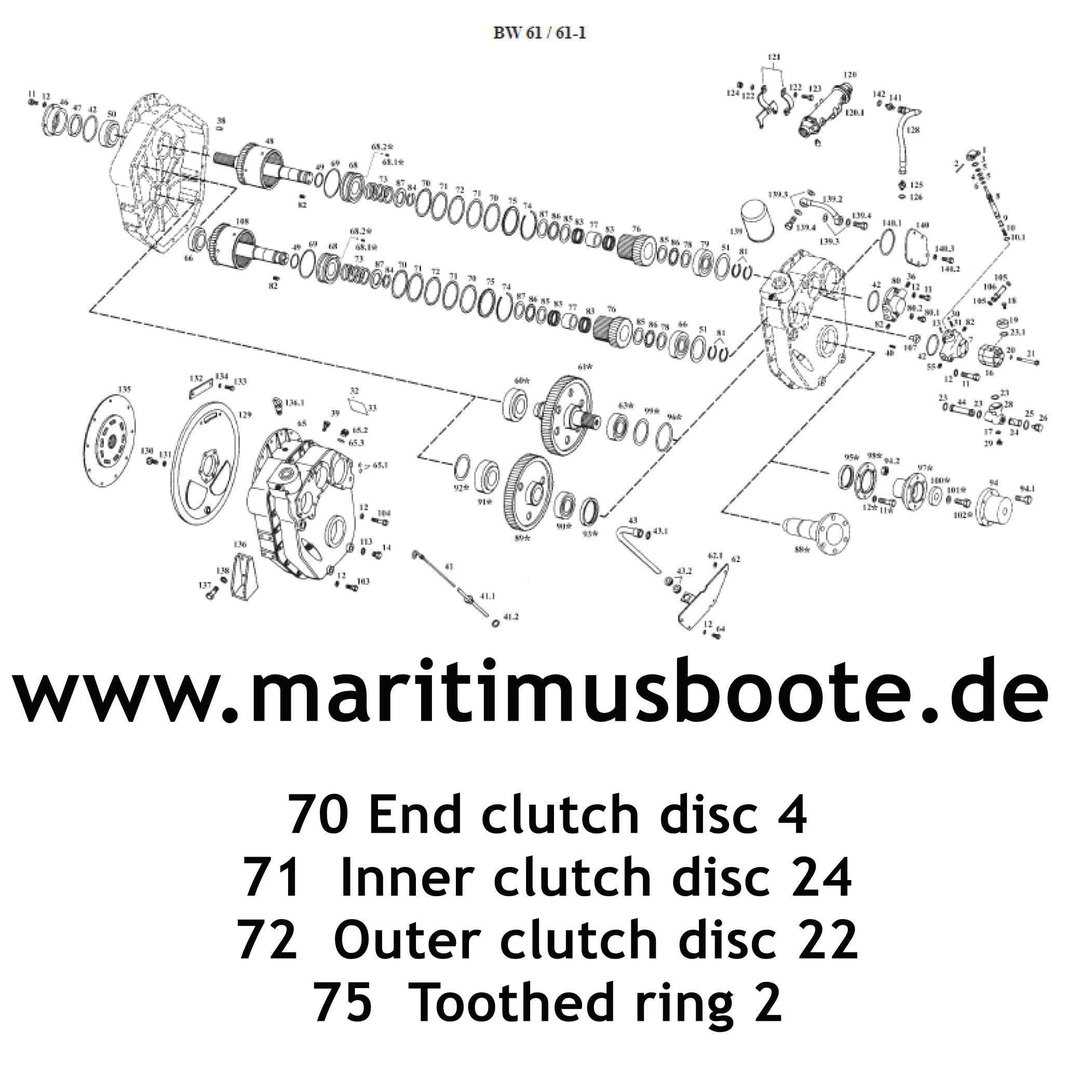

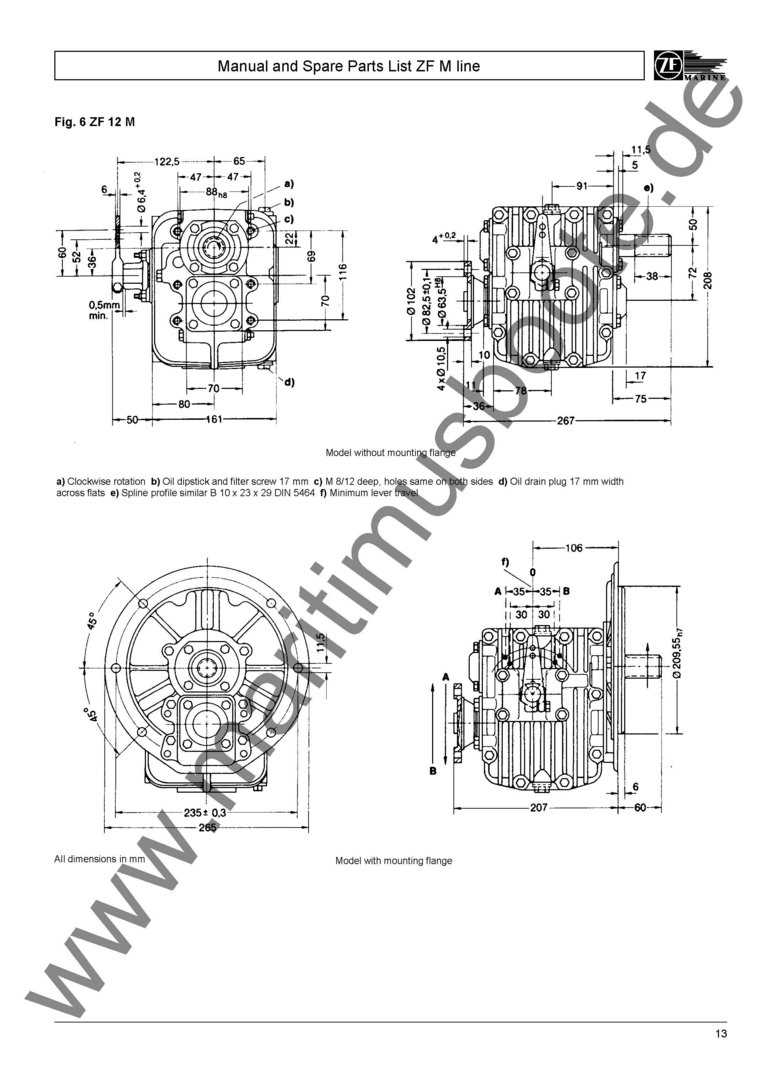

Key Components of ZF Marine Transmissions

The efficiency and reliability of ZF systems are attributed to a variety of essential elements that work together harmoniously. Understanding these core components is vital for anyone involved in maintenance or operation, as each part plays a significant role in the overall functionality of the equipment.

| Component | Description |

|---|---|

| Gear Set | Responsible for changing the speed and torque, allowing for optimal performance under different conditions. |

| Control Unit | This unit manages the operation of the system, ensuring smooth shifts and efficient power distribution. |

| Clutch Assembly | Facilitates engagement and disengagement, crucial for smooth operation and power transfer. |

| Lubrication System | Maintains optimal operating conditions by reducing friction and dissipating heat. |

| Output Shaft | Transfers power to the propulsion system, playing a key role in overall movement. |

Each of these elements must be carefully maintained and monitored to ensure the longevity and efficiency of the system. Understanding their functions enhances operational knowledge and facilitates better maintenance practices.

