Comprehensive Guide to Honda Motorcycle Parts Diagrams

Every enthusiast knows that grasping the intricate makeup of their two-wheeled companion is essential for maintaining optimal performance. Delving into the various elements that comprise these machines not only enhances the riding experience but also empowers owners to tackle repairs and modifications with confidence. With a comprehensive understanding of each section, one can appreciate the engineering marvels that contribute to the overall functionality and aesthetics.

Exploring the layout of a two-wheeled vehicle can illuminate the relationships between different components, offering insights into how they work in harmony. Whether it’s the heart of the engine, the sturdy frame, or the responsive braking system, knowing the location and function of each piece is crucial. This knowledge allows for better troubleshooting and can lead to more informed decisions during upgrades or routine maintenance.

Utilizing detailed visual representations can significantly aid in this understanding. These illustrations serve as invaluable references, guiding users through the complex arrangement of elements while highlighting their respective roles. As riders gain familiarity with these schematics, they develop a deeper connection to their machines, paving the way for a more rewarding and engaging riding experience.

Understanding Honda Motorcycle Parts Diagrams

Gaining insight into the various components of two-wheeled vehicles is essential for both enthusiasts and professionals. These visual representations serve as a valuable tool, illustrating the intricate relationships between different elements. By familiarizing oneself with these illustrations, one can enhance their knowledge of maintenance and repairs, ultimately leading to a better understanding of the overall mechanics involved.

Benefits of Familiarity

Recognizing the layout and function of each element allows for efficient troubleshooting and repair processes. This proficiency can save both time and resources, as it empowers individuals to identify issues quickly. Moreover, it facilitates communication with technicians and parts suppliers, ensuring that the correct replacements are acquired without unnecessary delays.

Navigating the Visual Representations

Each section of the illustration typically corresponds to a specific area of the vehicle, categorized logically. Key components are often highlighted, making it easier to locate them during inspections or repairs. Understanding the terminology used in these representations can further enhance comprehension, enabling users to engage more effectively with service manuals and guides.

Importance of Accurate Parts Identification

Ensuring the correct identification of components is crucial for the efficient operation and longevity of any vehicle. When each element is accurately recognized, it enhances the maintenance process, reduces the likelihood of errors, and promotes optimal performance. A clear understanding of individual elements allows for informed decisions regarding repairs and replacements, ultimately safeguarding the overall functionality.

Inaccuracies in identifying elements can lead to significant issues, including improper installations and increased wear and tear. These mistakes not only compromise the vehicle’s performance but can also lead to safety hazards for the rider. Thus, a meticulous approach to component recognition is essential for maintaining reliability and safety on the road.

| Consequences of Misidentification | Benefits of Accurate Recognition |

|---|---|

| Increased repair costs | Cost-effective maintenance |

| Potential safety risks | Enhanced safety for users |

| Frequent breakdowns | Improved performance and reliability |

| Time-consuming repairs | Streamlined service processes |

Ultimately, precise identification fosters a deeper understanding of the intricate systems involved, leading to more informed choices and a smoother riding experience. Prioritizing accuracy is not just a best practice; it’s a necessity for every enthusiast and professional alike.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. These illustrations serve as a roadmap, detailing how various elements fit together and function within a larger system. Familiarity with these visuals enables users to identify necessary pieces, facilitating informed decisions during service or upgrades.

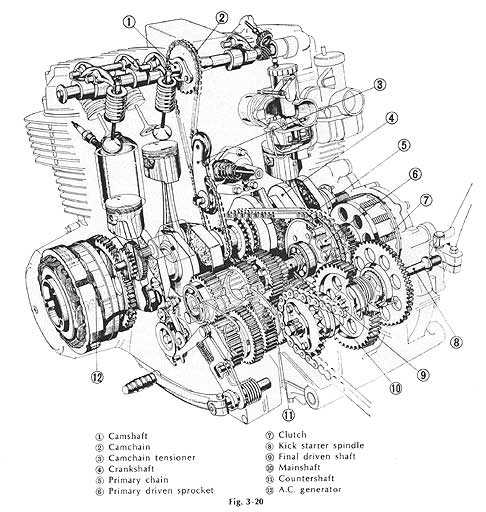

Identifying Components

Each item in the illustration is typically labeled with a unique reference number. Cross-referencing these numbers with a list or catalog provides specific information about each element, including its name, specifications, and availability. This step is crucial for ensuring that the correct components are sourced for any repair or replacement tasks.

Understanding Connections

Lines and arrows often indicate how different pieces interact or connect with each other. Recognizing these relationships is vital for grasping the assembly or disassembly process. A thorough comprehension of these connections can prevent errors during reassembly, ensuring optimal functionality once the work is completed.

