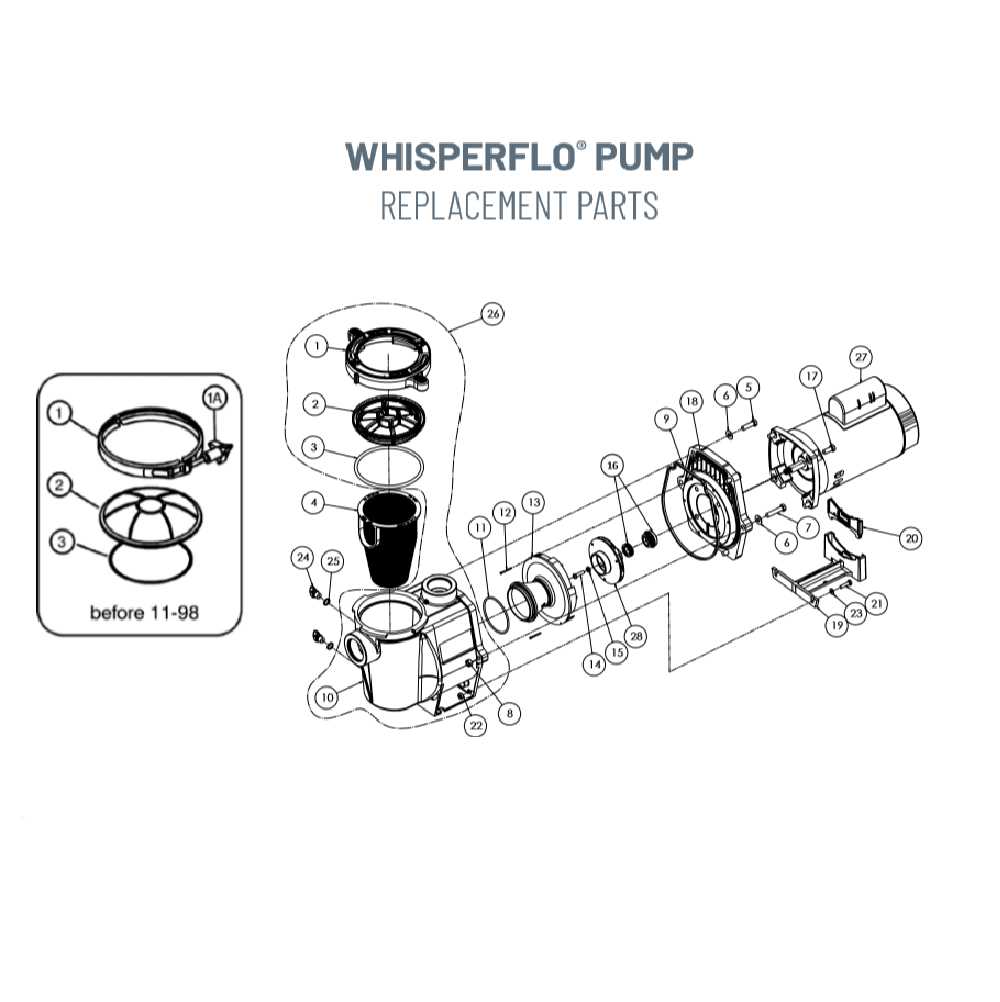

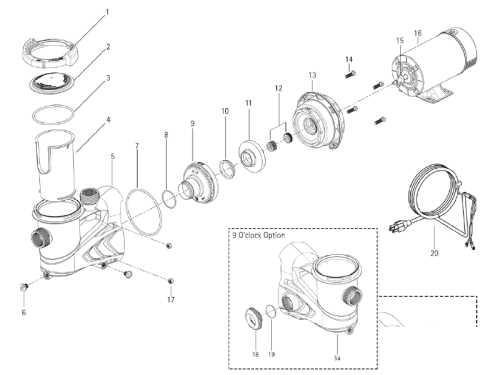

Pentair WhisperFlo Parts Diagram Explained

For anyone maintaining a swimming pool, a comprehensive understanding of the various elements that comprise the circulation system is essential. Knowing how each part interacts and contributes to overall functionality can significantly enhance performance and efficiency. This knowledge is particularly beneficial when troubleshooting issues or planning for upgrades.

