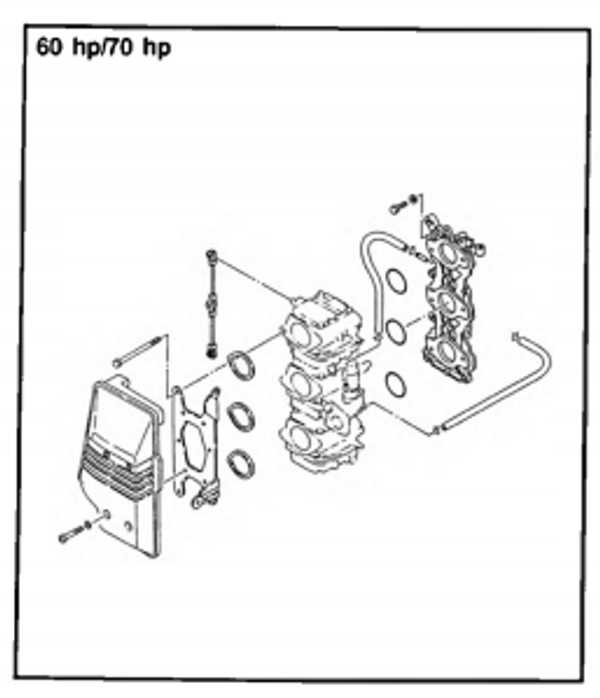

Parts Diagram for 90 HP Honda Outboard Motor

The intricate design of a 90 horsepower marine engine is a testament to engineering excellence, showcasing a range of components that work in harmony to deliver exceptional performance on the water. Understanding the arrangement and function of these elements is crucial for both maintenance and troubleshooting. A well-organized view of these components can help enthusiasts and technicians alike navigate the complexities of marine machinery.

Whether you are a seasoned mariner or a newcomer to the world of boating, familiarity with the various segments of this engine can enhance your ability to manage its upkeep effectively. Each section plays a pivotal role in ensuring smooth operation and longevity, from the propulsion system to the fuel delivery components. By delving into the specifics of this mechanical masterpiece, one can appreciate the craftsmanship that goes into designing and assembling such a powerful machine.

Furthermore, having access to a visual representation of these elements can significantly aid in identifying any issues that may arise during operation. With a clearer understanding of how each part interrelates, you can approach repairs and enhancements with confidence. This comprehensive exploration will provide valuable insights into the fundamental workings of your marine engine.

