Comprehensive Guide to Stihl TS 440 Parts Diagram

When it comes to maintaining your outdoor equipment, having a clear overview of its various elements is essential. This knowledge not only ensures optimal performance but also aids in timely repairs and replacements. A comprehensive understanding of each component can significantly extend the life of your machinery and enhance its efficiency during use.

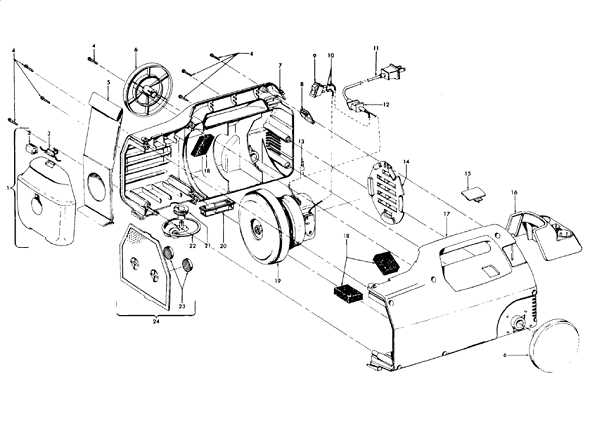

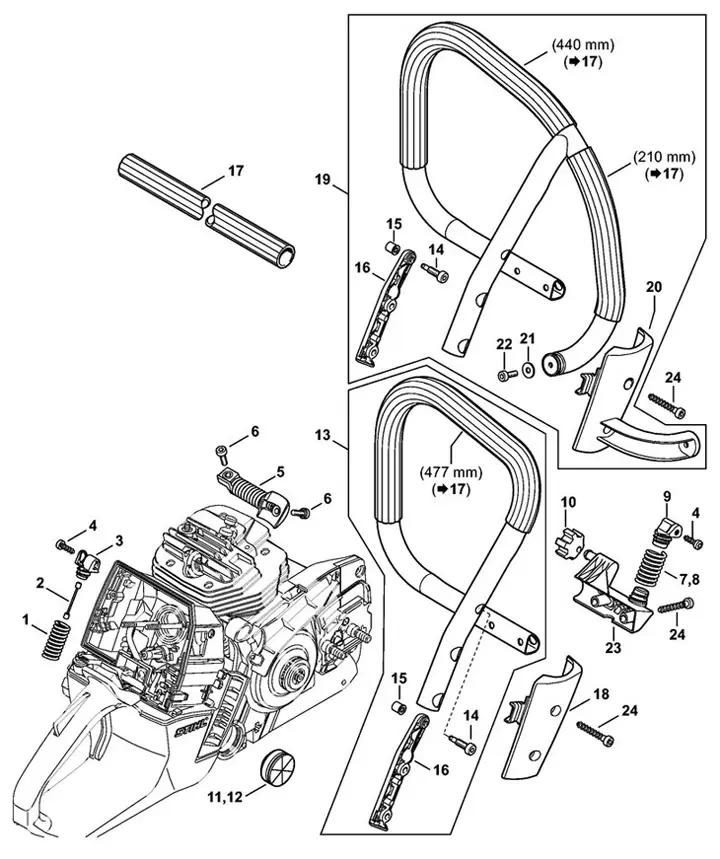

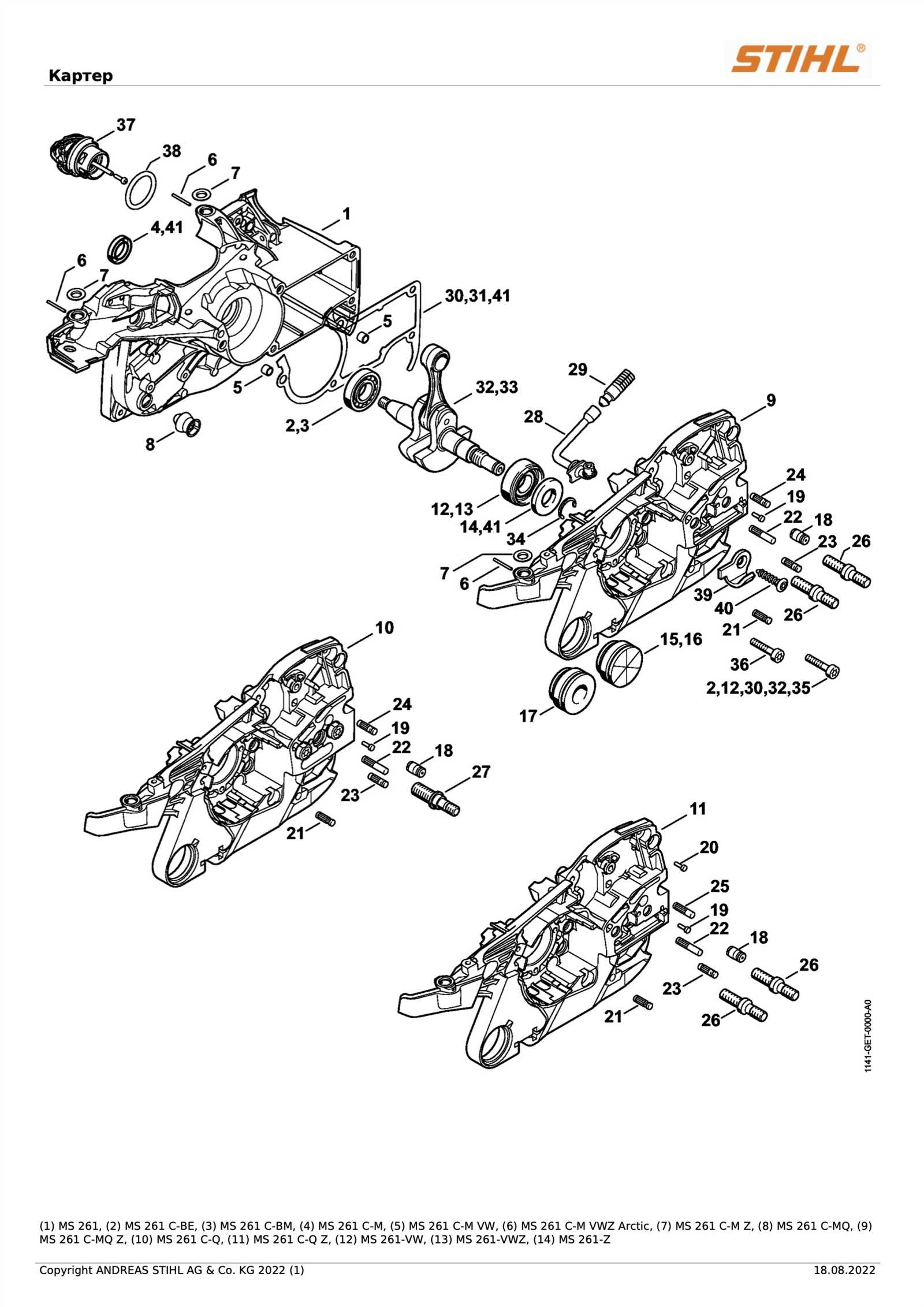

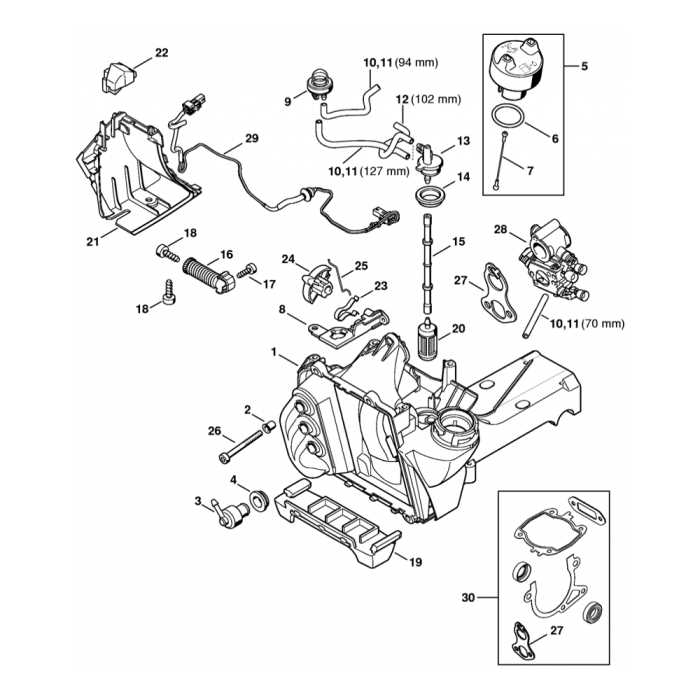

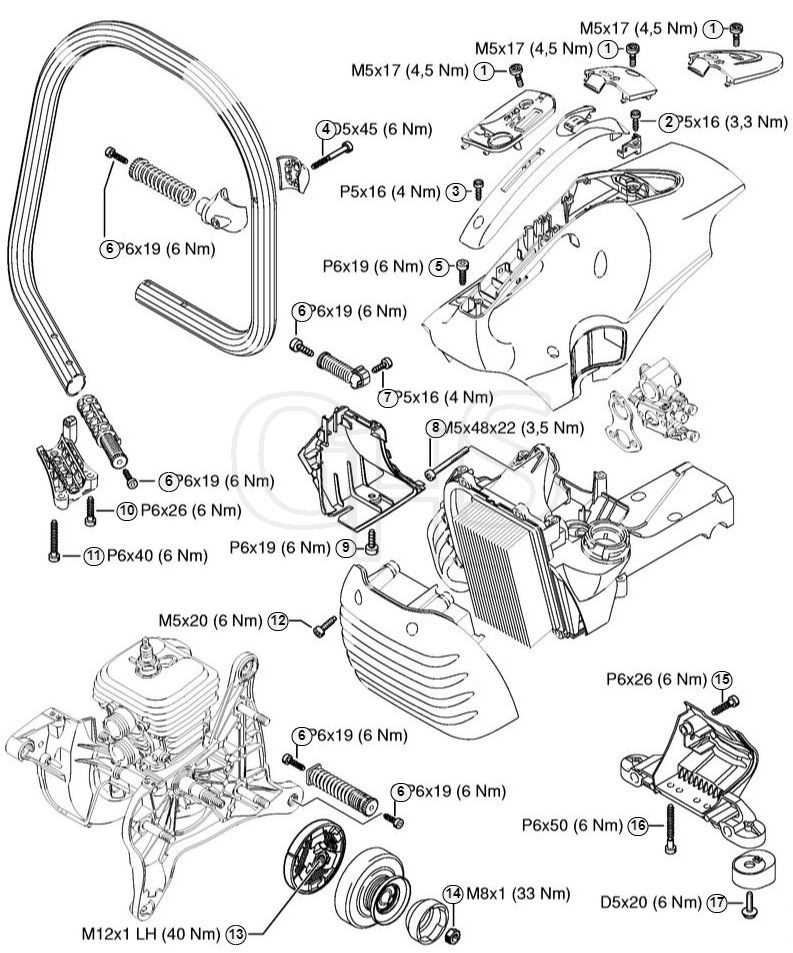

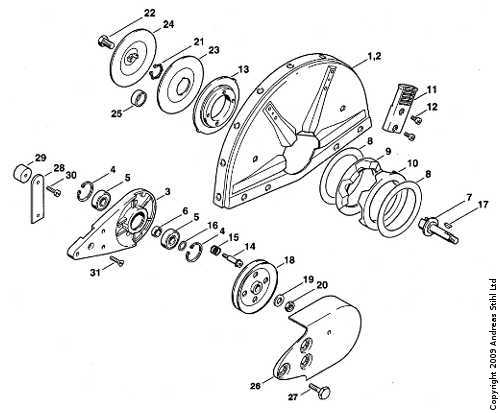

Visual representations serve as invaluable resources in this context, providing a detailed layout of individual parts and their interconnections. By examining these illustrations, users can quickly identify necessary components, making maintenance and assembly tasks much more manageable. The clarity offered by these resources empowers users to make informed decisions regarding repairs and upgrades.