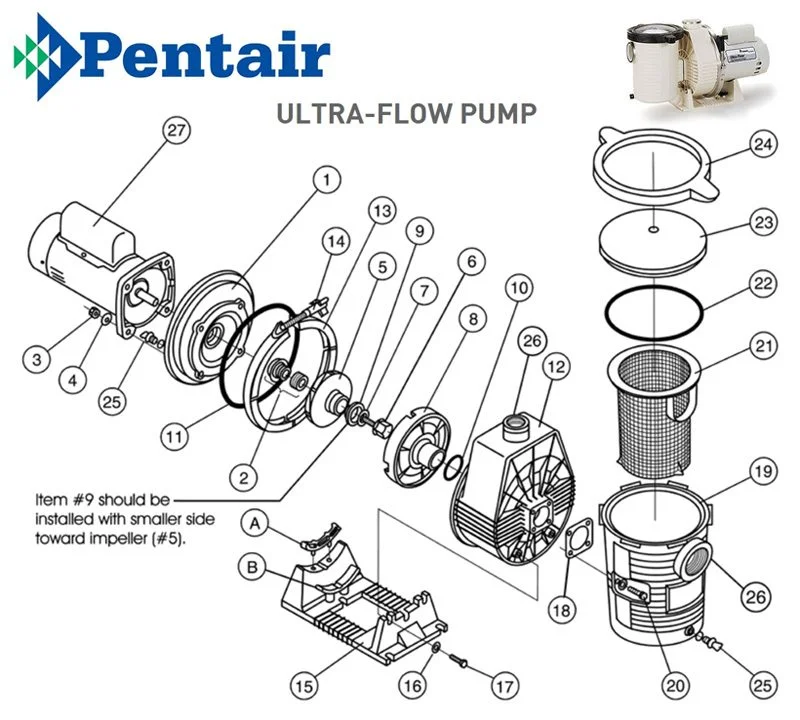

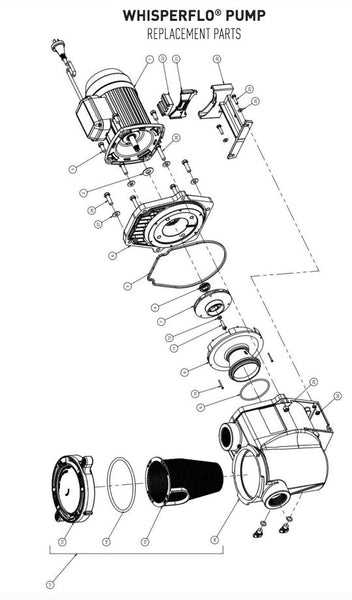

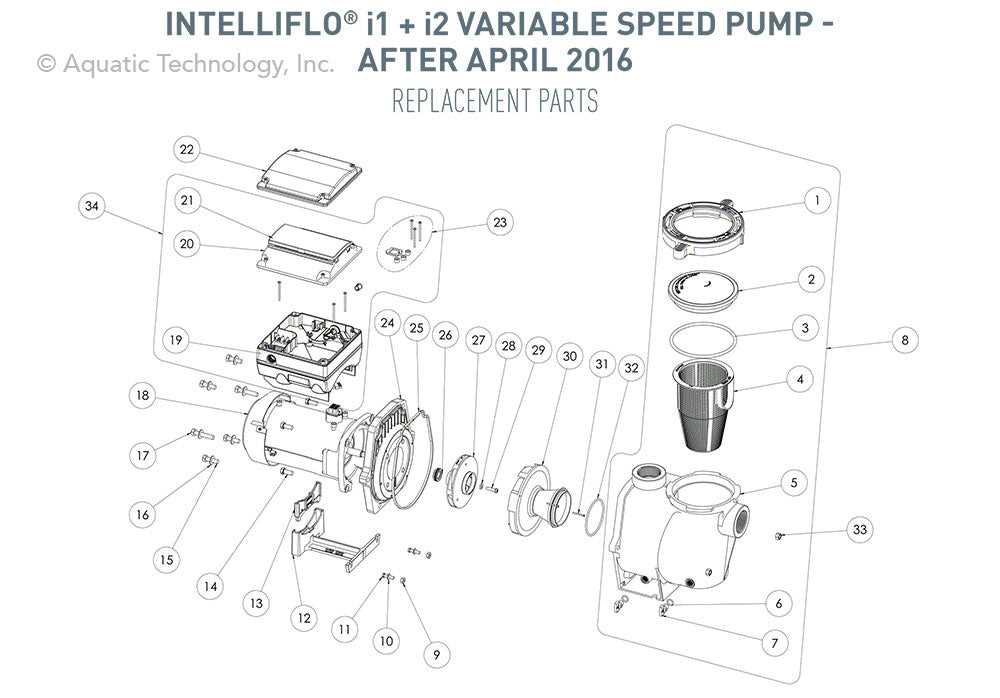

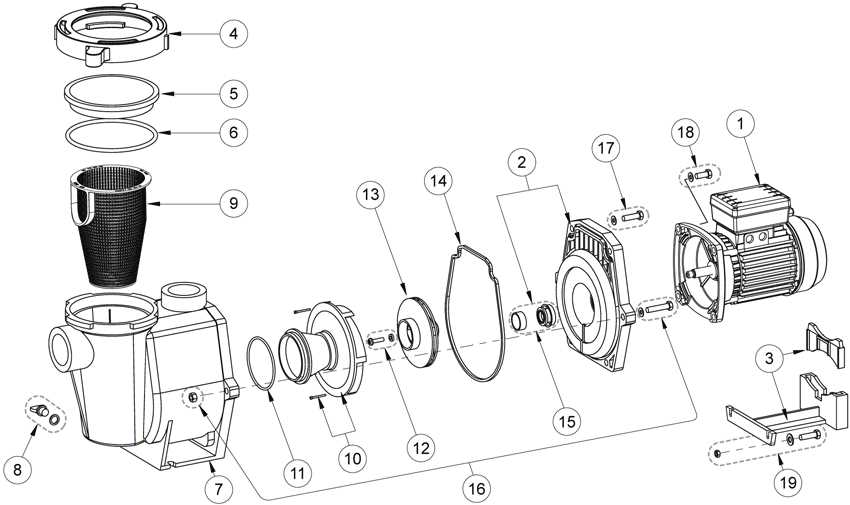

Visual representations of these elements can serve as invaluable tools, offering clarity on how each component fits into the larger assembly. By examining these illustrations, one can gain insights into the design and operational mechanics, ensuring that proper maintenance practices are followed. This is crucial for both longevity and reliability in pool systems.

In this section, we will delve into the specifics of key components associated with a popular model of pool pumps. By breaking down the configuration and purpose of each piece, readers will be better equipped to handle repairs and replacements. Ultimately, this understanding fosters a more enjoyable and stress-free swimming experience.

Pentair WhisperFlo Overview

This section provides a comprehensive insight into a high-efficiency water circulation system, designed for residential and commercial pools. Renowned for its durability and energy efficiency, this pump model caters to various aquatic environments, ensuring optimal performance and longevity.

Key Features

Among the standout characteristics of this system are its quiet operation, advanced hydraulic design, and user-friendly installation process. These features collectively contribute to reduced energy consumption and minimal maintenance needs, making it an ideal choice for pool owners seeking reliability and performance.

Specifications

| Feature | Description |

|---|---|

| Power Output | Varied horsepower options to suit different pool sizes |

| Efficiency Rating | Highly efficient design minimizes energy usage |

