Comprehensive Guide to Stihl FS100RX Parts Diagram

In the realm of outdoor maintenance, having a clear understanding of machinery and its various elements is essential for both efficiency and longevity. Knowing how the different components interact allows users to troubleshoot issues effectively and perform necessary repairs with confidence. This knowledge not only enhances the performance of your tools but also extends their lifespan.

Every piece of equipment is composed of numerous intricate parts, each playing a crucial role in the overall functionality. By familiarizing yourself with these individual elements, you can streamline maintenance tasks and ensure optimal performance during use. This exploration helps in recognizing wear and tear, making timely replacements, and ultimately achieving better results in your gardening endeavors.

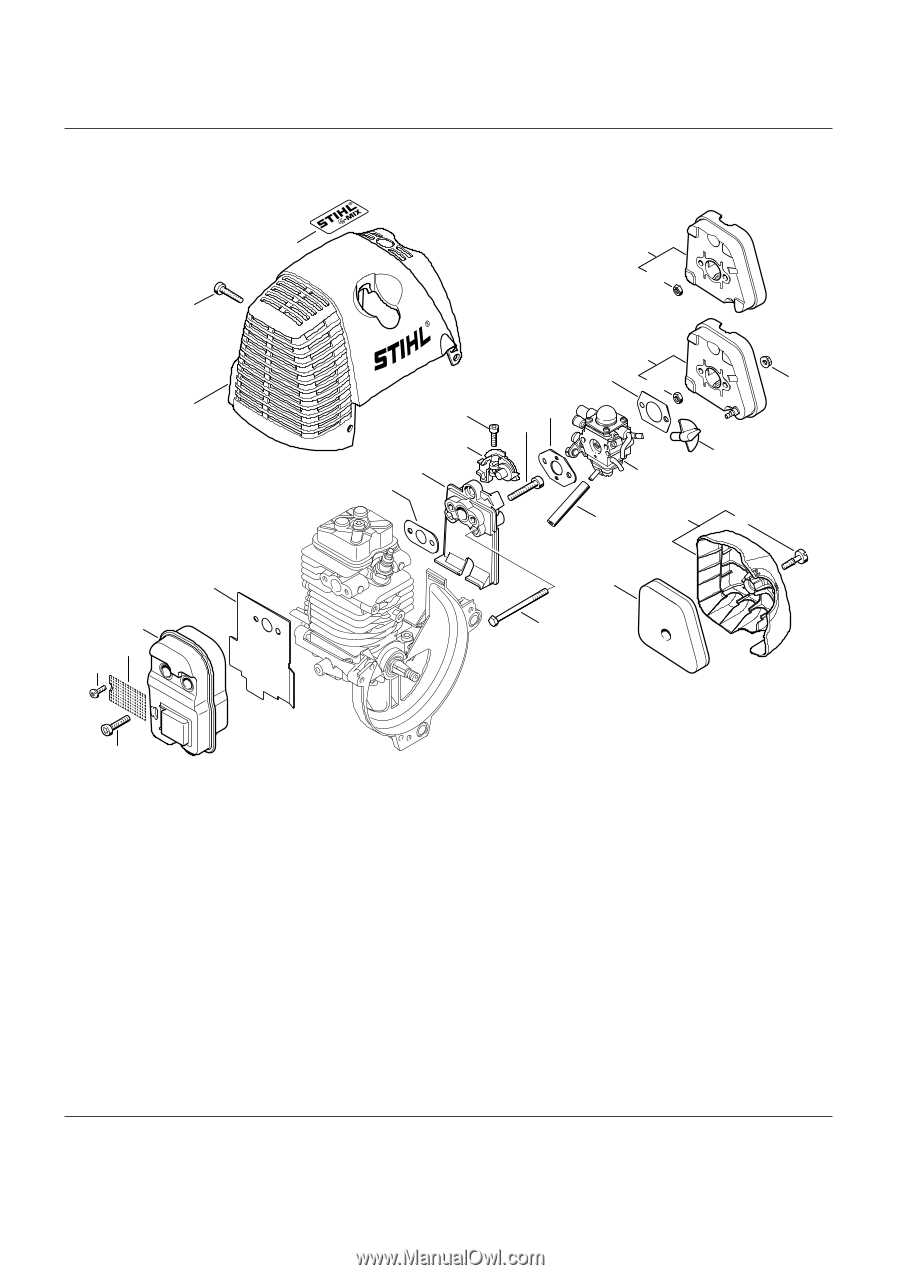

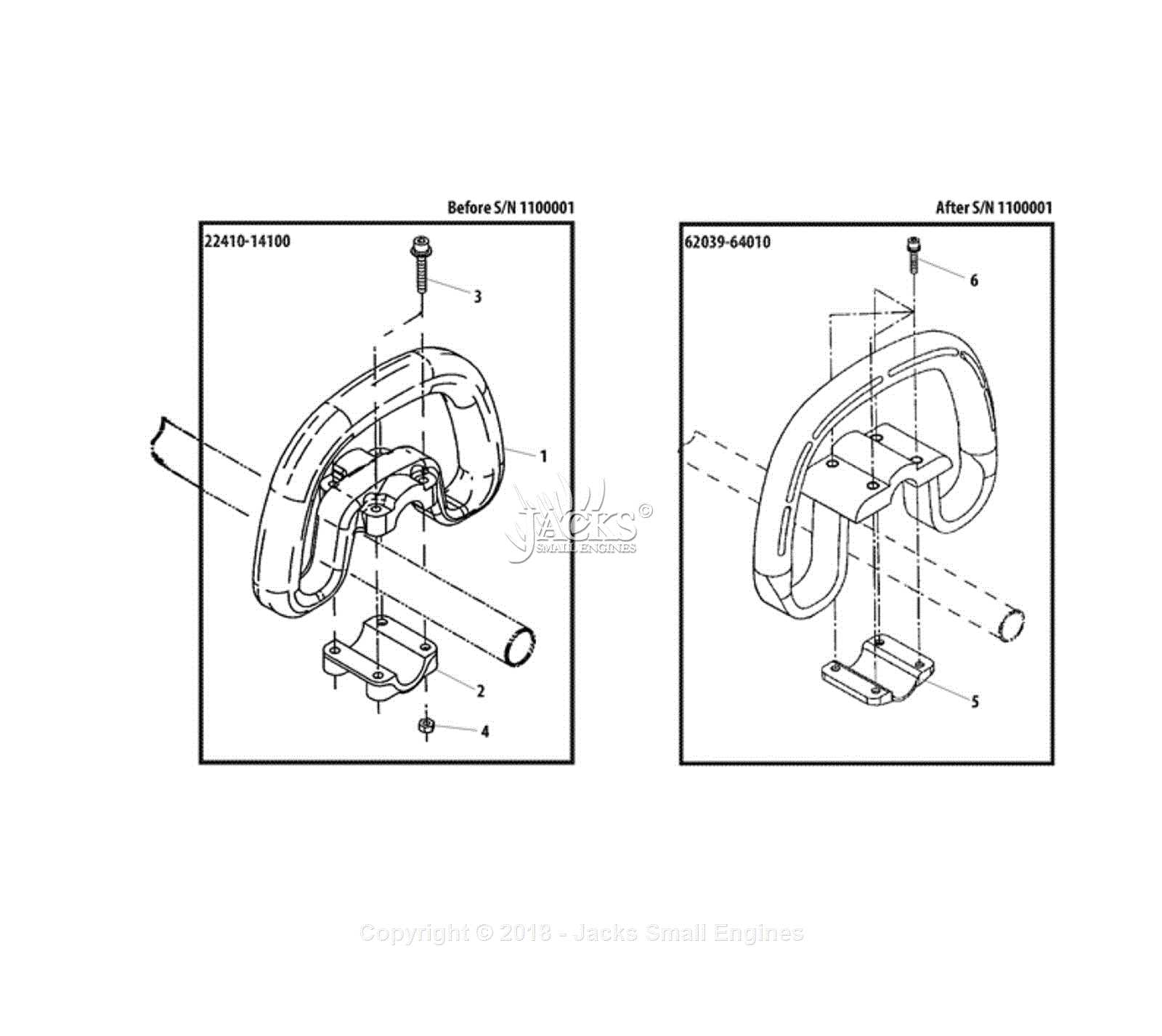

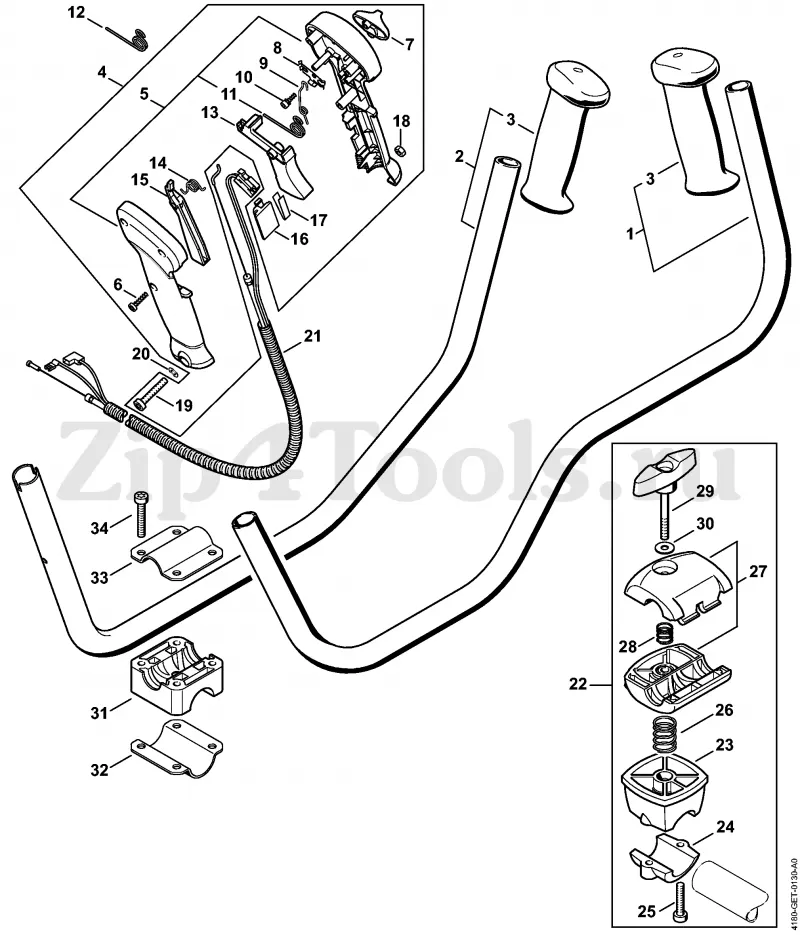

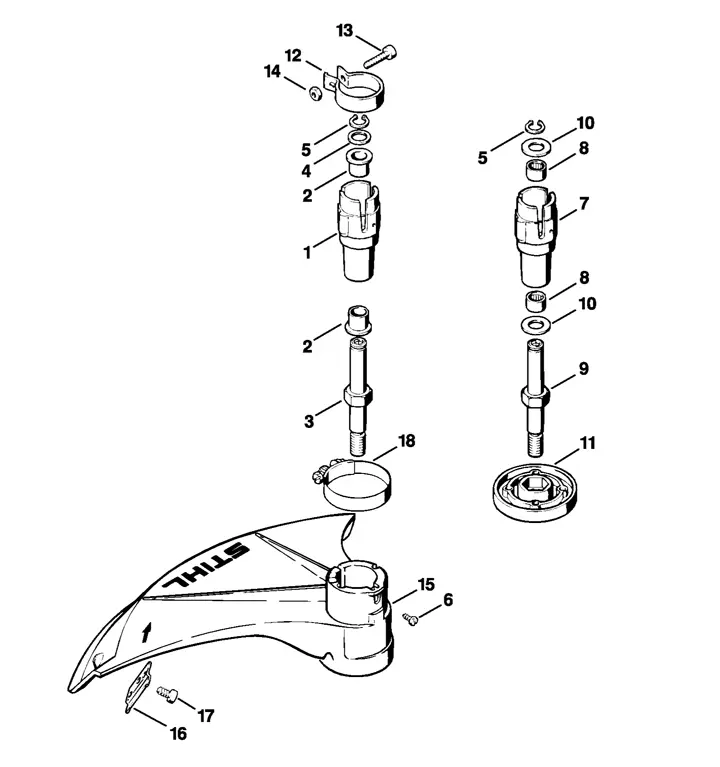

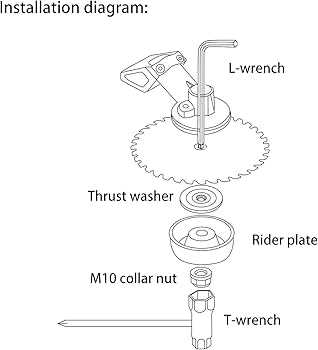

Moreover, visual representations of these components can serve as invaluable resources for understanding assembly and disassembly processes. They provide clarity on how parts fit together and can assist in identifying specific issues that may arise over time. Engaging with such resources can empower users to take control of their equipment’s maintenance, transforming daunting repair tasks into manageable projects.

Understanding the Stihl FS100RX