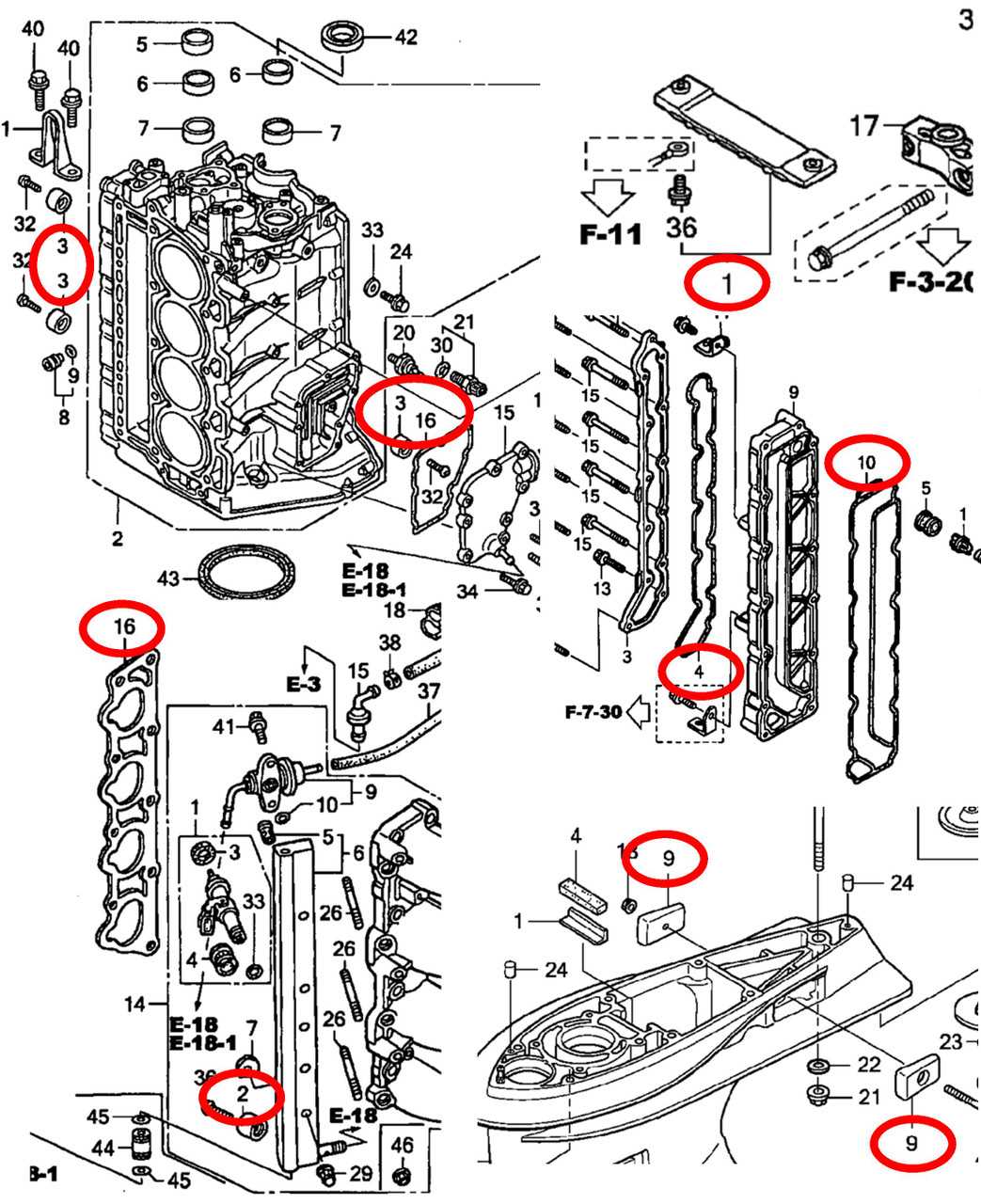

Essential Components of 90 HP Honda Engine

The engine’s performance relies heavily on its key elements, each contributing to overall functionality and efficiency. Understanding these critical components is vital for maintenance and repairs, ensuring longevity and optimal operation.

Here are the fundamental parts that make up this powerful engine:

| Component | Description |

|---|---|

| Cylinder Block | The main structure housing the cylinders, providing support for internal components. |

| Piston | Moves up and down within the cylinder, compressing the air-fuel mixture for combustion. |

| Crankshaft | Converts the linear motion of the piston into rotational motion, driving the output shaft. |

| Fuel System | Delivers the appropriate mixture of fuel and air to the engine for combustion. |

| Ignition System | Generates a spark to ignite the air-fuel mixture, initiating the combustion process. |

| Cooling System | Maintains optimal operating temperature by circulating coolant through the engine. |

| Exhaust System | Expels combustion gases from the engine, minimizing back pressure and enhancing performance. |

