Comprehensive Guide to Stihl 028 AV Parts Diagram

Every tool has its intricacies, and mastering the mechanics of your cutting equipment can significantly enhance its performance and longevity. In this section, we delve into the various components that make up this powerful machine, providing clarity on how each part functions within the system.

By familiarizing yourself with the arrangement and roles of individual elements, you can better troubleshoot issues, perform maintenance, and optimize efficiency. This knowledge empowers users to tackle repairs confidently, ensuring that their equipment remains reliable for all cutting tasks.

Whether you are a seasoned professional or an enthusiastic hobbyist, having a thorough understanding of your machine’s structure is essential. We aim to equip you with the insights necessary to navigate the complexities of your equipment seamlessly.

Overview of Stihl 028 AV Model

The model in discussion is renowned for its robust performance and versatility, making it a popular choice among outdoor equipment enthusiasts. Designed for both casual users and professionals, this tool excels in various applications, from light pruning to heavy-duty cutting tasks.

Features of this model include an efficient engine, ergonomic design, and advanced vibration dampening technology. These characteristics contribute to a comfortable user experience, allowing for extended periods of operation without fatigue. The combination of power and ease of handling sets this equipment apart from its competitors.

Maintenance is straightforward, with easily accessible components that simplify routine checks and repairs. This reliability ensures that users can depend on the tool for consistent performance in demanding conditions. Overall, this model represents a solid investment for those seeking quality and durability in their outdoor machinery.

Importance of Parts Diagrams

Understanding the components of any mechanical device is crucial for maintenance and repair. Visual representations of these elements play a significant role in facilitating this understanding. They provide clarity, helping users identify and locate specific pieces, ensuring efficient troubleshooting and servicing.

Enhanced Understanding

- Visual aids clarify the relationship between various components.

- They simplify the complexity of assembly and disassembly processes.

- Users can better grasp how parts interact within the system.

Efficient Repair Process

- Quick identification of faulty elements reduces downtime.

- Clear instructions minimize the risk of incorrect reassembly.

- Facilitates communication between technicians and customers.

Utilizing visual guides not only enhances knowledge but also streamlines repair workflows, making them indispensable tools for both novices and seasoned professionals.

Key Components of Stihl 028 AV

The efficient operation of a chainsaw relies on several crucial elements that work harmoniously to deliver power and performance. Understanding these components can enhance maintenance practices and improve the longevity of the equipment. Each part plays a specific role, contributing to the overall functionality and user experience.

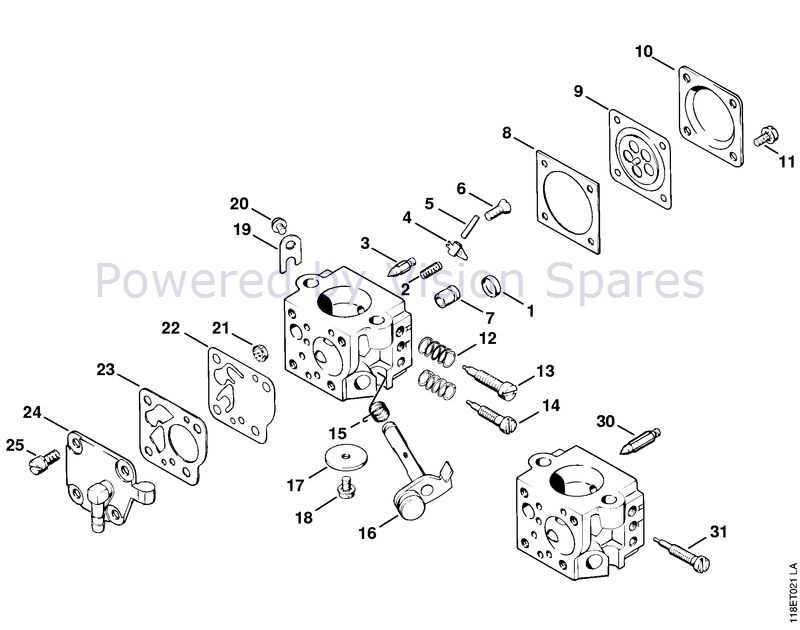

One of the most vital components is the engine, which provides the necessary power for cutting tasks. Its design ensures optimal fuel combustion, leading to improved efficiency and reduced emissions. Complementing the engine is the carburetor, responsible for mixing air and fuel in the correct proportions, ensuring smooth operation across various conditions.

