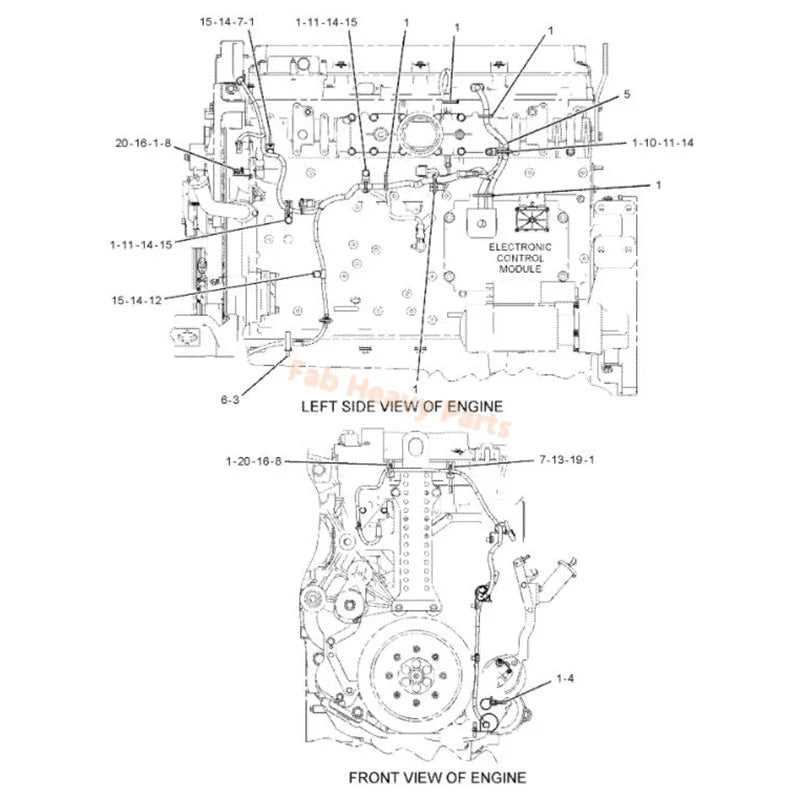

Understanding the Cat C13 Parts Diagram for Optimal Maintenance

The intricate design of machinery often includes a variety of elements that work harmoniously to ensure optimal performance. Each section plays a crucial role in the overall functionality of the system, contributing to efficiency and durability. Recognizing these components is essential for maintenance and repair.

