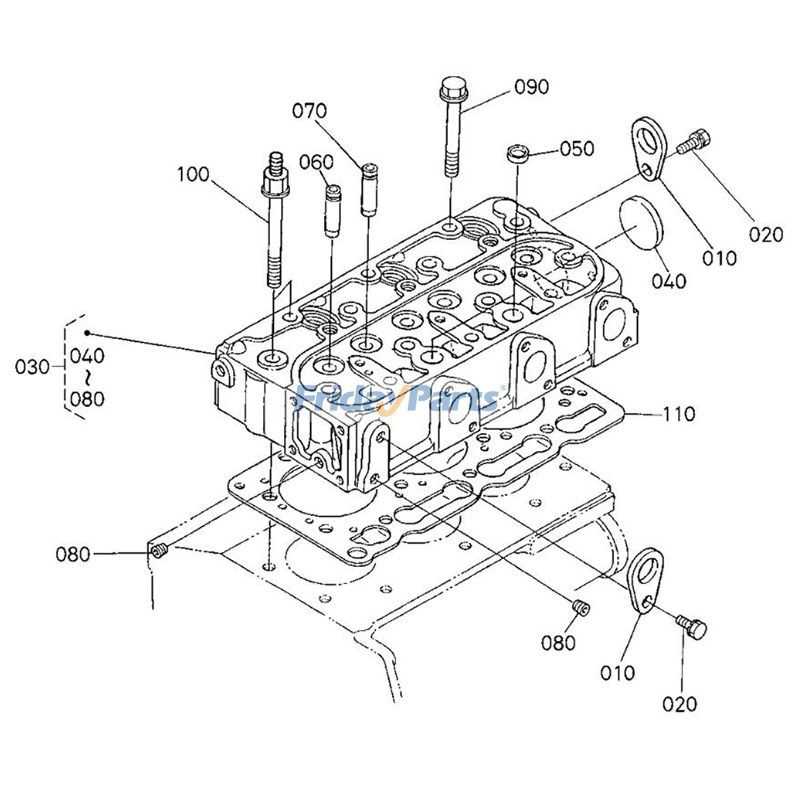

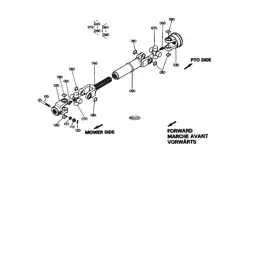

Kubota F2000 Parts Diagram Overview

Understanding the intricate arrangement of machinery elements is crucial for effective maintenance and operation. A comprehensive overview of each component allows operators to identify specific parts and comprehend their functions within the system. This knowledge enhances efficiency and promotes longevity in the equipment’s performance.

Illustrations and schematics serve as valuable tools for visualizing the connection between different sections. By examining these representations, users can gain insights into the interrelationships of the components, facilitating easier troubleshooting and repairs. This approach not only simplifies the process of identifying issues but also aids in the timely execution of necessary adjustments.

Moreover, having access to well-organized illustrations fosters a deeper understanding of the machine’s design. Such clarity equips users with the ability to make informed decisions regarding upgrades or replacements. Ultimately, a detailed exploration of the various elements contributes to the overall effectiveness and reliability of the machinery.

