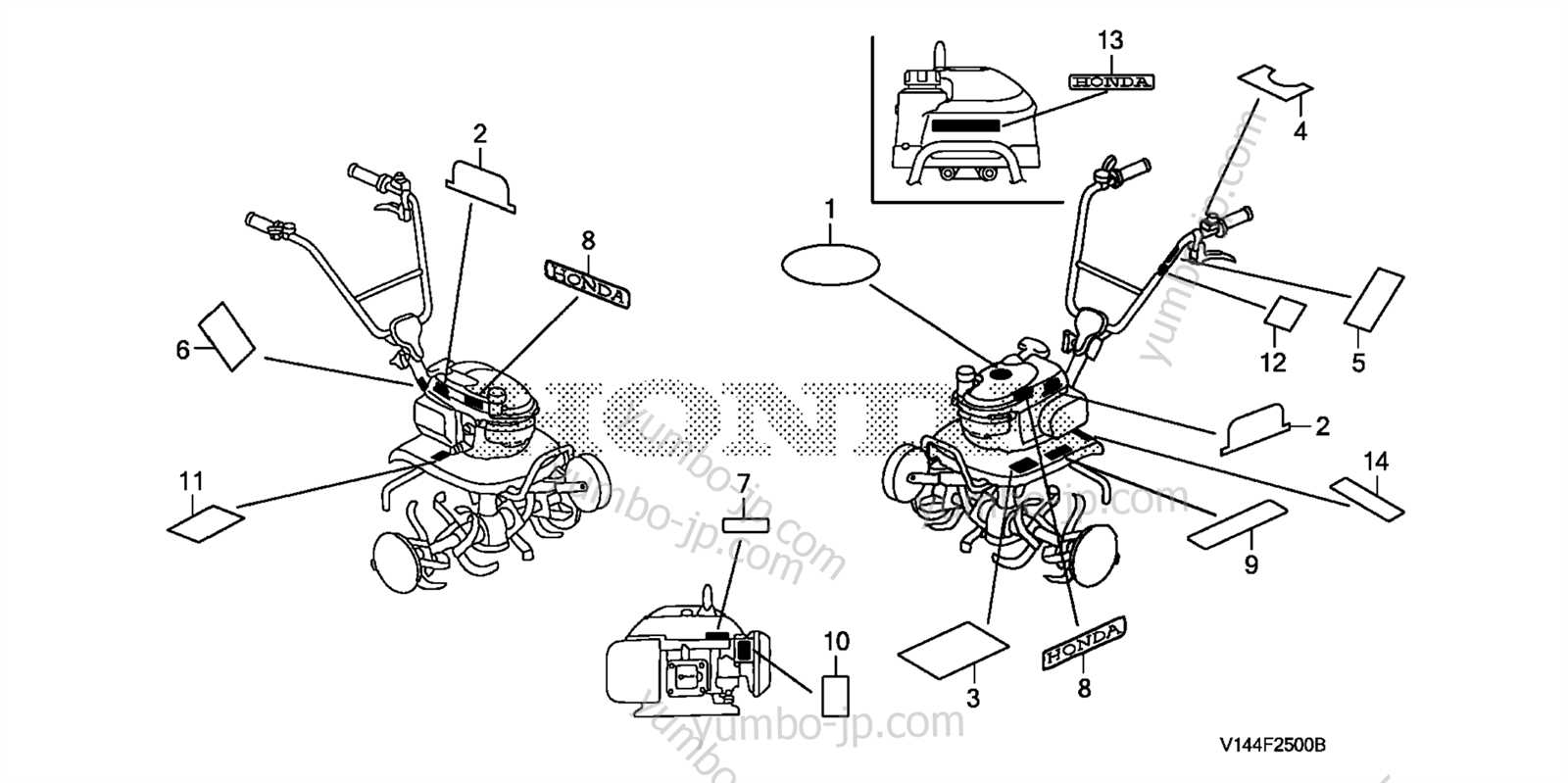

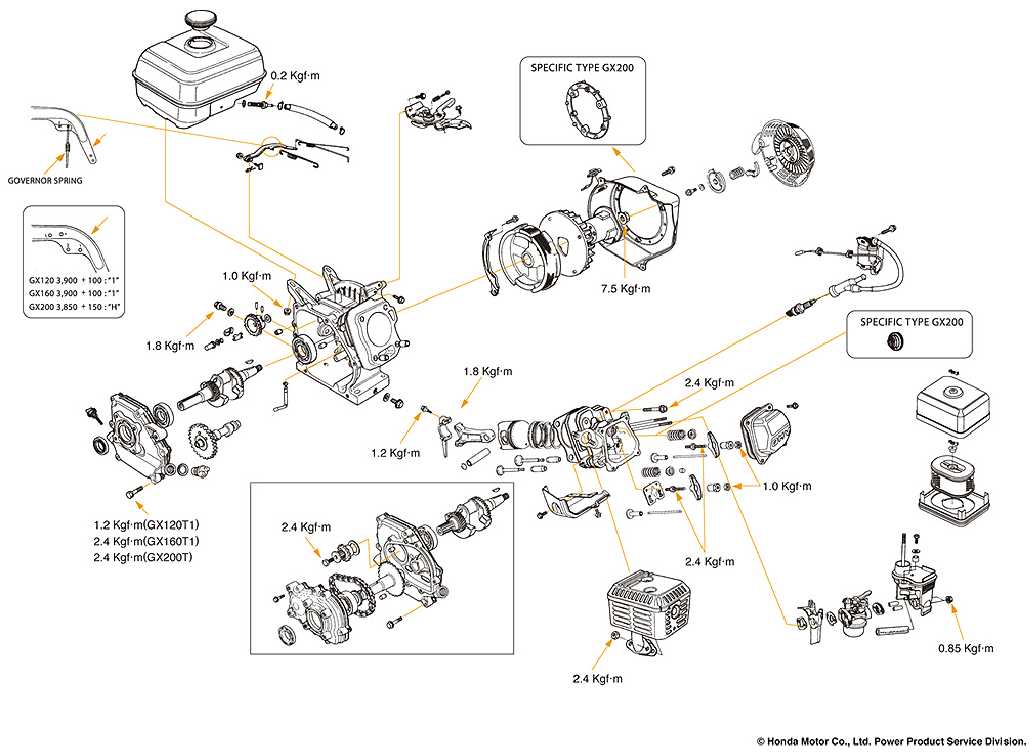

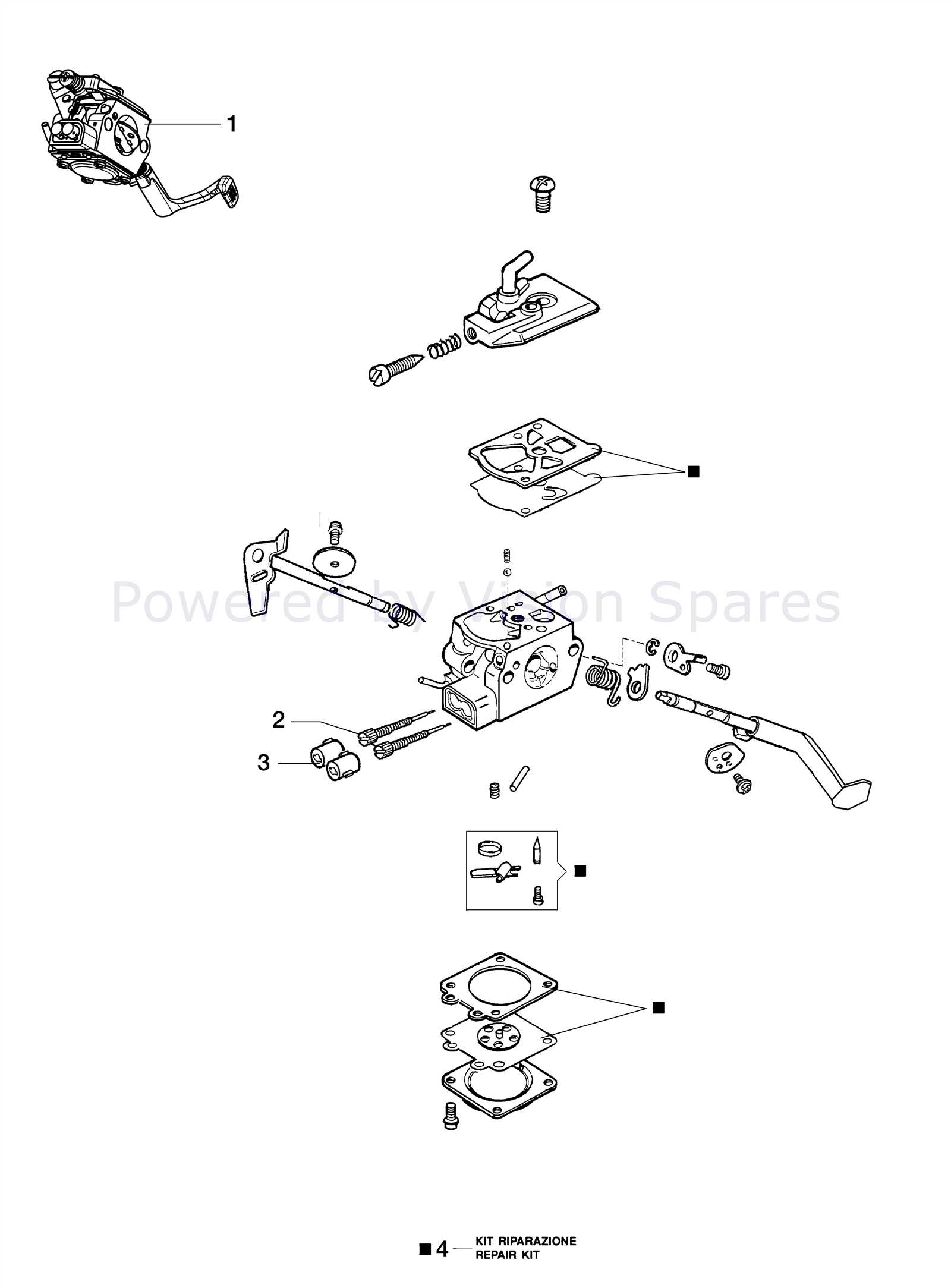

Honda GX200 Carburetor Parts Diagram Overview

In the realm of small engines, the efficiency of fuel delivery plays a crucial role in performance and reliability. A comprehensive grasp of the various components involved can significantly enhance maintenance practices and troubleshooting efforts. This section aims to unravel the complexities associated with these vital mechanisms, providing insight into their structure and function.

Exploring the intricate elements involved in fuel distribution is essential for both enthusiasts and professionals alike. Familiarity with these components not only aids in effective repairs but also fosters a deeper appreciation for the engineering that underpins these machines. Each piece, from the intake to the adjustment mechanisms, works harmoniously to ensure optimal operation.

Furthermore, having access to a detailed visual representation of these elements can serve as a valuable reference tool. By breaking down the individual components and their interrelations, users can develop a clearer understanding of how each part contributes to the overall system. This knowledge is instrumental for anyone looking to maintain or enhance engine performance.

Engine Component Breakdown of the GX200 Carburetor