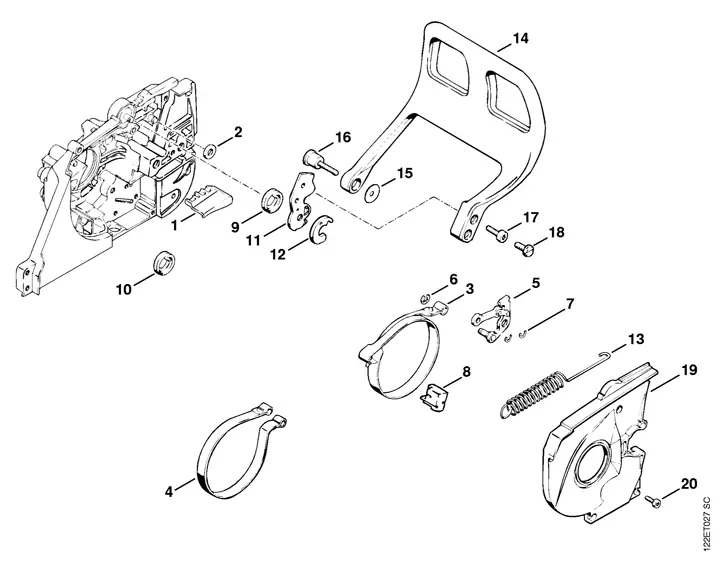

The cutting system, including the guide bar and chain, is essential for executing precise cuts. The guide bar serves as a support structure, while the chain is engineered for durability and sharpness, allowing for effortless slicing through wood. Regular inspection and maintenance of these components are critical for maintaining performance.

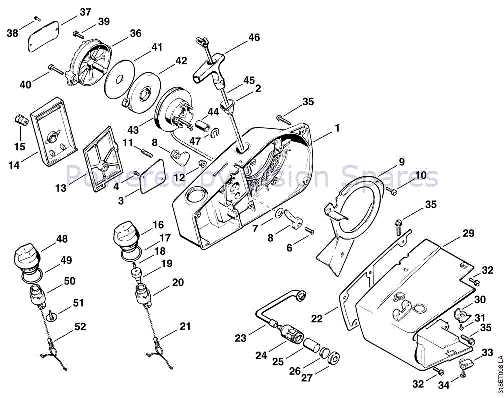

Another significant part is the ignition system, which initiates the combustion process. A well-functioning ignition ensures reliable starting and consistent operation. Additionally, the vibration dampening system enhances user comfort by minimizing vibrations during use, making prolonged operation less taxing.

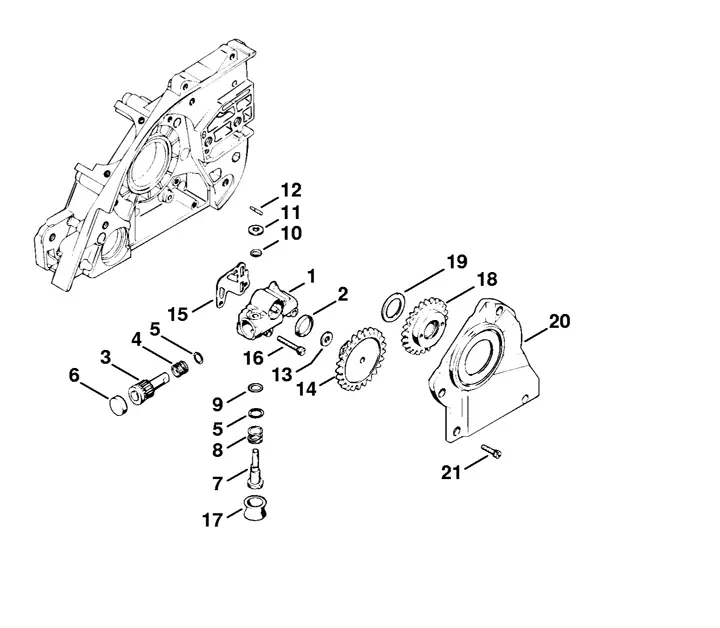

Finally, the fuel tank and oil reservoir are important for the effective functioning of the machine. Proper fuel management and lubrication of the chain are necessary to prevent overheating and wear, thereby extending the life of the tool. Understanding these key components helps users maintain their equipment more effectively and ensures optimal performance for a variety of cutting tasks.

