Dewalt Miter Saw Stand Parts Diagram Explained

The functionality of any cutting device heavily relies on its construction and the quality of its individual elements. A comprehensive knowledge of these components not only enhances user experience but also ensures safety and efficiency during operation. This section delves into the intricate assembly of a specific brand’s support system designed for precision cutting tasks.

Recognizing the various sections and how they interconnect is crucial for maintenance and optimal performance. Each segment serves a unique purpose, contributing to the overall effectiveness of the equipment. By familiarizing yourself with the layout and function of these pieces, you can make informed decisions regarding upgrades or repairs.

Moreover, understanding the structure allows users to appreciate the engineering behind the device. This insight fosters a deeper connection with the tool, empowering operators to utilize it to its fullest potential while ensuring longevity and reliability. Whether you’re a hobbyist or a professional, grasping the essentials of your cutting apparatus is key to mastering its use.

Dewalt Miter Saw Stand Overview

This section provides a comprehensive insight into a popular tool support system designed for enhanced stability and convenience during cutting tasks. It highlights the essential components and features that contribute to its functionality, making it a preferred choice among professionals and DIY enthusiasts alike.

The design is tailored for optimal usability, allowing for easy setup and adjustment. Users benefit from a robust framework that supports various cutting equipment, ensuring accuracy and safety. The portability factor also allows for seamless transportation to different job sites, making it a versatile addition to any toolkit.

| Feature | Description |

|---|---|

| Stability | Offers a solid base to prevent wobbling during operation. |

| Adjustability | Includes extendable arms for accommodating larger materials. |

| Portability | Lightweight design with wheels for easy transport. |

| Durability | Constructed from high-quality materials for long-lasting use. |

| Compatibility | Designed to work seamlessly with various cutting tools. |

Understanding the features and benefits of this tool support system will empower users to maximize their cutting efficiency and achieve professional results in their projects.

