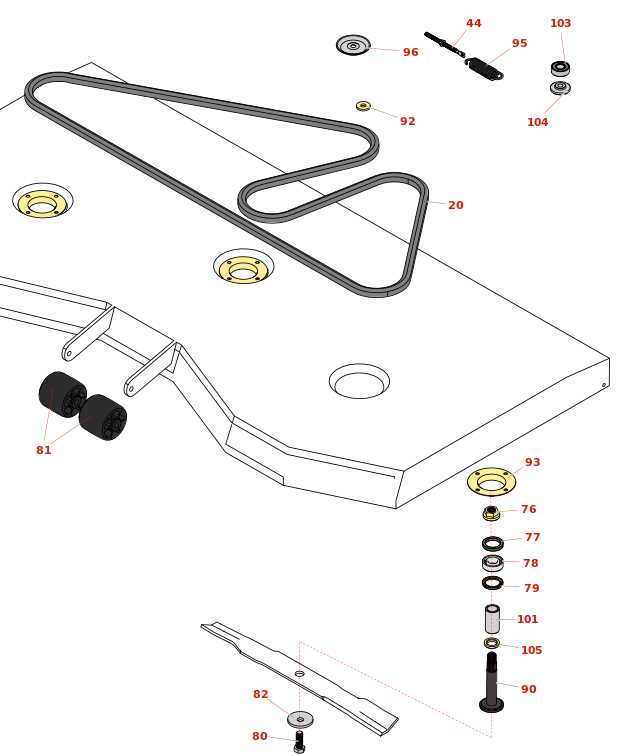

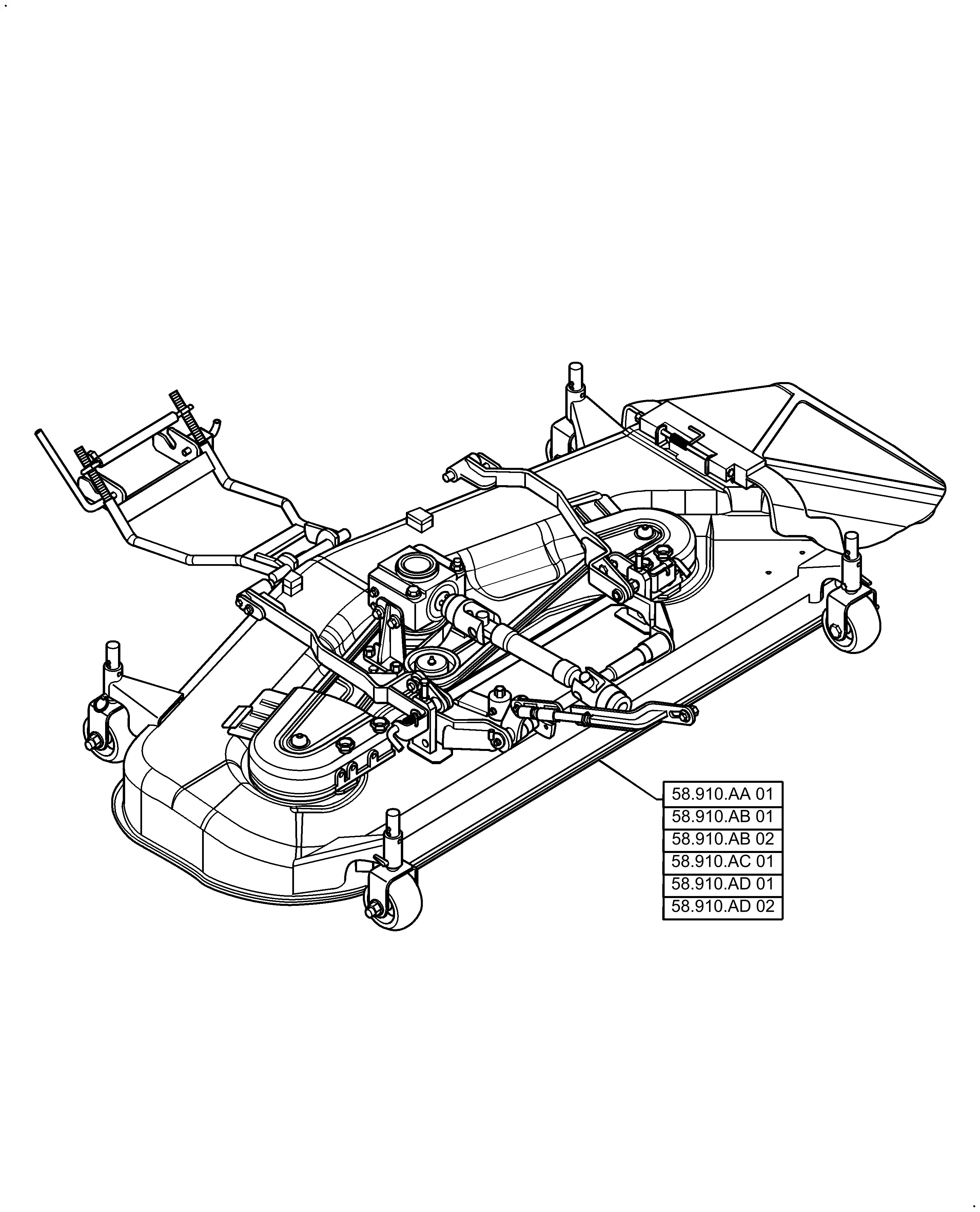

Drive Belt Routing for Optimal Performance

The proper alignment and installation of the drive belt are essential for achieving peak efficiency and durability in any machinery system. When the belt is positioned correctly, it ensures smooth transmission of power, reducing the risk of slippage or excessive wear over time. Understanding the route and maintaining it can significantly enhance the overall operation, minimizing downtime and extending the lifespan of key components.

Key Considerations for Belt Routing

To ensure optimal routing, inspect the belt path thoroughly, ensuring that it follows a clear, unobstructed line around all pulleys. Avoid any sharp bends or misalignments, as these can lead to premature wear or breakage. Regularly check the tension, ensuring it is tight enough for effective power transfer but not too tight to cause unnecessary strain on the system.

Maintenance Tips for Longevity

Periodically assess the belt for signs of wear, such as cracks or fraying edges. Replacing it before visible damage escalates can prevent costly repairs. Additionally, keeping pulleys clean and free of debris is crucial for smooth belt operation.

Spindle Assembly and Maintenance Tips