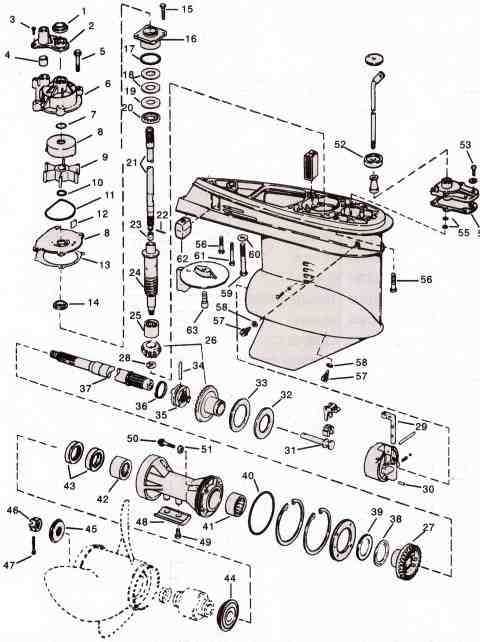

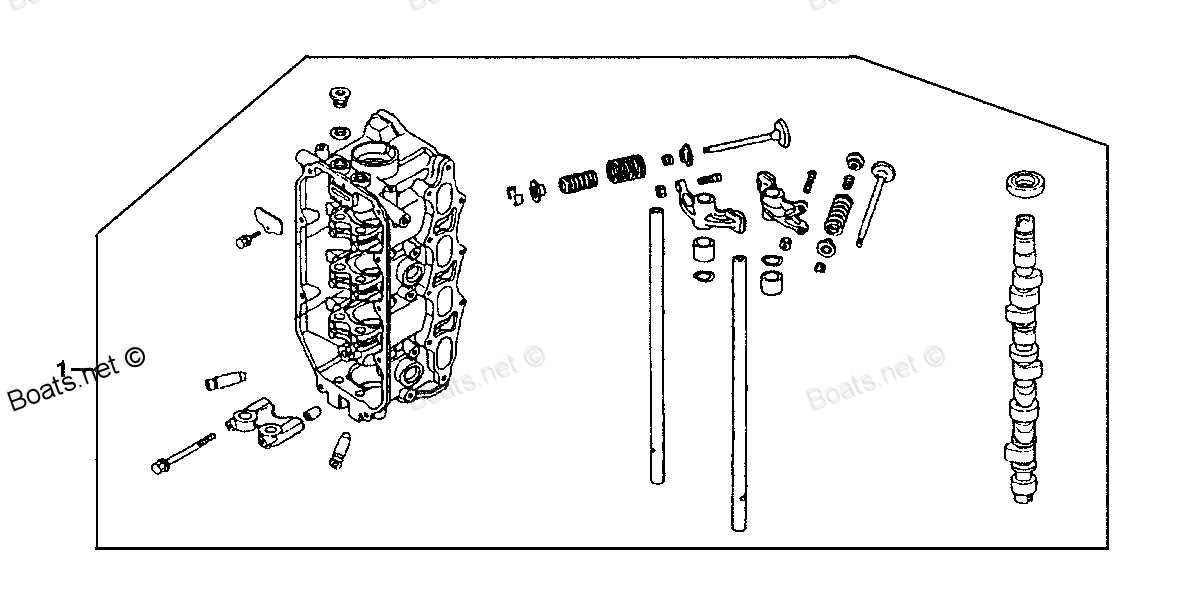

Understanding Outboard Motor Anatomy

The internal structure of marine propulsion systems plays a crucial role in their overall functionality and performance. A comprehensive understanding of these components allows for better maintenance, troubleshooting, and optimization of power delivery. This section explores the various elements that constitute these systems, shedding light on their specific functions and interrelationships.

Core Components

At the heart of every marine engine is the power unit, which is responsible for converting fuel into mechanical energy. This conversion involves several key elements, including the cylinder block, where combustion occurs, and the crankshaft, which transforms linear motion into rotational force. Additionally, the fuel system ensures that the right mixture reaches the combustion chamber, while the cooling system prevents overheating by dissipating excess heat generated during operation.

Supporting Structures

Complementing the core components are various supporting structures that enhance performance and user experience. The gearcase provides protection and houses the propulsion mechanism, while the steering system allows for precise maneuverability on the water. Understanding how these components interact is essential for optimizing performance and ensuring longevity.

Identifying Key Parts for Maintenance

Proper upkeep of a marine engine requires a clear understanding of its essential components. Recognizing these critical elements helps ensure optimal performance and longevity, allowing for timely interventions and replacements when necessary. This section outlines the main constituents that should be regularly inspected and maintained.

Fuel System Components

The fuel system is vital for efficient engine operation. Key elements include the fuel pump, filters, and injectors. Regular checks on these components can prevent fuel-related issues that may lead to poor performance or failure to start.

Cooling and Lubrication Systems

Effective cooling and lubrication are crucial for maintaining engine health. Pay attention to the thermostat, water pump, and oil filter. These parts play significant roles in regulating temperature and ensuring proper lubrication, which are essential for preventing overheating and wear.