In this section, we delve into the intricate anatomy of the fuel delivery system found within the powerhouse of the GX200 engine. Understanding the internal structure and functionality of these critical components is essential for maintaining optimal engine performance.

1. Essential Fuel Pathway Components

- The primary components responsible for directing and regulating fuel flow through the engine.

- Critical elements that ensure the engine receives the correct mixture of fuel and air.

- Components that facilitate the combustion process without excessive waste or inefficiency.

2. Precision Control Mechanisms

- Mechanisms that govern the precise amount of fuel entering the engine at different operating conditions.

- Regulatory devices that adjust fuel-air ratios to optimize engine performance across varying loads.

- Control components that ensure the engine operates efficiently without compromising durability.

This breakdown provides a detailed exploration into the structural elements crucial for the GX200 engine’s operational reliability and efficiency. By comprehending these components, users can effectively troubleshoot issues and conduct necessary maintenance to sustain peak engine performance.

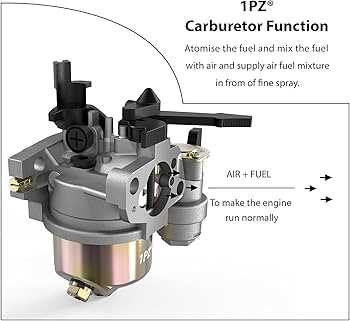

Understanding the Basics of Carburetion

The process of mixing air and fuel is crucial for the efficient operation of internal combustion engines. A well-functioning system ensures optimal performance and responsiveness, directly impacting the power output and fuel efficiency of the engine.

Key concepts in this process include:

- Air-Fuel Mixture: The correct balance between air and fuel is essential for effective combustion.

- Atomization: The transformation of liquid fuel into a fine mist allows for better mixing with air.

- Venturi Effect: A reduction in pressure that occurs as air flows through a narrow passage, aiding in fuel draw.

Components of this system play a vital role in maintaining the proper mixture and function. Understanding these elements can help troubleshoot common issues and enhance performance:

- Throttle Valve: Controls the amount of air entering the engine, influencing power output.

- Choke: Restricts airflow during startup, enriching the mixture for easier ignition.

- Float Chamber: Maintains a steady supply of fuel for consistent operation.

By grasping these fundamental principles, users can appreciate the importance of maintaining this system for overall engine health and efficiency.

Exploring the Function of a Small Engine Carburetor

In the realm of small engine mechanics, a crucial component plays a pivotal role in fuel delivery and engine performance. This component, integral to the engine’s operation, ensures optimal air-fuel mixture for combustion, thereby sustaining efficient power output. Understanding its function involves delving into the intricacies of air intake regulation and fuel atomization within the engine’s internal combustion process.