The spindle system plays a crucial role in ensuring efficient operation and optimal performance of the cutting equipment. Regular inspection and care of the spindle components can greatly enhance the lifespan and reliability of the machinery. Proper maintenance helps prevent wear and tear, which could lead to costly repairs and downtime.

Here are a few key tips to maintain the spindle assembly:

| Tip |

Description |

| Regular Lubrication |

Ensure the spindle bearings are properly lubricated to reduce friction and prevent overheating. |

| Inspect for Damage |

Regularly check for cracks, bending, or wear on the spindle shaft and housing to ensure they are in good condition. |

| Tighten Bolts |

Loose bolts can cause vibration and misalignment, so check and tighten them frequently. |

| Replace Worn Parts |

If any components of the spindle show signs of excessive wear, replace them immediately to prevent further damage. |

Following these basic guidelines will help ensure that your equipment runs smoothly and lasts longer, allowing for consistent and

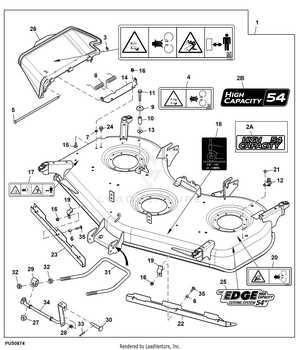

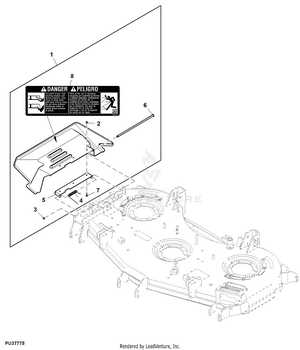

Discharge Chute Features and Function

The discharge chute is a crucial component that directs the flow of cut grass from the cutting assembly to the ground. Its design ensures effective dispersion, preventing clumping while promoting an even distribution of clippings. This feature enhances the overall performance of the machine, ensuring a clean and tidy finish in the landscape.