This section aims to provide insight into a popular outdoor power tool designed for efficient vegetation management. It is known for its robust performance and reliability, making it a preferred choice among professionals and enthusiasts alike.

Equipped with a powerful engine, this tool excels in handling tough tasks, from trimming grass to clearing dense underbrush. Its ergonomic design enhances user comfort during prolonged use, reducing fatigue and improving control. Furthermore, the lightweight construction allows for easy maneuverability in various environments.

Maintenance plays a crucial role in ensuring optimal functionality. Familiarity with the various components and their roles can greatly enhance the tool’s longevity and efficiency. Understanding the assembly of the machine allows users to troubleshoot issues more effectively and perform necessary repairs or replacements.

Overall, this power equipment represents a balance of strength and user-friendliness, making it an invaluable asset for anyone engaged in land management or landscaping activities.

Key Components of the FS100RX

Understanding the essential elements of this powerful cutting tool is crucial for effective operation and maintenance. Each component plays a vital role in ensuring optimal performance and longevity.

Engine: The heart of the machine, responsible for generating the power needed to drive the cutting mechanism. Its efficiency directly influences the overall effectiveness of the tool.

Cutting Head: This component houses the blade or line, enabling precise trimming and clearing of grass and weeds. The design affects both the cutting capacity and ease of use.

