Stihl MS361 Parts Diagram PDF Guide

When it comes to maintaining and repairing outdoor machinery, having a clear visual reference is essential. A well-organized illustration can significantly enhance your understanding of how various components fit together, making it easier to identify parts that may need attention or replacement. This resource is invaluable for both enthusiasts and professionals who strive for optimal performance in their tools.

Detailed visual guides not only help in troubleshooting issues but also facilitate more efficient assembly and disassembly processes. By familiarizing yourself with the layout and function of each segment, you can streamline your maintenance routines and ensure longevity in your equipment. Understanding these schematics can empower you to tackle repairs confidently, minimizing downtime.

Furthermore, such resources often include essential specifications and compatibility information, making them indispensable for anyone looking to source replacement items or upgrade their machinery. Whether you are a seasoned expert or a novice, having access to comprehensive visual aids can greatly enhance your experience and expertise in equipment management.

Understanding Stihl MS361 Components

Exploring the intricacies of a power tool reveals a world of interconnected elements that work harmoniously to achieve optimal performance. Each component plays a vital role, contributing to the overall efficiency and functionality of the machine. Gaining insight into these individual parts allows users to appreciate their importance and ensures better maintenance and operation.

Key Elements and Their Functions

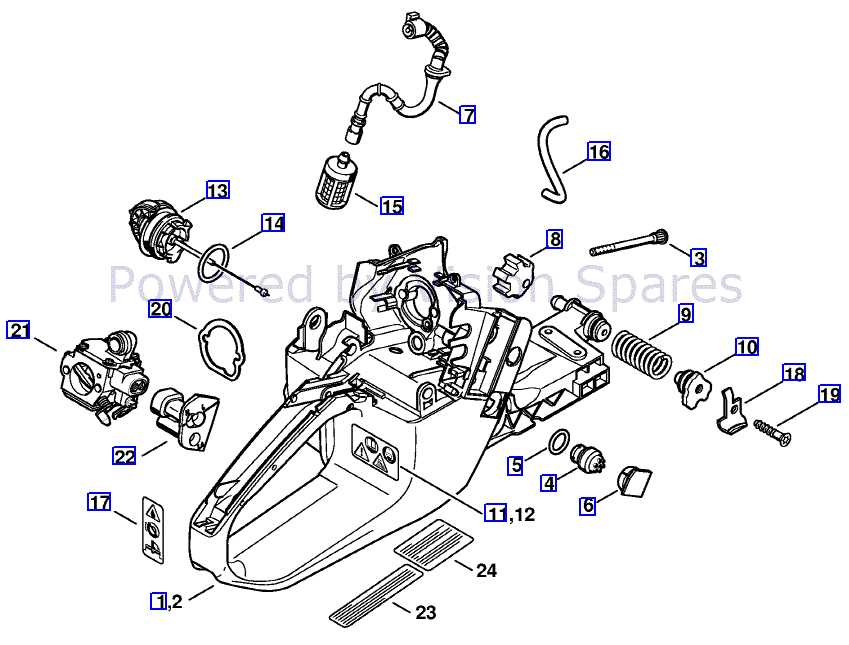

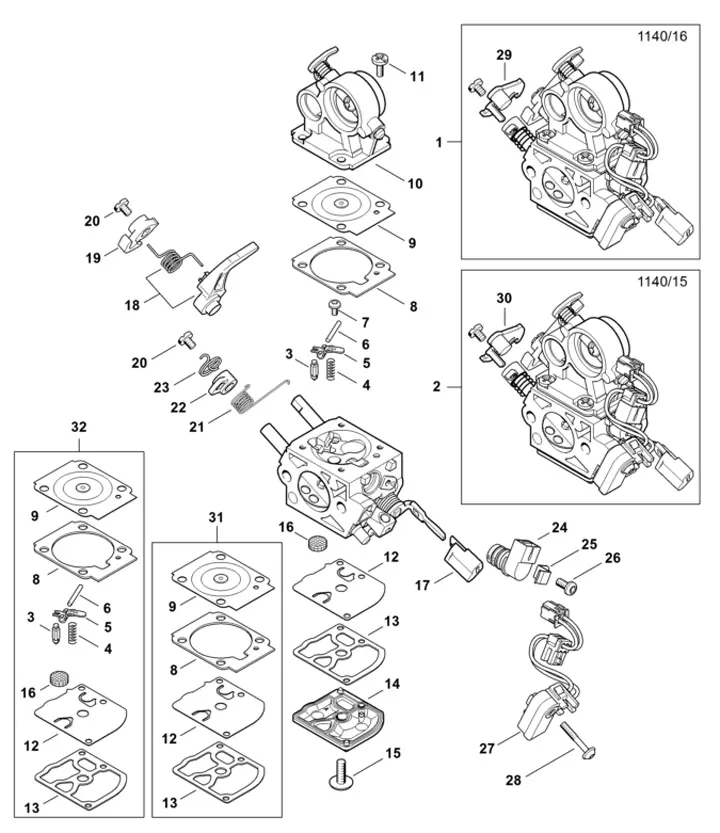

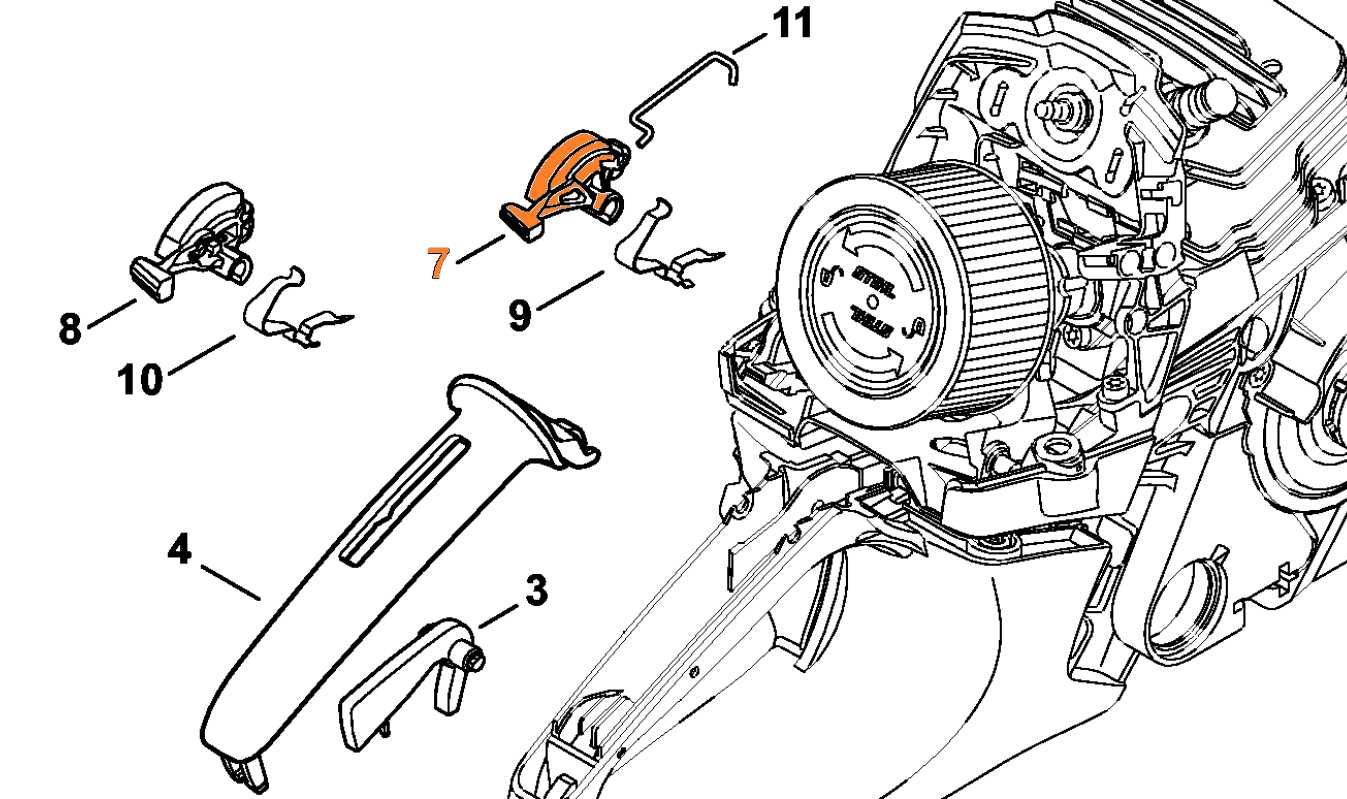

