Briggs and Stratton 500E Series 140cc Parts Diagram Overview

In the realm of small machinery, grasping the intricacies of engine construction is essential for effective maintenance and repair. A clear visual representation of the various elements involved can significantly enhance the understanding of how these engines operate. This segment delves into the organization and labeling of engine components, ensuring that both seasoned mechanics and novice users can easily identify and access the necessary pieces.

Within this context, a comprehensive overview serves as a guide to navigating the intricacies of engine assemblies. By examining each individual element, users can familiarize themselves with the essential features that contribute to overall functionality. This knowledge not only aids in efficient repairs but also promotes a deeper appreciation for the mechanics at play in everyday machinery.

The significance of accurately interpreting these layouts cannot be overstated. Whether one is troubleshooting a malfunction or performing routine upkeep, recognizing the role of each component is crucial. By providing clarity and insight, this exploration empowers users to take charge of their equipment and ensure optimal performance.

Understanding the Briggs and Stratton 500E Series

This segment provides an overview of a well-known small engine model commonly used in various outdoor equipment. With its reliable performance and robust design, this engine has become a preferred choice among homeowners and professionals alike. It features several components that work in harmony to deliver efficient power, making it suitable for lawn mowers, pressure washers, and other tools.

The engine is engineered to be user-friendly, ensuring that both maintenance and repairs can be carried out with ease. Familiarity with the fundamental parts and their functions is essential for anyone looking to optimize the performance of their equipment. Knowing how to access and replace individual components can significantly enhance longevity and efficiency.

Many users appreciate the simplicity of this engine’s layout, which allows for quick troubleshooting and repairs. Common elements include the fuel system, ignition components, and the air intake assembly, each playing a vital role in the overall operation. Understanding how these parts interact helps users maintain their equipment effectively.

Moreover, this engine is designed to operate under various conditions, showcasing versatility and reliability. By recognizing the features and specifications, users can ensure they select the right equipment for their specific needs. Engaging with the engine’s functionality not only aids in immediate repairs but also contributes to a better understanding of its overall operation.