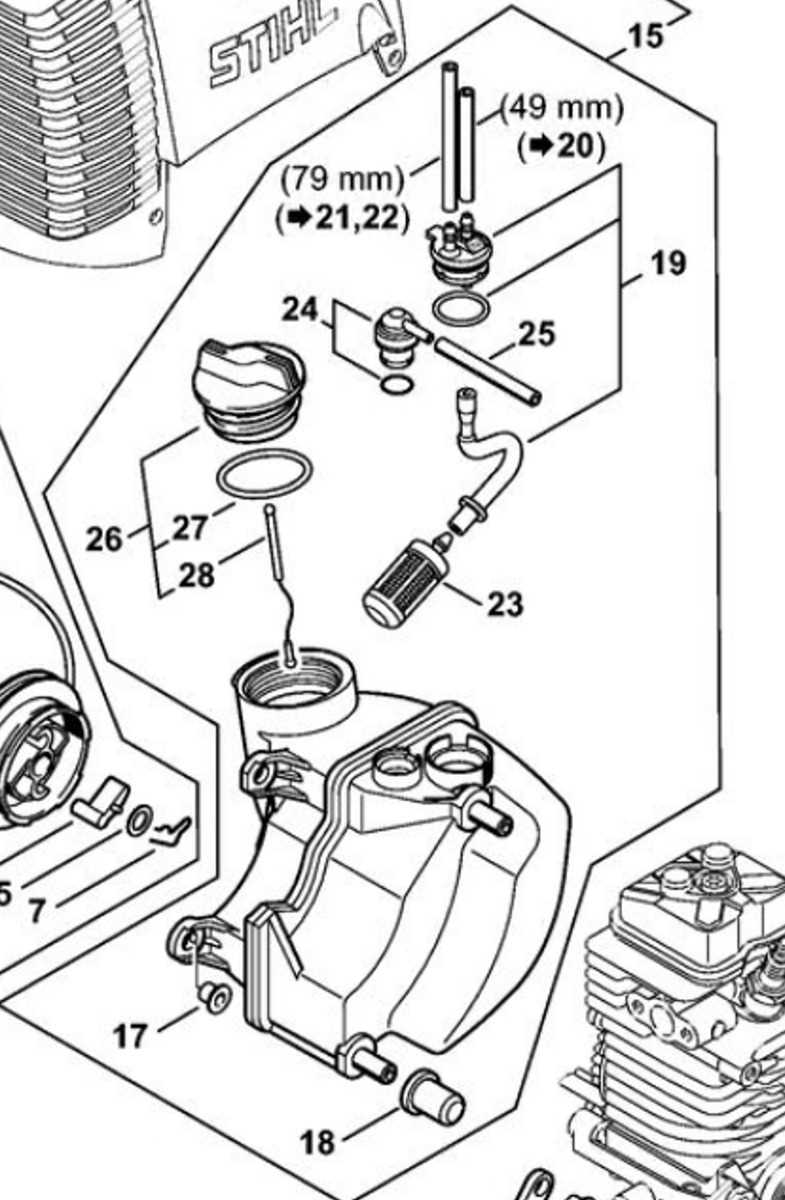

Fuel System: Comprising the tank, lines, and carburetor, this system ensures a steady supply of fuel to the engine, impacting performance and reliability. Proper maintenance of these parts is essential to avoid operational issues.

Handle and Control System: The ergonomic design of the handle, combined with intuitive controls, allows for comfortable handling and maneuverability, making it easier to tackle various tasks.

Drive Shaft: Connecting the engine to the cutting head, this component transmits power effectively. Its construction quality affects durability and resistance to wear.

Each of these components contributes significantly to the functionality of the machine, highlighting the importance of understanding their roles for maintenance and efficient operation.

Importance of a Parts Diagram

A visual representation of components plays a crucial role in understanding the assembly and maintenance of equipment. This tool aids users in identifying each element, ensuring proper handling and efficient repair processes.

Key benefits include:

- Enhanced Understanding: Visual aids provide clarity, making it easier to comprehend complex mechanisms.

- Streamlined Maintenance: Knowing the layout helps in timely servicing, preventing potential issues.

- Accurate Replacements: Identifying specific elements ensures that the correct replacements are made, reducing errors.

- Efficient Troubleshooting: Pinpointing faulty parts becomes simpler, allowing for quicker resolutions.

Utilizing a visual representation fosters a proactive approach to equipment care, ultimately prolonging the lifespan and performance of the machinery.

How to Read the Diagram

Understanding a technical illustration is crucial for effective maintenance and repair. These visual representations provide a detailed view of components and their relationships, helping users identify necessary parts and their functions. By familiarizing yourself with the layout and symbols used, you can streamline your workflow and enhance your repair skills.

Here are key elements to consider when interpreting these visuals:

- Component Labels: Look for clearly marked identifiers next to each element. These labels often correspond to specific parts or assemblies.

- Numbering System: Many illustrations use a numbering or lettering system to indicate the sequence or grouping of components. Pay attention to these designations for clarity.

- Lines and Arrows: Lines connecting different parts can indicate relationships or movement paths. Arrows typically show the direction of assembly or flow.

- Legend or Key: A legend may accompany the illustration, providing definitions for symbols and color codes used within the visual. Refer to this for clarification.

By keeping these factors in mind, you can effectively navigate technical illustrations and perform tasks with confidence. Proper understanding leads to more efficient repairs and better overall maintenance practices.

Common Replacement Parts Explained

Maintaining equipment often requires understanding the components that may need to be swapped out over time. Familiarity with these elements can enhance the lifespan and efficiency of your tool, ensuring it operates smoothly and reliably. This section outlines some frequently needed components that users should be aware of for optimal performance.