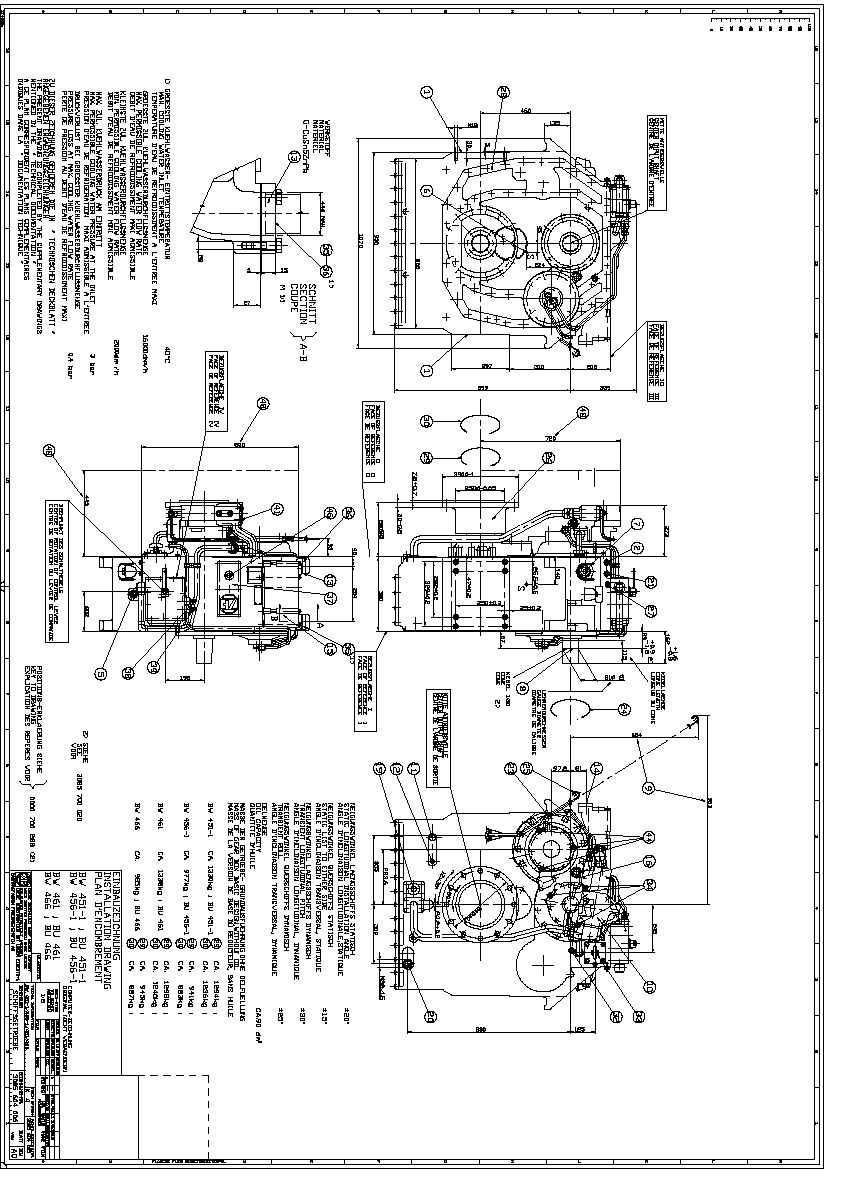

Importance of Transmission Diagrams

Understanding the intricate systems within mechanical devices is crucial for efficiency and maintenance. Visual representations serve as essential tools, enabling technicians and engineers to grasp complex relationships between components quickly. These illustrations simplify troubleshooting and enhance communication among professionals, ensuring that everyone is on the same page.

Clarity and Efficiency

Clear visual aids allow for swift identification of issues, streamlining the repair process. When details are organized visually, it reduces the likelihood of mistakes and promotes faster resolution of problems, ultimately leading to increased operational uptime.

Enhanced Learning and Training

For newcomers in the field, these visuals are invaluable for education and skill development. They provide a foundational understanding, making it easier to delve into the specifics of how each element interacts within the broader mechanism. This comprehensive insight is essential for cultivating expertise.

How to Read Transmission Schematics

Understanding technical illustrations can be a challenging yet rewarding task. These visual representations serve as a blueprint, providing critical information about the various components and their interconnections. Familiarizing yourself with the conventions used in these illustrations is essential for effective analysis and troubleshooting.