Key Components of 140cc Engines

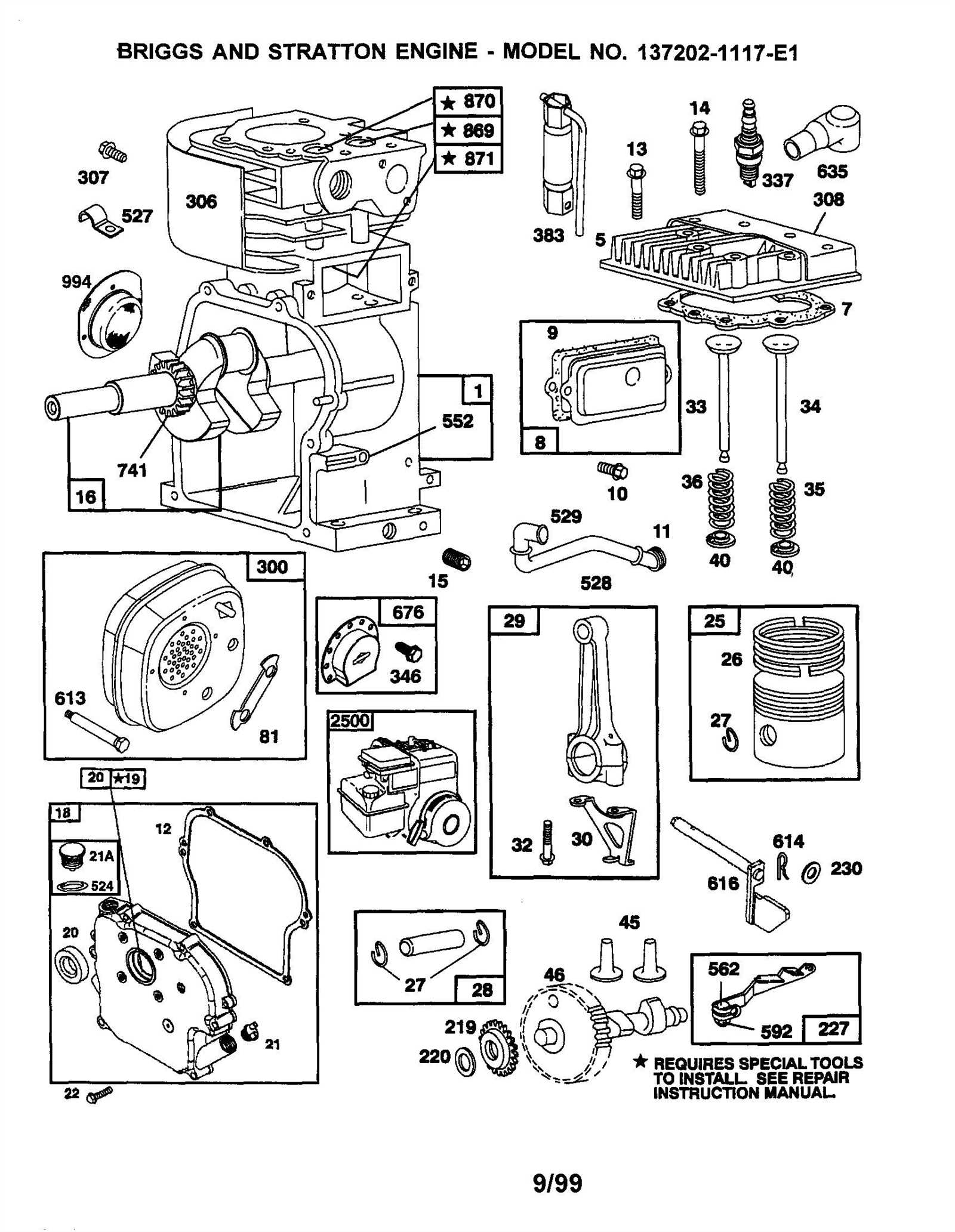

Understanding the essential elements of small power units is crucial for optimal performance and maintenance. Each engine consists of various parts that work in harmony to generate power and ensure efficiency. This section highlights the primary components found in compact engines, shedding light on their functions and importance.

Major Elements

Small engines are typically comprised of several key elements, each serving a specific role in the overall operation. The most significant components include the crankshaft, cylinder, piston, and fuel system. Each part contributes to the engine’s functionality and efficiency, making it vital to comprehend their interactions.

Fuel System Overview

The fuel system plays a critical role in ensuring that the engine receives the necessary power source. It consists of a fuel tank, fuel lines, and a carburetor. Proper maintenance of this system is essential for reliable performance.

| Component | Description |

|---|---|

| Crankshaft | Converts linear motion of the piston into rotational motion. |

| Cylinder | Houses the piston and is where combustion occurs. |

| Piston | Moves up and down within the cylinder, creating pressure for combustion. |

| Fuel Tank | Stores the fuel required for engine operation. |

| Carburetor | Mixes air and fuel to create a combustible mixture. |

Benefits of Regular Maintenance

Consistent upkeep of your equipment plays a crucial role in ensuring its longevity and optimal performance. By adhering to a routine maintenance schedule, you can prevent unexpected breakdowns and costly repairs, ultimately enhancing the overall efficiency of your machinery.

Enhanced Efficiency: Regular care allows machines to operate at peak efficiency. Clean filters, sharp blades, and well-lubricated components ensure that the equipment runs smoothly, reducing fuel consumption and increasing productivity.

Prolonged Lifespan: Just as humans require regular check-ups, machinery benefits from frequent inspections. Addressing minor issues before they escalate into major problems can significantly extend the life of your tools.

Cost Savings: Investing time in maintenance can lead to substantial savings in the long run. By preventing significant repairs and reducing energy consumption, you can save money that would otherwise go toward fixing breakdowns or replacing parts.

Improved Safety: Regular maintenance also contributes to a safer working environment. Well-maintained equipment is less likely to malfunction, reducing the risk of accidents and injuries.

Increased Resale Value: If you ever decide to sell your equipment, having a history of regular maintenance can enhance its resale value. Potential buyers are more likely to trust well-cared-for machinery, making it easier to sell at a favorable price.

In conclusion, routine maintenance is essential for ensuring that your equipment remains efficient, safe, and reliable. Embracing a proactive approach to upkeep can yield long-term benefits that outweigh the initial time and effort invested.

Common Issues and Troubleshooting Tips

When dealing with small engine equipment, various complications may arise that hinder optimal performance. Identifying these common challenges is essential for maintaining functionality and prolonging the life of the machine. This section outlines typical problems and offers practical solutions to address them effectively.

