Comprehensive Guide to Mercedes W204 Engine Parts Diagram

When delving into the intricacies of a vehicle’s internal mechanisms, one uncovers a complex network of interconnected elements that work in harmony to ensure optimal performance. This section aims to provide insight into the vital constituents that contribute to the overall functionality of modern automobiles.

Visualization plays a crucial role in comprehending how these elements interact. A detailed illustration can illuminate the relationships between various assemblies, enhancing one’s understanding of their respective roles and importance. By examining these visual aids, enthusiasts and technicians alike can gain clarity on the intricacies involved in automotive design.

Furthermore, a thorough exploration of these components enables individuals to identify potential issues and implement effective solutions. This knowledge not only aids in maintenance and repairs but also fosters a deeper appreciation for the engineering prowess behind contemporary vehicles.

Overview of Mercedes W204 Engine

This section provides a comprehensive insight into the internal combustion system of a specific luxury automobile model. Understanding the key components and their functions is essential for both enthusiasts and professionals alike.

Key Components

- Cylinders

- Pistons

- Crankshaft

- Camshaft

- Fuel Injectors

- Intake and Exhaust Valves

Functions and Features

- Combustion Process: The process involves air and fuel mixing to produce energy.

- Power Generation: The rotation of the crankshaft converts linear motion into rotational energy.

- Efficiency: Advanced technology ensures optimal fuel consumption and reduced emissions.

- Performance: Design elements enhance responsiveness and overall driving experience.

Understanding these elements provides a foundation for maintaining and enhancing vehicle performance.

Key Components of the Engine

The internal mechanism of a vehicle consists of several essential elements that work in harmony to ensure optimal performance. Understanding these vital components can provide insights into how the system operates and how to maintain it effectively.

| Component | Description |

|---|---|

| Cylinder Block | The main structure housing the cylinders, providing the foundation for various elements. |

| Pistons | Movable components that convert fuel combustion into mechanical energy. |

| Cylinder Head | Seals the top of the cylinders and contains intake and exhaust valves. |

| Crankshaft | Transforms the linear motion of pistons into rotational motion, powering the drivetrain. |

| Camshaft | Controls the timing of valve openings and closings for proper airflow management. |

| Timing Belt/Chain | Synchronizes the movements of the crankshaft and camshaft for accurate timing. |

| Oil Pump | Ensures proper lubrication of moving components, reducing friction and wear. |

| Fuel Injector | Delivers fuel into the combustion chamber at the right time and quantity for efficient combustion. |

Each of these components plays a crucial role in the overall functionality of the mechanism, contributing to performance, efficiency, and reliability.

Understanding Engine Diagrams

Visual representations of mechanical systems play a crucial role in comprehending how various components interact within a vehicle’s power unit. These illustrations serve as essential tools for both enthusiasts and professionals, enabling them to identify, troubleshoot, and maintain vital systems effectively.

Such representations typically include:

- Component names and locations

- Connections between different sections

- Flow paths of fluids and gases

- Operational sequences and functions

By analyzing these visuals, one can gain insights into the intricacies of the machinery and how each segment contributes to overall performance. Here are some benefits of utilizing these visuals:

- Enhanced understanding of functionality

- Improved diagnostic skills

- Efficient repair and maintenance processes

- Informed decision-making during upgrades

In summary, familiarity with these visual tools can empower individuals to navigate the complexities of mechanical systems with greater confidence and accuracy.

Common Issues with W204 Engines

Vehicles from this series have garnered attention for their performance and reliability, yet certain challenges can arise during their lifespan. Understanding these common problems can aid owners in early detection and maintenance, ensuring a smoother driving experience.

Frequent Problems

- Oil Leaks: Over time, seals and gaskets may wear out, leading to oil seepage. Regular inspections can help identify these issues before they escalate.

- Overheating: Cooling system malfunctions, such as a failing water pump or clogged radiator, can cause the temperature to rise. Monitoring coolant levels and temperature gauges is essential.

- Fuel Pump Failures: Inconsistent fuel delivery can lead to poor performance. Symptoms may include difficulty starting or engine stalling.

- Ignition Coil Issues: Faulty ignition components can result in misfires and decreased efficiency. Replacing worn coils can restore optimal function.

Preventive Measures

- Regular maintenance checks, including fluid levels and filter replacements.

- Timely replacement of worn parts, particularly in high-stress areas.

- Monitoring performance indicators, such as unusual noises or warning lights.

By staying vigilant and addressing these common challenges, owners can significantly enhance the longevity and reliability of their vehicles.