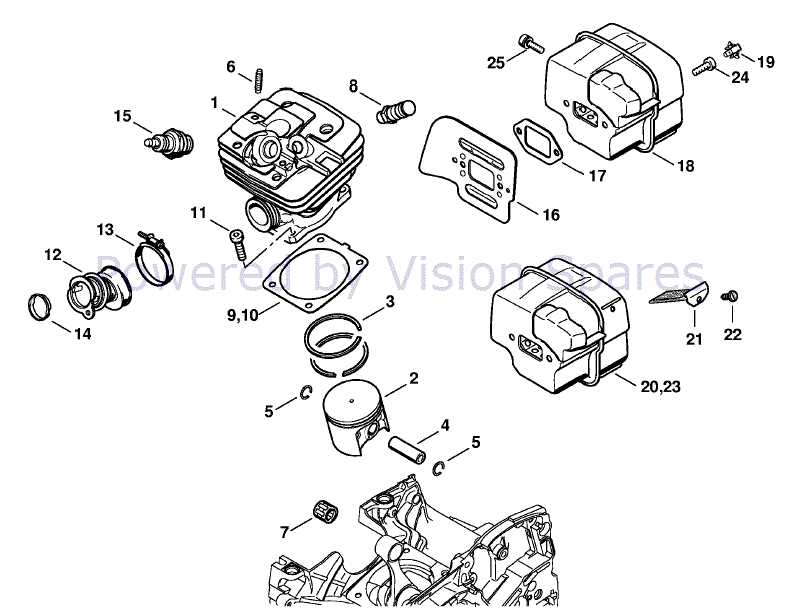

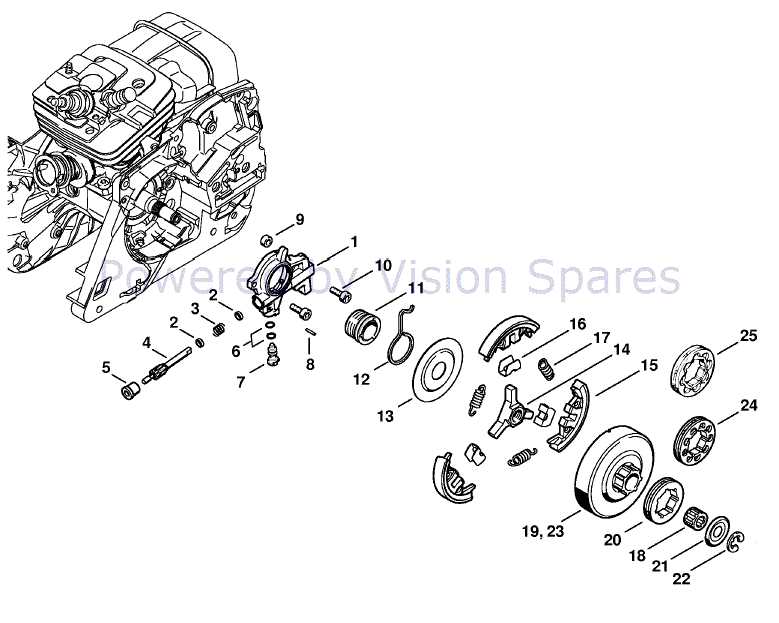

The core assembly consists of several crucial elements, such as the engine, guide bar, and chain. The engine generates the necessary power, while the guide bar provides support and direction for the chain, which performs the cutting action. Understanding how these pieces interact helps users recognize signs of wear and potential issues, facilitating timely repairs and enhancements.

Maintenance and Care

Importance of Parts Diagrams

Understanding the intricate details of any mechanical device is crucial for effective maintenance and repair. Visual representations serve as essential tools for both novices and experienced technicians, offering clarity on the components involved. These illustrations simplify the complexity of machinery, allowing users to easily identify individual elements and their functions.