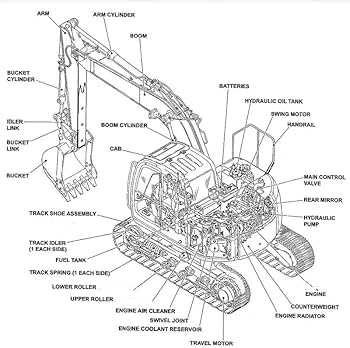

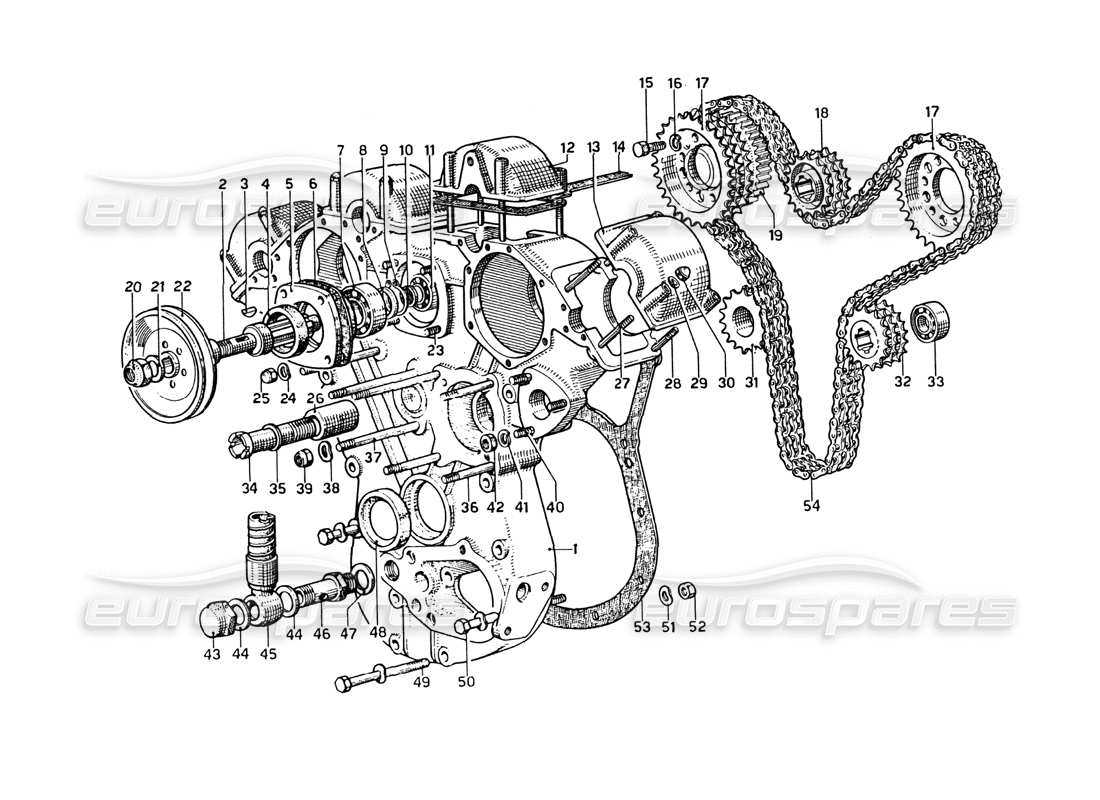

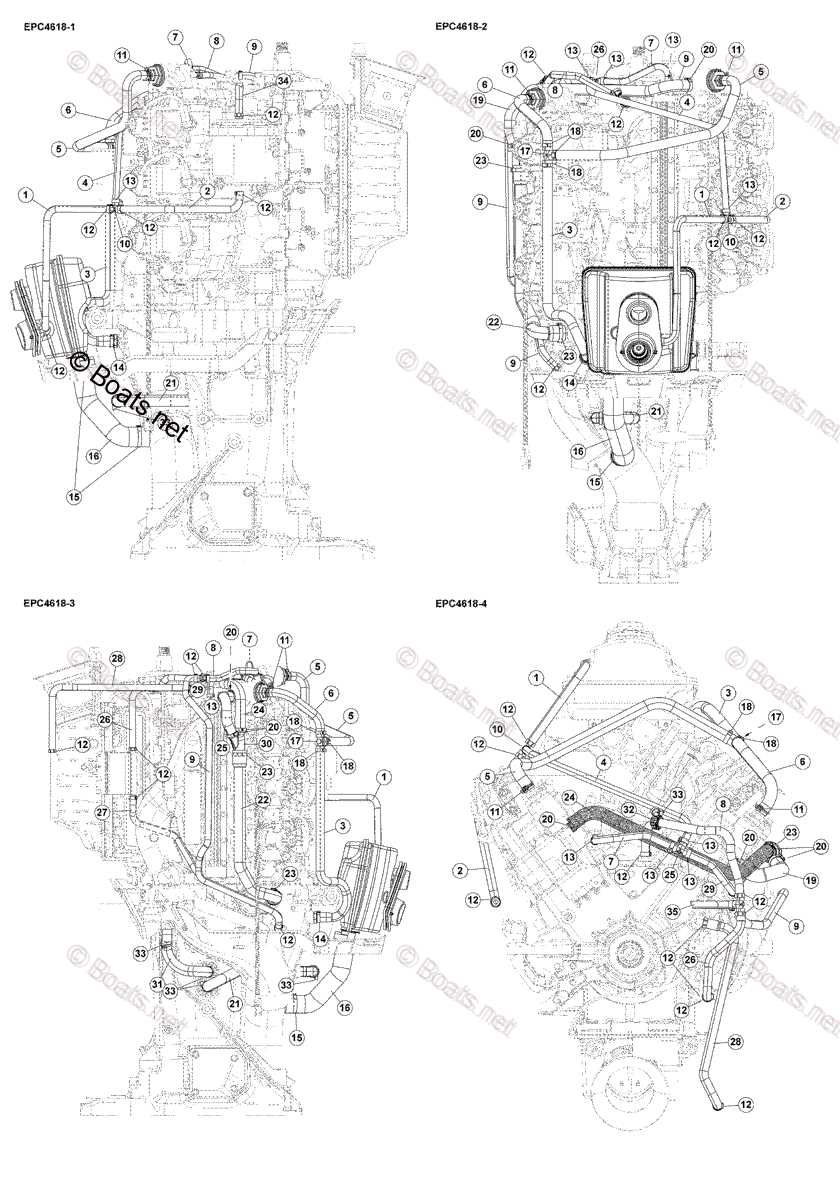

Within the realm of heavy machinery, it is vital to have a clear visual representation of each constituent. This allows operators and technicians to identify specific parts easily, enhancing their ability to troubleshoot issues and implement necessary repairs. A well-organized visual guide can serve as a valuable resource in this regard.

By examining the layout and interconnection of various elements, one can gain insights into how each piece contributes to the engine’s operation. Understanding these relationships not only aids in immediate repairs but also fosters a deeper appreciation for the engineering behind these powerful machines.

Understanding Cat C13 Engine Components

Gaining insight into the elements of an engine is essential for effective maintenance and operation. Each component plays a crucial role in the overall functionality, ensuring that the machinery runs smoothly and efficiently.

- Block: The foundational structure housing various parts.

- Pistons: These move up and down, converting energy into mechanical motion.

- Cylinder head: This part seals the top of the cylinders and contains vital mechanisms for air and fuel management.

- Crankshaft: It transforms the linear motion of the pistons into rotational energy.

