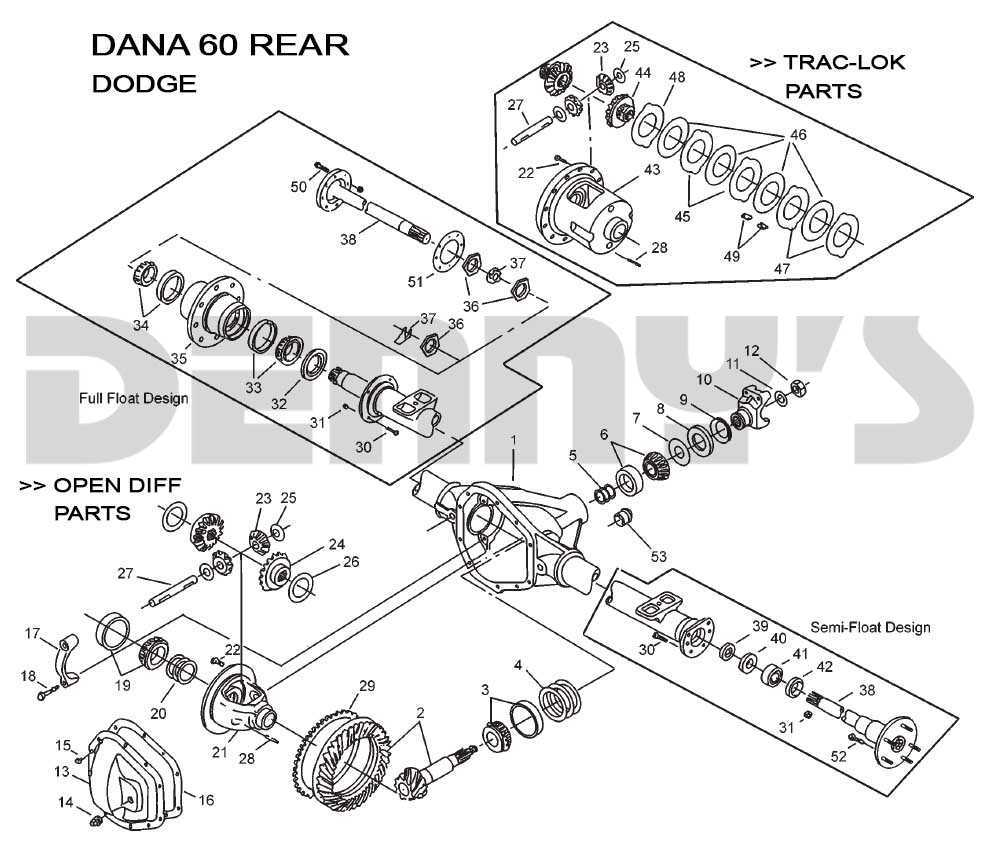

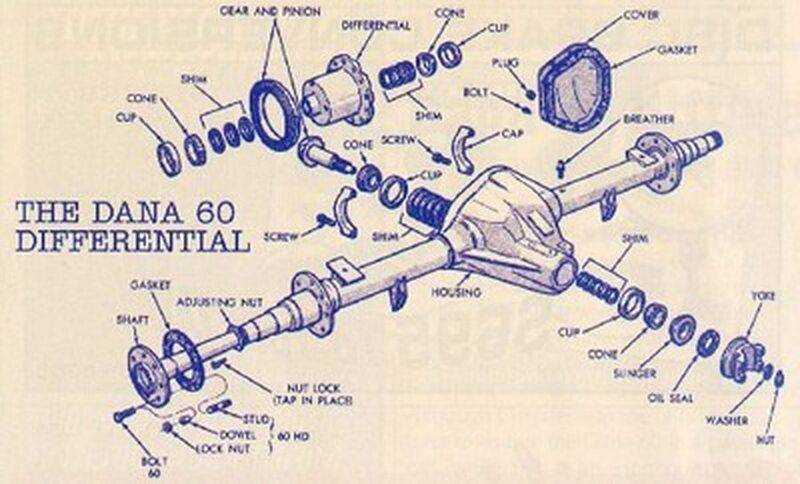

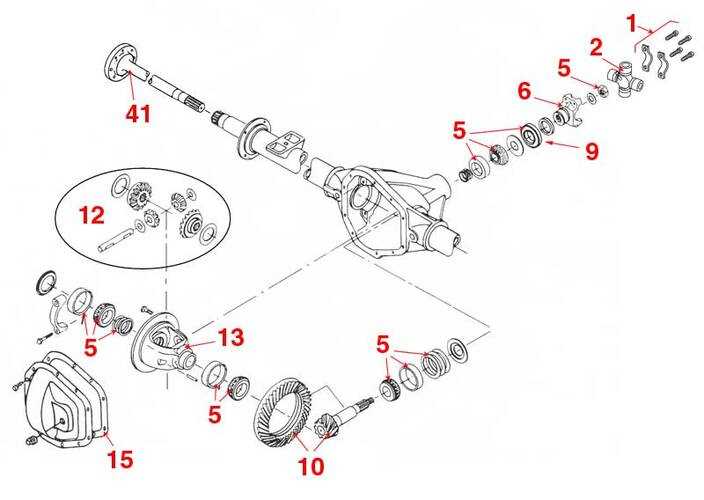

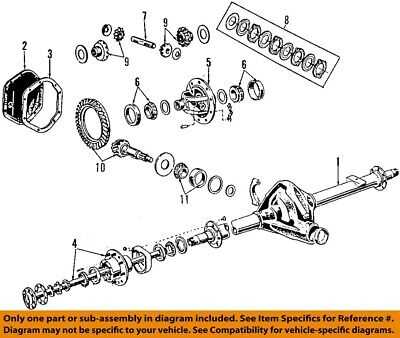

Dana 60 Rear Axle Parts Overview

Understanding the intricacies of mechanical structures is crucial for ensuring a smooth and reliable performance in various transportation systems. The ability to identify and recognize key elements can greatly enhance the efficiency and durability of these mechanisms. Each element plays a specific role in maintaining balance, control, and power distribution, contributing to the overall functionality.

In this context, it’s important to delve into the details of these interconnected elements, exploring their functions and how they work together to ensure seamless motion. By examining the arrangement and interactions of these crucial components, one gains insight into the technical prowess behind their operation. This knowledge is valuable for maintenance, troubleshooting, and optimizing performance in a variety of mechanical setups.

With a focus on structure and configuration, this guide aims to provide a deeper understanding of the complex interactions within these systems. The discussion will shed light on the relationships between different components, helping to appreciate the precision required for effective operation and longevity. This exploration is ideal for enthusiasts looking to improve their grasp of the subject.

Dana 60 Rear Axle Parts Overview

This section delves into the key elements that compose the structure of a robust differential system. It covers the integral components, ensuring smooth operation and durability in demanding conditions. Understanding these elements can provide insights into maintenance and optimal performance of the vehicle’s drivetrain system.

Core Mechanical Elements

The structure features several crucial mechanisms that work together to distribute power efficiently. Among these are the heavy-duty shafts and gear systems, which are designed to endure significant stress and provide consistent torque distribution. Their precise alignment ensures a balanced transfer of energy, preventing wear and extending the lifespan of the system.

Supportive Components

Supporting elements, such as sealing mechanisms and housings, play a vital role in maintaining the system’s integrity. These parts protect internal mechanisms from external factors like dust and moisture, ensuring that lubrication remains effective. The protective coverings and mounts also help to minimize vibrations, contributing to a smoother driving experience.