Key Components

Among the essential elements, a few stand out due to their pivotal roles in the functionality of your machine. Regularly checking and replacing these parts can prevent potential malfunctions and improve overall efficiency.

| Component | Description | Function |

|---|---|---|

| Fuel Filter | A small filter that removes impurities from the fuel. | Ensures clean fuel reaches the engine, preventing clogging and performance issues. |

| Spark Plug | Electrical component that ignites the air-fuel mixture. | Essential for starting the engine and maintaining smooth operation. |

| Trimmer Head | The part that holds the cutting line. | Facilitates effective trimming and cutting of grass and weeds. |

| Air Filter | Filters out dust and debris from the air entering the engine. | Prevents engine wear and maintains performance by ensuring a clean air supply. |

Maintenance Tips

Regular inspections and timely replacements of these components can significantly enhance performance and reliability. Establishing a routine maintenance schedule is advisable to keep your equipment in optimal working condition.

Identifying Worn Components

Recognizing deteriorated elements within your equipment is crucial for maintaining optimal performance. Regular inspections can help identify parts that may have lost their effectiveness, leading to decreased efficiency and potential damage. By understanding common signs of wear, you can ensure timely replacements and prolong the lifespan of your machine.

Here are some typical indicators of component wear:

| Component | Signs of Wear | Recommended Action |

|---|---|---|

| Cutting Blade | Chipping, dull edges, uneven cuts | Sharpen or replace |

| Fuel Filter | Clogging, reduced fuel flow | Clean or replace |

| Air Filter | Dirt buildup, discoloration | Clean or replace |

| Drive Shaft | Excessive play, unusual vibrations | Inspect for damage and replace if necessary |

| Bearings | Noisy operation, friction | Lubricate or replace |

By staying vigilant and proactive about maintenance, you can significantly enhance the functionality and durability of your equipment.

Where to Find Official Diagrams

Accessing reliable visual representations of equipment components is essential for proper maintenance and repair. Official resources ensure that you receive accurate and up-to-date information, which is crucial for ensuring the longevity and efficiency of your tools. Below are some of the most effective avenues for obtaining these essential resources.

| Source | Description |

|---|---|

| Manufacturer Website | The primary source for authentic illustrations, often available for free in the support section. |

| User Manuals | Included with your equipment, these documents usually contain detailed breakdowns of parts and their functions. |

| Authorized Dealers | Local retailers can provide access to official materials and may offer assistance in understanding them. |

| Online Forums | Community-driven platforms where users share resources and insights, often linking to official documents. |

| Service Centers | Professional service centers often have access to comprehensive parts lists and visuals for repairs. |

Utilizing these resources will not only help in identifying components but also in executing repairs and maintenance with confidence.

Tips for Proper Maintenance

Maintaining your equipment is essential for ensuring optimal performance and longevity. Regular care not only enhances efficiency but also minimizes the risk of breakdowns, allowing you to get the most out of your investment.

1. Clean After Use: Always clean the machine thoroughly after each use. Remove any debris, grass clippings, or dirt that may accumulate, as this can affect performance and lead to corrosion.

2. Regular Inspections: Conduct routine checks on all components. Look for signs of wear or damage, such as frayed wires or cracked parts, and address any issues immediately to prevent further damage.

3. Lubrication: Ensure that moving parts are properly lubricated according to the manufacturer’s guidelines. This helps reduce friction, prolongs the life of the machine, and maintains efficiency.

4. Fuel Quality: Use high-quality fuel and replace it regularly to prevent clogging and engine issues. Old or contaminated fuel can lead to poor performance and costly repairs.

5. Storage Practices: When not in use, store the equipment in a dry, clean place. Protect it from extreme temperatures and humidity, which can cause deterioration and operational issues.

6. Follow the Manual: Always refer to the user manual for specific maintenance recommendations. Following the manufacturer’s instructions will help you maintain the machine effectively and safely.

Ordering Stihl Parts Online

Acquiring components for outdoor equipment has never been easier, thanks to the convenience of online shopping. With just a few clicks, users can access a wide variety of essential items, ensuring their tools remain in optimal condition. This method allows for a seamless experience, saving both time and effort.

Finding Reliable Sources is crucial when searching for components online. It’s important to choose reputable retailers that specialize in outdoor machinery. Look for sites that offer detailed descriptions, specifications, and customer reviews to help make informed decisions.

Understanding Compatibility is essential before placing an order. Ensure the selected items match your specific model and requirements. Many websites provide helpful filtering options to narrow down choices based on equipment type and brand, making it easier to find what you need.