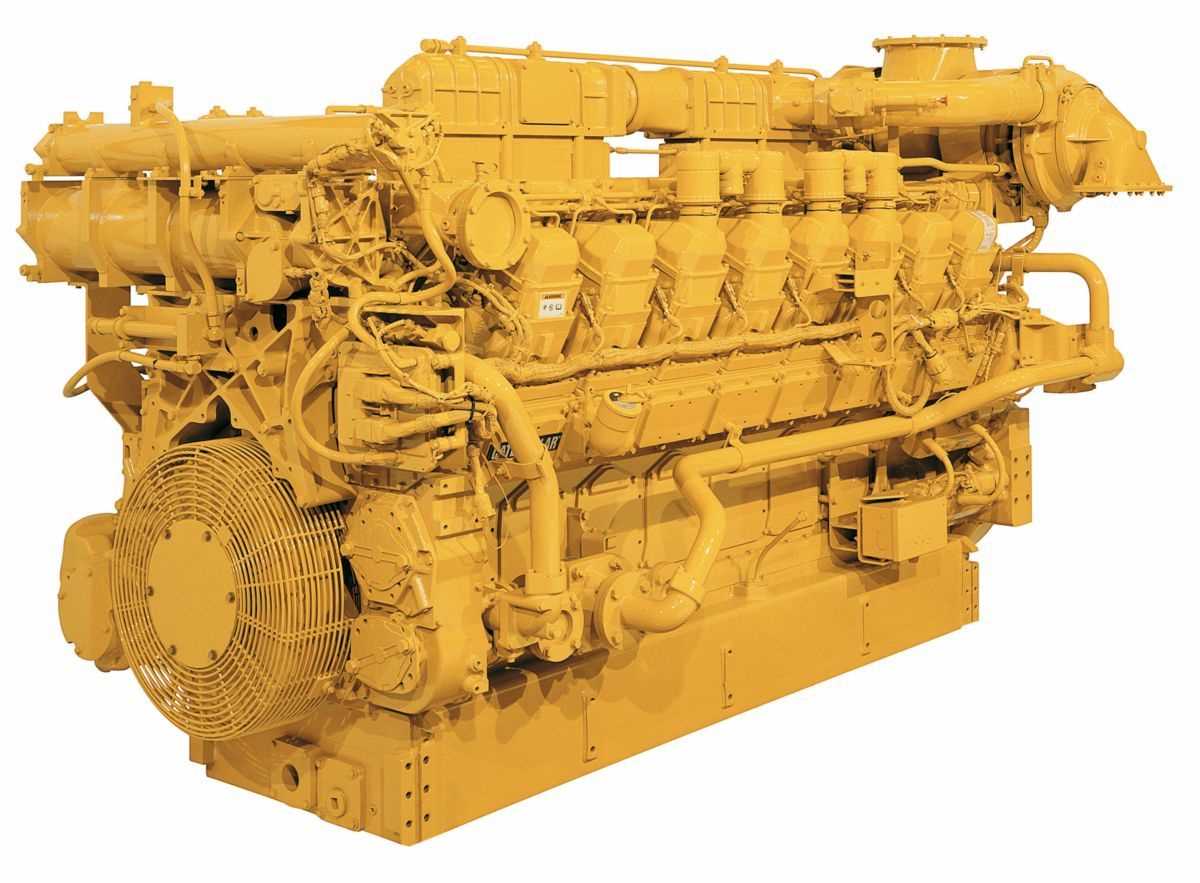

- Turbocharger: An essential component for enhancing performance by increasing air intake.

- Fuel injectors: Responsible for delivering the precise amount of fuel into the combustion chamber.

Each of these elements contributes significantly to the performance and efficiency of the engine, making it essential to understand their functions and interconnections.

Key Features of Cat C13 Parts

This section explores the essential characteristics that define the components of a specific engine model known for its reliability and performance. Understanding these features is crucial for effective maintenance and optimization of functionality.

One of the standout attributes is the robust construction, designed to withstand harsh operating conditions while providing longevity. Each element is engineered with precision, ensuring compatibility and seamless integration with other system components.

Moreover, the efficiency of these components plays a vital role in overall engine performance. Enhanced fuel efficiency leads to reduced operational costs, making it an economical choice for various applications. Additionally, advancements in technology have allowed for improved thermal management, contributing to better performance under load.

Ease of access for maintenance is another important characteristic, simplifying the servicing process and minimizing downtime. Well-organized layouts and thoughtful design ensure that technicians can perform necessary checks and replacements swiftly.

Finally, these components often come with comprehensive support from manufacturers, including detailed documentation and training resources, ensuring users can maximize their investment and maintain optimal functionality throughout the product’s life cycle.