Air Regulation and Fuel Atomization

One of the primary tasks is to regulate the influx of air into the engine, a process critical for combustion efficiency. This mechanism carefully adjusts the air intake, ensuring the right proportion relative to the fuel supply. Simultaneously, it atomizes the fuel, breaking it down into fine droplets that mix uniformly with the incoming air. This dual function is essential for generating the combustible mixture that drives the engine’s power stroke.

| Function | Description |

| Air Regulation | Controls the volume of air entering the engine. |

| Fuel Atomization | Breaks down fuel into fine droplets for efficient combustion. |

| Mixture Adjustment | Allows adjustment of the air-fuel mixture for varying engine conditions. |

| Choke Operation | Provides enriched mixture during cold starts for easier ignition. |

Maintenance and Optimization

Regular maintenance is crucial to ensure the carburetor operates at peak efficiency. This involves periodic cleaning to prevent clogging, adjustment of settings to match environmental conditions, and replacement of worn-out components when necessary. Optimization of the carburetor’s function not only enhances engine performance but also extends the engine’s lifespan, making it a cornerstone of small engine maintenance practices.

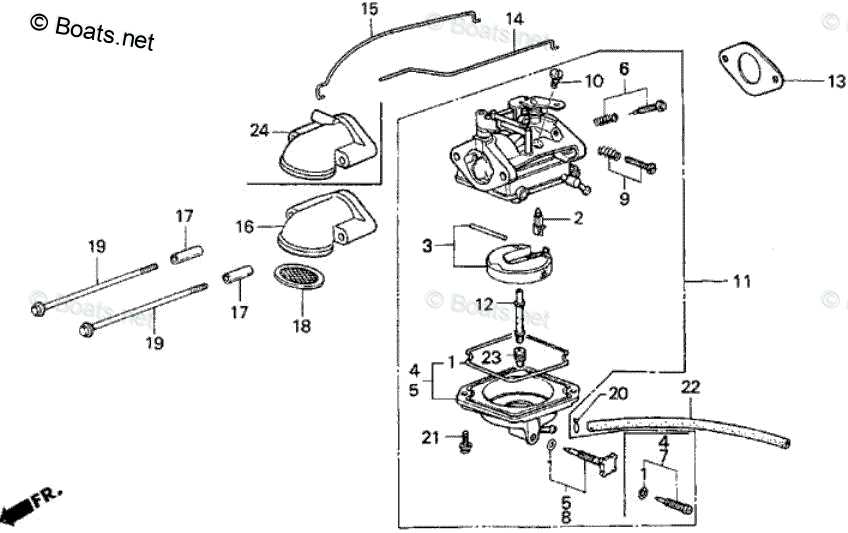

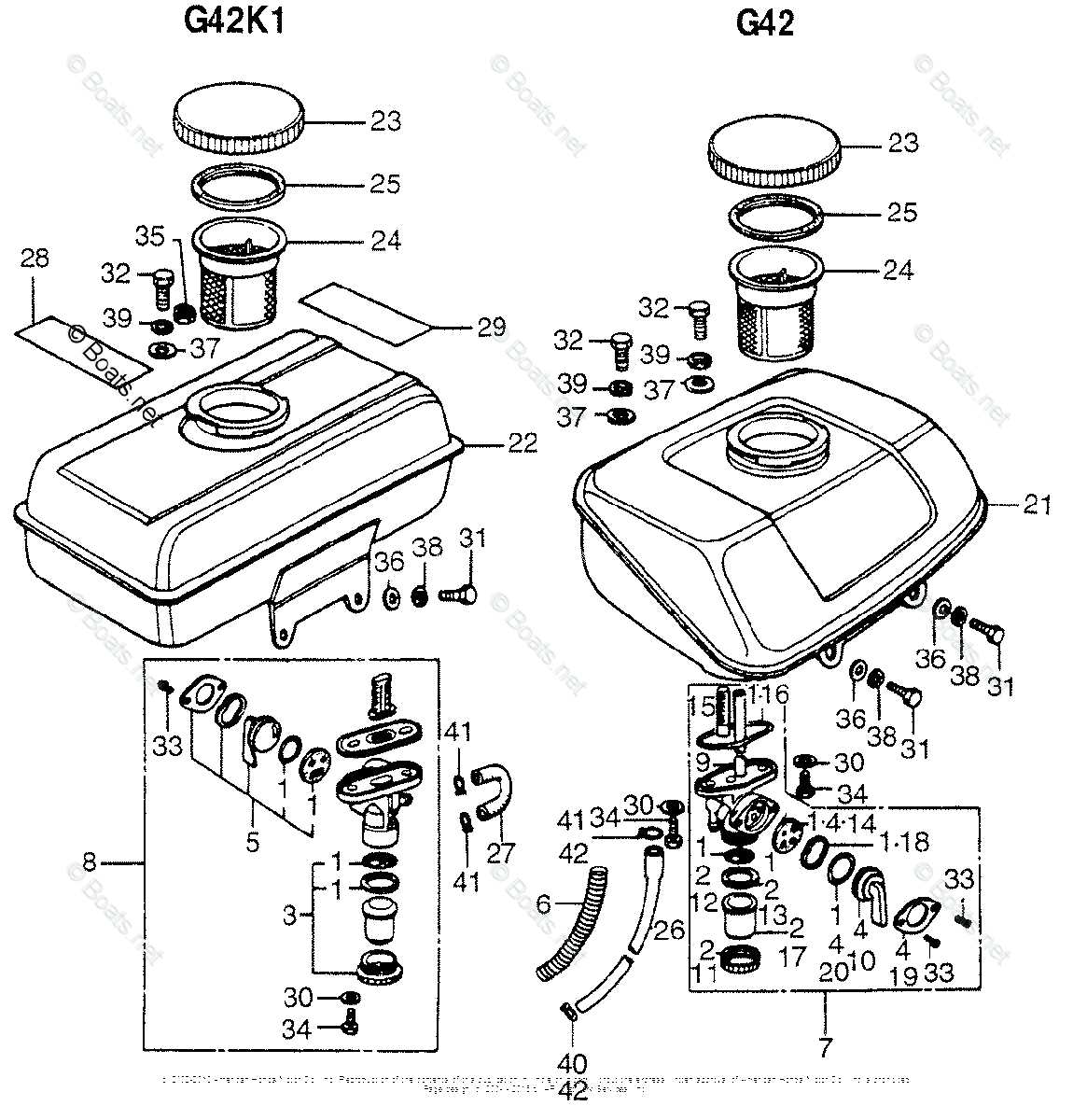

Identifying Key Components in the Carburetor System

Understanding the essential elements of a fuel delivery mechanism is crucial for maintaining optimal engine performance. Each component plays a specific role in ensuring that the air-fuel mixture is delivered efficiently to the combustion chamber. Recognizing these parts allows for better diagnostics and troubleshooting when issues arise.

Below is a table summarizing the main elements involved in the fuel mixing process, along with their functions:

| Component | Function |

|---|---|

| Float Chamber | Regulates the fuel level and maintains a steady supply. |

| Needle Valve | Controls the flow of fuel into the float chamber. |

| Venturi | Creates a vacuum to draw in fuel as air flows through. |

| Jet | Determines the amount of fuel mixed with air. |

| Throttle Valve | Regulates the amount of air-fuel mixture entering the engine. |

Each of these components must function correctly to ensure efficient engine operation. Regular inspection and maintenance can prevent performance issues and extend the life of the engine.

