Understanding the Briggs and Stratton 17.5 HP Engine Parts Diagram

When it comes to small machinery, a comprehensive grasp of individual elements is essential for effective maintenance and repair. Each unit consists of numerous components that work in harmony to ensure optimal performance. Familiarizing oneself with these components can significantly enhance the efficiency and longevity of the machine.

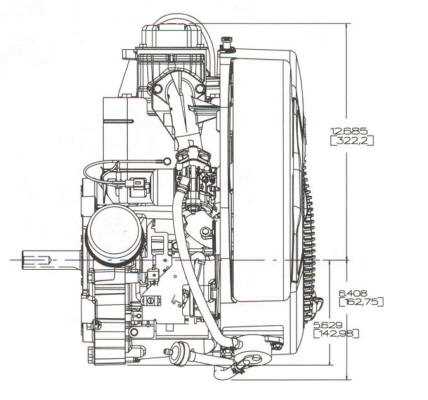

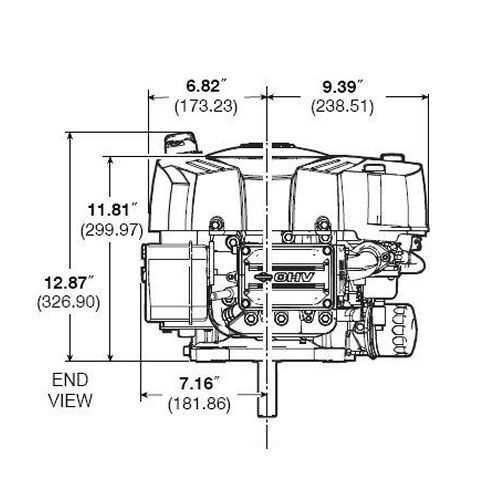

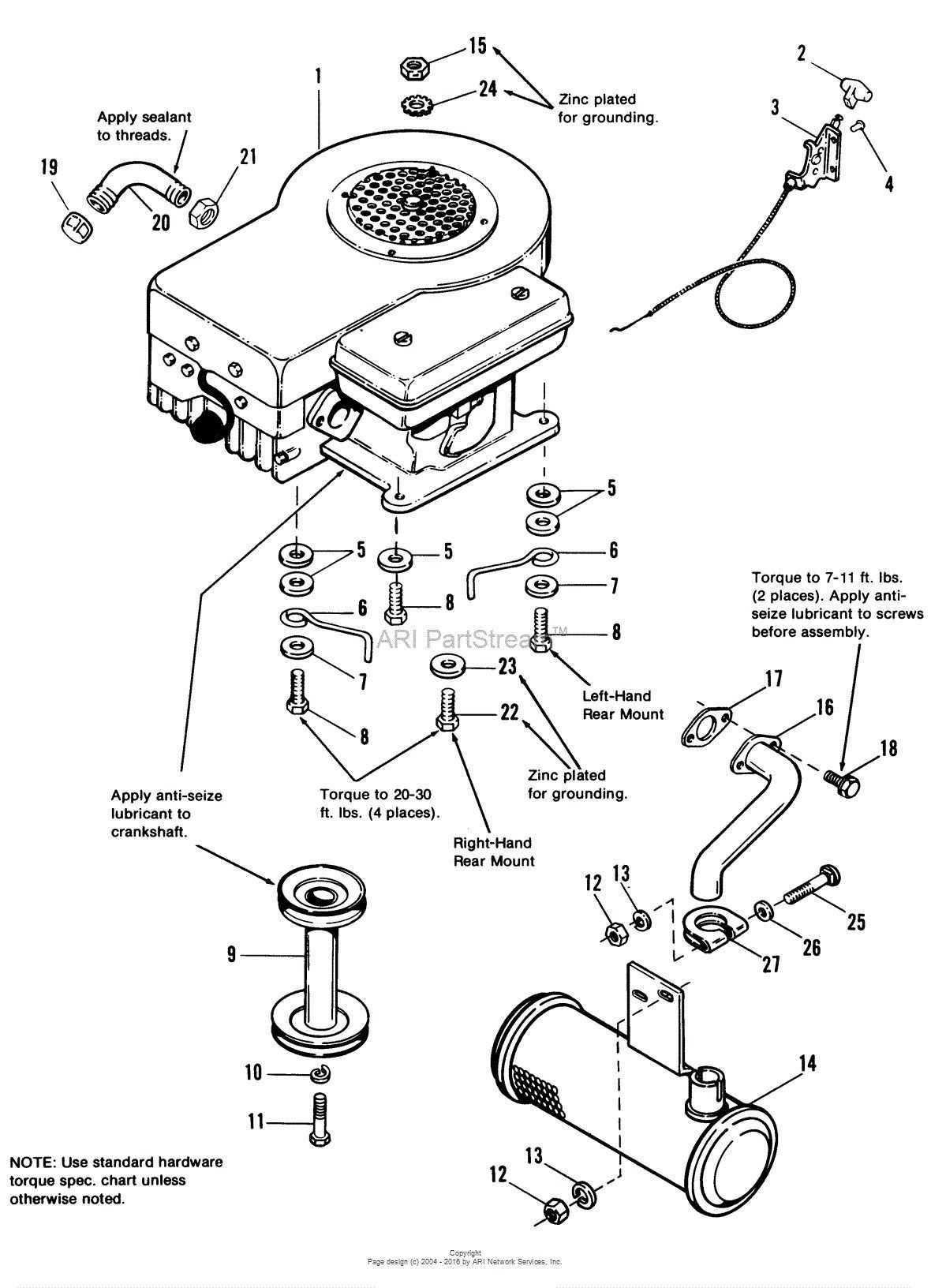

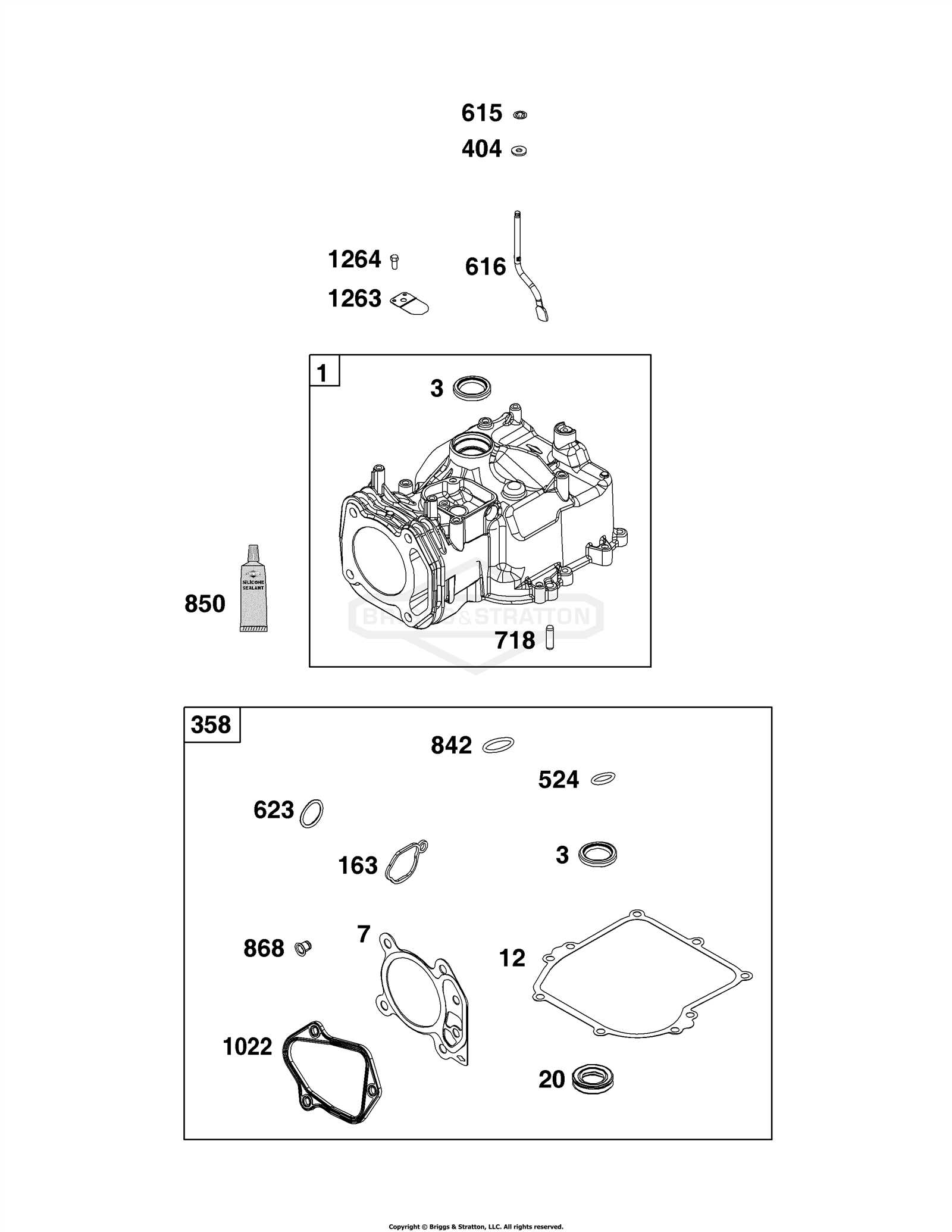

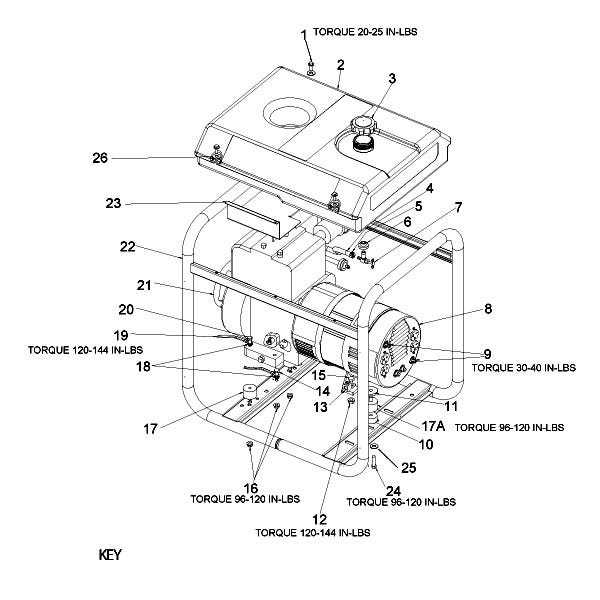

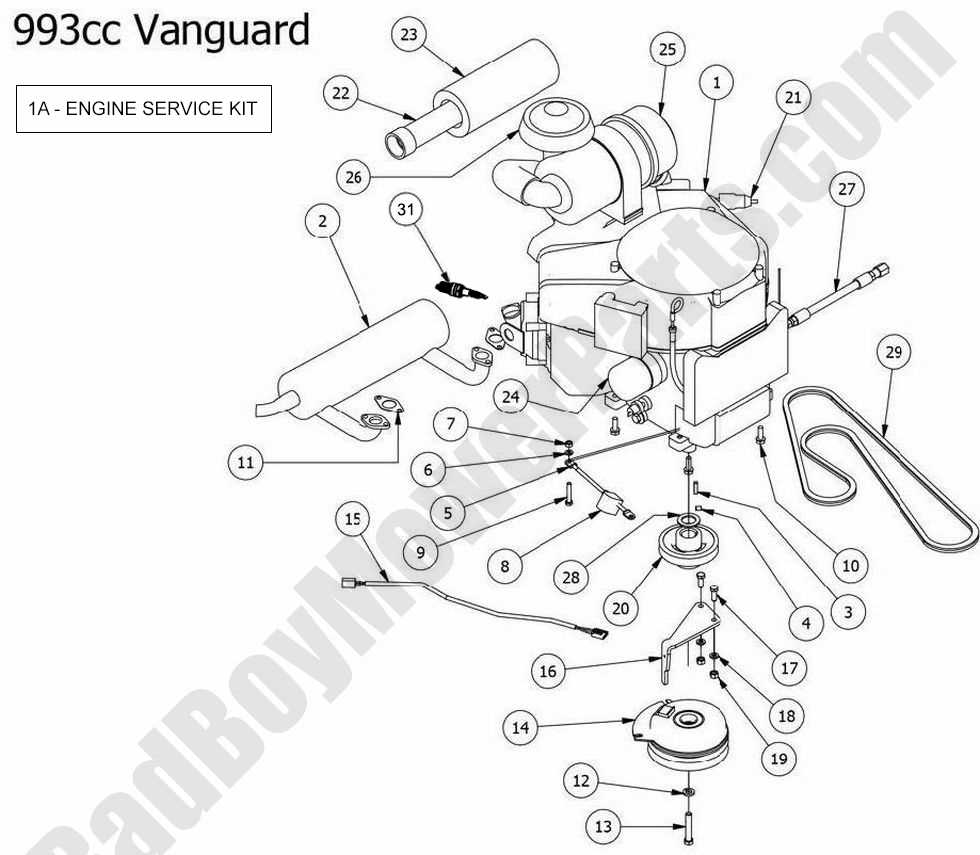