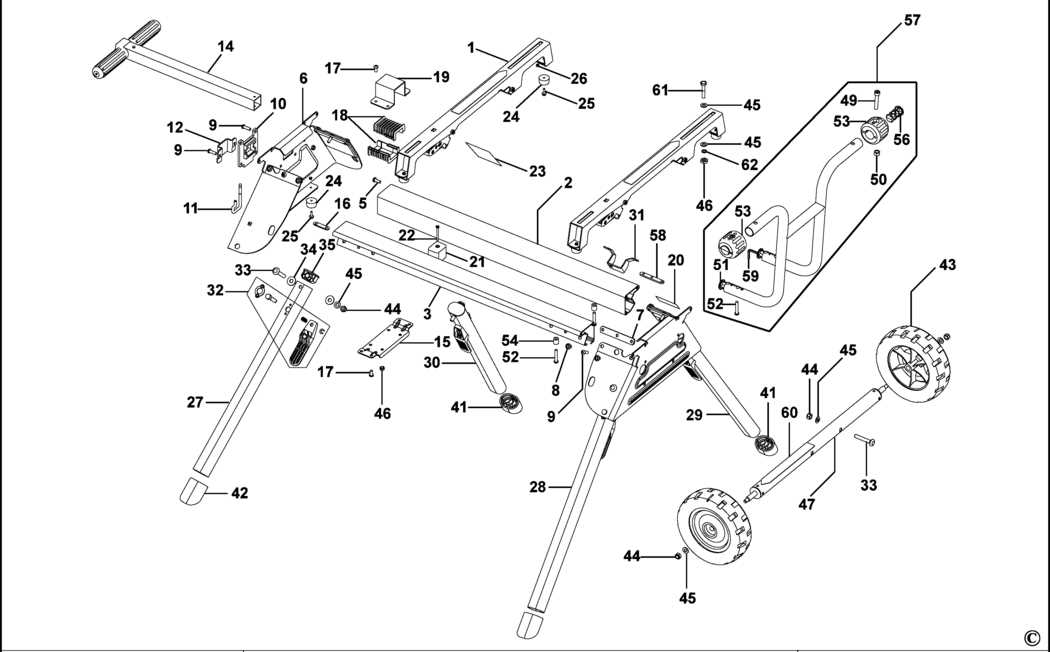

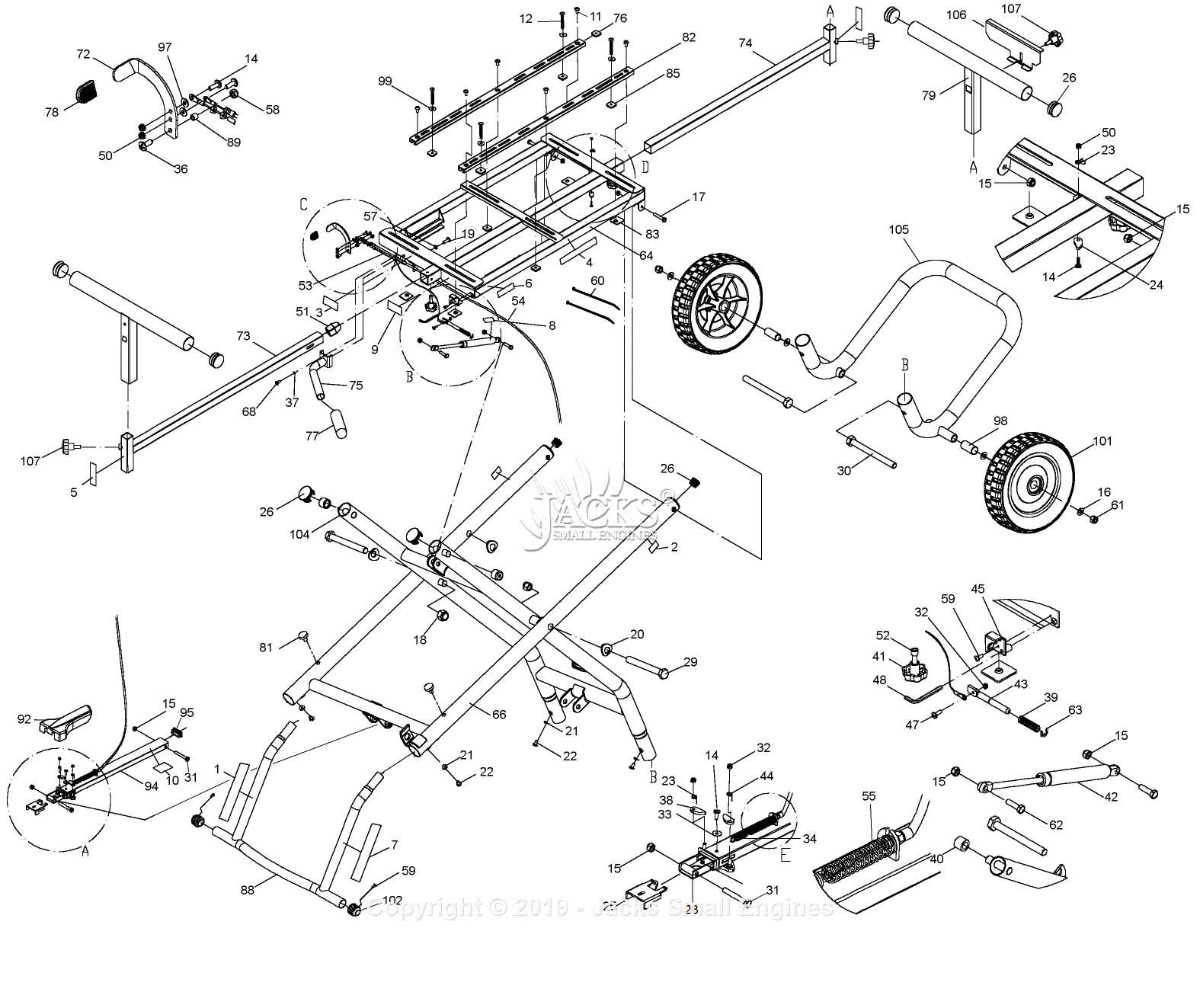

Key Components of the Stand

The essential elements of a woodworking support system play a crucial role in enhancing efficiency and stability during cutting tasks. Understanding these components can help users maximize functionality and ensure a seamless experience in their projects.