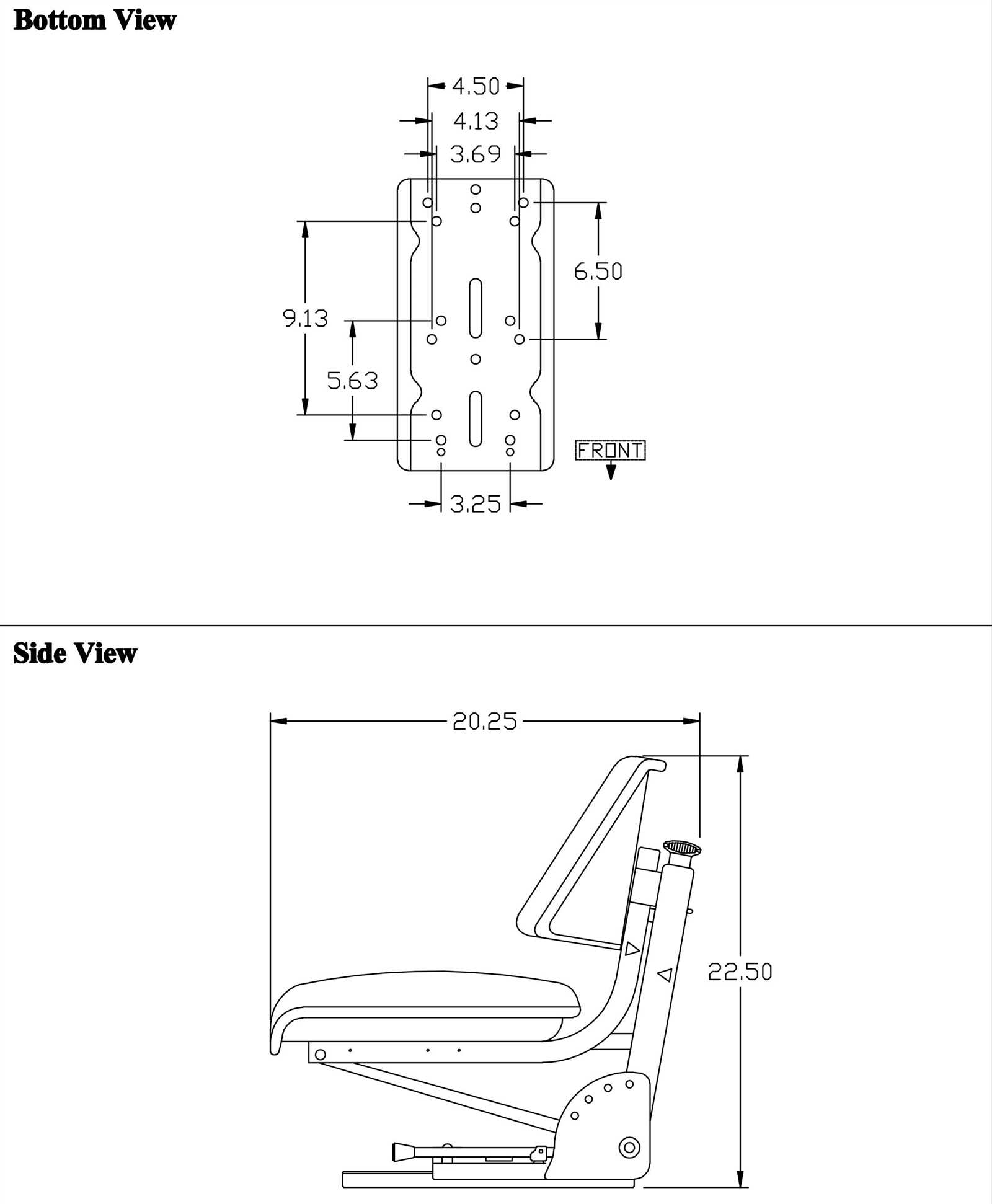

The effectiveness of any machinery relies significantly on its essential elements. In this section, we will explore various crucial components that contribute to the overall functionality and performance of this specific agricultural equipment. Understanding these elements is vital for maintenance and operational efficiency.

Key Functional Elements

Each machine comprises several integral parts that work in unison to ensure smooth operation. Here are some of the primary functional elements that play a vital role:

| Component | Description |

|---|---|

| Engine | The power source that drives all functions. |

| Transmission | Transfers power from the engine to the wheels. |

| Hydraulic System | Facilitates lifting and movement through hydraulic fluid. |

| Chassis | The framework that supports all components and provides stability. |

| Wheels | Enable movement across different terrains. |

Maintenance of Essential Parts

Regular inspection and servicing of these key components are crucial for longevity and optimal performance. Addressing wear and tear promptly ensures that the equipment continues to operate efficiently and reduces the risk of breakdowns during use.