| Noise Level | Engineered for quiet operation |

| Durability | Constructed with corrosion-resistant materials |

Understanding Pump Components

Pumps are vital devices in various systems, playing a crucial role in fluid movement and circulation. Each pump comprises several integral elements that work together to ensure optimal performance and efficiency. By familiarizing ourselves with these components, we can better appreciate their functions and significance in maintaining proper operation.

The motor serves as the powerhouse, converting electrical energy into mechanical energy to drive the pump. It is essential for providing the necessary force to move fluids through the system.

The impeller is a key component that enhances fluid movement. As it spins, it creates a centrifugal force that propels the liquid, facilitating flow and pressure generation.

The volute is designed to collect and direct the fluid exiting the impeller. Its shape is crucial for converting the kinetic energy from the fluid into pressure, thereby optimizing flow dynamics.

Seals and bearings play important roles in ensuring reliability. Seals prevent leakage, while bearings support the rotating parts, minimizing friction and wear over time.

Understanding these essential elements enables users to make informed decisions regarding maintenance and upgrades, ensuring the longevity and efficiency of the entire system.

Common Issues and Solutions

In any mechanical system, it is common to encounter various challenges that can affect performance and efficiency. Understanding these issues and their potential solutions is crucial for maintaining optimal operation. Below are some frequent problems and their recommended fixes.