Moreover, familiarizing yourself with the structure of your tool can lead to a more productive experience. Knowing the specific roles of different elements allows for better troubleshooting and enhances overall usability. With the right guidance, even those new to maintenance can approach their tasks with confidence and precision.

Understanding the Stihl TS 440

This section aims to provide insights into a specific model of a cutting tool widely used in various industries. Recognized for its durability and performance, this equipment plays a crucial role in tasks that require precision and efficiency. Familiarity with its components enhances user experience and ensures optimal functionality.

To better understand the construction and function of this tool, it is essential to explore its key elements. Below is a table outlining some of the main components and their purposes:

| Component | Function |

|---|---|

| Engine | Provides power for cutting operations. |

| Blade | Facilitates cutting through various materials. |

| Handle | Ensures user control and comfort during operation. |

| Fuel System | Delivers the necessary energy for the engine. |

| Cooling System | Maintains optimal operating temperature for efficiency. |

Understanding these components helps users maintain their tools effectively and troubleshoot any issues that may arise during use. Knowledge of the construction also contributes to enhanced safety and performance.

Key Features of the TS 440

This section highlights the essential characteristics of a high-performance cutting tool designed for professionals. It emphasizes reliability, efficiency, and user-friendly design, making it suitable for a variety of applications in construction and landscaping. The machine combines advanced technology with robust construction to meet the demands of its users.

Performance and Power

One of the standout attributes of this cutting equipment is its powerful engine, which ensures optimal performance even under challenging conditions. The efficient design minimizes fuel consumption while maximizing output, making it a cost-effective choice for heavy-duty tasks.

Safety Features

Safety is a top priority in the design of this tool. It includes several integrated features that help reduce the risk of accidents during operation. From effective vibration dampening to easily accessible controls, these elements enhance user safety and comfort.

| Feature | Description |

|---|---|

| Engine Power | High-performance engine providing robust cutting capabilities. |

| Weight | Lightweight design for improved maneuverability. |

| Vibration Control | Integrated dampening system to reduce operator fatigue. |

| Fuel Efficiency | Optimized fuel consumption for longer operational time. |

| Safety Mechanisms | Enhanced features to ensure safe usage during operation. |

Importance of Parts Diagrams

Visual representations of components are essential for understanding the assembly and functionality of equipment. They serve as invaluable resources for technicians and users alike, allowing for efficient troubleshooting and maintenance. By breaking down complex machines into manageable sections, these illustrations facilitate a clearer comprehension of individual elements and their interactions.

Furthermore, these visuals can enhance the learning experience for new users. When faced with intricate machinery, having a detailed guide enables one to familiarize themselves with the structure and operation of various elements. This knowledge is crucial for proper usage and long-term upkeep.

| Benefits | Description |

|---|---|

| Clarity | Illustrations provide a clear view of each component, aiding in identification. |

| Efficiency | Facilitates quicker repairs and replacements by showing exact placements. |

| Education | Serves as a learning tool for users to understand machinery better. |

| Organization | Helps keep track of components, ensuring nothing is overlooked during maintenance. |

In summary, these illustrations play a pivotal role in enhancing user experience and operational effectiveness. They not only simplify the repair process but also empower individuals with knowledge about their equipment.

Common Parts in the TS 440

The efficient operation of a cutting tool relies on various essential components that work together seamlessly. Understanding these elements not only aids in maintenance but also enhances performance and longevity. This section highlights the fundamental elements typically found in this type of machinery.

Engine: At the heart of the device, the power unit provides the necessary force for cutting. Its reliability is crucial for consistent performance.

Blade: The cutting instrument itself comes in various sizes and materials, designed for different applications. Selecting the appropriate blade is vital for achieving optimal results.

Air Filter: This component ensures that the engine receives clean air, preventing debris from causing damage. Regular cleaning or replacement is necessary to maintain efficiency.