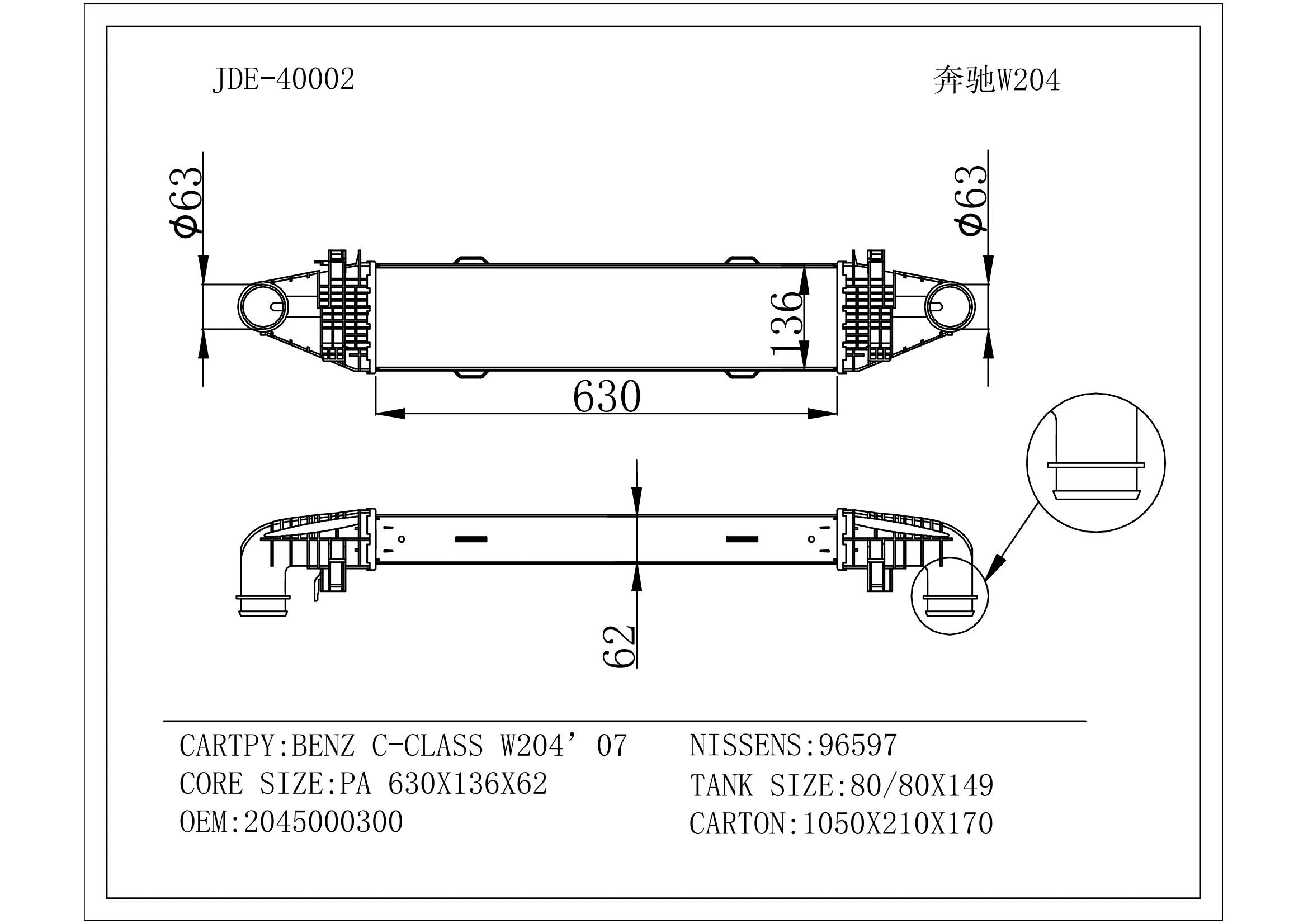

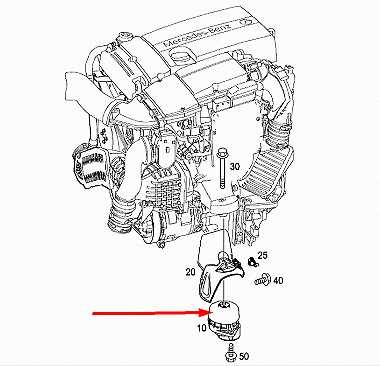

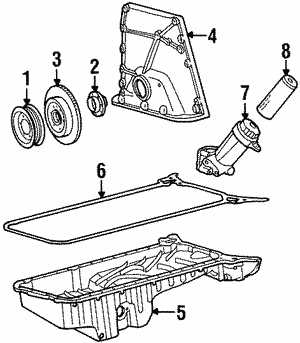

Parts Identification in Diagrams

Understanding the components within a visual representation is crucial for anyone involved in automotive maintenance and repair. Recognizing each element and its function can significantly enhance the efficiency of troubleshooting and assembly processes.