How to Read Parts Diagrams

Understanding the visual representation of components is essential for effective maintenance and repair. These illustrations provide valuable insights into the assembly and functionality of various machinery. By familiarizing oneself with these visuals, users can identify the necessary elements and their relationships, streamlining the process of troubleshooting and repairs.

Here are some key tips to effectively interpret these illustrations:

- Identify the Sections: Diagrams are usually divided into sections, each representing a different part of the equipment. Take note of these divisions to focus on specific areas.

- Examine the Labels: Pay attention to the labels accompanying each component. These often indicate part numbers or descriptions, which are crucial for ordering replacements.

- Understand the Symbols: Familiarize yourself with common symbols used in the illustrations. Each symbol typically represents a specific type of part or connection.

- Follow the Flow: Many diagrams show the flow of operation. Observing the path can help in understanding how each component interacts within the system.

- Use a Reference: Keep a reference guide or key nearby to clarify any unfamiliar terms or symbols encountered in the illustrations.

By applying these techniques, users can enhance their comprehension of visual representations, making repairs and maintenance more efficient.

Identifying Genuine Kubota Parts

When it comes to maintaining agricultural machinery, distinguishing authentic components from counterfeit ones is crucial. Utilizing original components ensures optimal performance and longevity of the equipment. This section will provide insights into recognizing quality elements that contribute to efficient operation.

Key Characteristics of Authentic Components

Recognizing true components involves examining several features that set them apart from imitations. Authentic items typically exhibit superior craftsmanship, precise measurements, and adherence to manufacturer specifications. Here are some common indicators:

| Characteristic | Genuine Parts | Counterfeit Parts |

|---|---|---|

| Material Quality | High-grade materials | Inferior materials |

| Packaging | Professional branding | Poorly printed labels |

| Weight | Consistent weight | Unusual weight variations |

| Warranty | Manufacturer warranty | No warranty |

Importance of Using Authentic Components

Choosing original components not only guarantees compatibility with your machinery but also enhances safety and reliability. Using substandard alternatives can lead to equipment failures, costly repairs, and even accidents. Therefore, it is essential to invest in quality components for long-term benefits.

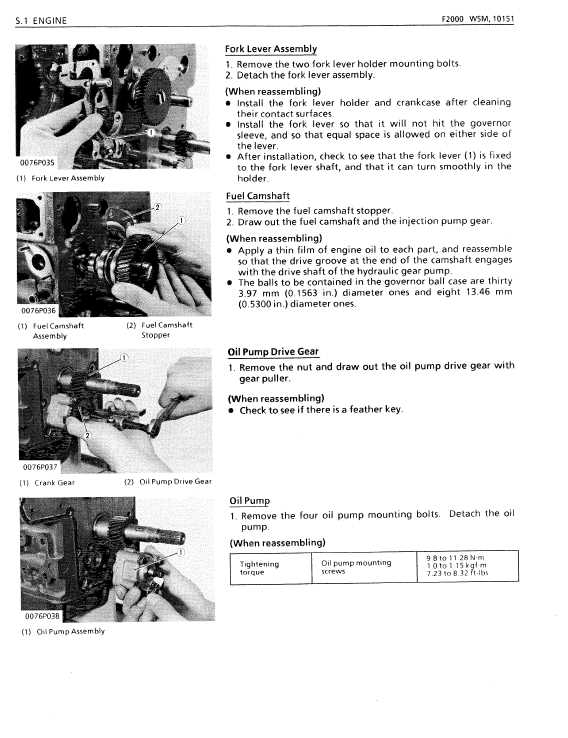

Maintenance Tips for Kubota F2000

Regular upkeep of your machinery is essential for ensuring its longevity and optimal performance. Adopting effective maintenance practices can prevent potential issues and enhance the overall efficiency of your equipment. By following a systematic approach, you can ensure that your machine remains in excellent working condition.