One significant advantage of utilizing these visual aids is the facilitation of accurate repairs. When users can see how parts fit together, they are better equipped to reassemble and troubleshoot issues without confusion. This reduces the risk of errors and enhances efficiency in the repair process.

| Benefits | Description |

|---|---|

| Enhanced Clarity | Visual aids provide a straightforward view of component layout. |

| Improved Efficiency | Quick identification of parts streamlines repair tasks. |

| Reduced Errors | Clear visuals minimize the chances of misassembly. |

| Educational Tool | Helps new users understand the structure and function of equipment. |

In conclusion, visual references are indispensable in the maintenance landscape. They enhance understanding, improve workflow, and ultimately lead to better functioning equipment. Mastery of these tools contributes significantly to successful upkeep and longevity of machinery.

Where to Find PDF Diagrams

Finding detailed schematics for equipment can significantly enhance maintenance and repair processes. Numerous resources are available online to help users locate these invaluable visual guides. Whether you’re seeking manuals for assembly or troubleshooting, knowing where to look is essential for effective service.

Manufacturer Websites: Most manufacturers provide downloadable resources directly on their official sites. This is often the most reliable source, ensuring that you access accurate and up-to-date information. Navigate to the support or resources section to find relevant documents.

Online Forums and Communities: Enthusiast forums often host a wealth of shared resources. Members frequently upload and exchange technical documentation, offering insights and advice. Engaging with these communities can lead to discovering hard-to-find materials.

Retailers and Distributors: Many authorized sellers offer downloadable resources alongside product listings. These documents may include schematics and assembly instructions that are directly linked to the items being sold.

Technical Libraries: Some online libraries specialize in technical documents. These platforms often require subscriptions but can provide access to a vast collection of materials, including schematics and guides for various models.

Search Engines: A targeted search using specific keywords can yield numerous results. Including the model name along with terms like “manual” or “schematic” can help narrow down the options effectively.

Utilizing these strategies can make the search for visual guides much more efficient, ensuring that you have the necessary information for effective equipment management.

Common Issues with MS361 Parts

When operating high-performance machinery, users often encounter various challenges related to individual components. Understanding these common concerns can enhance the overall experience and prolong the lifespan of the equipment. Various factors, such as wear and tear, improper maintenance, and environmental conditions, can lead to frequent complications.

Wear and Tear: Over time, the components may experience degradation due to regular use. This can manifest as diminished efficiency or unexpected breakdowns. Regular inspections are crucial to identify parts that may need replacement before they fail completely.

Fuel System Problems: The fuel delivery system can develop issues, such as clogged filters or malfunctioning pumps. These complications can result in performance loss, making it essential to ensure that fuel components are clean and functioning properly.

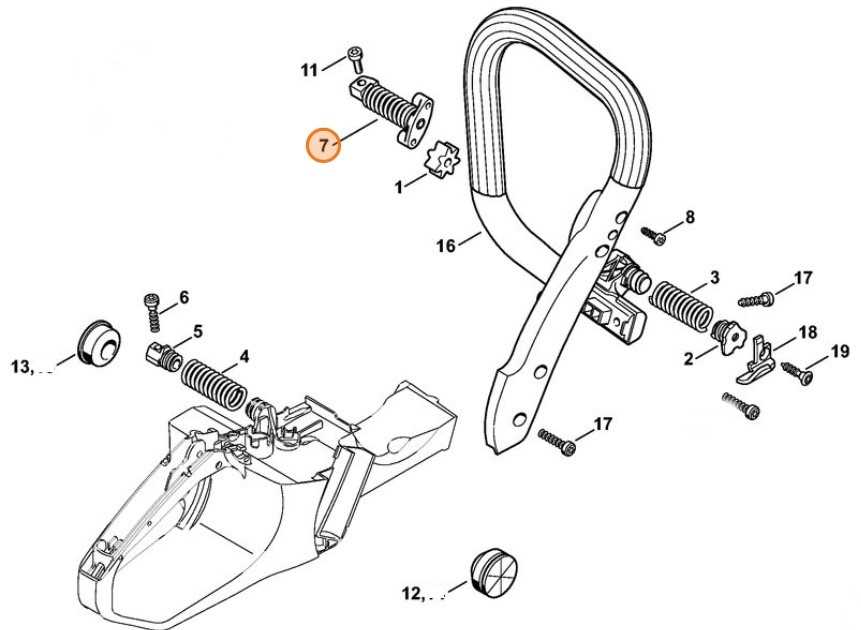

Chain Tensioning Issues: Proper chain tension is vital for optimal performance. Incorrect tension can lead to excessive wear or even accidents. Users should regularly check and adjust tension to maintain safety and efficiency.