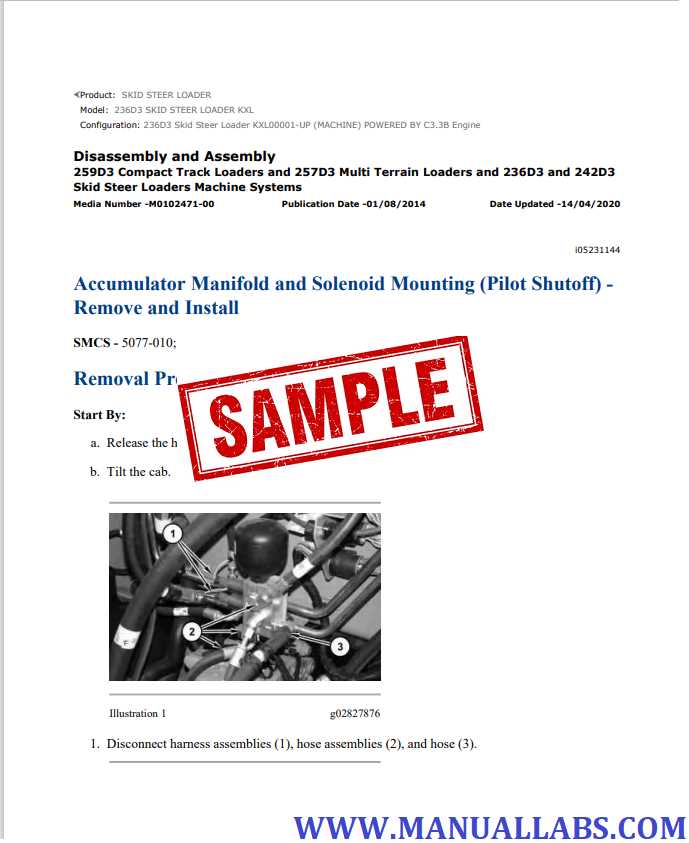

Importance of Accurate Parts Diagrams

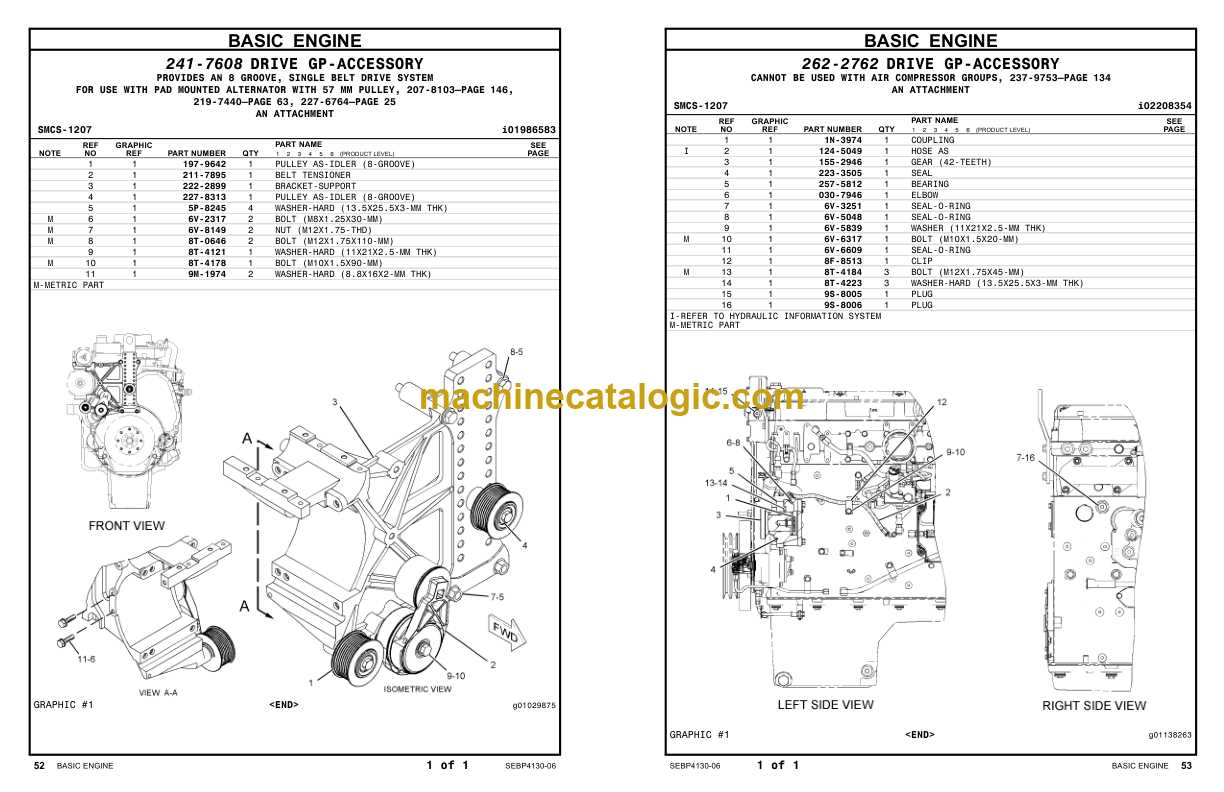

Having precise visual representations of components is crucial for effective maintenance and repair operations. These illustrations serve as a reliable reference, allowing technicians and engineers to identify specific elements quickly and efficiently. When dealing with complex machinery, clarity in visual guides can significantly reduce the time spent troubleshooting and assembling equipment.

Enhanced Understanding

Detailed schematics facilitate a deeper comprehension of how different elements interact within a system. By presenting intricate layouts, these visuals help users grasp the functionality and arrangement of components, fostering better problem-solving abilities. This enhanced understanding ultimately leads to improved performance and longevity of the equipment.