1. Routine Inspections: Conduct frequent checks on various components to identify any signs of wear or damage. This includes examining belts, filters, and fluid levels. Early detection of issues can save time and costs associated with major repairs.

2. Fluid Changes: Regularly replace engine oil, hydraulic fluid, and coolant as recommended by the manufacturer. Clean fluids are crucial for the smooth operation of your equipment, helping to prevent overheating and ensuring efficient performance.

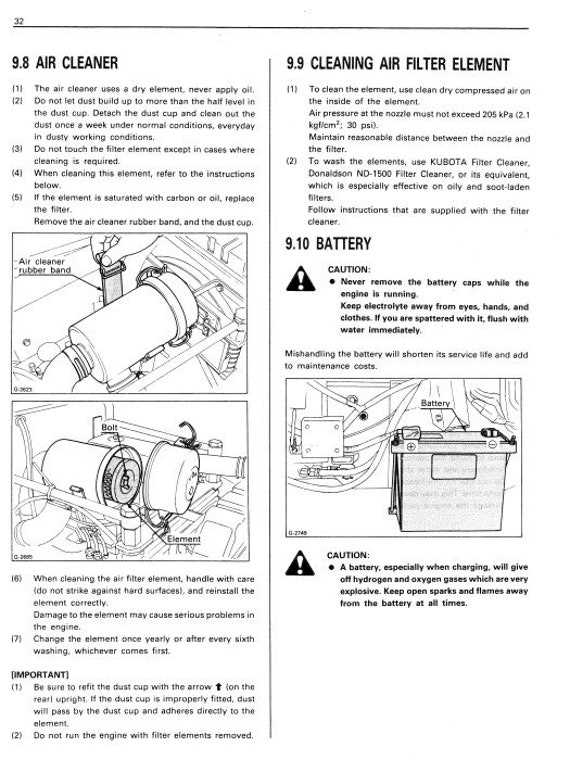

3. Air Filter Maintenance: A clean air filter is vital for the optimal functioning of the engine. Inspect and replace the air filter as necessary to ensure proper airflow and prevent contaminants from entering the system.

4. Tire Care: Maintain proper tire pressure and inspect for any signs of damage or uneven wear. Well-maintained tires enhance traction and stability, contributing to the overall efficiency of the machine.

5. Follow the Manual: Always refer to the manufacturer’s guidelines for specific maintenance schedules and recommendations. Adhering to these instructions will help you maintain your equipment effectively and prolong its lifespan.

Common Issues and Solutions

In the realm of machinery maintenance, various challenges can arise that hinder optimal performance. Understanding these common issues and their solutions is essential for ensuring smooth operation and longevity of the equipment. This section addresses typical problems that users may encounter and provides effective strategies for resolution.

One frequent complication involves engine performance, which may manifest as reduced power or difficulty starting. Regular inspection of fuel filters and air intake systems can alleviate such issues. Ensuring that these components are clean and free from blockages can significantly enhance overall functionality.

Another prevalent concern is overheating, often resulting from insufficient coolant levels or a malfunctioning radiator. Regular checks of coolant levels and the condition of hoses can prevent overheating incidents. Additionally, flushing the cooling system periodically helps maintain its efficiency.

Transmission difficulties may also arise, characterized by slipping or unresponsive gears. This issue often stems from low fluid levels or contaminated fluid. Regular fluid checks and timely changes can mitigate these problems and prolong the lifespan of the transmission system.

Finally, electrical problems may present themselves, impacting various functions such as lighting and starting systems. Inspecting wiring for wear and ensuring connections are secure can help resolve these electrical issues. Utilizing proper diagnostic tools can further assist in identifying underlying causes and implementing appropriate fixes.