Understanding the Structure of Dana 60

The composition of this robust mechanical component is crucial for ensuring efficient performance and durability. Its design incorporates various interconnected elements that work together, providing stability and power transfer capabilities. Each segment plays a role in maintaining balance and withstanding significant stress during use.

Core Components and Their Roles

The assembly features a central mechanism that supports rotational movement, allowing for smooth functionality in challenging conditions. Key elements include a central gear system, strong supports, and specialized bearings that ensure efficient movement and reduced friction. These elements are designed for precision, enhancing the overall efficiency and resilience of the unit.

Balancing Load and Force Distribution

This setup is designed to handle substantial loads while distributing force evenly. Its strategic arrangement of gears and supports helps in maintaining smooth operation even under high pressure. The balance of power within the structure ensures a consistent and stable performance, which is vital for heavy-duty applications.

Key Components in the Rear Axle

The mechanical structure in question contains several crucial elements that work together to ensure smooth motion and stability. Each piece plays a specific role, contributing to the overall functionality and durability of the entire setup. Understanding these elements helps in maintaining and optimizing the system for better performance.

Central Gear Assembly

The central part of the mechanism involves a gear system that transfers energy from the power source to the rotating elements. This assembly ensures that force is evenly distributed, allowing for efficient movement. It is designed to handle high levels of stress while maintaining precise control over the rotational speed.

Supportive Bearings and Seals

Bearings and seals are essential for reducing friction and protecting the internal components from external contaminants. These parts help in maintaining a smooth operation by ensuring that the moving elements remain properly aligned. Seals prevent moisture and debris from entering, which can significantly prolong the life of the entire system.