Frequent Problems

| Issue | Description |

|---|---|

| Noisy Operation | Unusual sounds may indicate loose components or air trapped in the system. |

| Reduced Flow Rate | Low water circulation can result from clogged filters or worn-out seals. |

| Leakage | Visible water accumulation often points to faulty gaskets or fittings. |

Recommended Solutions

Addressing the identified issues often requires specific interventions:

| Issue | Solution |

|---|---|

| Noisy Operation | Inspect and tighten loose parts; bleed air from the system. |

| Reduced Flow Rate | Clean or replace filters and check for seal deterioration. |

| Leakage | Replace damaged gaskets or ensure fittings are secure. |

Parts Replacement Guide

Maintaining the efficiency of your pool’s filtration system is crucial for ensuring clean and clear water. This section provides a comprehensive overview of how to identify and replace essential components to keep your equipment functioning optimally.

Identifying Components: Familiarizing yourself with the various elements of your system is the first step in the replacement process. Each part plays a specific role, and understanding their functions will aid in diagnosing issues effectively.

Replacement Steps: When a component shows signs of wear or malfunction, follow a systematic approach to replacement. Start by turning off the system and disconnecting the power supply. Carefully remove the faulty item, ensuring that you keep track of any screws or fasteners for reassembly.

Choosing Quality Replacements: Always opt for high-quality substitutes that match the specifications of your existing setup. Investing in reliable replacements can significantly extend the lifespan of your equipment and improve overall performance.

Reassembly: After installing the new component, reassemble the unit with attention to detail. Double-check that all connections are secure and that no tools are left behind before restoring power to the system.

Regular Maintenance: To prevent future issues, establish a routine maintenance schedule. Regular inspections and timely replacements will ensure your filtration system remains in peak condition.

Tools Needed for Maintenance

Proper upkeep of equipment requires a specific set of instruments that ensure efficient operation and longevity. Having the right tools at hand not only simplifies the process but also enhances the effectiveness of routine checks and repairs.

Essential tools include a variety of wrenches and screwdrivers, which allow for adjustments and replacements of various components. Additionally, a good-quality multimeter is crucial for checking electrical connections and diagnosing issues. A socket set can also be invaluable for removing and tightening nuts and bolts securely.

Other useful items are plumbing tape for sealing joints, a flashlight for illuminating hard-to-reach areas, and protective gloves to ensure safety during maintenance tasks. By equipping yourself with these essential tools, you can effectively manage the upkeep of your equipment.

How to Read Diagrams

Understanding illustrations is crucial for effective troubleshooting and maintenance. These visual representations provide essential information, enabling users to identify components and their relationships. Mastering the skill of interpreting these visuals can lead to more efficient repairs and enhanced functionality.

Key Elements to Consider

- Symbols: Familiarize yourself with the common symbols used to represent different components. Each symbol conveys specific information about the part it represents.

- Labels: Pay attention to any labels or annotations. They often include vital details such as part names, specifications, or installation guidelines.

- Connections: Examine the lines or arrows indicating connections between parts. These help illustrate how components interact within the system.

Steps to Effectively Interpret Visuals

- Start by reviewing the overall layout to gain a sense of the entire system.

- Identify each symbol and its corresponding label for clarity.

- Trace connections to understand the flow and interactions of the components.

- Refer to any accompanying documentation for additional context or detailed explanations.

By following these guidelines, you can enhance your ability to decode complex illustrations, leading to improved comprehension and application in practical situations.

Identifying Each Part

Understanding the components of a specific equipment model is essential for effective maintenance and repair. Each element plays a critical role in the overall functionality, and recognizing them can enhance troubleshooting skills and streamline replacement processes.

Motor: This vital component provides the necessary power to operate the system. It converts electrical energy into mechanical energy, driving the entire mechanism.

Impeller: A key piece in fluid movement, the impeller creates the flow of water. Its design directly affects the efficiency and performance of the unit.

Diffuser: This part directs the flow from the impeller, ensuring smooth transition and reducing turbulence, which contributes to optimal operation.

Strainer: Positioned at the inlet, this component filters debris and prevents blockages, safeguarding the system from potential damage.

Seal: Essential for preventing leaks, the seal ensures that water remains contained within the system, protecting other components from damage.

Housing: The outer shell encases all internal parts, providing structural integrity and protecting them from external elements.

By familiarizing oneself with these essential components, users can ensure proper functioning and extend the lifespan of the equipment.

Installation Tips for New Parts

When replacing components in a water circulation system, proper installation is crucial for optimal performance and longevity. Ensuring that each element is correctly positioned and secured will minimize the risk of leaks and malfunctions.