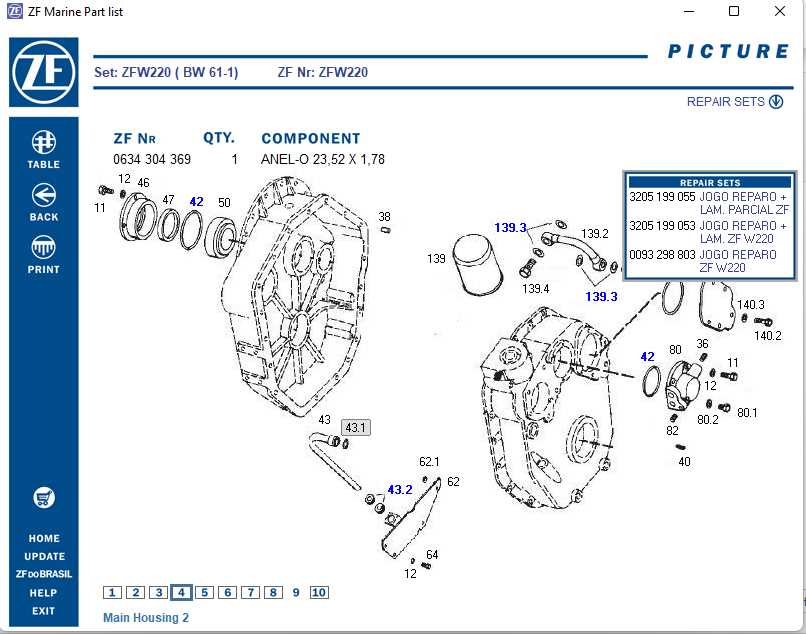

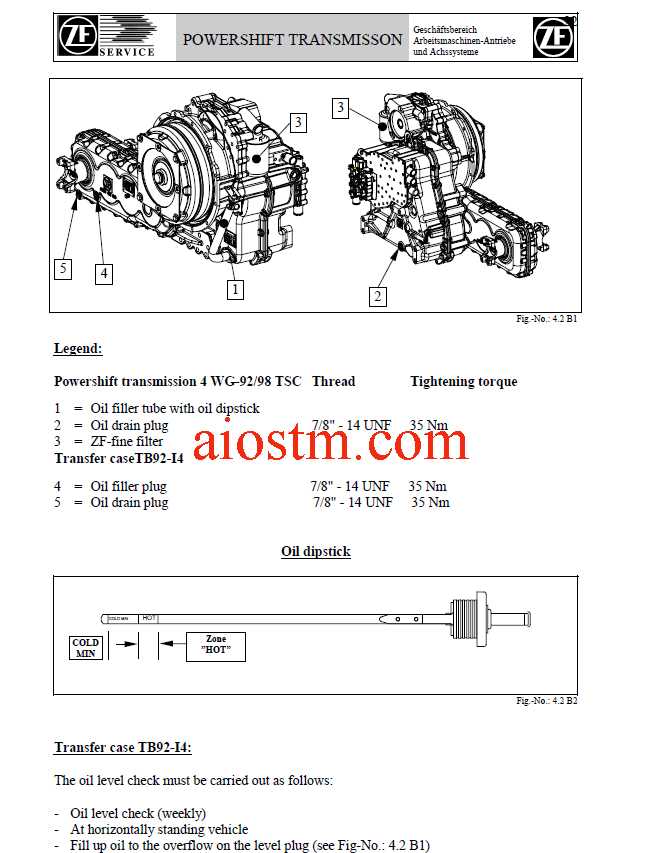

Start with Symbols: Each component in the schematic is represented by a unique symbol. Take the time to familiarize yourself with these symbols, as they convey vital information about the function and type of each part. Referencing a key or legend can be particularly helpful.

Follow the Flow: Most schematics are designed to indicate the flow of energy or signals. Understanding the direction in which the lines are drawn is crucial, as it reveals how components interact with one another. Look for arrows or lines that suggest movement or flow to gain insight into the system’s operation.

Note Connections: Pay attention to how components are interconnected. Dots at the junctions of lines typically indicate connections, while lines crossing without a dot may suggest that the elements are separate. This distinction is key for identifying the relationships between various elements.

Identify Groups: Components are often grouped together based on their function or location. Recognizing these clusters can simplify your understanding of the overall system. Look for labeled sections that highlight these groupings for additional clarity.

By mastering these techniques, you will enhance your ability to interpret technical illustrations effectively, paving the way for improved diagnostics and repairs.

Common Issues in Marine Transmissions

In the realm of aquatic vehicles, certain complications can frequently arise that hinder performance and reliability. Understanding these prevalent challenges is essential for effective maintenance and operation. Addressing these issues promptly can help extend the lifespan of the vessel’s mechanical components.

Overheating is a common concern, often resulting from insufficient cooling or fluid levels. When the temperature exceeds optimal ranges, it can lead to severe damage and reduce overall efficiency.

Slippage is another frequent problem, where the engagement between the engine and the drive system becomes inconsistent. This can manifest as delayed acceleration or loss of power, making navigation difficult and potentially dangerous.

Fluid Leaks can occur due to wear and tear on seals and gaskets. Even minor leaks can lead to significant issues if not addressed, as they compromise the effectiveness of the system and can result in complete failure.

Noise and Vibration are also indicators of underlying issues. Unusual sounds or excessive shaking can suggest problems with alignment or component wear, which may necessitate immediate inspection and repair.

Contaminated Fluid can cause a range of complications, as impurities can lead to inefficient operation and increased wear on internal components. Regular checks and fluid changes are crucial to prevent such problems.

By being aware of these typical difficulties, operators can take proactive measures to ensure their vessels remain in optimal condition, ultimately enhancing safety and performance on the water.

Maintenance Tips for ZF Parts

Proper care and regular attention to components can significantly enhance their longevity and performance. Adopting a proactive approach not only prevents costly repairs but also ensures smooth operation.