Reduction of Errors

Accurate visual aids play a vital role in minimizing mistakes during installation or repairs. When users have clear references, the likelihood of misplacing or incorrectly assembling components decreases significantly. This precision not only saves time but also prevents costly damages and downtime, ensuring that operations run smoothly and efficiently.

Common Issues with Cat C13 Engines

Engines of this model are known for their reliability, yet they can encounter various challenges during operation. Understanding these potential problems can help in maintaining optimal performance and preventing significant repairs. Regular monitoring and timely interventions are key to ensuring longevity and efficiency.

Overheating Problems

One prevalent issue is overheating, often caused by inadequate coolant levels or a malfunctioning thermostat. When temperatures rise beyond normal limits, it can lead to severe damage. Regular inspections of the cooling system, including hoses and radiators, are essential to prevent this problem.

Fuel System Complications

Another common concern involves the fuel system, which may experience clogging or leaks. Contaminated fuel can affect engine performance, leading to misfires or reduced power. Routine fuel filter replacements and using high-quality fuel can mitigate these risks significantly.

How to Read Parts Diagrams Effectively

Understanding complex schematics can greatly enhance your ability to identify components and their functions. Mastering this skill is essential for efficient maintenance and repairs.

Follow these steps to interpret these illustrations effectively:

- Familiarize Yourself with the Symbols:

- Learn common icons and their meanings.

- Understand color codes and line styles.

- Identify Key Sections:

- Locate the title or header for context.

- Focus on the legend or key for component identification.

- Trace Connections:

- Follow lines to see how parts interconnect.

- Note any annotations that provide additional information.

- Consult Supplementary Resources:

- Use manuals or guides for deeper insights.

- Look for online forums for community support.

By applying these techniques, you can navigate technical illustrations with confidence and efficiency.

Maintenance Tips for Cat C13 Parts

Proper upkeep of essential components is crucial for optimal performance and longevity. Regular attention not only enhances efficiency but also minimizes unexpected breakdowns, ensuring smoother operations over time. This section provides key insights into maintaining critical elements effectively.

Regular Inspection

Conducting frequent examinations of vital components can help identify wear and tear early. Look for signs of corrosion, leaks, or unusual noises during operation. Establish a schedule for these checks to ensure no detail is overlooked.

Lubrication and Cleaning

Maintaining cleanliness and adequate lubrication is vital for functionality. Use appropriate lubricants as recommended by the manufacturer to reduce friction and prevent premature wear. Additionally, keep all surfaces free from debris to promote efficient performance.

Identifying Cat C13 Components Easily

Understanding the various elements of an engine can significantly enhance maintenance and repair efficiency. Familiarizing oneself with the different components and their functions allows for quicker troubleshooting and better overall performance. This section aims to provide guidance on recognizing key elements, ensuring a seamless experience when dealing with engine-related tasks.

Key Components to Recognize

- Block: The main structure that houses critical components.

- Fuel Injectors: Responsible for delivering fuel into the combustion chamber.

- Turbocharger: Increases engine efficiency by forcing extra air into the combustion process.

- Oil Pump: Circulates lubricant to reduce friction and wear.

- Radiator: Cools the engine by dissipating heat from the coolant.

Tips for Effective Identification

- Utilize labeled schematics to understand component locations and functions.

- Familiarize yourself with common terminology used in engine maintenance.

- Engage with online forums or manuals for visual references and detailed descriptions.

- Consider hands-on practice to reinforce theoretical knowledge.

Aftermarket Parts vs. OEM Components

The choice between third-party offerings and manufacturer-sourced items often leads to a significant discussion among enthusiasts and professionals. Understanding the differences in quality, cost, and availability can help users make informed decisions for their machinery.

When considering aftermarket and original equipment components, several factors come into play:

- Quality: Aftermarket options may vary widely in quality, while OEM products typically ensure a consistent standard.

- Cost: Third-party parts often come at a lower price, appealing to budget-conscious buyers.

- Availability: Aftermarket items can be easier to source, especially for older models.

- Warranty: OEM components usually offer better warranty coverage, providing peace of mind.

Ultimately, the decision hinges on individual needs and preferences, weighing short-term savings against long-term reliability.