Engine Won’t Start

One of the most frequent issues encountered is the inability of the engine to start. This can be attributed to several factors, including insufficient fuel, a clogged air filter, or a malfunctioning spark plug. Checking the fuel level and ensuring that the fuel is fresh is a good first step. Additionally, inspecting the air filter for dirt and replacing it if necessary can significantly improve engine performance. If the problem persists, examine the spark plug for wear or damage, as replacing it may resolve the issue.

Overheating Problems

Overheating is another concern that can lead to severe engine damage. This issue often arises due to a lack of adequate lubrication, obstructed cooling fins, or a blocked exhaust system. Regularly checking the oil level and changing it as needed can prevent overheating. Furthermore, ensuring that the cooling fins are free from debris and that the exhaust is unobstructed will aid in maintaining a stable operating temperature.

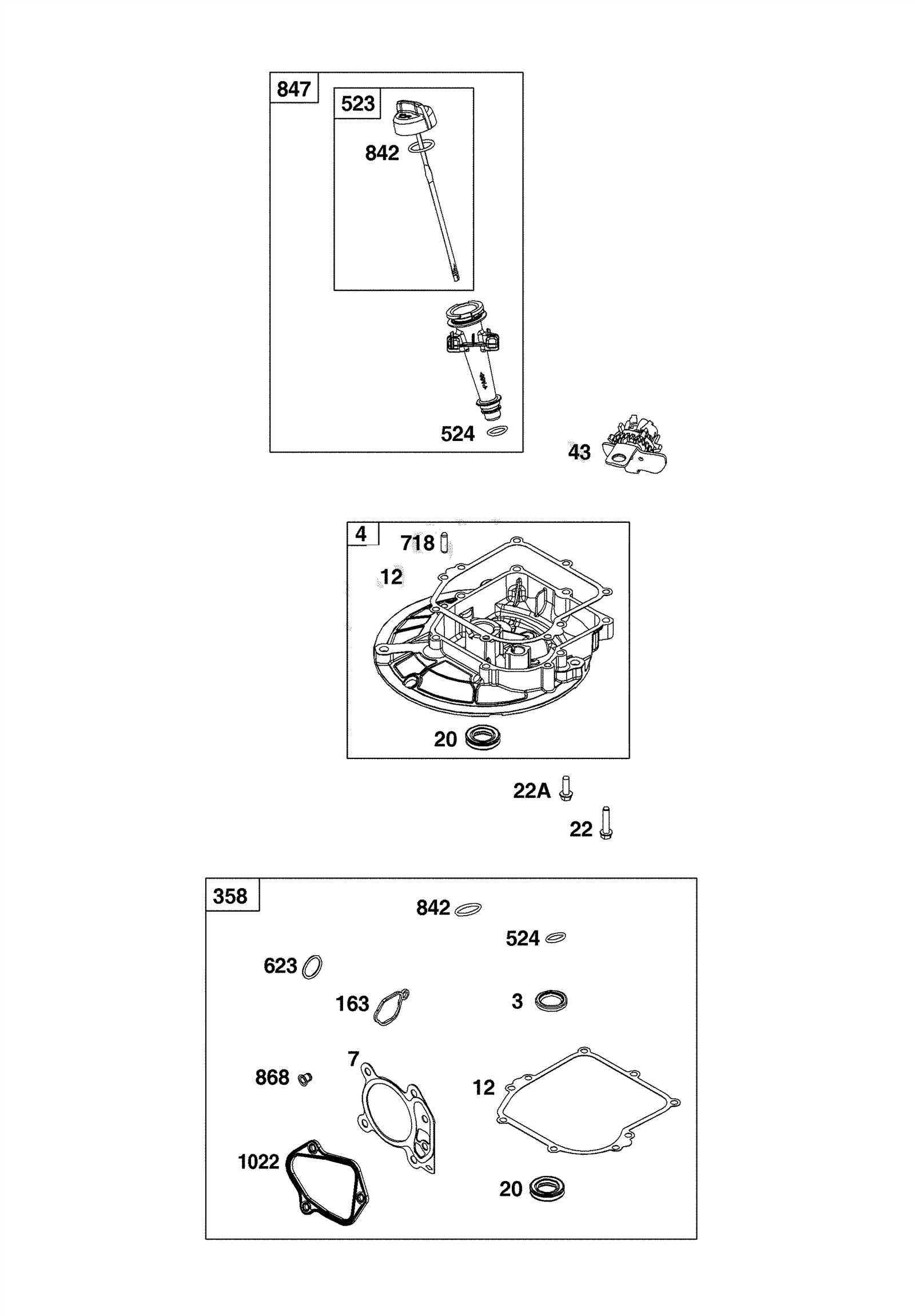

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations serve as guides, helping users identify individual elements and their relationships within a mechanism. Familiarity with these visuals enables individuals to locate the necessary pieces for replacement or assembly accurately.