One of the primary features is the adjustable height mechanism, which allows for customization according to user preference and project requirements. This flexibility ensures that materials are positioned at the most comfortable level for precise cutting.

Another vital component is the robust frame, designed to provide durability and support for heavy materials. This structural integrity is essential for maintaining balance and preventing any unwanted movement during operation.

Additionally, a reliable locking system is incorporated to secure tools in place, enhancing safety and precision. This feature prevents accidental shifts, allowing for uninterrupted workflow.

Lastly, the mobility wheels facilitate easy transportation across job sites, making it convenient for users to set up their workspace quickly. The combination of these elements contributes to a highly functional and versatile system for any woodworking enthusiast.

Benefits of Using a Miter Saw Stand

Utilizing a dedicated platform for cutting tools significantly enhances both efficiency and safety in various projects. Such a structure provides stability and convenience, allowing users to focus on precision rather than managing awkward setups. Here are some key advantages of incorporating this equipment into your workflow:

| Benefit | Description |

|---|---|

| Improved Stability | A robust base minimizes vibrations and prevents movement during operation, leading to more accurate cuts. |

| Enhanced Mobility | Many platforms come with wheels, making it easy to transport tools from one location to another without hassle. |

| Increased Productivity | Having a designated area to set up your equipment allows for quicker transitions between tasks, saving time on adjustments. |

| Versatile Adjustability | Most of these frameworks feature adjustable heights and extensions, accommodating various sizes of materials and user preferences. |

| Safety Features | Built-in safety measures, such as locks and stability aids, help reduce the risk of accidents during operation. |