Common Components in Honda Motorcycles

This section explores essential elements found in a well-engineered two-wheeled vehicle, highlighting their significance and functionality. Understanding these crucial components can enhance maintenance, performance, and overall riding experience.

| Component | Description | Function |

|---|---|---|

| Engine | The power unit that converts fuel into mechanical energy. | Provides propulsion and overall performance. |

| Transmission | System that transfers power from the engine to the wheels. | Enables gear shifting for different speeds. |

| Suspension | Assembly that supports the vehicle and absorbs shocks. | Enhances stability and comfort during rides. |

| Brakes | Devices used to slow down or stop the vehicle. | Ensures rider safety through effective deceleration. |

| Wheels | Circular components that support the vehicle and facilitate movement. | Provides traction and stability on various terrains. |

| Frame | The structural foundation that holds all components together. | Offers strength and rigidity to withstand forces during operation. |

Finding OEM vs. Aftermarket Parts

When it comes to maintaining and enhancing your two-wheeled vehicle, understanding the differences between original equipment and alternative components is crucial. Each option presents its own set of benefits and considerations that can impact both performance and cost.

Original equipment manufacturer (OEM) components are designed specifically to fit your vehicle as intended by the maker. They typically offer:

- Guaranteed compatibility with your model

- High-quality standards

- Manufacturer’s warranty for peace of mind

On the other hand, aftermarket alternatives may provide cost-effective solutions, often appealing to those looking to save money or customize their ride. Benefits include:

- Wider variety of options and styles

- Potential for lower prices

- Possibility of enhanced performance features

Ultimately, the choice between these two types of components depends on individual preferences, budget, and intended use. Consider your specific needs and do thorough research to make the best decision for your vehicle’s upkeep.

Tips for Using Parts Diagrams Effectively

Utilizing visual representations of components can significantly enhance your understanding and efficiency when working on your vehicle. These illustrations not only provide clarity but also help you identify the specific elements you need for maintenance or repair tasks.

Understanding the Layout

Before diving into the illustrations, take a moment to familiarize yourself with their structure. Each section typically groups related items, making it easier to locate what you need. Pay attention to labels and notes that may indicate compatibility or specific variations.

Organizing Your Workflow

When planning your project, organize your approach by referencing these visuals. Create a checklist based on the components illustrated, ensuring you gather everything before starting. This preparation can save time and prevent disruptions during the repair process.

| Tip | Description |

|---|---|

| Familiarize with Symbols | Learn the common symbols used to denote various elements for quicker navigation. |

| Group Related Items | Identify clusters of components to streamline your tasks. |

| Check Compatibility | Always verify that the parts you intend to use match the specifications shown. |

Where to Access Honda Parts Diagrams

Finding detailed illustrations of components for your vehicle is essential for effective maintenance and repairs. Numerous resources are available to help you navigate the intricate world of spare parts and their configurations.

- Official Manufacturer Websites: Most manufacturers provide access to comprehensive resources, including technical documentation and visual guides.

- Authorized Dealers: Local dealerships often have the latest resources and can assist with specific queries regarding component layouts.

- Online Forums: Enthusiast communities frequently share valuable insights, including links to detailed layouts and user-generated content.

- Aftermarket Websites: Numerous online retailers offer extensive libraries of illustrations and specifications, allowing for easier identification of components.

- Service Manuals: Printed or digital service manuals typically contain detailed images and information about individual parts, along with instructions for repairs.

Utilizing these resources can greatly enhance your understanding and ability to locate the necessary elements for your vehicle, ensuring you have the right information at your fingertips.

Benefits of Visual Reference in Repairs

Utilizing visual aids during maintenance tasks offers significant advantages, enhancing the efficiency and accuracy of the repair process. When complex systems are represented visually, it becomes easier to understand the relationships between components, leading to more effective troubleshooting and assembly.

One major benefit is the reduction of errors. Visual references provide clear indications of where each element fits within the structure, minimizing the chances of misplacing or overlooking essential parts. This clarity helps technicians avoid costly mistakes and ensures that repairs are conducted with greater precision.

Moreover, visual materials can streamline the workflow. Technicians can quickly identify the necessary components and their arrangements, saving valuable time during repairs. This efficiency not only speeds up the process but also improves overall productivity, allowing for a quicker turnaround on tasks.

Additionally, visual references can serve as excellent educational tools. They facilitate the learning process for new technicians, helping them grasp intricate systems more rapidly. By observing how parts interact visually, learners can develop a deeper understanding of mechanical principles, enhancing their skills for future endeavors.

In conclusion, employing visual references in repair work is a powerful strategy that boosts accuracy, efficiency, and educational value. As the complexity of machinery continues to grow, these aids become increasingly essential for effective maintenance practices.

Identifying Specific Models and Years

Understanding the nuances of different models and their respective production years is essential for accurate maintenance and repairs. Each variant may have unique components and specifications, making it crucial to pinpoint the exact version when seeking information or replacement elements.