Electrical Failures: Components that rely on electrical systems may encounter problems, such as faulty wiring or malfunctioning ignition systems. These issues can cause starting difficulties or operational inconsistencies, requiring thorough troubleshooting.

Environmental Factors: Exposure to extreme weather conditions can adversely affect component integrity. Moisture, dirt, and temperature fluctuations can lead to rust or other forms of damage. Protective measures should be taken to safeguard the machinery during storage and use.

By staying vigilant and addressing these common issues, users can ensure their equipment remains reliable and effective for a long time.

Replacement Parts for Stihl MS361

When it comes to maintaining your chainsaw, having access to high-quality components is essential for ensuring optimal performance and longevity. Whether you need to replace worn-out elements or upgrade specific features, understanding the available options can significantly enhance your experience and efficiency in handling tasks.

Essential Components

Key elements of any chainsaw contribute to its functionality. Regularly checking these parts will help you identify when a replacement is necessary to keep your machine running smoothly.

| Component | Description | Importance |

|---|---|---|

| Chain | The cutting element that provides the saw’s ability to slice through wood. | Critical for efficient cutting. |

| Guide Bar | Supports the chain and helps guide it through the wood. | Essential for maintaining proper chain alignment. |

| Air Filter | Prevents debris from entering the engine. | Important for engine health and performance. |

| Fuel Filter | Ensures that only clean fuel reaches the engine. | Vital for preventing engine damage. |

| Spark Plug | Ignites the fuel-air mixture to start the engine. | Crucial for reliable engine operation. |

Finding Quality Replacements

Locating reliable sources for your replacements is paramount. Whether you opt for original equipment or compatible aftermarket options, prioritize quality to ensure seamless compatibility and durability.

Maintaining Your MS361 Chainsaw

Proper upkeep of your cutting tool is essential for optimal performance and longevity. Regular maintenance not only ensures safety but also enhances efficiency, allowing for smoother operation during use. By implementing a consistent care routine, you can prevent potential issues and extend the lifespan of your equipment.

Routine Inspections are crucial. Regularly check for any signs of wear or damage, particularly in critical components like the chain and bar. A well-maintained cutting edge improves cutting performance and reduces the strain on the engine.

Cleaning is another vital aspect of maintenance. After each use, remove debris and sap from the exterior and air filters. This prevents clogging and helps maintain optimal airflow, which is essential for engine efficiency.

Lubrication plays a key role in the smooth functioning of moving parts. Ensure that all necessary components are adequately lubricated to reduce friction and wear. Pay particular attention to the chain oil reservoir, as insufficient lubrication can lead to rapid deterioration of the chain and bar.

Fuel Quality should not be overlooked. Use high-quality fuel and the appropriate oil mixture to ensure proper combustion and engine health. Poor fuel can lead to starting issues and reduced performance over time.

By adhering to these maintenance practices, you can enjoy reliable performance and an extended lifespan for your cutting tool. Regular attention to detail will not only keep your equipment in top shape but also enhance your overall cutting experience.