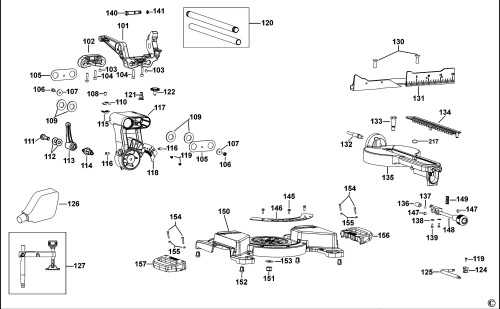

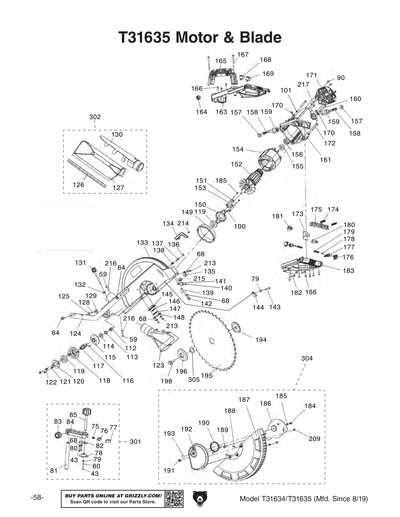

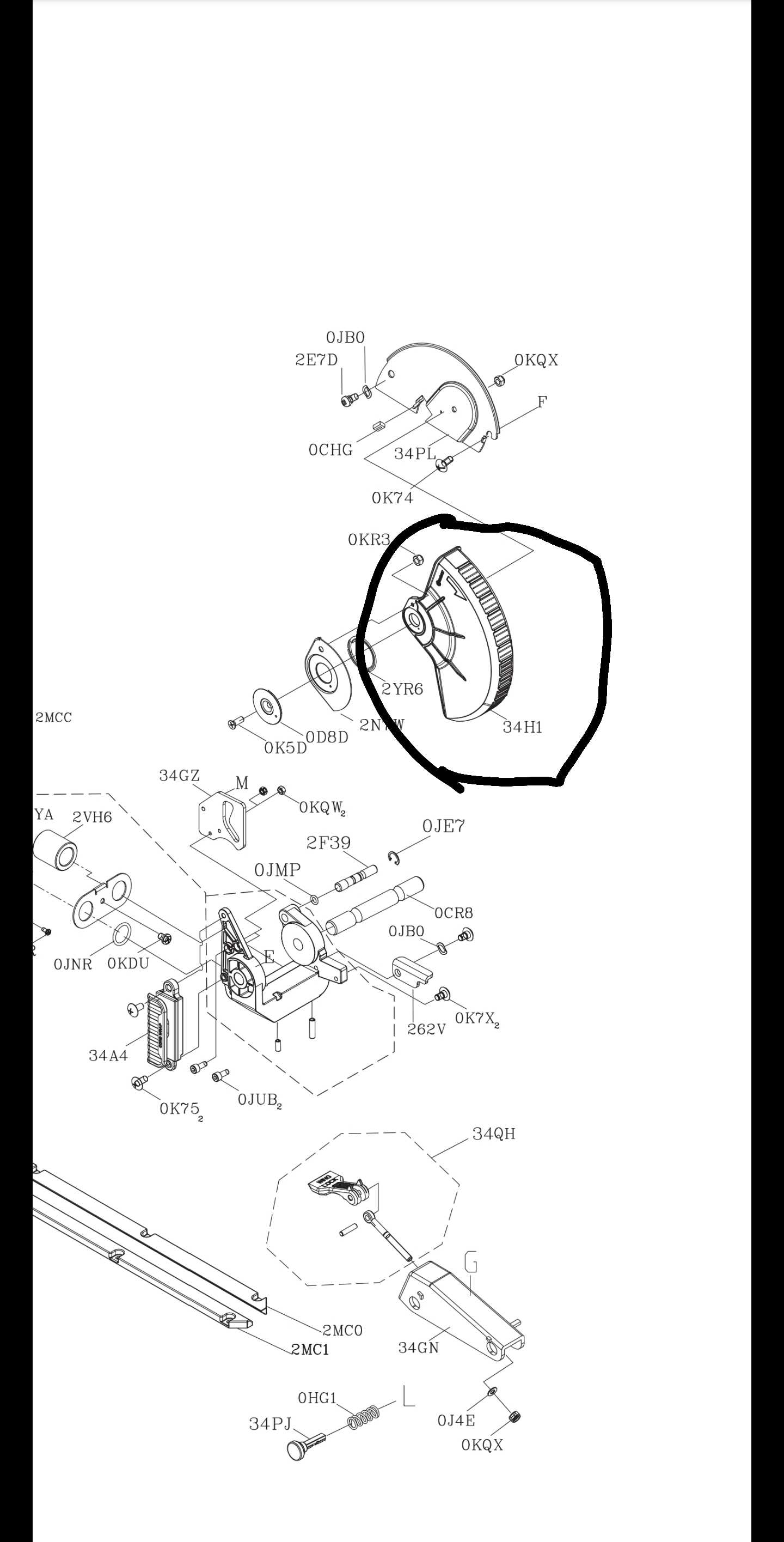

Understanding the Parts Diagram

Comprehending the visual representation of components is essential for effective assembly and maintenance of any equipment. This illustration serves as a guide, enabling users to identify and understand each element’s function within the system. Familiarity with this schematic not only streamlines the setup process but also enhances troubleshooting capabilities.

Each section of the illustration provides vital information, such as the names and arrangements of various elements. By examining these details, users can ensure that all pieces are correctly aligned and functioning optimally. The clarity offered by the depiction reduces confusion and aids in quick reference during repairs.

Furthermore, recognizing how individual components interact contributes to a deeper understanding of the entire mechanism. This knowledge empowers users to make informed decisions regarding maintenance and upgrades, ultimately prolonging the lifespan of the equipment.

Assembly Instructions for the Stand

Proper assembly of your equipment support structure is crucial for stability and efficiency. This section will guide you through the necessary steps to ensure a secure and functional setup, enabling you to work effectively and safely.

Preparation Before Assembly

Before you begin, gather all components and tools required for the construction. Ensure you have a clear workspace and review the included instructions for any specific notes. This preparation will help streamline the process and prevent any potential confusion.

Step-by-Step Assembly Process

Start by laying out the main framework components on a flat surface. Connect the legs to the horizontal beams, ensuring each joint is properly aligned. Use the provided fasteners to secure these connections tightly. Double-check each attachment to maintain stability.