Assembly Guide for Dana 60 Axle

This guide provides detailed instructions on assembling a robust vehicle component known for its strength and durability. The process involves precise alignment and fitting of various elements to ensure optimal performance and reliability.

Preparation and Necessary Tools

Before beginning, ensure all required tools and materials are available. This includes specialized wrenches, torque tools, and lubricants for smooth operation. Proper organization will streamline the assembly process, reducing the chances of errors.

- Socket set and torque wrench

- High-quality lubricant

- Protective gloves and eyewear

Step-by-Step Assembly Instructions

Follow the steps carefully to align and secure each component accurately. Begin by placing the main structure onto a stable work surface, then proceed with attaching smaller elements.

- Position the main structure horizontally and ensure it is balanced.

- Insert the rotating shafts, making sure they align smoothly with the housing.

- Secure the bearings in place, applying the recommended amount of grease for smooth rotation.

-

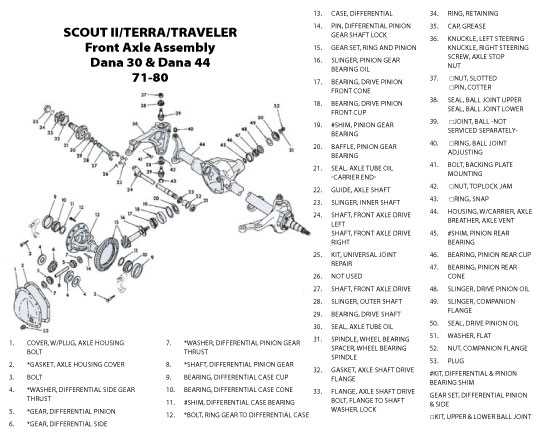

Exploring Differential Parts in Dana 60

Understanding the various elements within a differential mechanism is essential for those looking to optimize vehicle performance. This section highlights the key components, their roles, and how they contribute to smooth functionality during movement.

Main Internal Components

- Carrier Assembly: A crucial piece that houses gears, allowing for the transfer of rotational force and maintaining stability during turns.

- Ring Gear: A large gear that directly engages with the drive mechanism, translating power into movement. Its size and quality greatly affect performance.

- Pinion Gear: Works in tandem with the ring gear to control torque and provide a balanced distribution of power.

Supporting Elements

These secondary elements ensure the longevity and smooth operation of the entire setup.

- Bearings: Reduce friction between moving parts, helping to maintain smooth rotations and minimize wear.

- Seals: Prevent fluid leaks, protecting internal com

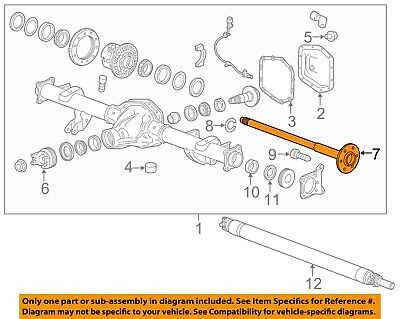

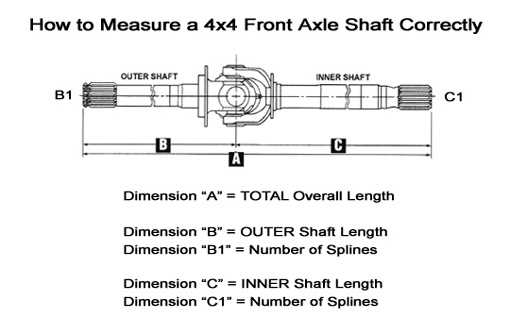

Axle Shaft Specifications and Features

The following section outlines essential characteristics and specifications of the shaft components commonly used in heavy-duty vehicle applications. These components play a critical role in transmitting power and ensuring optimal performance across various terrains.

Specification Description Material High-strength steel alloy for enhanced durability and resistance to wear. Diameter Typically ranges from 30mm to 40mm, depending on the load requirements. Length Varies based on vehicle design; usually between 700mm and 1200mm. Thread Type Fine and coarse threads are available for different mounting applications. Load Rating Can support loads up to 10,000 lbs, tailored for off-road and heavy-duty use. Common Replacement Parts for Dana 60

When maintaining high-performance vehicles, it is crucial to understand the essential components that often require replacement over time. Several key items contribute to the overall functionality and durability of the system, ensuring optimal operation under various conditions. Below is a list of frequently replaced components that are vital for enhancing longevity and performance.