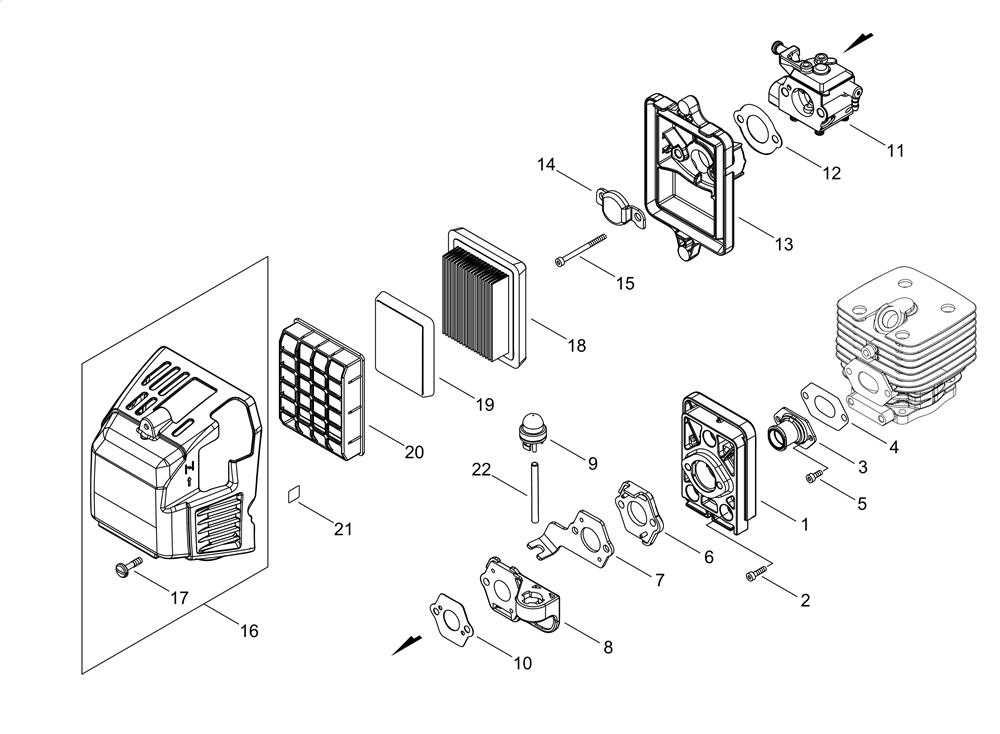

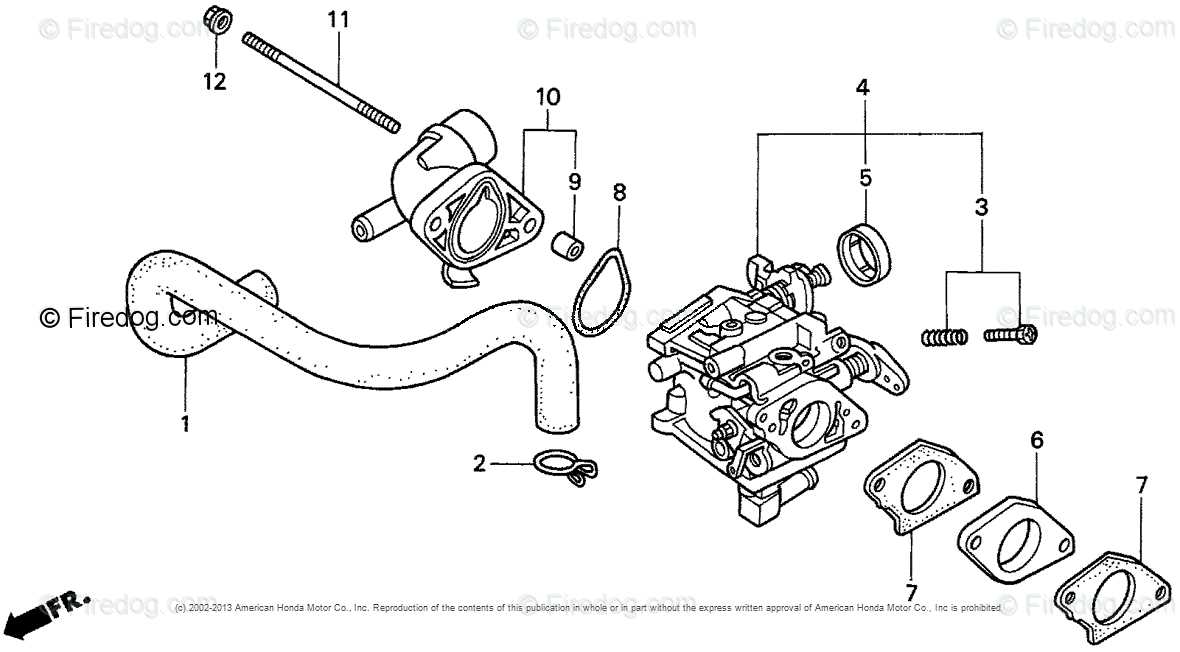

Step-by-Step Assembly of GX200 Carburetor Parts

This section provides a comprehensive guide to reassembling the components of a small engine fuel delivery system. Understanding the configuration and the sequence of assembly is crucial for optimal performance and reliability.

Necessary Components

Before beginning the assembly process, ensure you have all the required elements at hand. This will streamline the procedure and prevent any interruptions. Below is a list of essential components:

| Component | Description |

|---|---|

| Float | Regulates the fuel level in the chamber. |

| Jet | Controls the fuel flow into the mixing area. |

| Needle | Works with the float to manage fuel entry. |

| Cover | Encloses the assembly, ensuring proper sealing. |

| Gasket | Prevents leaks between the cover and the body. |

Assembly Steps

Follow these detailed steps to assemble the fuel delivery mechanism effectively:

1. Begin by placing the gasket onto the base of the body to ensure a secure fit.

2. Insert the float and needle assembly, ensuring that the needle aligns correctly with the seat in the body.

3. Position the jet in its designated slot, tightening it to prevent any movement.

4. Carefully place the cover on top, ensuring all components are seated properly.

5. Secure the cover using the appropriate screws, ensuring not to overtighten.

By adhering to these steps, you can ensure the efficient functioning of the assembly, contributing to the overall performance of your equipment.