Fuel System: Comprising the tank, lines, and carburetor, this assembly is responsible for delivering the right fuel mixture to the engine. Proper maintenance of this system is essential for smooth operation.

Starter Mechanism: A reliable starting system is key for initiating the cutting process. This includes components that facilitate easy ignition under various conditions.

Handles: Ergonomic grips provide comfort and control during use. Their design contributes significantly to user safety and efficiency.

Familiarity with these critical elements can empower users to effectively care for their equipment, ensuring it remains in peak condition for all cutting tasks.

How to Access the Parts Diagram

Finding the necessary illustrations and information for your equipment can streamline maintenance and repairs. Accessing these resources is essential for anyone looking to ensure their tools function optimally.

Here are several methods to locate the desired visuals:

- Manufacturer’s Website: Visit the official site to find a dedicated section for documentation. This often includes user manuals and schematics.

- Online Retailers: Many retailers provide access to technical resources for the products they sell. Searching for your model may yield helpful links.

- Repair Forums: Online communities often share helpful documents and advice. Engaging with these forums can provide insights and resources from experienced users.

- Service Centers: Authorized service centers can provide official manuals and parts breakdowns upon request.

By utilizing these resources, you can easily access the necessary information to assist in repairs and ensure your equipment remains in excellent condition.

Identifying Components Easily

Understanding the various elements of machinery can significantly enhance maintenance and repair efficiency. By recognizing specific components, operators can troubleshoot issues more effectively and ensure that each part is functioning as intended. This familiarity allows for quicker identification of replacement items and better overall performance of the equipment.

Common Components Overview

Familiarity with typical components helps in quick identification and understanding their functions. Below is a brief overview of key elements often found in machinery similar to the one in focus:

| Component | Description |

|---|---|

| Blade | The cutting tool responsible for executing precise cuts. |

| Engine | The power source that drives the entire system. |

| Fuel Tank | Stores the fuel necessary for the engine to operate. |

| Air Filter | Prevents dust and debris from entering the engine. |

| Handle | Provides the user with control and maneuverability. |

Tips for Easy Identification

To facilitate the identification process, consider the following strategies:

- Refer to the user manual for specific details about each component.

- Use online resources that offer visual guides or tutorials.

- Label parts during disassembly for easier reassembly.

- Keep a maintenance log to track any changes or replacements made.

Maintenance Tips for TS 440

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By following a systematic maintenance routine, you can prevent common issues, enhance efficiency, and ensure safe operation. Here are some key tips to help you maintain your machine effectively.

Routine Inspections

Conducting frequent checks is vital. Look for any signs of wear and tear, such as frayed wires or loose components. Ensure that all moving parts are well-lubricated and free from debris. Regular inspections can help identify potential problems before they escalate, saving you time and money in the long run.

Cleaning and Storage

After each use, clean the unit thoroughly to remove dust and debris. This helps prevent buildup that could impair functionality. Store your equipment in a dry, sheltered location to protect it from environmental factors. Proper storage ensures that your machine remains in top condition, ready for the next task.

Remember: Consistent maintenance practices not only improve performance but also extend the life of your machinery. Invest time in caring for your equipment, and it will reward you with reliable service for years to come.

Common Issues and Solutions

When operating any cutting equipment, users may encounter various challenges that can affect performance and efficiency. Understanding these common problems and their solutions can help ensure smoother operation and extend the lifespan of the machine.

Frequent Problems

- Engine Failure to Start

- Overheating Issues

- Inconsistent Cutting Performance

- Vibration During Operation

Effective Solutions

- Engine Failure to Start:

- Check fuel levels and ensure the mixture is correct.

- Inspect the spark plug for wear and replace if necessary.

- Examine the air filter and clean or replace it to improve airflow.

- Overheating Issues:

- Ensure adequate cooling by cleaning any debris from vents.

- Monitor fuel quality to avoid clogging and overheating.

- Consider the load; reduce the workload to prevent overheating.