How to Read Parts Diagrams

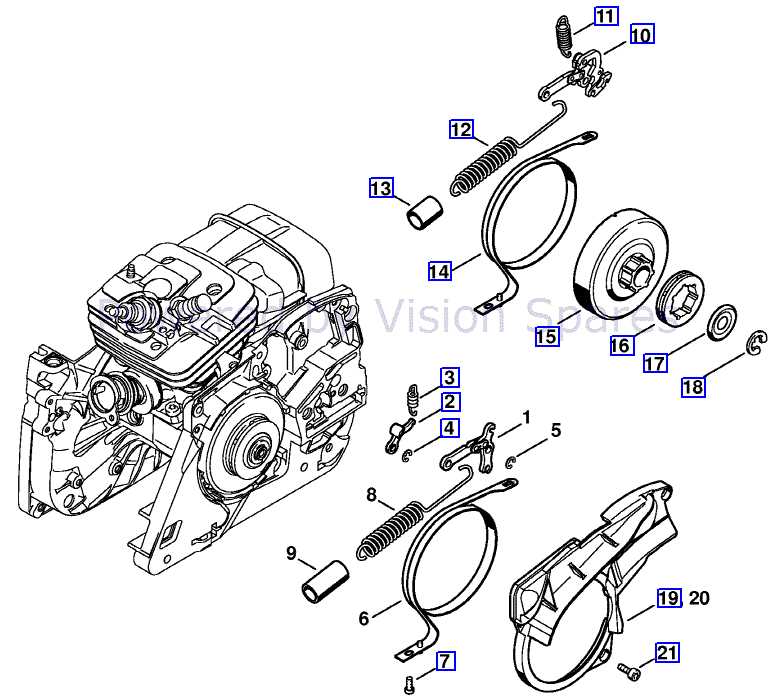

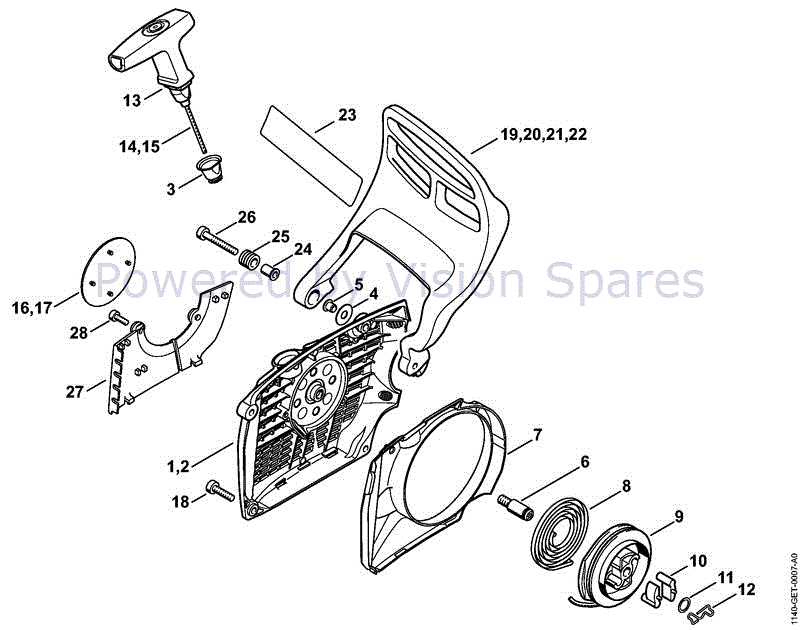

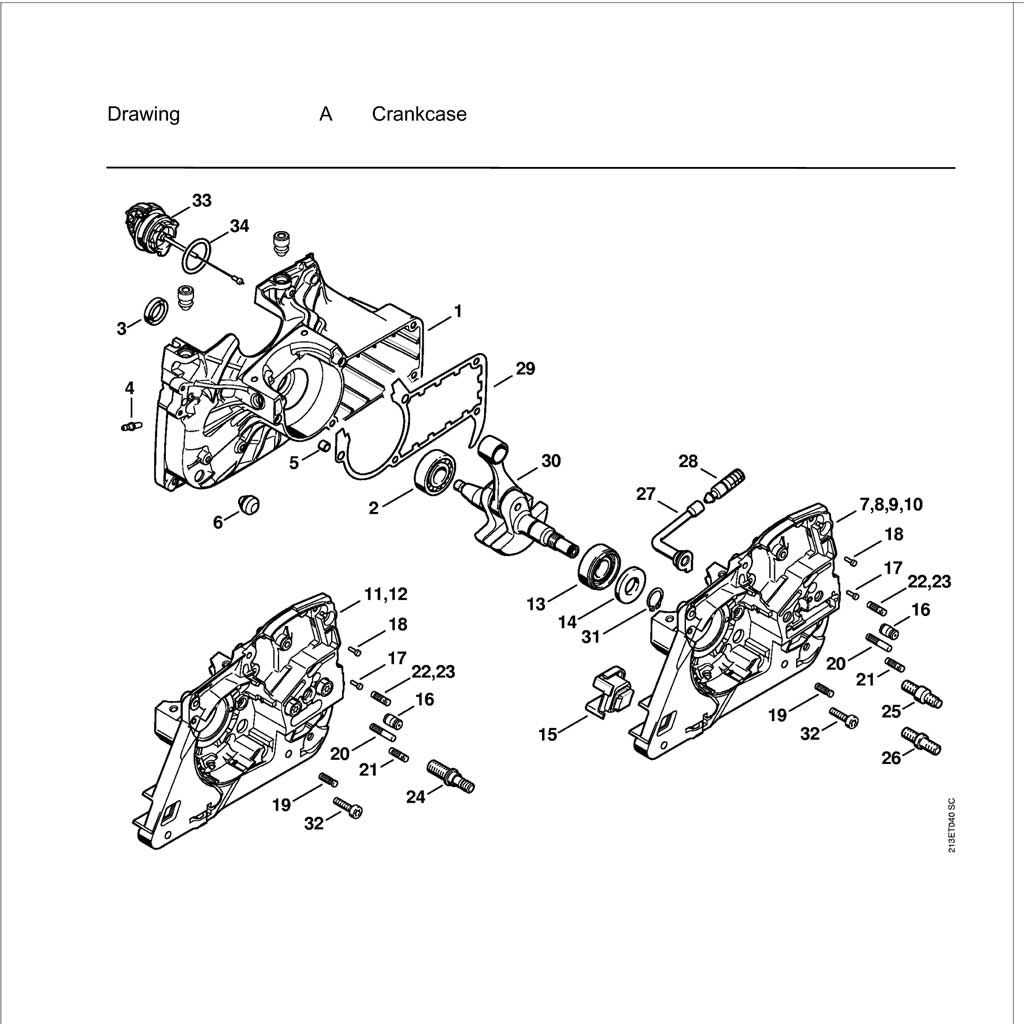

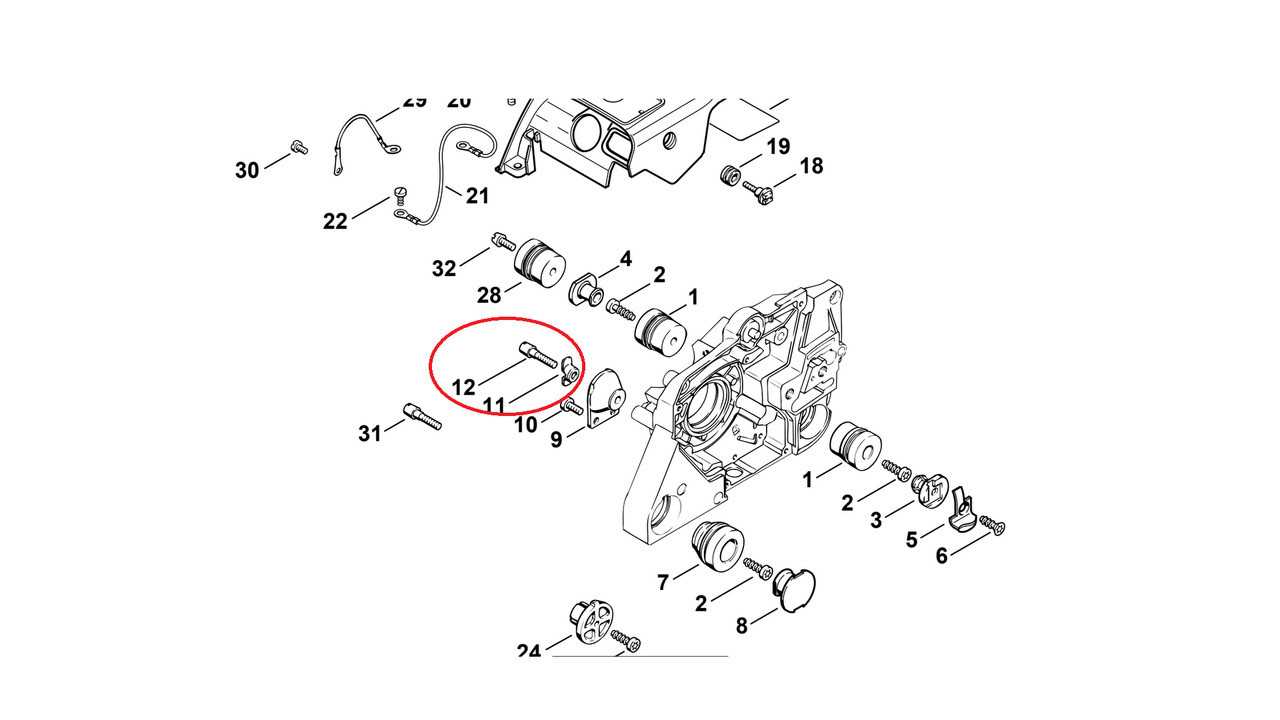

Understanding visual schematics is essential for efficient assembly and maintenance of equipment. These illustrations provide a comprehensive overview of components and their relationships, enabling users to identify individual elements quickly. Grasping the layout and symbols used in these visuals can greatly enhance your repair or assembly process.

Firstly, familiarize yourself with the overall structure of the illustration. Most schematics will have a clear title or reference number, which is crucial for identifying the specific assembly or model. Look for a legend or key that explains the symbols used; this will help clarify what each part represents. Commonly, different shapes or lines indicate various types of components or connections.

Next, pay attention to the arrangement. Components are often organized logically, reflecting their physical placement in the machinery. Following the flow from one part to another can provide insights into how they interact. This spatial awareness can be beneficial when troubleshooting or reassembling.

Finally, utilize the reference numbers that accompany each component. These numbers usually correspond to a list or catalog that provides additional details such as specifications, compatibility, and ordering information. By cross-referencing these numbers, you can ensure that you are using the correct replacements during maintenance or repairs.

Stihl MS361 Repair Tips