Next, attach any additional support elements, such as cross-bracing, which will enhance the overall rigidity of the structure. Once everything is in place, perform a final inspection to confirm all fasteners are tightened and that there are no loose parts.

Common Issues and Solutions

When working with cutting equipment and their support systems, users may encounter various challenges that can hinder performance and efficiency. Identifying these common problems and understanding how to address them is essential for maintaining smooth operation.

1. Unstable Base

If the support structure is wobbling or unstable, it can lead to inaccurate cuts. Ensure that all legs are fully extended and locked in place. If the surface is uneven, consider using leveling pads or adjusting the height of the legs.

2. Difficulty in Adjustment

When making height or angle adjustments, some may find the mechanisms stiff or unresponsive. Regularly lubricate the adjustment knobs and ensure that no debris is obstructing the moving parts. If issues persist, inspect for any wear or damage that may require replacement.

3. Poor Mobility

Transporting equipment can become cumbersome if wheels are stuck or damaged. Check the wheel bearings for dirt or corrosion, and clean or lubricate as necessary. If the wheels are worn out, replacing them can greatly enhance mobility.

4. Inconsistent Cutting Precision

If cuts are not precise, it may be due to misalignment. Regularly check and calibrate the cutting angle settings, ensuring that everything is squared off. Also, inspect the cutting surface for any warping or damage that could affect the outcome.

5. Component Wear

Over time, various components can wear out, leading to diminished performance. Periodically inspect all parts for signs of wear or damage and replace any that do not meet safety and operational standards. Regular maintenance can prolong the life of your equipment.

Comparing Different Stand Models

When selecting a support structure for cutting tools, it’s essential to evaluate various options available in the market. Each model presents distinct features, benefits, and drawbacks that cater to different user needs. This comparison aims to highlight the key differences and help you make an informed decision.

| Model | Weight Capacity | Portability | Setup Time | Price Range |

|---|---|---|---|---|

| Model A | 500 lbs | High | 5 minutes | $150 – $200 |

| Model B | 600 lbs | Medium | 10 minutes | $180 – $250 |

| Model C | 400 lbs | Very High | 3 minutes | $120 – $170 |

| Model D | 700 lbs | Low | 15 minutes | $250 – $300 |

By understanding these differences, users can better align their choice with specific project requirements and personal preferences, ultimately enhancing their overall experience and efficiency in tasks.

Maintenance Tips for Longevity

Ensuring the durability and performance of your equipment requires consistent care and attention. Regular maintenance not only enhances efficiency but also extends the lifespan of the tools you rely on. Here are essential practices to keep your apparatus in optimal condition.

Regular Cleaning

Dust and debris can accumulate over time, impacting functionality. Regularly wipe down surfaces and remove any buildup from moving parts. Use a soft brush or compressed air to clear out hard-to-reach areas. This simple step can prevent corrosion and ensure smooth operation.

Lubrication and Inspection

Frequent lubrication of critical components is vital. Apply appropriate oils or greases to hinges and moving parts to minimize friction. Additionally, inspect all elements for wear and tear. Addressing minor issues promptly can prevent larger, costly repairs down the line. Regular checks help maintain safety and performance.

Compatibility with Various Miter Saws

Ensuring compatibility between equipment and their supporting structures is essential for achieving optimal performance and safety. This section delves into the versatility of supports designed for cutting tools, highlighting how they can accommodate a range of models from different manufacturers.

When selecting a support system, it’s crucial to consider the dimensions, weight capacity, and design features that align with your cutting equipment. The following table outlines key specifications and compatibility considerations for various cutting tools:

| Tool Brand | Model | Weight Capacity | Compatible Features |

|---|---|---|---|

| Brand A | Model 1 | 300 lbs | Adjustable height, quick-release mounts |

| Brand B | Model 2 | 350 lbs | Integrated extensions, stability locks |

| Brand C | Model 3 | 250 lbs | Portability features, foldable design |

| Brand D | Model 4 | 400 lbs | Dual-support arms, heavy-duty wheels |

By understanding these aspects, users can make informed decisions that enhance the efficiency and safety of their cutting tasks.