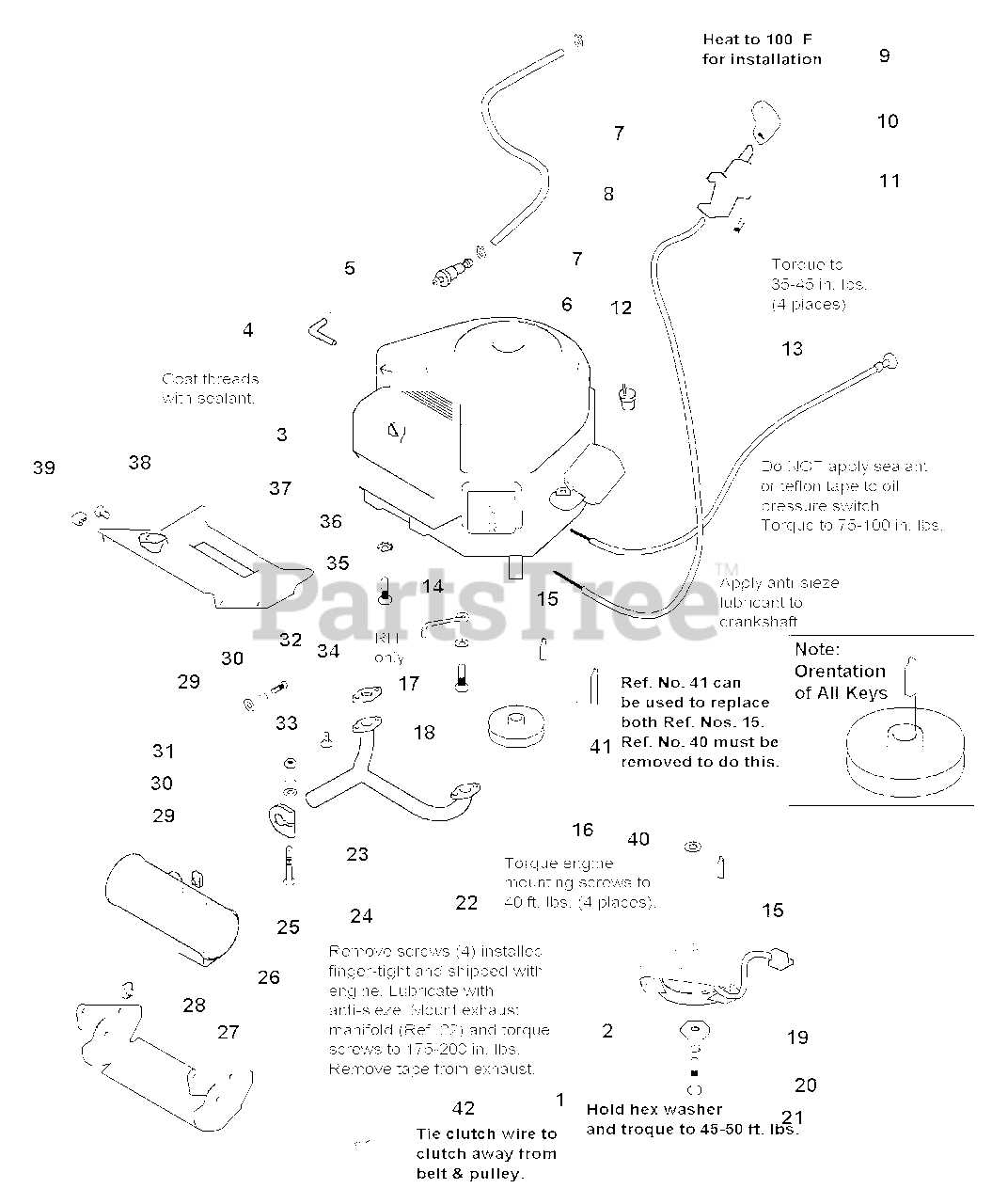

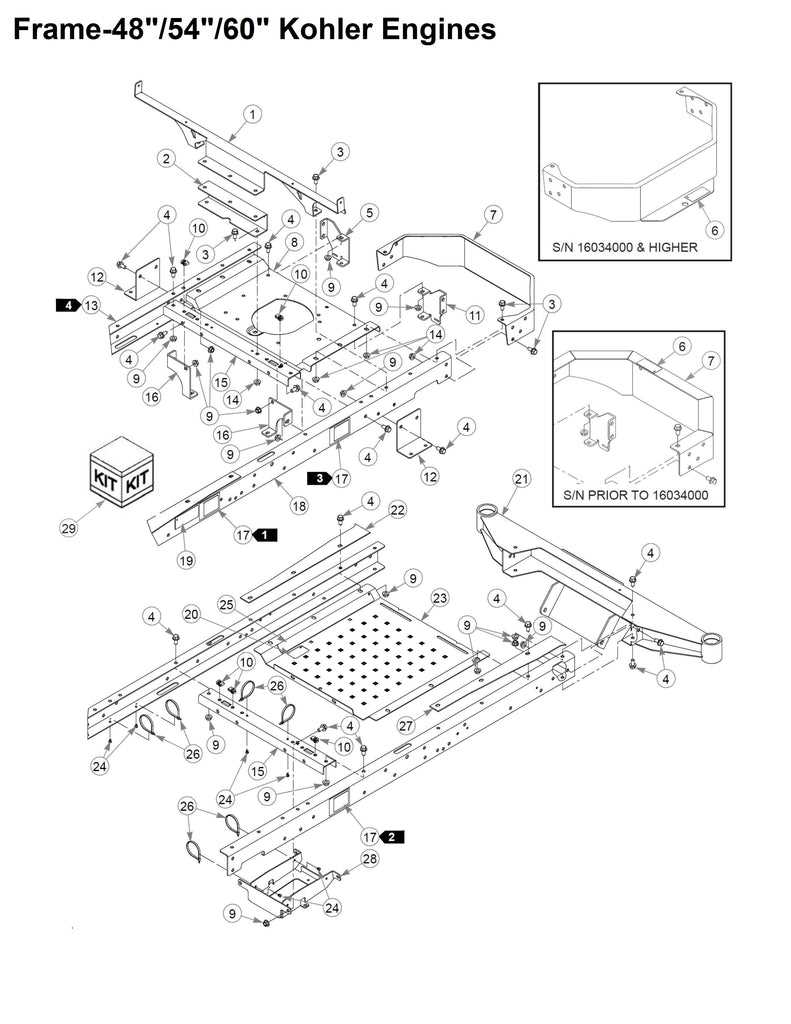

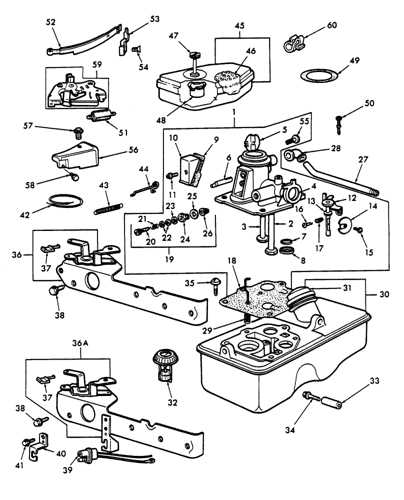

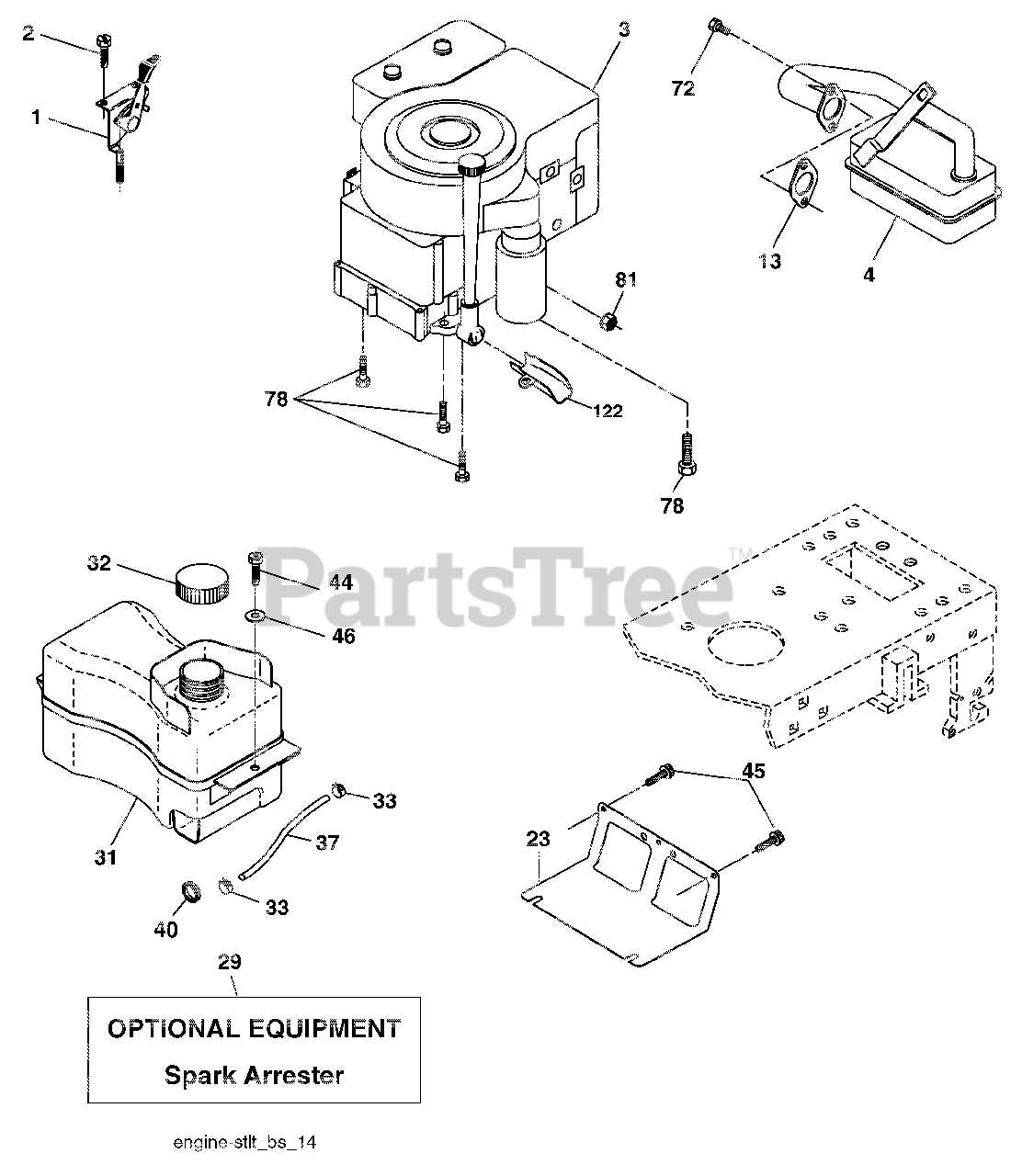

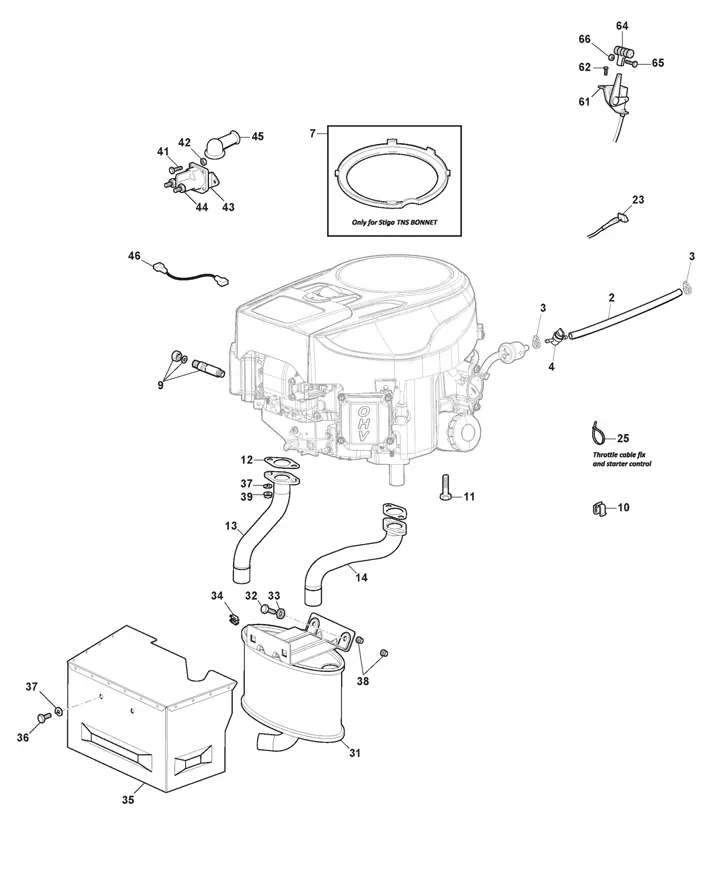

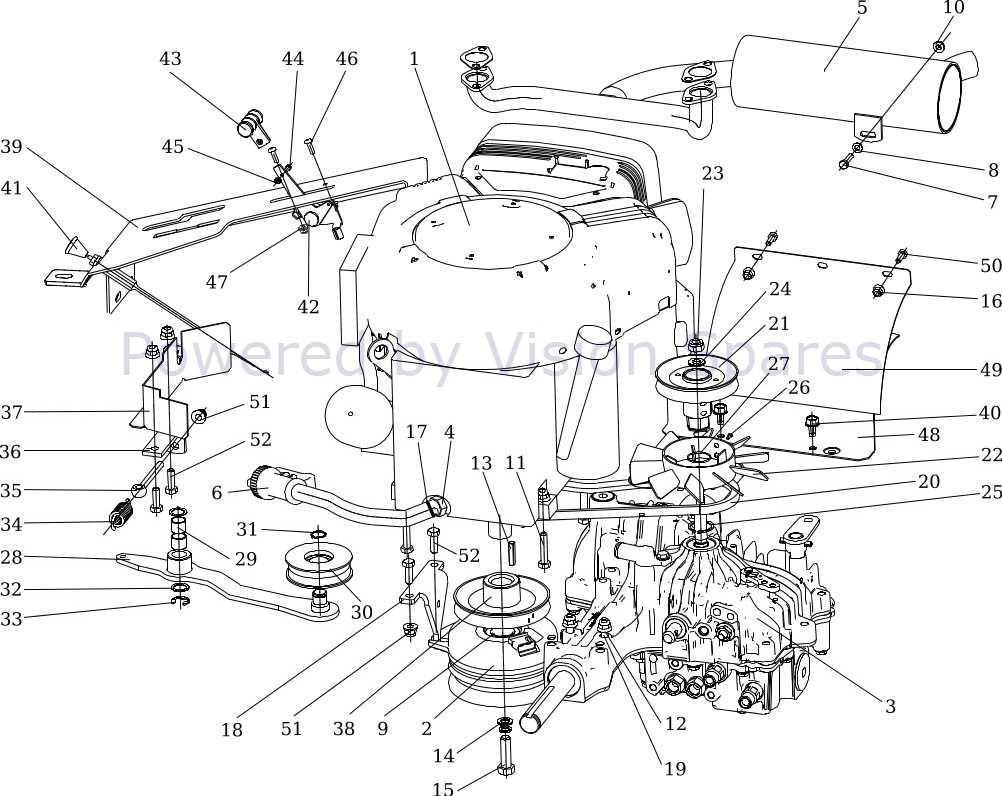

This section delves into the intricate layout of the various components, offering a visual representation that aids in identifying each piece’s function and location. Such diagrams serve as invaluable resources for technicians and enthusiasts alike, simplifying the troubleshooting process and facilitating repairs.

Whether you are a seasoned mechanic or a novice user, having access to a detailed schematic can greatly improve your understanding. By breaking down the assembly into manageable sections, you can tackle any maintenance task with confidence, ensuring that your equipment remains in peak condition for years to come.

Understanding the Briggs and Stratton Engine

The intricacies of small power units play a crucial role in the functionality of various outdoor machinery. These compact power sources are engineered for durability and efficiency, making them essential for lawn care, gardening, and various industrial applications. Gaining insights into their structure and operation can significantly enhance maintenance practices and overall performance.

