Stihl BG 86 Leaf Blower Parts Diagram Overview

Maintaining outdoor spaces can be challenging, especially when seasonal debris becomes overwhelming. To address these demands, specialized tools are designed to streamline garden maintenance, making tasks quicker and easier. This article will explore the internal components and essential elements of one such device, helping enthusiasts and professionals understand its structure.

A well-maintained outdoor device relies on the synergy of multiple internal elements working together efficiently. Whether it’s for regular upkeep or more intensive yard work, knowing how these elements interact can greatly improve performance. Familiarity with the structure not only ensures smoother operation but also extends the equipment’s life.

This guide provides valuable insights into the various modules and connections found in high-performance outdoor tools. By exploring these details, users can quickly identify potential issues and enhance their ability to perform basic repairs and upkeep with confidence.

Exploring Components of the Stihl BG 86

The device consists of several interconnected elements designed to provide efficient airflow and smooth operation. Each piece plays a critical role, contributing to overall functionality and user experience. Understanding these elements can help with maintenance and ensure the machine performs optimally over time.

Engine Unit: This core section powers the entire system, ensuring the necessary force is generated to move air through the mechanism. Proper care of this part is essential for long-term efficiency.

Air Intake System: This part draws in air and filters out debris, preventing internal components from clogging. Regular cleaning helps maintain smooth airflow.

Control Handles: These sections offer a comfortable grip and house important switches, allowing users to adjust power and airflow easily. Ergonomic design ensures minimal fatigue during operation.

Nozzle Attachments: Interchangeable extensions direct the flow with precision, making the equipment versatile for different tasks. These attachments allow for focused or dispersed air patterns as needed.

By under

Understanding the Engine Assembly

The engine is the core mechanism responsible for powering the entire system, requiring precise alignment of components to operate smoothly. A well-maintained engine ensures reliable performance and long service life, with various internal elements working together harmoniously.

Main Components Overview

- Cylinder: Houses the piston, allowing it to compress air and fuel during operation.

- Piston: Moves up and down within the cylinder to generate the necessary pressure.

- Crankshaft: Converts the linear motion of the piston into rotational force.

- Carburetor: Regulates the air-fuel mixture entering the combustion chamber.

- Flywheel: Maintains consistent engine speed and generates airflow for cooling.

How Components Interact

- The piston compresses the air-fuel mixture inside the cylinder, preparing it for ignition.

- As the mixture ignites, the expansion forces the piston downward, creating power.

- The crankshaft converts this energy into rotational movement, which drives external

How the Air Filter Works

The air filter plays a crucial role in maintaining optimal performance in various equipment. Its primary function is to prevent contaminants from entering the engine, ensuring that only clean air is utilized during operation. This process helps in enhancing efficiency and prolonging the life of the machine.

Importance of Clean Air Intake

Keeping the intake air free from dirt and debris is essential for the smooth functioning of the engine. A clean filter allows for better combustion, leading to improved power output and fuel efficiency. When the air supply is obstructed, it can result in reduced performance and increased wear on engine components.

Filter Maintenance and Replacement

Regular maintenance of the air filtration system is vital. Users should periodically inspect the filter for signs of dirt buildup and replace it as needed. A well-maintained filter not only ensures proper airflow but also helps in minimizing emissions, contributing to a cleaner environment.

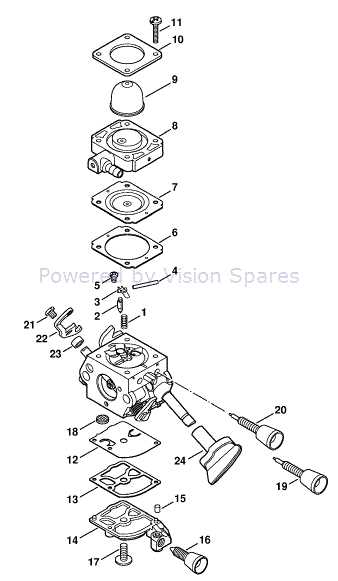

The Role of the Carburetor

The carburetor plays a crucial function in the operation of various engines, particularly those used in outdoor equipment. Its primary purpose is to mix air and fuel in the correct proportions, ensuring optimal combustion within the engine. A well-functioning carburetor is vital for maintaining engine performance and efficiency.

Key Functions of the Carburetor

- Air-Fuel Mixture: The device regulates the ratio of air to fuel, which is essential for efficient combustion.

- Atomization: It breaks the fuel into tiny droplets, allowing for better mixing with air.

- Adjustability: Many models allow users to modify the air-fuel mixture based on specific operational needs.

Common Issues and Maintenance

- Clogging: Dirt and debris can obstruct the jets, leading to poor performance.

- Adjustment: Regular tuning may be required to ensure the correct mixture, particularly with changing environmental conditions.