Tools Needed for Cat C13 Repairs

Effective maintenance and repairs require a specific set of instruments to ensure efficiency and accuracy. Understanding which tools are essential can greatly enhance the repair process, minimizing downtime and maximizing performance.

Essential Hand Tools

Basic hand tools such as wrenches, screwdrivers, and pliers are indispensable for disassembly and reassembly tasks. Torque wrenches are crucial for applying the correct tension to bolts, while socket sets allow for easier access to tight spaces.

Specialized Equipment

In addition to standard tools, specialized equipment like diagnostic scanners and compression testers provide deeper insights into engine performance and potential issues. These tools are essential for accurately pinpointing problems and ensuring thorough repairs.

Safety Precautions During Engine Work

When undertaking maintenance or repairs on any motor unit, ensuring a safe working environment is paramount. Various hazards can arise from mechanical components, fuel, and electrical systems. Proper precautions not only protect the individual performing the work but also safeguard the equipment and surrounding personnel.

Essential Safety Measures

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and steel-toed boots.

- Ensure the work area is well-ventilated to minimize exposure to harmful fumes.

- Disconnect the battery before performing any electrical work to prevent accidental shocks.

- Use tools that are specifically designed for the task to avoid injury and damage to components.

- Keep a fire extinguisher nearby, especially when working with flammable materials.

Work Environment Considerations

- Maintain a clean workspace to reduce the risk of slips and falls.

- Store all fluids in proper containers to avoid leaks and spills.

- Utilize jack stands and ramps when elevating equipment to ensure stability.

- Follow manufacturer guidelines for specific procedures and torque specifications.

- Never work alone; having a second person can provide assistance in case of an emergency.

By adhering to these precautions, individuals can significantly reduce the risks associated with engine maintenance, ensuring a safer and more efficient working experience.

Where to Find Replacement Parts

Locating components for machinery can often be a daunting task. However, there are several reliable avenues to explore for sourcing the necessary items to ensure optimal performance and longevity of your equipment.

Start by checking authorized dealers and service centers, as they typically carry a comprehensive selection of genuine components. Online marketplaces also offer a wide range of options, where you can compare prices and availability. Additionally, joining forums or community groups dedicated to your specific machinery can provide valuable insights and recommendations from fellow enthusiasts and professionals.

Don’t overlook local salvage yards or surplus stores, as they can be treasure troves for hard-to-find components at a fraction of the cost. By delving into these resources, you can find what you need to maintain your machinery effectively.

Understanding Warranty for Engine Parts

When investing in components for heavy machinery, understanding the warranty associated with those components is essential. A warranty serves as a promise from the manufacturer regarding the performance and longevity of the item. This section delves into the critical aspects of warranties related to engine components, providing insights into what consumers should know.

Warranties typically encompass several key elements:

- Coverage Duration: This refers to the length of time the warranty is valid. It can range from a few months to several years, depending on the manufacturer and the type of component.

- Scope of Coverage: Not all issues may be covered. Understanding what is included and excluded is vital for avoiding surprises.

- Claim Process: Familiarizing oneself with the steps required to file a warranty claim ensures a smoother experience in case of defects.

In addition, there are important considerations to keep in mind:

- Documentation: Always retain receipts and warranty information for future reference.

- Maintenance Requirements: Many warranties stipulate that regular maintenance must be performed to keep the warranty valid.

- Transferability: Some warranties may be transferable to new owners, adding value if you decide to sell your equipment.

Understanding these aspects will not only protect your investment but also enhance the overall reliability of your machinery.

Upgrading Components for Better Performance

Enhancing the efficiency of your machinery involves selecting superior elements that can significantly improve its functionality. By focusing on key upgrades, you can optimize performance and ensure longevity, leading to more reliable operations.

Key Areas for Improvement

- Engine Upgrades

- Fuel System Enhancements

- Cooling Systems

- Exhaust Modifications

Benefits of Upgrading

- Increased Power Output

- Improved Fuel Efficiency

- Enhanced Durability

- Better Heat Management

Investing in these upgrades not only elevates performance but also contributes to a more sustainable and efficient operation overall.