Maintaining and fixing your outdoor power equipment is crucial for optimal performance and longevity. This section provides essential advice for effective repairs, ensuring your tool operates smoothly and efficiently.

Common Issues and Solutions

- Engine Troubles: If the engine fails to start, check the fuel quality and ensure the air filter is clean. Replace spark plugs as needed.

- Chain Problems: If the chain is not moving properly, inspect for dullness or damage. Regular sharpening and proper tension adjustment are key.

- Vibration: Excessive shaking may indicate loose components. Tighten screws and bolts, and check for worn parts.

Preventive Maintenance Tips

- Always use high-quality fuel and oil to prevent engine wear.

- Regularly clean the air filter and replace it when necessary.

- Inspect and lubricate moving parts frequently to avoid premature wear.

- Store the tool in a dry place to prevent rust and corrosion.

Ordering Genuine Stihl Parts

When maintaining outdoor power equipment, ensuring the use of authentic components is essential for optimal performance and longevity. Sourcing these quality items not only guarantees compatibility but also enhances the reliability of your machinery.

To procure original items, consider visiting authorized dealers or trusted retailers. They often provide an extensive selection of components tailored for specific models, ensuring you find exactly what you need. Additionally, many of these vendors offer online platforms, making it convenient to browse and order from the comfort of your home.