Common Issues with Honda Outboards

When it comes to marine engines, various challenges can arise during operation, impacting performance and reliability. Identifying these issues early on is crucial for maintaining optimal functionality and ensuring a smooth experience on the water.

Engine Overheating

One frequent problem is engine overheating, which can lead to severe damage if not addressed promptly. Overheating often results from inadequate coolant flow or blockages in the cooling system. Regular maintenance, including checking for debris in the water intake and ensuring proper coolant levels, can help prevent this issue.

Fuel System Troubles

Another common challenge involves complications within the fuel delivery system. Clogged filters, contaminated fuel, or malfunctioning injectors can hinder performance. It’s essential to use high-quality fuel and conduct periodic inspections to ensure the system remains in top condition.

Tools Needed for Repairs

Performing maintenance and fixing issues with marine machinery requires a selection of essential instruments. These tools facilitate efficient work, ensuring that tasks are completed accurately and safely. A well-equipped toolkit not only enhances productivity but also helps prevent potential damage during repairs.

Basic Hand Tools

Starting with basic hand tools, a good set includes wrenches, screwdrivers, and pliers. These instruments are fundamental for tightening or loosening components, as well as for general adjustments. Additionally, having a torque wrench is crucial for applying the correct amount of force when securing bolts, which is vital for the longevity of the equipment.

Specialized Equipment

In addition to standard tools, certain specialized equipment is beneficial for more complex tasks. A multimeter is essential for electrical diagnostics, while a compression tester can help assess the condition of the engine. Investing in quality tools will yield better results and ensure a smoother repair process, ultimately leading to improved performance and reliability.

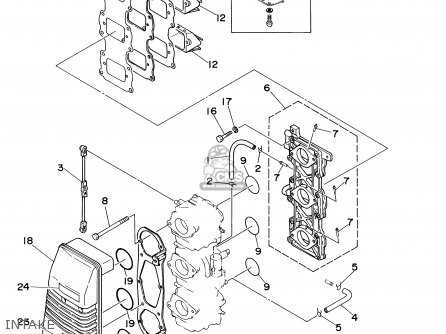

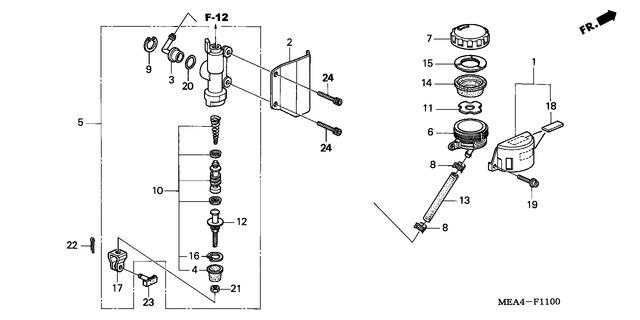

Exploring the Fuel System Design

The fuel delivery system is a critical component in marine engines, ensuring the right amount of fuel reaches the combustion chamber for optimal performance. This system’s design includes various elements working in harmony to facilitate efficient fuel intake and distribution, which is essential for the engine’s reliability and power output.

A key aspect of this system involves the fuel pump, responsible for drawing fuel from the tank and delivering it to the engine. The pump’s efficiency is vital, as it must maintain a consistent flow rate to meet the engine’s demands, especially during acceleration and high-speed operation. Additionally, filters are incorporated to eliminate impurities, preventing damage to engine components and ensuring smooth operation.

The fuel lines also play a significant role, as they transport the fuel under pressure from the tank to the engine. These lines must be constructed from durable materials to withstand the harsh marine environment while minimizing the risk of leaks or blockages. Furthermore, proper routing and securing of these lines are essential to prevent wear and tear caused by vibration or movement.

Another critical element is the fuel injectors, which atomize the fuel for efficient mixing with air in the combustion chamber. The design and calibration of these injectors directly impact engine performance, fuel efficiency, and emissions. Advanced technologies may be employed to optimize fuel delivery based on varying operational conditions, further enhancing overall engine functionality.