- Sealing: Proper sealing is essential to prevent air leaks, which can disrupt the mixture balance.

Ignition System and Its Maintenance

The ignition system plays a crucial role in the overall performance and reliability of a power tool. It is responsible for creating the spark that ignites the fuel-air mixture within the engine, ensuring smooth operation. Regular maintenance of this system is essential to prevent starting issues and maintain optimal functionality.

To keep the ignition system in top shape, it is important to perform routine checks and replace worn components as necessary. Below is a summary of the main components of the ignition system and their maintenance requirements:

Component Maintenance Tips Spark Plug Inspect for wear, clean or replace if necessary. Ensure proper gap settings. Ignition Coil Check for damage, secure connections, and proper function. Replace if malfunctioning. Wiring Inspect for fraying or damage. Ensure all connections are tight and secure. Fuel Mixture Use the correct fuel-to-oil ratio to prevent fouling of the ignition components. By following these maintenance tips, users can enhance the longevity and efficiency of their ignition systems, leading to improved performance in their equipment.

Fuel Tank and Line Overview

The fuel reservoir and associated tubing are critical components in any outdoor power equipment. They are responsible for storing and delivering the necessary fuel for the engine’s operation. Understanding their functionality and design can significantly enhance maintenance and troubleshooting efforts.

The fuel tank is typically constructed from durable materials, ensuring it can withstand various environmental conditions. It features a secure closure to prevent leaks and contamination. Meanwhile, the fuel line connects the tank to the engine, facilitating the flow of fuel during operation. This line must remain intact and free from obstructions to ensure optimal performance.

Regular inspections of the fuel reservoir and lines are essential. Signs of wear, such as cracks or leaks, should be addressed immediately to avoid operational issues. Proper care and maintenance of these components not only enhance longevity but also improve the overall efficiency of the machine.