Key Components: At the heart of these machines are several vital elements that work in harmony to produce energy. Each component, from the combustion chamber to the fuel delivery system, contributes to the effective conversion of fuel into mechanical work. Familiarity with these parts allows for better troubleshooting and repairs, ensuring longevity and reliability.

Maintenance Tips: Regular upkeep is essential for optimal functioning. Checking oil levels, inspecting filters, and cleaning spark plugs are simple yet effective ways to maintain peak performance. Understanding how each part interacts can also aid in identifying potential issues before they become significant problems.

Key Features of 17.5 HP Engine

This power unit stands out in its category due to several remarkable attributes that enhance performance and reliability. Users benefit from its robust design, ensuring durability and efficiency during operation.

Power Output: With substantial horsepower, this model provides the necessary strength for a variety of applications, from lawn care to heavier machinery tasks. The ability to handle demanding conditions makes it a preferred choice for many.

Fuel Efficiency: This unit is engineered to optimize fuel consumption, allowing for longer operation times without frequent refueling. This feature not only saves costs but also reduces environmental impact.

Ease of Maintenance: Designed for user convenience, this machinery includes accessible components for routine checks and servicing. Minimal downtime ensures that work can continue without unnecessary interruptions.

Compact Design: Its space-saving configuration allows for easy integration into various setups, making it suitable for both residential and commercial use. This versatility expands its applicability across different fields.

Advanced Cooling System: The innovative cooling mechanism helps maintain optimal operating temperatures, preventing overheating and extending the lifespan of the unit. This reliability is crucial for prolonged use in diverse conditions.

Robust Build Quality: Constructed with high-quality materials, this model offers resilience against wear and tear, ensuring that it can withstand tough environments while delivering consistent performance.

Parts Diagram Overview

This section provides a comprehensive look into the various components that make up a specific power unit. Understanding the arrangement and function of these elements is essential for maintenance, troubleshooting, and upgrades. A clear visualization assists users in identifying each part’s role, promoting efficient operation and longevity.

Key Components

Among the crucial elements are the combustion chamber, fuel delivery system, and cooling apparatus. Each of these parts works in harmony to ensure optimal performance. Familiarity with their layout enables quick identification of potential issues.

Benefits of Visualization

Utilizing a schematic representation enhances comprehension of how each component interacts. This knowledge not only aids in repairs but also assists in making informed decisions regarding replacements or enhancements. Proper maintenance can significantly extend the lifespan of the machinery.

Importance of Regular Maintenance

Consistent upkeep is essential for ensuring the longevity and efficiency of any mechanical device. By adhering to a scheduled maintenance plan, owners can prevent minor issues from escalating into significant problems, ultimately saving time and money.

Regular check-ups help identify wear and tear before it affects performance. Components that receive routine attention are less likely to fail unexpectedly, allowing users to maintain optimal functionality.

Additionally, preventive care enhances safety by reducing the risk of accidents caused by malfunctioning equipment. Operators can enjoy peace of mind, knowing that their machinery is operating reliably.

Moreover, proper maintenance can lead to improved fuel efficiency and lower emissions. This not only benefits the environment but also translates into cost savings for the user.

In conclusion, prioritizing regular maintenance is a wise investment that promotes the effective operation and durability of mechanical systems, ensuring they perform at their best for years to come.

Common Replacement Parts Explained

When maintaining outdoor machinery, understanding essential components is crucial for efficient operation. Various elements may wear out over time, necessitating replacement to ensure optimal performance. Here, we will explore frequently substituted components that play significant roles in functionality.

| Component | Description | Importance |

|---|---|---|

| Cylinder Head | The upper part of the block that houses the combustion chamber. | Vital for sealing the combustion chamber and maintaining compression. |

| Fuel Filter | Removes contaminants from fuel before it enters the combustion chamber. | Essential for ensuring clean fuel supply, preventing damage. |

| Spark Plug | Ignites the air-fuel mixture within the combustion chamber. | Crucial for starting and maintaining engine efficiency. |

| Oil Filter | Traps impurities in the oil to keep it clean. | Helps prolong the life of internal components by maintaining oil quality. |

| Air Filter | Prevents dirt and debris from entering the intake system. | Important for maintaining optimal air flow and engine performance. |

Regularly monitoring these components can greatly enhance the longevity and reliability of your machinery. Knowing when to replace them is key to effective upkeep and performance maintenance.

How to Read Engine Diagrams

Understanding technical illustrations is crucial for effective maintenance and repair. These visuals provide a detailed overview of components and their relationships, enabling users to troubleshoot and assemble machinery with confidence. Mastering the art of interpreting these graphics can save time and prevent costly mistakes.

When approaching a technical illustration, consider the following elements:

| Element | Description |

|---|---|

| Legend | Contains symbols or abbreviations that represent different components or functions within the system. |

| Labels | Identify specific parts, often accompanied by numbers for easy reference. |

| Lines and Arrows | Indicate connections, flows, or directions of movement, helping to visualize the operation. |

| Views | Different perspectives, such as top-down or side views, provide a comprehensive understanding of the layout. |

To enhance comprehension, take notes and cross-reference with accompanying manuals or guides. Familiarity with common terminology used in technical illustrations can also aid in decoding complex visuals. With practice, reading these graphics will become an invaluable skill in maintenance and repair tasks.