To begin interpreting these illustrations, it’s important to recognize the various symbols and labels used. Each component typically has a unique identifier, often accompanied by a corresponding number or letter. This information allows users to cross-reference with lists that provide detailed descriptions and specifications.

| Symbol | Description |

|---|---|

| Circle | Indicates a detachable item. |

| Square | Represents a stationary component. |

| Arrow | Shows direction of movement or flow. |

| Shaded Area | Highlights a specific section for focus. |

By mastering these elements, individuals can streamline the repair process. It’s advisable to always consult the accompanying documentation for further insights and ensure all parts are compatible with the intended model. This knowledge not only enhances efficiency but also fosters confidence in handling mechanical systems.

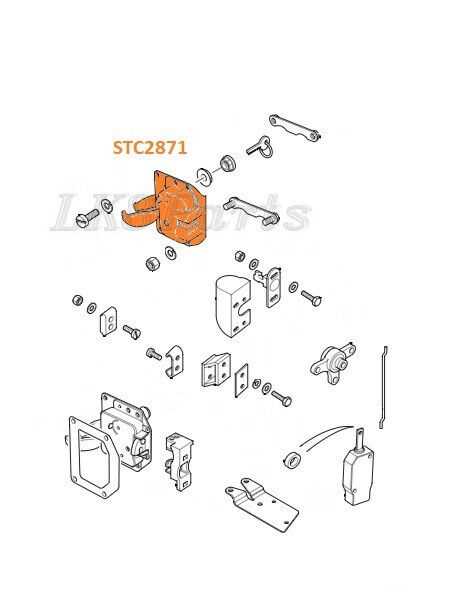

Replacement Parts for Enhanced Performance

Upgrading components within your small engine can significantly enhance its efficiency and longevity. Selecting the right replacements ensures optimal functionality and addresses wear and tear that can accumulate over time. This proactive approach not only maximizes performance but also minimizes the risk of unexpected failures.

When considering replacements, it is essential to focus on high-quality alternatives that match or exceed the original specifications. Components such as air filters, spark plugs, and fuel lines play a crucial role in maintaining smooth operation. Regularly changing these items contributes to better fuel efficiency and overall performance.

Additionally, investing in specialized accessories can elevate your engine’s capabilities. For instance, using upgraded ignition systems or high-flow carburetors can lead to noticeable improvements in power output and responsiveness. It is advisable to consult technical resources or professional guidance to ensure compatibility and effectiveness when selecting these enhancements.

In summary, selecting appropriate replacement components is vital for achieving peak performance from your small engine. By prioritizing quality and considering upgrades, you can enjoy a more reliable and efficient machine for all your outdoor tasks.

Tools Needed for Repairs

When undertaking maintenance tasks, having the right tools is essential for ensuring efficient and effective repairs. A well-equipped toolbox not only simplifies the process but also minimizes the risk of damage to components. Proper instruments facilitate precise work and enhance the overall outcome of the job.

Essential Tools

Begin with basic hand tools such as wrenches, screwdrivers, and pliers. These items are crucial for disassembling and reassembling various components. Additionally, a torque wrench is beneficial for ensuring that fasteners are tightened to the manufacturer’s specifications, preventing issues that arise from over or under-tightening.

Specialized Equipment

In some cases, specialized tools may be required. For instance, a multimeter is invaluable for diagnosing electrical problems, while a compression tester helps assess engine performance. Keeping a clean workspace and having access to cleaning supplies, such as degreasers and rags, can significantly aid in the repair process.

Installing New Parts: A Guide

Replacing components in your equipment can significantly enhance its performance and longevity. This guide provides essential steps and tips for efficiently installing new elements, ensuring optimal functionality and reliability. Whether you are a seasoned enthusiast or a novice, understanding the installation process is crucial for maintaining your machinery in top condition.