In summary, the design of the fuel delivery system is a complex interplay of various components, each contributing to the engine’s performance and longevity. Understanding this system is crucial for maintaining and optimizing engine efficiency, ultimately leading to a better experience on the water.

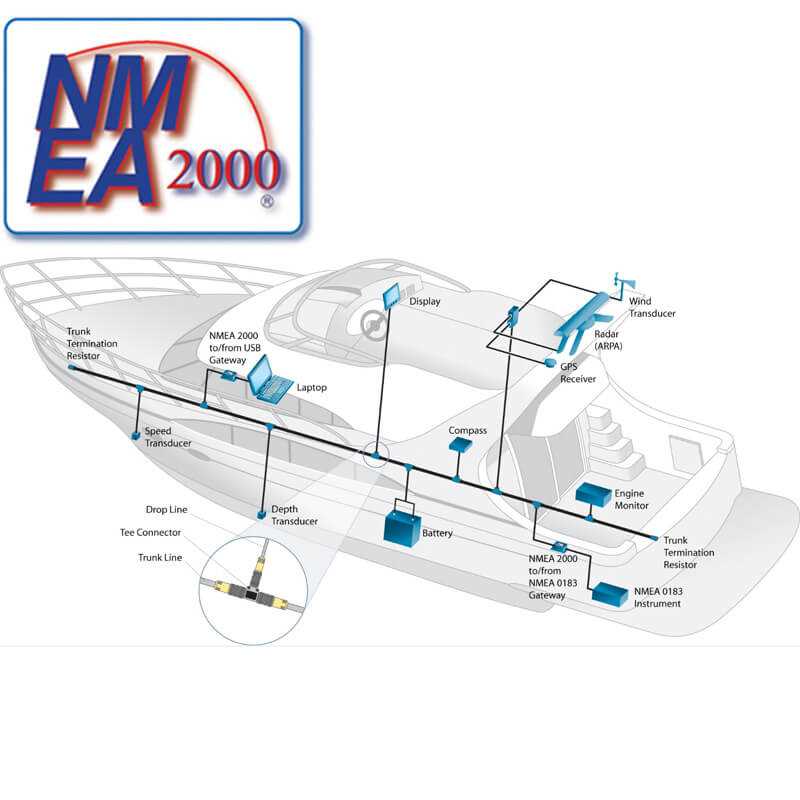

Electrical System Overview and Components

The electrical framework of marine propulsion systems plays a crucial role in ensuring optimal performance and reliability. This system encompasses various elements that work together to power critical operations, facilitate communication, and support navigation functions. Understanding the components within this structure is essential for maintaining efficiency and addressing potential issues that may arise during operation.

Key components of the electrical system include the battery, ignition system, wiring harness, and various sensors. Each part contributes to the overall functionality, providing the necessary power and control for the vessel’s operations. Below is a table outlining the primary elements and their functions:

| Component | Function |

|---|---|

| Battery | Stores electrical energy for starting the engine and powering accessories. |

| Ignition System | Generates the spark needed to ignite the fuel-air mixture in the engine cylinders. |

| Wiring Harness | Connects various electrical components, ensuring proper communication and power distribution. |

| Sensors | Monitor engine performance and environmental conditions, providing feedback for optimal operation. |

| Control Panel | Displays critical information such as engine status, temperature, and battery voltage. |

Regular inspection and maintenance of these components are vital for preventing malfunctions and ensuring the safety and efficiency of the marine vessel.

Cooling System Functionality Explained

The cooling system is a crucial component designed to maintain optimal operating temperatures within an engine. By effectively regulating heat, it prevents overheating, ensuring that the engine runs smoothly and efficiently. This section delves into the various aspects of this essential mechanism, highlighting its purpose and functionality.

Key Functions of the Cooling Mechanism

- Heat Dissipation: The primary role of the cooling system is to remove excess heat generated during the combustion process.

- Temperature Regulation: It helps maintain the engine’s temperature within a specified range, promoting efficiency and longevity.

- Component Protection: By keeping the engine cool, it protects critical components from heat-related damage.