Before beginning, gather all necessary tools and familiarize yourself with the new elements. Review any provided instructions carefully, as they offer essential insights into the specific requirements for installation.

Start by turning off the system and disconnecting power to prevent accidents. Drain any remaining water to facilitate a clean working environment. As you remove the old components, take note of their arrangement and any additional fittings to avoid confusion during reassembly.

When installing the new pieces, ensure all gaskets and seals are intact and properly placed to prevent leaks. Tighten connections gently, following the recommended torque specifications, as overtightening can cause damage.

After everything is in place, double-check all connections and fittings. Once satisfied, restore power and run the system to check for any irregularities. It’s advisable to monitor the system closely during the initial operation to catch any potential issues early.

Where to Buy Replacement Parts

Finding quality components for your pool equipment is essential for maintaining optimal performance. Fortunately, there are various sources where you can acquire these essential items, ensuring your system operates smoothly and efficiently.

- Authorized Retailers: Check with authorized dealers who specialize in pool supplies. They often carry a wide selection of genuine components.

- Online Marketplaces: Websites like Amazon, eBay, and specialized pool equipment retailers provide convenient access to numerous options, often at competitive prices.

- Local Pool Supply Stores: Visiting local shops can be beneficial as staff can offer personalized advice and recommendations tailored to your specific needs.

- Manufacturer Websites: Directly purchasing from the manufacturer’s website can ensure you receive authentic items and may also provide helpful resources.

- Wholesale Distributors: If you’re looking to buy in bulk, consider reaching out to wholesale suppliers who can offer significant savings.

Always ensure that you verify compatibility with your equipment before making a purchase, and consider customer reviews to gauge the quality of the components. This diligence will help you maintain the longevity and performance of your system.

Benefits of Regular Maintenance

Routine upkeep is essential for ensuring optimal performance and longevity of any mechanical system. By adhering to a consistent maintenance schedule, users can experience improved efficiency, reduce the likelihood of unexpected breakdowns, and ultimately save on costly repairs. Regular attention not only keeps equipment running smoothly but also enhances safety and reliability.

Improved Efficiency

Regular inspections and servicing help identify potential issues before they escalate. This proactive approach ensures that all components function at their best, reducing energy consumption and enhancing overall performance. When systems operate efficiently, they not only deliver better results but also contribute to lower operating costs.

Extended Lifespan

Frequent maintenance contributes to the durability of mechanical systems. By addressing wear and tear early, users can avoid major damages that lead to replacements. This attention to detail fosters a longer lifespan for equipment, allowing for a greater return on investment and minimizing the frequency of upgrades.

Pentair WhisperFlo vs. Competitors

This section explores the differences between a renowned pool pump and its competitors, focusing on performance, efficiency, and user satisfaction. By analyzing various models, we can better understand which option offers the best value for pool owners.

Performance Comparison

When evaluating pool pumps, performance is a critical factor. Key aspects include flow rate, energy consumption, and noise levels. Below is a comparison table highlighting these features among popular models:

| Model | Flow Rate (GPM) | Energy Efficiency (kWh/year) | Noise Level (dB) |

|---|---|---|---|

| Model A | 70 | 900 | 60 |

| Model B | 65 | 850 | 58 |

| Model C | 75 | 950 | 62 |

User Satisfaction

Another essential factor to consider is user feedback. Many customers prioritize durability and ease of maintenance. While some pumps are lauded for their longevity, others may require frequent repairs. Reviews and ratings can offer valuable insights into the reliability of different options in the market.

Customer Reviews and Feedback

Understanding customer experiences can significantly enhance the decision-making process for potential buyers. Reviews and feedback offer valuable insights into the effectiveness and reliability of various products. By examining these perspectives, one can gauge the overall satisfaction levels and discover any recurring issues or advantages highlighted by users.

Positive feedback often emphasizes durability and performance, with many users praising the efficiency and ease of installation. Customers frequently note how the product has exceeded their expectations, particularly in terms of longevity and operational consistency. This kind of input can reassure prospective purchasers about their investment.

Conversely, constructive criticism provides a balanced view, shedding light on areas for improvement. Some users report challenges related to compatibility with existing systems or specific maintenance requirements. Such insights are essential for those looking to make informed choices, as they highlight potential pitfalls that could arise post-purchase.

In summary, the collection of reviews serves as a useful tool for understanding user sentiment. By considering both positive remarks and constructive feedback, buyers can better navigate their options and select a product that aligns with their needs and expectations.