Design Characteristics

One of the primary attributes of the discharge chute is its shape and angle, which are engineered to optimize the ejection of clippings. The material used in its construction is typically durable, designed to withstand the rigors of outdoor use. Additionally, many chutes are adjustable, allowing users to modify the discharge direction based on their preferences or specific lawn conditions.

Maintenance Considerations

Regular maintenance of the discharge chute is essential for ensuring its longevity and optimal performance. This includes checking for blockages, cleaning debris, and inspecting for any wear or damage. Keeping the chute clear will promote better airflow and prevent issues that could affect the cutting efficiency of the equipment.

| Feature |

Description |

| Shape |

Engineered to enhance clipping dispersion. |

| Material |

Durable construction to withstand outdoor conditions. |

| Adjustability |

Can be modified to change discharge direction. |

| Maintenance |

Regular cleaning and inspection to ensure efficiency. |

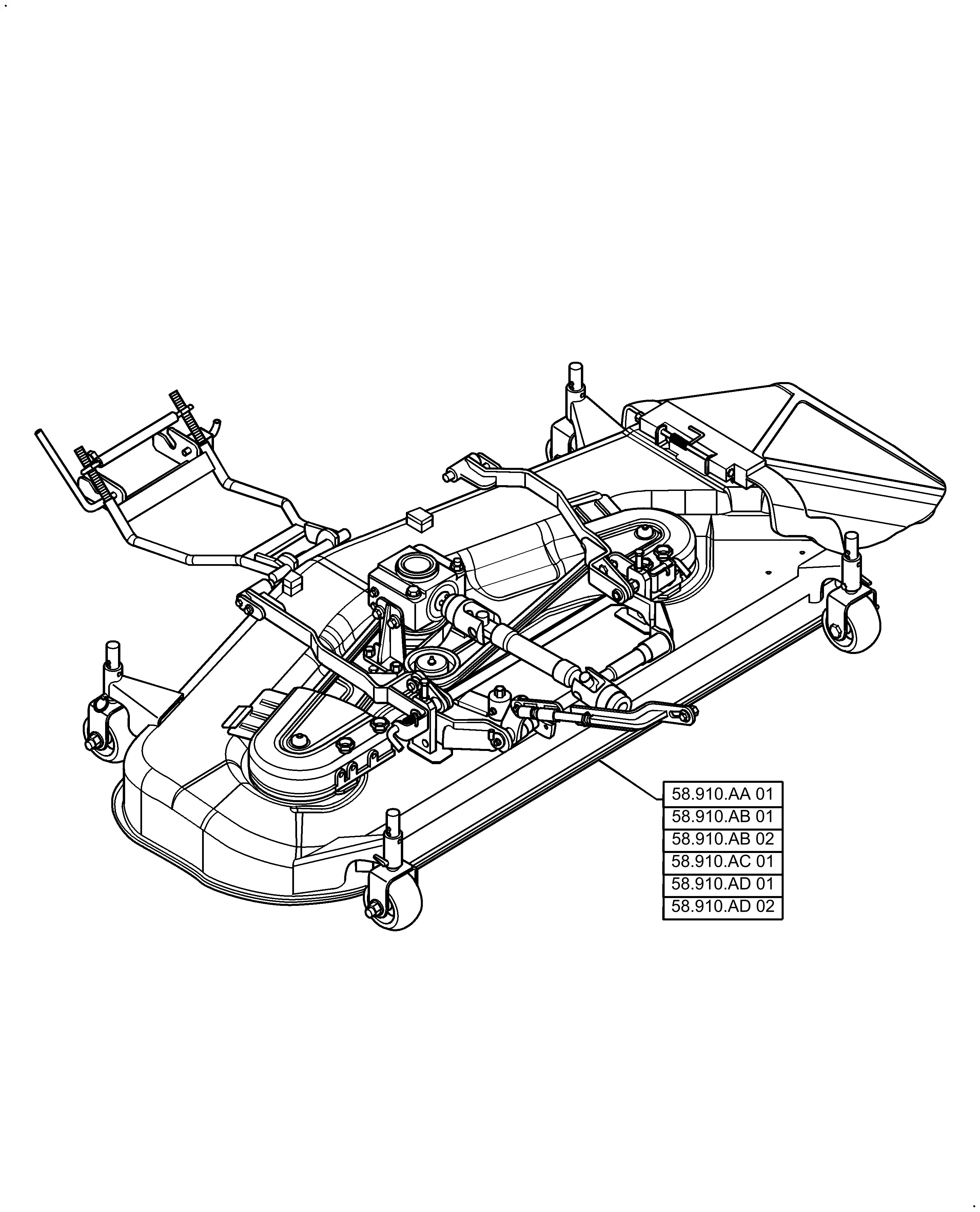

Deck Leveling and Adjustment Guide

Achieving the proper alignment of your cutting equipment is crucial for optimal performance and even results. Properly adjusting the cutting unit helps ensure a uniform cut, minimizes scalping, and extends the lifespan of the blades. This guide outlines the necessary steps to achieve effective leveling and adjustment, enhancing both the quality of your lawn care tasks and the durability of your equipment.

Follow these essential steps to adjust and level your cutting apparatus:

- Preparation:

- Ensure the equipment is on a flat, level surface.

- Check that the blades are clean and sharp.

- Wear appropriate safety gear during adjustments.

- Initial Measurements:

- Use a measuring tape to determine the height of the blades from the ground.

- Take measurements from multiple points across the width to check for discrepancies.

- Adjusting Height:

- Locate the adjustment mechanisms on the cutting unit.

- Turn the adjustment knobs or levers to raise or lower the blades as needed.

- Re-measure the height after each adjustment to ensure uniformity.

- Final Check:

- Conduct a test run to observe the cutting performance.

- Inspect the quality of the cut to confirm it meets your expectations.

- Make any additional adjustments as necessary for the best results.

Regularly checking and adjusting your cutting unit not only improves performance but also helps to avoid uneven wear and tear. Maintaining the correct height will lead to a healthier lawn and enhance the overall efficiency of your equipment.

Common Wear Parts and Replacements

Regular maintenance of outdoor equipment is crucial to ensure optimal performance and longevity. Certain components are prone to wear over time due to their constant interaction with the environment and mechanical stress. Identifying these elements and knowing when to replace them can significantly enhance efficiency and prevent further damage.

Key Components to Monitor

One of the most frequently replaced items are the blades, which can become dull or damaged after extensive use. Maintaining sharp blades is essential for effective cutting, as they provide cleaner results and reduce the strain on the engine. Additionally, belts used for driving the mechanism may stretch or wear, leading to slippage or reduced power transfer. Timely replacement of these belts ensures smooth operation.

Signs of Wear and Recommended Actions

When observing unusual noises or vibrations, it may indicate that components such as bearings or spindles require inspection. Regularly checking for play or resistance in these parts can help prevent more significant issues down the line. Furthermore, monitoring fluid levels and the condition of filters is essential for maintaining overall functionality and avoiding unexpected breakdowns.

How to Change the Mower Blades

Regularly replacing the cutting elements is essential for maintaining optimal performance and achieving a clean cut. This task, while straightforward, requires careful attention to detail to ensure safety and efficiency. Below are the steps to effectively change the cutting components.

- Gather necessary tools and materials, including:

- Wrench or socket set

- Safety gloves

- Protective eyewear

- Replacement blades

- Grease or lubrication (optional)

- Ensure the machine is powered off and disconnected from any power source.