Common Issues and Troubleshooting Tips

Understanding typical problems and their solutions is essential for maintaining optimal performance in small engines. Recognizing signs of malfunction can save time and resources, ensuring smoother operation and longevity. This section outlines frequent challenges and effective strategies for resolving them.

| Issue | Possible Causes | Troubleshooting Steps |

|---|---|---|

| Engine won’t start | Fuel blockage, faulty ignition, low compression | Check fuel supply and filter, inspect spark plug, perform a compression test |

| Rough idling | Dirty components, air leaks, incorrect adjustment | Clean the fuel delivery system, check for gasket damage, adjust idle settings |

| Power loss during operation | Clogged passages, worn parts, insufficient fuel | Inspect and clean all pathways, replace worn components, ensure proper fuel flow |

| Excessive fuel consumption | Rich fuel mixture, leakage, malfunctioning float | Adjust mixture settings, check for leaks, inspect float for proper operation |

| Engine overheating | Poor ventilation, low oil level, debris accumulation | Ensure adequate airflow, check oil levels, clean any obstructing materials |

Importance of Regular Carburetor Maintenance

Consistent upkeep of fuel delivery systems is crucial for optimal engine performance and longevity. Neglecting these essential components can lead to a myriad of problems, affecting not only the efficiency of the engine but also its overall reliability. Regular maintenance ensures that the system operates smoothly, providing the necessary fuel-air mixture for effective combustion.

Enhancing Performance

Routine inspection and cleaning of these components can significantly improve the engine’s performance. Accumulation of dirt and debris can hinder fuel flow, leading to poor acceleration and reduced power. By ensuring that everything is functioning correctly, you can experience a noticeable enhancement in responsiveness and efficiency.

Preventing Costly Repairs

Taking proactive measures in maintenance can help avoid more extensive and expensive repairs down the line. When these systems are allowed to degrade, the risk of breakdown increases, which may result in significant downtime and repair costs. Regular attention not only preserves the lifespan of the engine but also safeguards your investment.