Common Issues with Stihl 028 AV

When dealing with outdoor power equipment, users often encounter specific challenges that can hinder performance. Identifying these frequent problems is crucial for maintaining optimal functionality and extending the lifespan of the machinery. Understanding common malfunctions allows for timely interventions and repairs, ensuring smooth operation during use.

Fuel System Problems

One prevalent issue involves the fuel system, which may lead to difficulties in starting or inconsistent performance. Blocked fuel lines, degraded gaskets, or a malfunctioning carburetor can disrupt the fuel flow, causing the engine to run poorly or not start at all. Regular maintenance, including cleaning and inspecting these components, can help mitigate such issues.

Ignition Failures

Another common challenge arises from ignition failures. Problems with the spark plug or ignition coil can prevent the engine from firing. Signs of this issue include the engine turning over but failing to start or stalling during operation. Routine checks and timely replacements of worn-out parts are essential for reliable ignition and overall performance.

Understanding the Parts List

When it comes to maintaining machinery, having a clear overview of the components involved is essential. This section aims to provide insights into the various elements that make up the device, helping users identify and understand their function and importance. A well-structured inventory can simplify repairs and enhance overall performance.

Key Components Explained

Every machine consists of several integral units that contribute to its operation. Familiarizing yourself with these units enables you to pinpoint issues more effectively. For instance, components like the ignition system, fuel delivery mechanisms, and cutting elements play pivotal roles in ensuring the equipment runs smoothly. Understanding these parts allows for informed troubleshooting and maintenance.

Navigating the Inventory

Utilizing a comprehensive inventory can be a game-changer when it comes to repairs. By referencing a detailed list, you can easily locate the required items, reducing downtime. Furthermore, knowing the specifics of each part, such as its dimensions and compatibility, ensures that any replacements or upgrades will be seamless. This knowledge not only aids in maintenance but also extends the life of the equipment.

How to Interpret the Diagram

Understanding a schematic representation of a tool is essential for effective maintenance and repair. Such visuals provide a comprehensive overview of the various components and their relationships, allowing users to grasp the assembly and functionality of the equipment. Proper interpretation enables efficient troubleshooting and ensures that the right parts are addressed during repairs.

Key Elements to Focus On

- Labels: Pay attention to the annotations that identify each component. These often include part numbers and descriptions.

- Connections: Look for lines that indicate how parts are linked, which can help in understanding the flow of operation.

- Color Coding: Some diagrams use colors to differentiate between types of parts, such as electrical versus mechanical components.

Steps for Effective Interpretation

- Start by familiarizing yourself with the overall layout. Identify major sections that group related components.

- Cross-reference labels with any available documentation to verify part specifications.

- Use the diagram as a guide during disassembly and reassembly, ensuring that all parts are correctly positioned.

By following these guidelines, users can effectively navigate the schematic and enhance their understanding of the tool’s inner workings.

Where to Find Replacement Parts

When seeking components for your equipment, it’s essential to know where to look for reliable sources. Whether you’re in need of a specific element for maintenance or repair, various options can ensure you find the right fit. This section explores the best avenues for obtaining necessary items, helping you keep your machinery in optimal condition.

Authorized Dealers

One of the most dependable ways to source components is through authorized dealers. These outlets typically offer a range of genuine products and can provide expert advice on compatibility and installation.