Comparing Prices is another advantage of online shopping. Users can quickly browse multiple websites to find the best deals, ensuring they receive high-quality components at competitive prices. Don’t forget to consider shipping costs and delivery times, as these can vary significantly between retailers.

Reading Customer Feedback can offer valuable insights into the quality and reliability of products. Pay attention to both positive and negative reviews to gauge the overall satisfaction of previous buyers. This information can help in making a more confident purchasing decision.

Once you’ve gathered all necessary information, placing an order is typically straightforward. Most retailers provide user-friendly interfaces, allowing you to add items to your cart and proceed to checkout with ease. Keep an eye out for promotions or discounts that may enhance your shopping experience.

In summary, the process of acquiring components online provides a flexible and efficient solution for maintaining outdoor equipment. By selecting reliable sources, understanding compatibility, comparing prices, and reading customer feedback, you can ensure a successful shopping experience.

DIY Repairs and Safety Tips

Engaging in home maintenance can be rewarding, but it requires knowledge and care. Understanding the components of your equipment and how they function is essential for effective repairs. With the right approach, you can extend the life of your tools while ensuring your safety and efficiency.

Essential Repair Techniques

Before diving into any repair, familiarize yourself with the tool’s inner workings. Utilize a reliable guide or manual to identify key components. Always start with basic maintenance tasks, such as cleaning and inspecting parts for wear and tear. When replacing any worn elements, opt for high-quality substitutes to maintain performance. Remember to keep your workspace organized to avoid losing small pieces.

Safety First

Safety should always be your top priority. Wear appropriate protective gear, including gloves, goggles, and sturdy footwear, to guard against potential hazards. Ensure that your tool is turned off and disconnected from power sources before starting any work. If you’re unsure about a repair, consult a professional to avoid accidents. Additionally, maintain a clear workspace to minimize risks during your projects.

Frequently Asked Questions About Parts

This section aims to address common inquiries regarding components and their functionalities in various machinery. Understanding the intricacies of these elements can enhance maintenance practices and prolong the life of equipment.

What should I consider when replacing a component?

When looking to substitute a part, ensure compatibility with your model. It’s also vital to assess the quality of the replacement, as well as to follow the manufacturer’s recommendations for optimal performance.

How do I identify the correct component for my machine?

Identification can typically be done by referencing the model number and checking specifications outlined in the user manual. Additionally, consulting online resources or contacting support can provide clarity.

Are there generic alternatives available?

Yes, many third-party manufacturers produce compatible components. However, it’s essential to verify that these alternatives meet quality standards to ensure safety and efficiency.

What maintenance practices should I follow?

Regular inspections and cleaning of components can prevent premature wear. Additionally, keeping a maintenance log can help track when replacements are necessary.

How can I ensure my equipment runs efficiently?

Using genuine or high-quality replacements, adhering to a regular maintenance schedule, and following operational guidelines can significantly enhance the efficiency and lifespan of your machinery.

Benefits of Using Genuine Parts

Utilizing authentic components in your machinery offers numerous advantages that contribute to performance, longevity, and safety. When you choose original items, you ensure that your equipment functions as intended, minimizing the risk of malfunctions and enhancing overall efficiency.

Quality Assurance: Genuine components are manufactured to meet strict standards, ensuring superior quality and reliability. This reduces the likelihood of wear and tear, allowing your machine to operate smoothly over time.

Perfect Fit: Original items are designed specifically for your equipment, guaranteeing compatibility. This precise fit helps to avoid issues related to improper installation or functionality, which can often arise with generic alternatives.

Enhanced Performance: By using authentic components, you can expect optimal performance from your machinery. These parts work in harmony with other components, providing better efficiency and effectiveness in various applications.

Safety: Utilizing original items contributes to safer operation. Inferior components may compromise safety features, potentially leading to accidents or injuries. Genuine parts ensure that all safety mechanisms are intact and functioning properly.

Long-Term Savings: Although genuine components may have a higher upfront cost, they can lead to significant savings in the long run. Their durability reduces the need for frequent replacements and repairs, ultimately lowering maintenance expenses.

In summary, investing in authentic components not only enhances the performance and safety of your machinery but also promotes a more cost-effective and reliable operation over time.