- Optimal Performance: A well-functioning cooling system enhances the overall performance of the engine, ensuring reliable operation.

Cooling Mechanism Components

Several key elements contribute to the effective operation of the cooling system:

- Water Pump: Circulates coolant throughout the engine.

- Thermostat: Regulates coolant flow based on temperature.

- Heat Exchanger: Transfers heat from the coolant to the surrounding water or air.

- Cooling Hoses: Connect different components, facilitating the flow of coolant.

Understanding the functionality of the cooling system is vital for maintaining the reliability and efficiency of an engine. Regular inspection and maintenance of its components can prevent potential issues and prolong the engine’s lifespan.

Choosing Quality Replacement Parts

When it comes to maintaining and enhancing the performance of your marine engine, selecting high-quality components is essential. The durability and reliability of these components can significantly influence the overall functionality and longevity of your vessel. Opting for superior alternatives not only ensures optimal performance but also promotes safety on the water.

Understanding the Importance of Quality

Quality replacements are engineered to meet specific performance standards, ensuring that they work seamlessly with your engine. Low-quality substitutes may appear to be cost-effective initially, but they often lead to further issues down the line, ultimately resulting in increased expenses and potential safety hazards. Investing in reliable components guarantees that your engine operates smoothly and efficiently.

Research and Recommendations

Before making a purchase, conduct thorough research. Look for reputable manufacturers and read customer reviews to gauge the experiences of other users. Recommendations from experienced individuals in the marine community can also guide you toward reputable suppliers. Additionally, consulting your engine’s manual can provide insight into the specifications required for each component.

Consider OEM vs. Aftermarket

When selecting replacements, you’ll often encounter two options: original equipment manufacturer (OEM) and aftermarket products. While OEM components are designed specifically for your engine, aftermarket alternatives may offer comparable quality at a lower price. Evaluate both options based on factors like warranty, compatibility, and performance to make an informed decision.

Tips for Troubleshooting Engine Problems

Identifying and resolving issues with your engine can be a complex process, but understanding common symptoms and diagnostic techniques can simplify the task. By following a systematic approach, you can effectively pinpoint the root cause of the malfunction and determine the necessary repairs.

- Listen for Unusual Noises: Pay attention to any strange sounds that may indicate internal problems, such as knocking, grinding, or excessive vibration.

- Check for Leaks: Inspect the area around the engine for any signs of fluid leaks, which could point to gasket failures or hose issues.

- Monitor Performance: Observe how the engine behaves during operation. Notice if there are changes in power, acceleration, or responsiveness.

- Inspect Fuel Supply: Ensure that the fuel system is delivering an adequate supply of clean fuel. Look for clogged filters or faulty pumps.

- Evaluate Electrical Components: Examine the wiring, connectors, and ignition system for any signs of damage or corrosion that could disrupt performance.

By methodically following these tips, you can effectively troubleshoot and address engine problems, ensuring optimal performance and longevity.

Benefits of Regular Maintenance Checks

Routine inspections and upkeep of marine machinery play a crucial role in ensuring optimal performance and longevity. Consistent attention to mechanical components helps identify potential issues before they escalate into costly repairs, thereby promoting safety and reliability on the water.

Enhanced Performance

Regular maintenance activities can significantly boost the efficiency of marine engines. By ensuring that all components are functioning as intended, operators can experience smoother operation, improved fuel efficiency, and increased overall power. This leads to a more enjoyable experience on the water.

Cost Savings

Investing time and resources in routine checks can lead to substantial savings over time. Preventative measures reduce the likelihood of major breakdowns that often result in expensive repairs and prolonged downtime. Maintaining equipment properly is more economical than addressing issues after they arise.

| Maintenance Activity | Frequency | Benefits |

|---|---|---|

| Engine Oil Change | Every 100 hours | Improves lubrication, enhances efficiency |

| Fuel System Inspection | Every season | Prevents clogging, ensures optimal performance |

| Cooling System Check | Every 50 hours | Prevents overheating, extends engine life |

| Battery Maintenance | Monthly | Ensures reliability, avoids unexpected failures |