Troubleshooting Engine Issues

Identifying and resolving problems with small machinery can be crucial for maintaining performance and longevity. By systematically analyzing symptoms, users can often find straightforward solutions. Here are some common concerns and steps to address them.

- Starting Difficulties

- Check the fuel level and ensure it’s fresh.

- Inspect the spark plug for wear or damage.

- Examine the battery connections for corrosion.

- Unusual Noises

- Listen for any rattling or knocking sounds that may indicate loose components.

- Ensure all fasteners are tightened and secure.

- Look for signs of wear in belts and bearings.

- Poor Performance

- Clean or replace the air filter to ensure proper airflow.

- Inspect fuel lines for clogs or leaks.

- Adjust the carburetor settings if necessary.

- Overheating

- Check coolant levels if applicable.

- Examine the cooling fins for debris.

- Ensure the oil is at the correct level and in good condition.

By following these guidelines, operators can often diagnose issues effectively, leading to timely repairs and enhanced reliability of their equipment.

Recommended Tools for Repairs

When undertaking maintenance or fixing machinery, having the right tools is essential for a successful outcome. Using appropriate equipment not only ensures efficiency but also enhances safety during the repair process. Below are some recommended tools that will facilitate your tasks effectively.

Essential Hand Tools

| Tool | Description |

|---|---|

| Socket Set | Ideal for loosening or tightening bolts and nuts with precision. |

| Wrenches | Necessary for various sizes of fasteners, providing versatility in repairs. |

| Screwdriver Set | Used for securing or removing screws in different configurations. |

Power Tools for Efficiency

| Tool | Description |

|---|---|

| Drill | Essential for creating holes or driving screws quickly. |

| Impact Wrench | Provides high torque for loosening stubborn fasteners. |

| Angle Grinder | Useful for cutting, grinding, and polishing materials. |

Finding Genuine Replacement Parts

Locating authentic components for machinery is crucial for maintaining performance and longevity. When seeking out replacements, ensuring quality and compatibility is essential to avoid future issues. The right choice can significantly enhance operational efficiency and reduce the risk of unexpected breakdowns.

Understanding the Importance

Using original materials helps to guarantee that all pieces fit together seamlessly. Imitation products may seem appealing due to their lower cost, but they often lack durability and reliability, potentially leading to costly repairs down the line. Therefore, investing in genuine components is a wise decision.

Where to Look

Authorized dealers and official websites are the best sources for high-quality replacements. These platforms often provide detailed information about each item, ensuring you find exactly what you need. Additionally, consulting the user manual can offer insights into specific requirements and compatibility, further simplifying the search process.

Checking for Quality

When selecting new components, examine them for marks of authenticity, such as logos or certification. Reviews and recommendations from other users can also serve as valuable resources, helping to ensure that you choose a reputable supplier. Taking these steps can significantly reduce the risk of encountering subpar replacements.

Step-by-Step Repair Process

This section outlines a detailed approach for addressing issues with small power units. Following a systematic procedure ensures effective troubleshooting and restoration of functionality.

-

Gather Tools and Materials

- Wrenches and sockets

- Screwdrivers

- Replacement components

- Cleaning supplies

-

Prepare the Workspace

- Choose a well-ventilated area

- Organize tools for easy access

- Ensure safety gear is available

-

Disconnect Power Source

- Remove the spark plug wire

- Ensure no fuel is present in the system

-

Inspect Components

- Check for visible damage

- Assess wear and tear on critical parts

-

Replace Faulty Parts

- Remove defective elements carefully

- Install new components following the manufacturer’s guidelines

-

Clean the System

- Remove debris and buildup

- Use appropriate cleaners for various surfaces

-

Reconnect Power Source

- Reattach the spark plug wire

- Ensure all connections are secure

-

Conduct a Test Run

- Start the unit in a controlled environment

- Monitor for unusual sounds or vibrations

-

Finalize Maintenance

- Perform any additional checks as needed

- Document repairs and maintenance for future reference

Upgrading Your Engine Performance

Enhancing the output and efficiency of your power unit involves several strategic modifications and adjustments. By focusing on key components and incorporating advanced technologies, you can achieve significant improvements in both speed and fuel consumption. This section explores effective methods to elevate the overall capability of your machinery.

Key Modifications

One of the most impactful upgrades includes improving the airflow through the intake system. Installing a high-performance air filter allows for better filtration and increased air supply, leading to enhanced combustion. Additionally, adjusting the exhaust system can further optimize airflow, allowing your unit to expel gases more efficiently and increasing horsepower.

Tuning and Maintenance

Regular tuning and maintenance are crucial for sustaining performance. Consider recalibrating the ignition timing for a more efficient combustion cycle. Regular oil changes with high-quality lubricants will reduce friction and wear, contributing to a longer lifespan. Lastly, using premium fuel can also result in better performance and reduced emissions, making your setup more eco-friendly.