Before you begin, it is essential to gather all necessary tools and replacement components. Ensure that you have the right equipment, such as wrenches, screwdrivers, and any specialized tools that may be required. Taking the time to prepare your workspace will facilitate a smoother installation process.

Once you are ready, start by disconnecting the power source to ensure safety. This step is vital to prevent any accidental starts while you work. Carefully remove the old component by loosening screws or bolts, following any specific instructions related to your equipment. Take note of how the previous part was installed, as this will aid in the correct placement of the new item.

When you are ready to install the new piece, align it correctly with the mounting points. Secure it in place by tightening screws or bolts as specified in the manual. It is essential to avoid overtightening, as this may damage the new component or the surrounding structure.

After installation, double-check all connections and ensure that everything is securely fastened. Reconnect the power source and perform a test run to confirm that the new component functions as intended. Regular maintenance and timely replacement of worn items will keep your machinery operating efficiently and effectively for years to come.

Safety Precautions During Repairs

When performing maintenance on machinery, adhering to safety protocols is crucial to prevent accidents and injuries. Proper precautions not only protect the individual conducting the repairs but also ensure the equipment is handled correctly and remains in optimal condition. Awareness of potential hazards and implementing preventive measures can significantly reduce risks associated with mechanical work.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is essential. This includes safety goggles to shield the eyes from debris, gloves to protect hands from sharp edges and chemicals, and sturdy footwear to safeguard against falling objects. Utilizing ear protection is also advisable when working with loud machinery to prevent hearing damage.

Work Environment Considerations

Maintain a clean and organized workspace to minimize hazards. Ensure that tools are in good condition and easily accessible, and that the area is well-lit to facilitate clear visibility. Be aware of your surroundings and avoid working in wet or cluttered areas, as these conditions can lead to slips, trips, and falls. Additionally, disconnecting power sources before beginning any repair work is a vital step in safeguarding against electrical shocks.

Where to Find Genuine Parts

Finding authentic components for your small engine is crucial for ensuring its optimal performance and longevity. High-quality replacement items can significantly enhance functionality and reliability. Here are several reliable sources to consider when searching for original items.

- Authorized Dealers: Start by visiting authorized retailers that specialize in engine equipment. These outlets typically carry a wide range of genuine components and can provide guidance on selection.

- Manufacturer’s Website: The official website often has a dedicated section for replacement components. You can search by model or part number to find exactly what you need.

- Local Repair Shops: Many local mechanics and repair shops have access to authentic components. Consulting with professionals can also lead you to reputable suppliers.

- Online Marketplaces: Numerous e-commerce platforms specialize in engine supplies. Always check seller ratings and product reviews to ensure authenticity.

- Community Forums: Engaging with online communities can provide valuable insights. Other enthusiasts often share their experiences and recommend trusted suppliers.

Prioritizing genuine components will enhance the performance of your equipment and ensure safety during use. Invest the time to research and source quality replacements to maintain your engine in top condition.

FAQs About Briggs and Stratton Engines

This section addresses common inquiries regarding small power units renowned for their reliability and efficiency. Whether you’re a seasoned mechanic or a casual user, understanding these engines can enhance your experience and maintenance practices.

General Questions

- What types of engines are available?

There are various models designed for different applications, including lawn mowers, generators, and pressure washers.

- How can I determine the engine model?

Check the label or sticker on the engine, typically located on the side or near the air filter, for model information.

Maintenance Queries

- What are the basic maintenance tasks?

Routine tasks include changing the oil, cleaning or replacing air filters, and inspecting spark plugs.

- How often should I perform maintenance?

Follow the manufacturer’s recommendations, usually every 25-50 hours of operation or annually, whichever comes first.

Troubleshooting Issues

- What should I do if the engine won’t start?

Check the fuel level, inspect the battery (if applicable), and ensure that the choke is in the correct position.

- Why is the engine running rough?

This may be due to dirty fuel, clogged air filters, or faulty spark plugs. Regular maintenance helps prevent these issues.

Performance Enhancements

- Can I upgrade my engine’s performance?

Yes, various aftermarket components can improve efficiency, such as high-performance air filters and exhaust systems.

- Are there fuel options for better performance?

Using higher-octane fuel can enhance performance, but always check the specifications to ensure compatibility.