- Inconsistent Cutting Performance:

- Check the cutting blade for sharpness and damage.

- Ensure proper tensioning of the blade or chain.

- Evaluate the cutting technique and adjust if necessary.

- Vibration During Operation:

- Inspect mounting points and ensure all screws are tightened.

- Look for any worn-out parts that might need replacement.

- Use anti-vibration accessories if available to minimize discomfort.

Where to Find Replacement Parts

When it comes to maintaining and repairing your outdoor power equipment, sourcing the right components is essential for ensuring optimal performance and longevity. Fortunately, there are several avenues you can explore to locate the necessary items efficiently and affordably.

Authorized Dealers

One of the most reliable sources for obtaining high-quality components is through authorized dealers. These retailers specialize in specific brands and offer genuine parts that are guaranteed to fit and function properly. Additionally, they often provide expert advice and support to help you with your repairs.

Online Marketplaces

Another convenient option is to browse various online marketplaces. These platforms typically feature a wide array of products from different sellers, allowing you to compare prices and availability easily. Just ensure you verify the reputation of the seller and check for customer reviews to avoid potential issues.

| Source Type | Advantages | Considerations |

|---|---|---|

| Authorized Dealers | Genuine quality, expert support | Potentially higher prices |

| Online Marketplaces | Wide selection, competitive pricing | Check seller reliability |

| Local Repair Shops | Personalized service, local support | Limited selection |

Using Genuine Stihl Parts

Opting for authentic components in your outdoor equipment ensures longevity and optimal performance. These original elements are specifically designed to fit seamlessly, providing reliability and enhancing the overall efficiency of your machine.

When you choose genuine components, you are investing in quality that has been rigorously tested. Counterfeit or generic alternatives may seem cost-effective initially, but they often compromise the functionality and safety of your tools. The use of substandard materials can lead to premature wear and potential damage, ultimately resulting in higher repair costs.

Additionally, authentic components come with a warranty that offers peace of mind. This guarantee not only covers manufacturing defects but also underscores the commitment to excellence from the manufacturer. By using original elements, you ensure that your equipment remains compliant with safety standards, protecting both the user and the environment.

In conclusion, selecting genuine components is a wise decision for maintaining your outdoor machinery. It promotes reliability, safety, and efficiency, ensuring that your investment serves you well for years to come.

Upgrades for Enhanced Performance

Improving the efficiency and capability of your cutting equipment can lead to significant gains in productivity. By implementing targeted enhancements, users can achieve better performance, durability, and precision in their tasks. This section explores various upgrades that can elevate your tool’s functionality and ensure it meets demanding operational standards.

One of the most impactful modifications involves optimizing the power system. Upgrading to a high-performance engine component can increase output while reducing fuel consumption. Additionally, enhancing the cutting mechanism with advanced blades or attachments can provide cleaner cuts and increased lifespan.

| Upgrade | Description | Benefits |

|---|---|---|

| Engine Enhancements | Install a high-performance carburetor or air filter. | Boosts power and efficiency; improved fuel economy. |

| Cutting Attachments | Use specialized blades for different materials. | Provides versatility and improved cutting quality. |

| Vibration Dampening | Add vibration-reducing grips or pads. | Enhances user comfort and control during operation. |

| Weight Reduction | Replace heavy components with lightweight alternatives. | Makes the tool easier to handle and reduces fatigue. |

Investing in these enhancements not only improves operational efficiency but also prolongs the life of the equipment. Carefully selecting upgrades tailored to specific needs can yield impressive results and ensure that your tool remains competitive in the field.

Frequently Asked Questions

This section addresses common inquiries regarding the maintenance and components of cutting machines. Here, users can find answers to typical concerns, enhancing their understanding and ensuring optimal performance of their equipment.

Common Inquiries

- What are the essential maintenance steps for my cutting device?

- How can I identify wear and tear on crucial components?

- Where can I purchase replacement elements?

Operational Queries

- What should I do if the machine fails to start?

- How do I adjust the cutting depth effectively?

- What safety precautions should I take while operating the equipment?