First and foremost, it’s important to locate the vehicle identification number (VIN) or other identification markers. This information often reveals vital details about the specific iteration, including its manufacturing year and design features. For instance, certain models might have undergone significant upgrades or modifications over the years, influencing both performance and compatibility with various components.

Additionally, consulting user manuals or manufacturer resources can provide clarity on the distinctions between various iterations. These documents typically outline changes made over the years, enabling enthusiasts and technicians to easily discern which elements are suited for their particular model. Engaging with online communities or forums can also offer insights and shared experiences, enhancing the understanding of specific variants.

Common Mistakes When Using Diagrams

Utilizing visual representations can significantly enhance understanding and efficiency in maintenance tasks. However, certain pitfalls may hinder their effectiveness. Recognizing these errors is essential for maximizing the benefits of these resources.

One frequent mistake is misinterpreting the symbols and notations used in the illustrations. Every visual guide has its own set of conventions, and failing to grasp these can lead to confusion and incorrect assembly.

Another common error involves neglecting to cross-reference information. Relying solely on one source can result in oversight of critical details that may be outlined elsewhere.

Additionally, overlooking the order of operations can create complications. It’s vital to follow the prescribed sequence, as this often ensures that each step logically leads to the next, preventing unnecessary frustration.

Finally, a lack of attention to scale and sizing can lead to improper fitment. Understanding the dimensions and proportions illustrated is crucial for achieving a successful outcome in any repair or assembly task.

Utilizing Diagrams for Custom Modifications

Understanding schematics can significantly enhance your ability to personalize your ride. These visual representations serve as a roadmap, allowing enthusiasts to identify components, assess functionality, and plan modifications with precision.

When embarking on customization, consider the following advantages of using these illustrations:

- Clear Visualization: Detailed images help you understand how various elements interact within the system.

- Component Identification: Easily locate specific parts, making it simpler to source alternatives or upgrades.

- Planning Modifications: Use the layouts to strategize changes without risking damage to existing structures.

To maximize the effectiveness of these schematics, follow these steps:

- Study the Layout: Familiarize yourself with the overall configuration before diving into specific modifications.

- Highlight Key Areas: Mark sections that require attention or would benefit from enhancement.

- Document Changes: Keep a record of all modifications made for future reference and troubleshooting.

By leveraging these visual tools, you can transform your vehicle into a reflection of your style and preferences while ensuring optimal performance and reliability.

Maintaining Your Honda Motorcycle Efficiently

Ensuring optimal performance and longevity of your two-wheeled vehicle involves regular upkeep and attention to detail. A systematic approach to maintenance can prevent issues and enhance the overall riding experience. Understanding essential components and routine checks is key to achieving reliable operation.

Routine Checks

Establishing a maintenance schedule is crucial. Regular inspections can help identify potential problems before they escalate. Here are some critical aspects to consider:

| Task | Frequency | Details |

|---|---|---|

| Oil Change | Every 3,000 miles | Replace with recommended oil type. |

| Tire Inspection | Monthly | Check for wear and proper inflation. |

| Brake Fluid Check | Every 6 months | Ensure fluid is at the correct level. |

| Chain Lubrication | Every 500 miles | Apply lubricant to ensure smooth operation. |

Storage and Seasonal Care

Proper storage techniques can significantly impact the lifespan of your vehicle. During off-seasons, consider the following practices:

- Clean and wax the exterior to protect against corrosion.

- Use a battery maintainer to prevent discharge.

- Store in a dry, temperature-controlled environment.

Resources for Further Research and Help

Accessing reliable information and assistance can significantly enhance your understanding of mechanical components and their assembly. Whether you’re looking to troubleshoot an issue or simply seeking to expand your knowledge, a variety of resources are available to guide you on your journey.

Online Forums and Communities: Engaging with fellow enthusiasts in digital forums can provide valuable insights. These platforms often host discussions where you can ask questions, share experiences, and learn from others who have faced similar challenges.

Official Manufacturer Websites: Many manufacturers offer comprehensive resources, including manuals and technical specifications, directly on their websites. These documents can be essential for accurate information regarding specific components and maintenance procedures.

Video Tutorials: Visual learners may find video content particularly helpful. Numerous channels dedicated to mechanical repairs showcase step-by-step guides that can clarify complex processes and provide tips from experienced technicians.

Local Workshops and Mechanics: Consulting with professionals in your area can also be beneficial. Many workshops offer advice or can assist with repairs, providing hands-on experience and expertise that can deepen your understanding.

Books and Guides: A variety of literature exists on the subject, ranging from comprehensive manuals to specific repair guides. These texts can serve as invaluable references, offering detailed explanations and illustrations for those who prefer traditional learning methods.