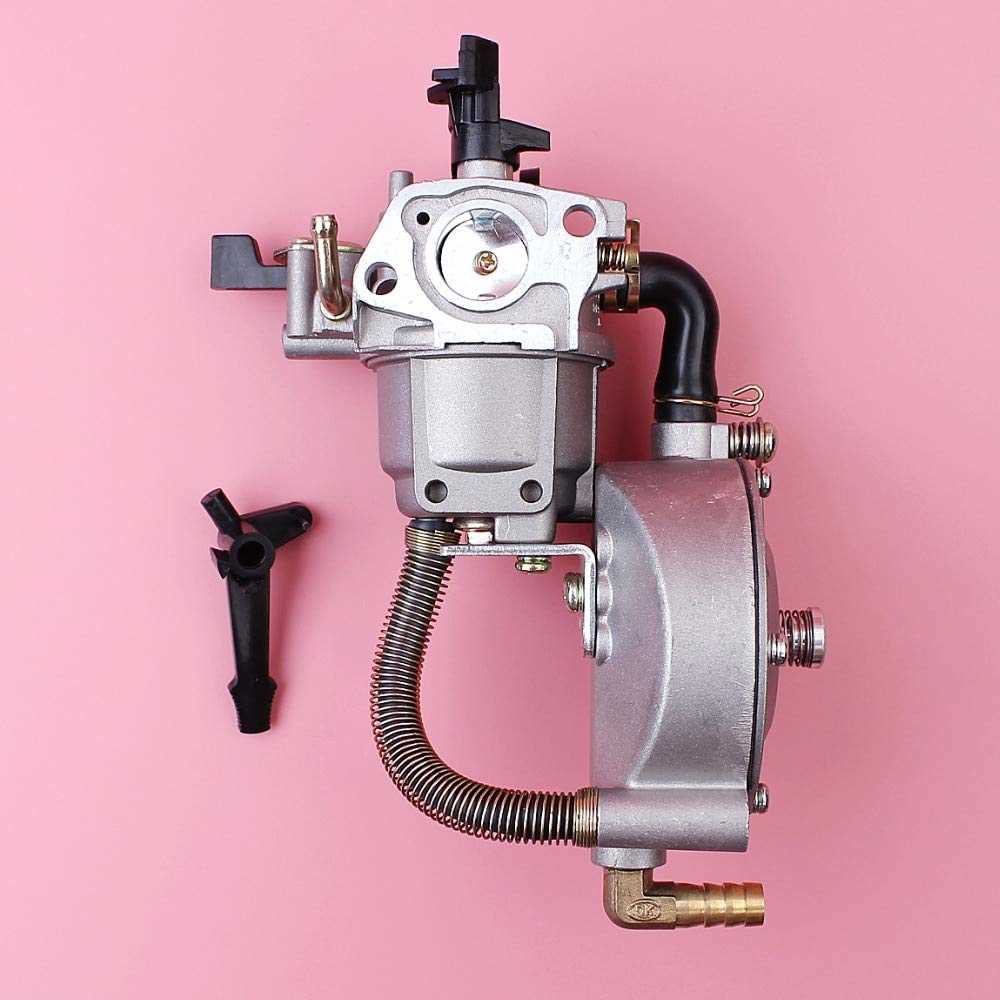

Comparison of OEM vs. Aftermarket Carburetor Parts

The choice between original equipment manufacturer (OEM) components and those produced by third-party suppliers is crucial for maintaining engine performance and reliability. Understanding the differences in quality, cost, and compatibility can help users make informed decisions based on their specific needs and preferences.

Quality and Performance

OEM components are typically designed to meet the exact specifications of the engine, ensuring optimal functionality and longevity. In contrast, aftermarket alternatives can vary significantly in quality. Some may offer improved performance or innovative features, while others might fall short, leading to potential issues such as poor fuel efficiency or increased wear.

Cost Considerations

Price is often a deciding factor for many consumers. OEM items tend to be more expensive due to their guaranteed compatibility and reliability. Aftermarket options usually come at a lower cost, appealing to budget-conscious individuals. However, lower prices can sometimes mean sacrificing quality, leading to higher long-term costs if replacements are needed sooner than expected.

Ultimately, the decision between OEM and aftermarket components involves balancing quality, performance, and cost. Users should carefully assess their priorities to choose the best fit for their engines.

Enhancing Performance with Upgraded Carburetor Kits

Upgrading your engine’s fuel delivery system can lead to significant improvements in performance and efficiency. By replacing standard components with high-quality kits designed for enhanced airflow and fuel mixture, enthusiasts can unlock the full potential of their machines. These modifications not only optimize combustion but also contribute to smoother operation and increased power output.

Benefits of High-Performance Kits

One of the primary advantages of utilizing upgraded systems is improved throttle response. With better tuning capabilities, users can achieve a more precise fuel-air mixture, which is crucial for optimal performance. Additionally, these enhancements often lead to increased fuel efficiency, allowing for longer run times between refueling and reduced operational costs.

Choosing the Right Upgrade

Selecting the appropriate performance kit involves considering the specific needs of your engine. Factors such as intended use, terrain, and desired power levels play a crucial role in making the right choice. It’s essential to research various options and consult with experts to find a solution that aligns with your performance goals.

Environmental Considerations and Carburetor Settings

Considering the ecosystem, when adjusting the mechanism that blends fuel and air for optimal engine performance, it is crucial to take into account the impact on the surrounding environment. Environmental factors such as air quality and emissions regulations play a significant role in determining the appropriate settings for this essential component of internal combustion engines. Ensuring that the fuel mixture is finely tuned not only enhances engine efficiency but also reduces the potential for environmental harm by minimizing emissions. By calibrating the fuel-air mixture precisely, engine operators can contribute to sustainability efforts and maintain compliance with environmental standards.

Safety Precautions When Handling Carburetor Parts

When working with intricate fuel delivery systems, it is essential to prioritize safety. Proper handling and awareness of potential hazards can prevent accidents and ensure efficient maintenance. This section outlines crucial safety measures to adopt during the process.

Personal Protective Equipment

- Always wear safety goggles to protect your eyes from debris.

- Use gloves to avoid skin contact with chemicals and sharp components.

- Consider wearing a dust mask to prevent inhalation of fine particles.

Work Environment

- Ensure the workspace is well-ventilated to disperse any harmful fumes.

- Keep flammable materials away from the work area.

- Maintain an organized workspace to reduce the risk of accidents.

By adhering to these safety guidelines, you can effectively minimize risks and ensure a safer experience while working on fuel delivery systems.

Resources for Finding Genuine Honda GX200 Parts

When searching for authentic components for small engines, it’s crucial to have reliable resources at your disposal. Ensuring that you acquire the right elements not only guarantees optimal performance but also prolongs the lifespan of your machinery. Below are some effective avenues to consider when sourcing high-quality replacements.

Authorized Dealers and Retailers

- Check local authorized distributors for a selection of genuine items.

- Visit official websites of manufacturers to locate certified sellers.

- Explore online marketplaces that specialize in engine supplies and have a reputation for selling original products.

Online Forums and Communities

- Join dedicated forums where enthusiasts discuss maintenance and part sourcing.

- Participate in social media groups focused on small engine repairs to gain insights on trusted suppliers.

- Seek recommendations from experienced users about reliable online sources.

By utilizing these resources, you can confidently find the necessary components that meet quality standards and ensure the efficiency of your engine.