Safety Features of Dewalt Stands

When working with power tools, ensuring safety is paramount. Various platforms designed for equipment use come equipped with multiple protective features that significantly reduce the risk of accidents. These innovations aim to enhance user security while maximizing efficiency during projects.

| Feature | Description |

|---|---|

| Stability Locks | Mechanisms that secure the platform in place, preventing unintended movement during operation. |

| Load Capacity Indicators | Markings that help users understand the maximum weight limit, reducing the risk of overload and potential tipping. |

| Non-Slip Feet | Rubberized bases that provide excellent grip on various surfaces, minimizing slippage during use. |

| Quick Release Mechanisms | Features that allow for rapid setup and takedown, promoting safe handling and reducing the chances of injury. |

| Integrated Safety Straps | Straps that secure tools in place, ensuring stability and preventing falls while in use. |

By incorporating these safety elements, platforms enhance user confidence and contribute to a safer working environment, allowing craftsmen to focus on their tasks without unnecessary worry.

Upgrading Your Miter Saw Setup

Enhancing your cutting station can significantly improve your workflow and accuracy. By investing in quality accessories and optimizing your workspace, you can elevate both performance and convenience. This section explores various upgrades that can transform your setup into a more efficient and user-friendly environment.

Essential Accessories

One of the best ways to improve your cutting experience is by adding essential accessories. Consider adding a robust extension to support larger materials, or a laser guide to ensure precise alignments. Clamps and supports can also help secure your workpieces, providing stability and enhancing safety during operation.

Workspace Optimization

Creating an organized workspace is crucial for efficiency. Ensure that your cutting area is free of clutter and equipped with adequate lighting. Additionally, incorporating mobile storage solutions can help keep tools and materials accessible, allowing for a seamless workflow. Properly arranging your equipment can reduce downtime and enhance overall productivity.

Customer Reviews and Feedback

This section highlights the opinions and experiences of users who have engaged with the product. Feedback plays a crucial role in understanding the functionality, durability, and overall satisfaction derived from using the equipment. Users often share their insights, which can guide potential buyers in making informed decisions.

User Experiences

Many customers express satisfaction with the product’s stability and ease of use. Reviews frequently mention how the design facilitates smooth operation, making tasks more efficient. Several users appreciate the thoughtful features that enhance portability, allowing for effortless transport between job sites.

While most feedback is positive, some users note areas for enhancement. Common suggestions include the need for clearer assembly instructions and additional accessories for improved versatility. Constructive criticism from users often leads to updates and modifications, ensuring the product evolves to meet the needs of its audience.

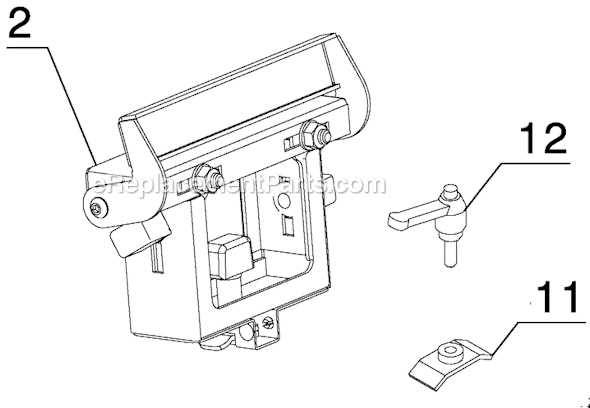

Where to Buy Replacement Parts

Finding the right components for your tools is essential to maintaining their functionality and longevity. Whether you need to replace worn-out elements or upgrade your equipment, there are several reliable sources to consider for acquiring the necessary items. Understanding where to look can save you time and ensure you get quality replacements that fit perfectly.

Authorized Retailers

Visiting authorized dealers is one of the best ways to guarantee you receive genuine components. These retailers typically stock a wide range of items specific to your equipment, ensuring compatibility and performance. Additionally, they often have knowledgeable staff who can assist you in identifying the correct pieces you need.

Online Marketplaces

Online platforms offer a convenient alternative for sourcing components. Many websites specialize in tool parts, providing detailed descriptions and images to help you make informed decisions. Be sure to check customer reviews and ratings to confirm the reliability of the seller before making a purchase.