When examining a visual guide, it’s essential to focus on several key aspects:

- Labels: Clear annotations help identify each component swiftly.

- Color Coding: Different colors can indicate various functions or systems, simplifying the identification process.

- Numbering: Sequential numbers often correspond to a parts list, ensuring that you can reference specific items easily.

In addition to these features, familiarity with common shapes and configurations is beneficial:

- Geometric Shapes: Many elements have standard shapes that can indicate their purpose, such as circular filters or rectangular housing units.

- Orientation: The way components are positioned can provide insight into their function and how they interact with one another.

By paying attention to these details, individuals can more effectively navigate and utilize visual representations, leading to improved accuracy in repairs and maintenance tasks.

Role of the Engine Block

The fundamental component that serves as the backbone of any internal combustion mechanism plays a critical role in overall performance and efficiency. It acts as a structural framework that houses various crucial elements, providing stability and support while facilitating essential processes within the system.

Structural Integrity

One of the primary functions of this central element is to maintain structural integrity under varying operational conditions. It withstands high temperatures and pressures generated during combustion, ensuring that all connected components operate smoothly. The durability of the framework is essential for longevity and reliability, as it directly impacts the overall performance of the machine.

Cooling and Lubrication

In addition to structural support, the component is designed to promote efficient cooling and lubrication. It features passages that allow coolant to flow, helping to dissipate heat generated during operation. Similarly, oil channels ensure that moving parts are adequately lubricated, reducing friction and wear, thus enhancing efficiency and performance.

In conclusion, the importance of this foundational element cannot be overstated, as it not only provides structural support but also facilitates essential functions that contribute to the effective operation of the entire mechanism.

Importance of the Cylinder Head

The cylinder head plays a crucial role in the overall functionality of an internal combustion system. It serves as a vital component that influences performance, efficiency, and emissions. Understanding its significance can help in maintaining optimal operation and prolonging the lifespan of the assembly.

Key Functions

- Sealing the Combustion Chamber: The cylinder head forms a critical seal for the combustion space, ensuring maximum pressure and efficiency during the combustion process.

- Heat Dissipation: It facilitates the transfer of heat away from the combustion process, which is essential for preventing overheating and maintaining operational integrity.

- Air and Fuel Flow: The design allows for the effective intake of air and fuel, as well as the expulsion of exhaust gases, which is vital for optimal engine performance.

Maintenance Considerations

Regular inspection and maintenance of the cylinder head are essential to avoid costly repairs and ensure longevity. Key considerations include:

- Checking for cracks or warping due to high temperatures.

- Ensuring proper torque settings for bolts to prevent leaks.

- Monitoring gasket integrity to avoid fluid leaks.

By prioritizing the maintenance of this essential component, vehicle owners can enhance performance and ensure reliability for years to come.

Function of the Crankshaft

The crankshaft plays a crucial role in converting linear motion into rotational energy. This transformation is essential for the overall functionality of a mechanical system, as it connects various components to facilitate efficient power delivery. Understanding its operation reveals the intricacies of how energy is harnessed and utilized within a machine.

Mechanical Motion Conversion

The primary function of the crankshaft is to convert the reciprocating motion of pistons into rotational motion. This process involves the use of connecting rods that link the pistons to the crankshaft, allowing for a continuous and smooth rotation. The crankshaft is designed to withstand significant forces, making it a vital component for performance and reliability.

Balance and Stability

Another important aspect of the crankshaft’s design is its role in maintaining balance and stability within the system. An imbalanced crankshaft can lead to excessive vibrations, resulting in wear and tear on other components. Therefore, manufacturers meticulously engineer the crankshaft to ensure that it operates smoothly and efficiently, contributing to the overall longevity of the machinery.

| Function | Description |

|---|---|

| Motion Conversion | Transforms linear movement into rotational energy. |

| Force Distribution | Distributes forces evenly across the system. |

| Stability | Maintains balance to reduce vibrations and wear. |

Understanding the Camshaft System

The camshaft system plays a vital role in the overall performance of a vehicle’s internal mechanisms. It is responsible for regulating the timing and movement of various components, ensuring that the airflow into and out of the combustion chambers is optimized. This system is essential for efficient operation and power delivery, impacting both the vehicle’s responsiveness and fuel economy.

Within the camshaft assembly, the primary elements include the camshaft itself, which is a rotating shaft with strategically positioned lobes. These lobes control the opening and closing of valves, allowing for the precise timing necessary for effective combustion. The synchronization between the camshaft and the crankshaft is crucial, as it ensures that the movement of the valves aligns perfectly with the motion of the pistons.