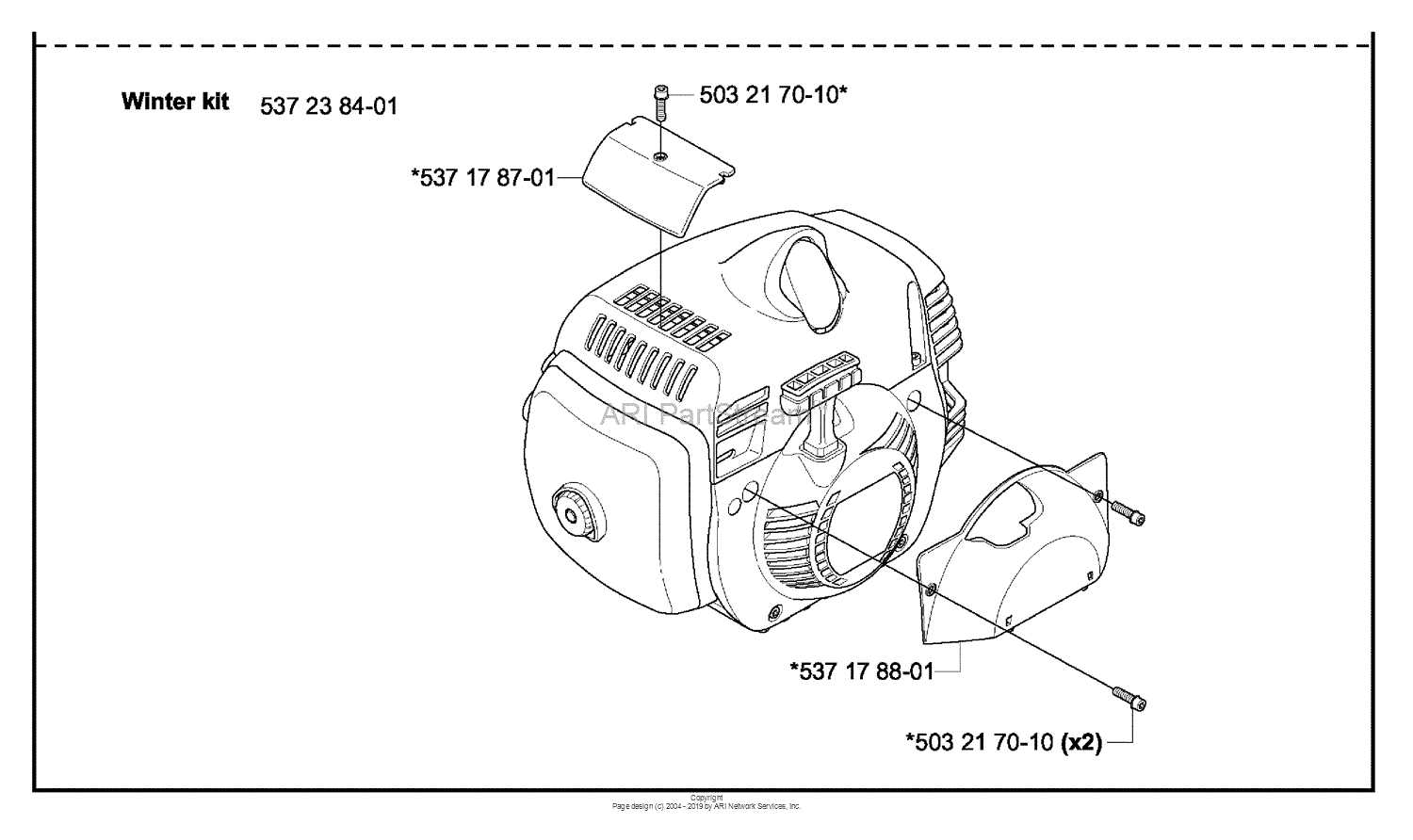

Examining the Fan Housing Structure

The structure that houses the air circulation mechanism is crucial for optimal performance. This assembly plays a vital role in ensuring efficient airflow, which directly impacts the overall functionality of the equipment. Understanding its components and configuration can provide insights into maintaining and enhancing performance.

Components Overview

The main elements of the air circulation housing include the casing, support mounts, and airflow pathways. Each component contributes to the effective movement of air, which is essential for the device’s efficiency.

Component Description Function Casing The outer shell that protects internal parts. Maintains structural integrity and shields components. Support Mounts Attachments that secure the assembly to the main body. Provides stability and alignment for proper operation. Airflow Pathways Channels designed for directing air movement. Ensures efficient air circulation and minimizes turbulence. Importance of Maintenance

Regular inspection of this assembly is essential to prevent blockages and wear. Keeping the air circulation housing clean can significantly enhance the performance and longevity of the device.

Throttle Trigger Functionality Explained

The throttle trigger plays a crucial role in controlling the power output of outdoor power equipment. This component allows the user to regulate the engine speed, ensuring optimal performance based on the task at hand. By adjusting the flow of fuel and air into the combustion chamber, it influences the machine’s overall efficiency and effectiveness.

When the operator engages the throttle trigger, it directly impacts the engine’s RPM (revolutions per minute). A gentle squeeze can lead to a gradual increase in speed, perfect for tasks requiring precision, while a firmer pull results in maximum power for demanding jobs. Understanding how this mechanism works is essential for achieving the best results, as it ensures the equipment operates smoothly and effectively during use.

Handle Assembly and User Comfort

The design and configuration of the handle significantly influence the overall experience of operating the equipment. An ergonomic handle allows users to maintain a comfortable grip while minimizing fatigue during extended use. This assembly often includes features that enhance control and stability, making it easier to navigate various terrains and tasks.

Incorporating adjustable elements within the handle assembly can further improve usability, allowing for customization based on individual preferences. This adaptability is crucial for achieving optimal comfort and efficiency during operation.

Component Description Grip Soft-touch material providing comfort and reducing vibrations. Trigger Ergonomically designed for easy access and control. Adjustable Handle Allows users to modify the height for personalized comfort. Support Bracket Enhances stability, ensuring a firm hold during operation. Replacing the Blower Tube Easily

Replacing the tube of your equipment can significantly enhance its performance and efficiency. This process can be simple and quick if you follow a few straightforward steps. Whether you are performing maintenance or upgrading, knowing how to do this will save you time and effort.

Here’s a step-by-step guide to assist you:

- Ensure the equipment is turned off and cool before beginning.

- Gather the necessary tools, such as a screwdriver and a replacement tube.

- Locate the attachment point of the tube; it is usually at the rear end of the unit.

- Loosen any screws or fasteners holding the tube in place.

- Carefully detach the old tube by pulling it straight out.

- Align the new tube with the attachment point and push it securely into place.

- Reattach any screws or fasteners to secure the new tube.

- Check for any loose connections and ensure everything is tightly fitted.

Following these steps will help you replace the tube efficiently, ensuring optimal performance from your equipment.

Common Wear Parts and Repairs

Maintaining equipment often requires attention to components that experience frequent use and may wear out over time. Understanding these elements can help in ensuring the longevity and efficiency of your device. Identifying signs of wear can prevent more significant issues and expensive repairs.

Frequent Replacement Components

Several elements are commonly subject to replacement due to regular wear. These include gaskets, filters, and hoses. Gaskets ensure a proper seal, preventing leaks and maintaining optimal performance. Filters keep debris from entering the system, which can impede functionality. Hoses transport fluids and air, and any cracks or leaks can lead to reduced efficiency.

Maintenance Tips

Regular inspection and timely replacement of these components can save time and money in the long run. It is advisable to follow the manufacturer’s guidelines for maintenance schedules and to use quality replacements to ensure compatibility and durability. Keeping your equipment clean and stored properly will also enhance its lifespan.