Finding Replacement Parts Easily

Locating suitable components for your machinery can be a straightforward process if approached with the right strategies. Whether you are in need of specific elements for maintenance or repairs, understanding where to search and how to identify quality replacements is crucial.

Here are some effective methods to streamline your search:

- Online Retailers: Numerous websites specialize in providing various components for different equipment. Ensure to use reliable sources that offer detailed descriptions and customer reviews.

- Local Dealers: Visiting nearby dealerships can be beneficial, as they often have access to authentic and compatible items. Engaging with knowledgeable staff can also provide insights into the best options available.

- Parts Catalogs: Consulting detailed catalogs can aid in identifying necessary items. These resources typically include specifications and compatibility information, simplifying the selection process.

- Online Forums: Participating in online communities dedicated to machinery can yield helpful recommendations. Users often share experiences and tips about sourcing reliable components.

- Manufacturer Websites: Visiting the official websites of manufacturers can lead you to original equipment suppliers. They often provide lists of authorized distributors, ensuring that you receive genuine parts.

By utilizing these approaches, you can enhance your chances of finding the right components efficiently, ensuring your equipment remains in optimal condition.

Tools Needed for Repairs

When it comes to maintaining machinery, having the right tools is essential for effective repairs. Proper equipment not only ensures that tasks are completed efficiently but also helps prevent potential damage to components. This section outlines the key instruments required for successful maintenance and restoration tasks.

Basic Hand Tools are the foundation for any repair project. Wrenches, screwdrivers, and pliers are indispensable for loosening and tightening various fasteners. Socket sets also play a crucial role in accessing hard-to-reach areas, making the repair process smoother.

Power Tools can significantly expedite the repair process. A cordless drill is versatile for driving screws and drilling holes. Additionally, an angle grinder may be necessary for cutting or smoothing surfaces, especially in metal components.

Specialized Instruments are often required for specific tasks. A torque wrench ensures that bolts are tightened to the manufacturer’s specifications, preventing over-tightening. Moreover, diagnostic tools, such as multimeters, can help identify electrical issues and ensure proper functionality.

Having a well-stocked toolbox with these essential tools will make maintenance tasks more manageable and help prolong the life of the equipment.

Expert Recommendations for Owners

Owning a specialized machine requires not only knowledge but also careful attention to maintenance and repairs. To ensure longevity and optimal performance, it’s essential to consider a few expert tips tailored for operators of such equipment. By following these insights, you can enhance both efficiency and reliability.

Regular Maintenance Practices

Consistent upkeep is vital for any machinery. Schedule routine inspections to identify wear and tear before it becomes a significant issue. Pay attention to components that experience the most stress, as they are often the first to show signs of failure. Additionally, adhering to the manufacturer’s service intervals can prevent unexpected breakdowns.

Utilizing Quality Components

Investing in high-quality replacement components is crucial. Opt for reputable brands that offer durability and compatibility with your model. This choice not only ensures that the machinery operates smoothly but also contributes to its overall lifespan. Keep a stock of essential items on hand to minimize downtime during repairs.

Resources for Further Assistance

When seeking guidance for maintenance or troubleshooting of agricultural machinery, it’s essential to access reliable information sources. Numerous platforms offer valuable insights, from user manuals to online forums, which can greatly enhance your understanding and enable effective repairs or replacements.

Online Forums and Communities

Engaging with online forums allows users to share their experiences and solutions. These communities often contain discussions about various issues, where you can find advice and insights from fellow users.

Official Manufacturer Resources

Consulting official resources from the manufacturer can provide detailed information regarding specific models. These resources may include maintenance guidelines, safety tips, and recommended practices to ensure optimal performance.

| Resource Type | Examples |

|---|---|

| User Manuals | Downloadable PDFs, printed guides |

| Online Forums | Dedicated websites, social media groups |

| Manufacturer Websites | Technical support, product information |

| Instructional Videos | YouTube, manufacturer channels |