Online Marketplaces

The internet provides a vast array of platforms where you can search for components. Many online retailers specialize in equipment accessories, offering detailed descriptions and customer reviews to aid your decision-making process.

| Source Type | Advantages | Considerations |

|---|---|---|

| Authorized Dealers | Genuine items, expert advice | Potentially higher prices |

| Online Marketplaces | Wide selection, often lower prices | Quality can vary, check reviews |

| Local Repair Shops | Personalized service, immediate availability | Limited stock, may not have all items |

Maintaining Your Stihl Chainsaw

Proper upkeep of your cutting tool is essential for optimal performance and longevity. Regular maintenance not only enhances efficiency but also ensures safety during operation. By adhering to a few straightforward practices, you can keep your equipment in top condition and ready for any task.

Regular Cleaning

After each use, it’s crucial to clean the exterior and components of your tool. Remove any debris, sawdust, or residue that may have accumulated. Pay special attention to the air filter and chain, as these areas are prone to clogging. A clean machine operates more effectively and can prolong the life of its parts.

Routine Checks and Replacements

Frequent inspections of vital components such as the chain, bar, and spark plug can prevent malfunctions. Ensure that the chain is properly tensioned and sharpened to guarantee efficient cutting. Additionally, replace worn parts promptly to avoid further damage. Regular oiling of the chain and lubrication of moving parts will also enhance performance and reduce wear.

By committing to these maintenance practices, you can ensure that your cutting tool remains a reliable companion for all your outdoor projects.

Tools Needed for Repairs

When undertaking maintenance or repair tasks on any machinery, having the right tools is crucial for efficiency and effectiveness. Proper equipment not only facilitates the repair process but also ensures that the job is done correctly, reducing the risk of further issues. Below are essential tools that should be part of your toolkit.

Basic Hand Tools

Start with a set of fundamental hand tools, which include screwdrivers, wrenches, and pliers. These items are vital for loosening and tightening various components. A torque wrench can also be beneficial for applying the correct amount of force to fasteners, ensuring they are secured without being overtightened.

Specialized Equipment

In addition to standard tools, some repairs may require more specialized equipment. A fuel line tool is essential for handling fuel systems, while a compression tester can help diagnose engine performance issues. Lastly, a reliable parts cleaning solvent will aid in maintaining cleanliness and functionality during the repair process.

Safety Tips During Maintenance

Ensuring safety while performing maintenance on equipment is paramount. Proper precautions not only protect the individual working on the machine but also prolong its lifespan and ensure optimal performance. Understanding the risks involved and taking appropriate measures can prevent accidents and injuries.

Preparation and Equipment

Before starting any maintenance task, it is essential to prepare adequately. Wear appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear. Ensure that the workspace is clean and free of obstacles. Check that all tools are in good condition and suitable for the job at hand.

Safe Handling Practices

When handling parts or operating machinery, always follow safety protocols. Disconnect the power source before conducting any repairs or adjustments. Avoid wearing loose clothing or jewelry that could get caught in moving parts. If using fuel or chemicals, store them safely and follow all handling guidelines to minimize the risk of fire or spills.

Regularly reviewing safety procedures and maintaining a focused mindset can significantly reduce the likelihood of accidents during maintenance tasks. Stay aware of your surroundings and ask for help when needed to ensure a safe working environment.

Upgrading Components for Better Performance

Enhancing the functionality of outdoor power equipment can lead to significant improvements in efficiency and reliability. By focusing on specific elements of the machinery, users can achieve greater power output, reduced fuel consumption, and an overall boost in operational effectiveness. Whether for personal use or professional landscaping, optimizing these components is a worthwhile investment.

Key Areas for Enhancement

Several critical areas can be targeted for upgrades. The ignition system plays a vital role in engine performance; upgrading to a high-efficiency spark plug can improve ignition timing and combustion efficiency. Additionally, replacing the air filter with a high-flow variant allows for better airflow, which can enhance engine breathing and power delivery.

Material Choices and Their Impact

Material selection also greatly influences performance. Components made from lightweight yet durable materials can reduce overall weight and improve maneuverability. For instance, a new lightweight handlebar or a stronger, more flexible chain can lead to better handling and reduced user fatigue. Investing in high-quality materials ensures longevity and reliability, making the equipment more resilient to wear and tear.

In conclusion, upgrading critical components is an effective strategy for enhancing the performance of outdoor machinery. Careful selection of parts and materials can lead to noticeable improvements, ensuring that the equipment operates at its best for years to come.