1. Regular Inspections: Conduct routine checks to identify signs of wear or damage early. This proactive measure can save you from more extensive issues down the line.

2. Cleanliness is Key: Keep all elements clean and free from debris. Dirt and contaminants can lead to malfunction and decreased efficiency.

3. Lubrication: Ensure that all moving parts are adequately lubricated. This reduces friction and prolongs the life of the components.

4. Follow Manufacturer Guidelines: Adhere to the recommended maintenance schedules and procedures provided by the manufacturer for optimal performance.

5. Monitor Performance: Pay attention to any changes in operation. Unusual noises or decreased efficiency may indicate the need for immediate attention.

By implementing these practices, you can effectively extend the lifespan of your ZF components and maintain their ultimate functionality.

Upgrading Your Transmission Components

Enhancing the performance of your vehicle’s drive system can lead to significant improvements in efficiency and responsiveness. By investing in quality components, you can ensure smoother operation and extend the lifespan of your machinery. This upgrade not only optimizes functionality but also contributes to overall reliability and durability.

When considering enhancements, it’s essential to evaluate each element’s role within the system. Upgraded gears, improved clutches, and reinforced shafts can dramatically impact performance. Additionally, examining the compatibility of these new components with existing systems is crucial for achieving optimal results.

Researching the latest advancements in technology can provide insights into which modifications will best suit your needs. Many enthusiasts find that custom solutions tailored to specific applications yield the most significant benefits. Engaging with knowledgeable professionals can further assist in making informed decisions, ensuring that every upgrade is a step toward excellence.

Ultimately, the goal of upgrading these crucial elements is to create a seamless experience, enhancing power transfer and responsiveness. As you embark on this journey, keep in mind the importance of quality, compatibility, and expert advice to achieve the best possible outcome.

Identifying Faults in Diagrams

Recognizing discrepancies in visual representations is crucial for effective troubleshooting and maintenance. Understanding where potential errors may arise can significantly enhance problem-solving capabilities.

Common issues to look for include:

- Inconsistencies in labeling

- Missing components

- Misalignment of connections

- Ambiguous symbols

- Incorrect scaling

To systematically approach fault identification, follow these steps:

- Review the key for symbols and terms.

- Cross-reference with official documentation.

- Examine the layout for logical flow.

- Test individual elements against specifications.

- Consult with experienced technicians for insights.

By employing these strategies, one can effectively pinpoint and address inaccuracies, leading to improved operational efficiency.

Comparing ZF with Other Brands

When assessing the capabilities of various manufacturers, it becomes essential to understand the unique strengths and weaknesses that each brings to the table. ZF stands out in numerous ways, offering advanced technology and reliable performance. This comparison aims to highlight the key distinctions and advantages that ZF products have in relation to their competitors.

Innovation and Technology: ZF is renowned for its commitment to innovation, often integrating cutting-edge features that enhance efficiency and functionality. In contrast, some other brands may focus on traditional designs, which can limit their adaptability to evolving industry demands.

Durability and Reliability: One of ZF’s most significant advantages lies in the durability of its offerings. Products are designed to withstand rigorous conditions, ensuring longevity and reduced maintenance needs. Other brands may offer competitive options, but they often fall short in terms of reliability under similar stressors.

Customer Support and Service: ZF provides comprehensive customer support, ensuring that users have access to assistance whenever needed. While some competitors may have a decent support system, ZF’s reputation for responsiveness and expertise gives it an edge in customer satisfaction.

Market Presence: With a strong global presence, ZF has established itself as a trusted name in various sectors. Although other brands may also hold significant market share, ZF’s consistent performance and reputation contribute to its credibility and consumer trust.

Ultimately, while several manufacturers offer viable options, ZF’s focus on innovation, reliability, and customer service sets it apart, making it a preferred choice for many users seeking high-quality solutions.