It’s important to verify the authenticity of the components by checking for proper branding and certifications. Utilizing genuine products ensures your equipment operates efficiently and minimizes the risk of malfunctions caused by inferior substitutes.

Lastly, consult your user manual or online resources for guidance on selecting the correct items for your machinery. Investing time in researching and ordering original components will pay off in the long run, keeping your equipment in peak condition.

Benefits of Using Original Components

Utilizing authentic parts for machinery and equipment brings a multitude of advantages that enhance performance and longevity. Original components are specifically designed to fit seamlessly and operate efficiently, ensuring that users experience the best functionality from their devices.

Quality Assurance

One of the primary benefits of using genuine components is the assurance of quality. These parts are manufactured to meet strict industry standards, which guarantees:

- Durability and reliability over time.

- Consistent performance that matches the equipment’s specifications.

- Enhanced safety features that prevent accidents and malfunctions.

Compatibility and Warranty

Another significant advantage is compatibility. Original components are designed to work harmoniously with your equipment, which leads to:

- Reduced risk of damage to the machinery.

- Easier installation and maintenance processes.

- Preservation of warranties, as using non-genuine parts may void manufacturer guarantees.

In conclusion, choosing original components not only enhances the efficiency and safety of your equipment but also ensures peace of mind through reliable performance and quality assurance.