Essential Components

The following elements play significant roles in the smooth functioning of the assembly:

Component Description Ring Gear The main gear responsible for transferring power to the wheels. Pinion Gear A smaller gear that meshes with the ring gear to facilitate rotation. Carrier Assembly Holds the ring gear and supports the differential action. Differential Bearings Support the differential and allow smooth rotation of the gears. Seals and Gaskets Prevent fluid leaks and protect internal components from contaminants. Replacement Considerations

When selecting replacements, it is important to consider quality and compatibility with existing systems. Utilizing premium materials enhances performance and reduces the likelihood of future failures. Regular inspections can help identify worn components early, allowing for timely replacements.

Maintenance Tips for Rear Axle Parts

Regular upkeep of critical components is essential to ensure optimal performance and longevity of your vehicle. Understanding the importance of maintenance can prevent costly repairs and enhance the overall driving experience.

Routine Inspection

Conducting frequent assessments of the key elements helps identify potential issues early. Pay attention to the following:

- Check for signs of wear and tear, including cracks and corrosion.

- Inspect seals and gaskets for leaks, which can lead to fluid loss.

- Ensure that mounting hardware is secure and free from rust.

Lubrication Practices

Proper lubrication is vital for smooth operation. Consider the following practices:

- Use high-quality lubricant recommended for your specific setup.

- Apply lubricant to all moving parts to minimize friction and wear.

- Regularly change the lubricant according to the manufacturer’s guidelines.

By adhering to these essential maintenance tips, you can significantly extend the lifespan of your vehicle’s components and improve overall efficiency.

Identifying Issues in Dana 60 Assembly

When it comes to the assembly of specific drivetrain components, recognizing potential problems is crucial for optimal performance. Ensuring that every piece is correctly fitted and functions harmoniously can significantly enhance the durability and reliability of the entire system.

Common Problems to Look For

- Misalignment: Incorrect positioning of elements can lead to uneven wear and decreased efficiency.

- Worn Bearings: Over time, bearings can deteriorate, affecting the smooth operation of the unit.

- Inadequate Lubrication: Insufficient grease can cause overheating and rapid deterioration of components.

- Cracks and Defects: Inspect for any visible fractures or irregularities in the structure that may compromise integrity.

Diagnostic Steps

- Perform a visual inspection of all components for signs of wear or damage.

- Check for proper alignment by measuring the distances between critical points.

- Assess lubrication levels and ensure that all moving parts are adequately serviced.

- Test the assembly under load to identify any irregular noises or vibrations.

Compatibility of Dana 60 with Upgrades

The ability to enhance the performance and durability of specific vehicle components is essential for many enthusiasts and off-road drivers. Understanding how certain modifications can integrate with existing systems allows for a more robust and reliable setup. This section explores various upgrade options and their compatibility with the mentioned component.

Common Upgrades and Their Benefits

- High-Performance Differentials: Upgrading to a more robust differential can improve traction and torque management.

- Improved Gearing: Switching to lower or higher gear ratios can optimize power delivery for different driving conditions.

- Heavy-Duty Suspension: Enhancing the suspension system provides better stability and load handling, essential for off-road applications.

- Disc Brake Conversions: Upgrading to disc brakes can improve stopping power and reliability.

Compatibility Considerations

When selecting upgrades, it’s important to consider various factors:

- Measurement Specifications: Ensure that any upgraded components match the original dimensions.

- Material Strength: Choose parts made from high-quality materials to ensure durability and performance.

- Weight Distribution: Modifications should not adversely affect the vehicle’s balance and handling.

- Installation Requirements: Some upgrades may require specific tools or professional installation for optimal results.

Ultimately, aligning enhancements with existing frameworks will lead to a more effective and enjoyable driving experience.

Locating Diagrams for Axle Components

Understanding the layout of essential components in a vehicle’s drive system is crucial for effective maintenance and repairs. These illustrations serve as visual guides, making it easier to identify various elements and their functions. With accurate schematics, you can enhance your knowledge and streamline the process of working on the mechanical systems.

To efficiently locate illustrations for these components, consider the following resources:

- Manufacturer Manuals: Original manuals often contain detailed diagrams that showcase the layout and specifications of critical parts.

- Online Forums: Enthusiast communities frequently share resources, including schematics and personal experiences that can provide valuable insights.

- Repair Shops: Professional garages may offer access to technical documentation and diagrams for various vehicle models.

- Parts Suppliers: Websites of parts distributors often feature illustrations that assist in identifying compatible components.

When searching for visual references, ensure that you are accessing reputable sources to obtain the most accurate and up-to-date information. Familiarity with these diagrams can significantly enhance your understanding and ability to address mechanical issues.