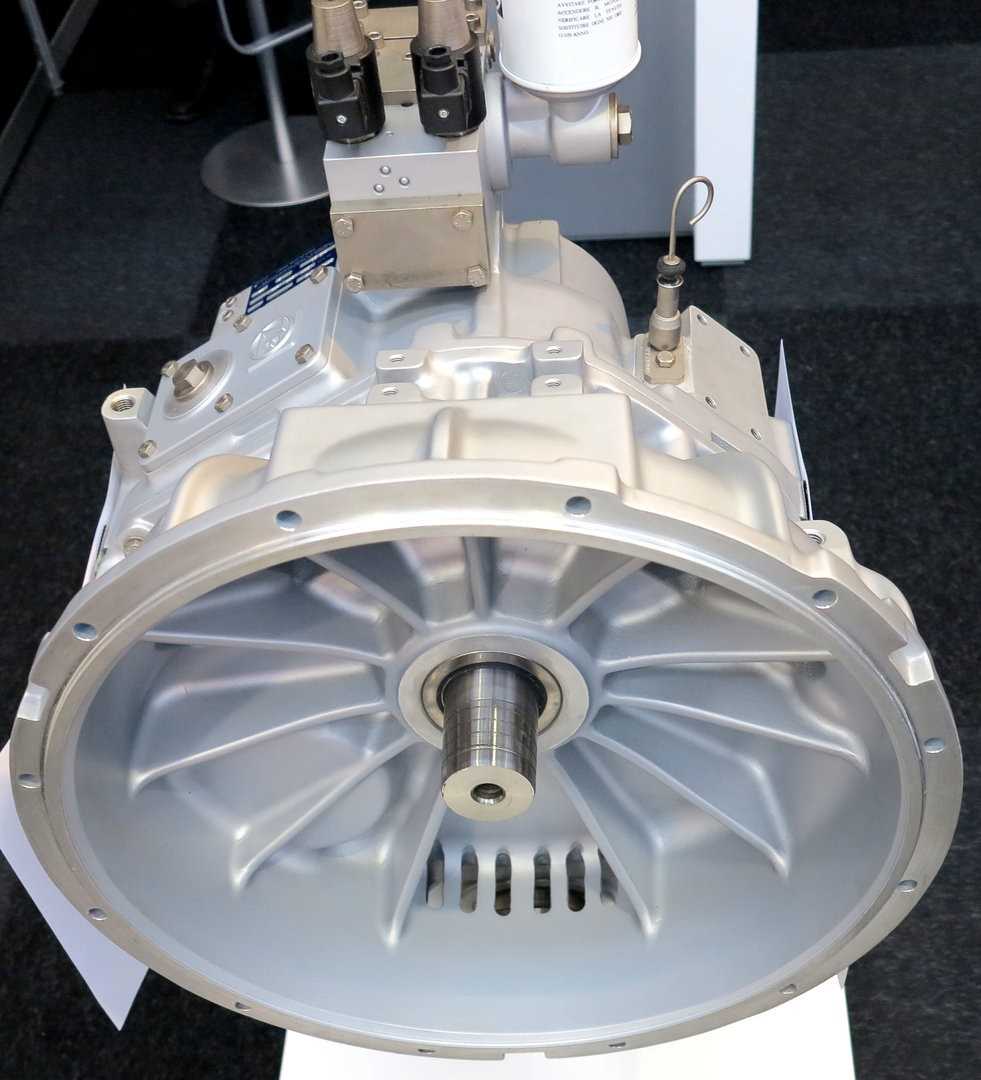

Application of ZF Transmissions in Vessels

ZF systems play a crucial role in the operation of various watercraft, providing reliable performance and efficiency. Their engineering excellence ensures smooth power delivery, enabling vessels to navigate diverse environments with ease. These systems are designed to meet the specific needs of different types of vessels, enhancing overall functionality and safety.

Key Features of ZF Systems

- Robust design for durability in challenging conditions

- Advanced engineering for improved fuel efficiency

- Seamless integration with propulsion units

- Enhanced maneuverability and control

Types of Vessels Utilizing ZF Solutions

- Commercial ships

- Luxury yachts

- Fishing vessels

- Military crafts

By incorporating these innovative systems, vessel operators can ensure optimal performance, reliability, and longevity, which are essential in today’s competitive maritime industry.

Resources for Further Learning

To enhance your understanding of complex mechanical systems, a variety of materials are available for exploration. These resources will guide you in acquiring deeper insights and practical knowledge.

- Online Courses: Platforms like Coursera and Udemy offer specialized classes on mechanical engineering principles.

- Technical Books: Consider reading texts focused on engineering design and mechanics to grasp foundational concepts.

- Forums and Communities: Join online groups such as Reddit or specialized engineering forums to engage with peers and experts.

- YouTube Channels: Explore channels dedicated to mechanical engineering for visual learning and demonstrations.

- Industry Journals: Subscribe to journals that publish research and case studies related to engineering advancements.

Utilizing these resources can significantly elevate your comprehension and practical skills in the field.