- Lift the cutting platform for easier access to the blades.

- Using the appropriate tool, loosen and remove the fasteners securing the blades.

- Carefully detach the old blades from their mounts.

- Position the new blades in place, ensuring they are aligned correctly.

- Reattach the fasteners securely, tightening them according to the manufacturer’s specifications.

- Lower the cutting platform back to its operational position.

- Reconnect the power source and perform a test run to ensure everything is functioning properly.

Following these steps will help ensure your cutting equipment is in prime condition, providing excellent results throughout the cutting season.

Role of the Anti-Scalp Wheels

Anti-scalp wheels are crucial components in maintaining the health and appearance of a lawn. Their primary function is to prevent the cutting mechanism from digging into the ground, which can result in uneven grass height and damage to the turf. By supporting the cutting apparatus and allowing it to float over irregularities in the terrain, these wheels play a significant role in achieving a smooth and consistent cut.

Functionality and Benefits

These wheels operate by absorbing shocks and distributing the weight of the cutting assembly, ensuring that it remains level during operation. This not only enhances the quality of the cut but also minimizes the risk of scalping, where the blades may inadvertently remove too much grass, leading to unsightly patches. In addition, effective use of these wheels contributes to the longevity of the cutting equipment, reducing wear and tear that can occur when the blades come into contact with hard surfaces.

Adjustment and Maintenance

Regular inspection and adjustment of the anti-scalp wheels are essential for optimal performance. Properly calibrated wheels will maintain the desired cutting height while allowing for flexibility over varied landscapes. Ensuring that these wheels are in good condition can greatly enhance the overall functionality of the equipment, promoting a healthier lawn and a more efficient mowing experience.

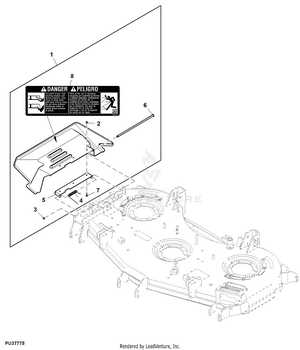

Cleaning and Protecting the Deck

Maintaining the surface of your equipment is essential for optimal performance and longevity. Regular cleaning helps prevent the buildup of debris, grass clippings, and dirt, which can lead to corrosion and impair functionality. Implementing protective measures further enhances durability and ensures that the machinery operates efficiently over time.

Steps for Effective Cleaning

- Start by disconnecting the power source to ensure safety during maintenance.

- Utilize a stiff brush or scraper to remove accumulated debris from the surface.

- Wash with a garden hose to rinse off any remaining dirt and grime.

- Allow the area to dry completely before proceeding with protective treatments.

Protective Measures

- Apply a protective coating to shield the surface from moisture and corrosion.

- Inspect for any signs of wear and address them promptly to prevent further damage.

- Store the equipment in a dry, sheltered area to reduce exposure to the elements.

Following these steps will help maintain the condition of your machinery, ensuring it remains functional and effective for years to come.

Troubleshooting Common Deck Issues

When it comes to maintaining your lawn equipment, recognizing and addressing typical challenges is crucial for optimal performance. Understanding the most frequent problems can help ensure that your apparatus functions smoothly and efficiently, allowing you to achieve the best results in your gardening tasks.

Uneven Cutting Results

If you notice that the grass is being cut unevenly, it can be a source of frustration. This issue may arise from several factors, including improper height settings or a buildup of debris on the surface. To remedy this, first check the height adjustment settings to ensure they are uniform across all corners. Additionally, inspect for any accumulated grass or dirt that could obstruct the blades. Regular cleaning and maintenance can prevent this problem from recurring.

Excessive Vibration and Noise

Excessive vibrations or unusual noises can indicate underlying mechanical issues. Often, this stems from dull or damaged blades, which can not only impair cutting efficiency but also lead to further complications. Inspect the blades for wear and ensure they are sharpened regularly. Furthermore, examine all attachment points for looseness or damage, as secure connections are essential for smooth operation.

|