Types of Camshaft Systems

There are various configurations of camshaft systems, including single overhead cam (SOHC) and dual overhead cam (DOHC) setups. SOHC designs feature one camshaft per cylinder bank, while DOHC arrangements include two camshafts, allowing for more precise control of the intake and exhaust valves. This difference in design can significantly affect performance characteristics and tuning potential.

Maintenance and Common Issues

Regular maintenance of the camshaft system is crucial to ensure longevity and optimal function. Common issues may arise from wear and tear, such as camshaft lobe degradation or valve timing discrepancies. Early detection and resolution of these problems can prevent more severe damage and costly repairs down the line.

In summary, a thorough understanding of the camshaft system is essential for any automotive enthusiast or professional. Its impact on performance, efficiency, and reliability cannot be overstated, making it a critical component of any advanced vehicular design.

Fuel Injection Mechanism Explained

The fuel injection system plays a crucial role in optimizing combustion within a vehicle’s power unit. By precisely delivering the right amount of fuel into the combustion chamber, it ensures efficient operation and performance. This technology has evolved significantly, enhancing power output and reducing emissions through better fuel atomization and timing.

Types of Fuel Injection Systems

There are various types of fuel delivery systems, each with its unique method of operation. The most common include port fuel injection and direct injection. Port fuel injection involves spraying fuel into the intake manifold, mixing it with air before entering the combustion chamber. In contrast, direct injection injects fuel directly into the combustion chamber under high pressure, allowing for more precise control and improved efficiency.

Benefits of Modern Fuel Injection

Modern fuel injection systems offer numerous advantages over older carburetor technologies. They provide better fuel economy, enhanced throttle response, and lower emissions. Additionally, advanced electronic controls allow for real-time adjustments based on various factors, ensuring optimal performance under different driving conditions. This adaptability contributes to smoother operation and a more enjoyable driving experience.

Cooling System Components

The efficiency of any vehicle relies significantly on its ability to regulate temperature. A well-designed cooling assembly is crucial for maintaining optimal operating conditions, preventing overheating, and ensuring the longevity of various mechanical systems. This section delves into the essential elements that make up a vehicle’s cooling apparatus.

Key Elements

- Radiator: The primary unit responsible for dissipating heat from the coolant as it circulates through the system.

- Water Pump: This component circulates coolant throughout the engine and radiator, maintaining flow and preventing hotspots.

- Thermostat: A temperature-regulating valve that opens and closes to control the coolant flow based on engine temperature.

- Coolant Reservoir: A storage tank for excess coolant, allowing for expansion and contraction as temperatures change.

- Hoses: Flexible tubes that transport coolant between various components, ensuring a continuous flow within the system.

Additional Components

- Fan: An auxiliary device that helps cool the radiator, especially when the vehicle is stationary or moving slowly.

- Heater Core: A mini radiator that uses hot coolant to warm the cabin during colder conditions.

- Temperature Sensors: Devices that monitor coolant temperature, providing feedback for engine management systems.

Understanding these components and their functions is vital for diagnosing potential issues and ensuring the reliability of the entire cooling system. Proper maintenance and timely replacements can lead to enhanced performance and reduced risk of overheating.

Electrical System Overview

The electrical framework of a vehicle plays a crucial role in its overall functionality, ensuring the seamless operation of various components. This intricate network is responsible for powering essential features, enhancing safety, and improving driving comfort through advanced technologies.

Moreover, modern automobiles incorporate sophisticated electronic control units (ECUs) that manage various functions, from engine performance to driver assistance features. These units rely on a complex interplay of sensors and actuators, enabling real-time adjustments and optimizations that enhance vehicle efficiency and safety.

Understanding the layout and functionality of the electrical system is essential for effective troubleshooting and maintenance. A well-maintained electrical framework not only ensures reliable operation but also extends the longevity of the vehicle’s components.

Maintenance Tips for W204 Engine Parts

Ensuring optimal performance of your vehicle requires regular care and attention to various components. By following specific maintenance practices, you can prolong the lifespan of essential mechanisms and enhance overall efficiency. Here are some valuable suggestions to keep your system running smoothly.

Regular Inspections

Conducting routine checks can help identify potential issues before they escalate. Focus on the following:

- Examine fluid levels and look for leaks.

- Inspect belts and hoses for wear and tear.

- Check the condition of filters and replace them as needed.

Scheduled Servicing

Adhering to a regular service schedule is crucial for maintaining high performance. Consider these steps:

- Change the oil and oil filter at recommended intervals.

- Replace spark plugs according to manufacturer guidelines.

- Ensure the cooling system is flushed and refilled as necessary.

By implementing these practices, you can enhance reliability and extend the life of your vehicle’s essential systems. Regular attention and care will result in a more enjoyable driving experience and fewer unexpected repairs.