Understanding the Parts Diagram of Briggs and Stratton Engines

The intricacies of small power units reveal a fascinating interplay of elements that work in harmony to deliver performance and reliability. Each individual piece plays a crucial role, contributing to the overall functionality and efficiency of the machinery. Grasping the relationships among these components enhances not only repair knowledge but also fosters a deeper appreciation for mechanical design.

In this exploration, we will delve into the various constituents that make up these vital machines. From ignition systems to fuel delivery mechanisms, each segment is engineered with precision to ensure optimal operation. Understanding their arrangement and interaction is key for anyone looking to maintain or troubleshoot these units effectively.

By familiarizing oneself with the specific roles and arrangements of these parts, enthusiasts and professionals alike can improve their skills in diagnosing issues and performing necessary upkeep. This knowledge serves as a foundation for enhancing both performance and longevity, ultimately leading to a more satisfying experience in working with small machinery.

Understanding Briggs and Stratton Engines

When delving into the world of small power units, it’s essential to grasp the fundamental aspects that define their operation and efficiency. These machines are widely recognized for their reliability and performance across various applications, from lawn maintenance to construction tasks. Understanding their core components and functionalities can significantly enhance your experience and knowledge.

Essentially, these power sources are composed of several critical elements that work in harmony. Each component plays a unique role, contributing to the overall functionality and efficiency of the system. Familiarity with these elements allows for better maintenance and troubleshooting, ensuring longevity and optimal performance.

Moreover, recognizing the significance of regular upkeep cannot be overstated. Proper care not only extends the lifespan of these machines but also enhances their performance, making tasks easier and more efficient. A well-maintained unit operates smoothly, reducing the risk of unexpected breakdowns and improving overall productivity.

Importance of Parts Diagrams

Understanding the layout and components of machinery is essential for effective maintenance and repair. Visual representations serve as invaluable resources, enabling users to identify individual elements and their interconnections. This clarity is crucial for troubleshooting and ensuring that each piece functions optimally within the larger assembly.

Facilitating Repairs

When addressing mechanical issues, having a clear reference can significantly expedite the repair process. Users can pinpoint the exact location of each component, allowing for more efficient disassembly and reassembly. This not only saves time but also reduces the risk of errors that could arise from guesswork.

Enhancing Understanding

Visual aids contribute to a deeper comprehension of how different elements interact. For those unfamiliar with a particular machine, these representations demystify complex structures. By studying the layout, individuals can gain insights into operational principles, leading to better overall performance.

| Benefit | Description |

|---|---|

| Efficiency | Speeds up the repair process by providing clear guidance. |

| Accuracy | Reduces errors during assembly and disassembly. |

| Education | Helps users understand machine operations and components. |

| Accessibility | Makes complex machinery more approachable for novices. |

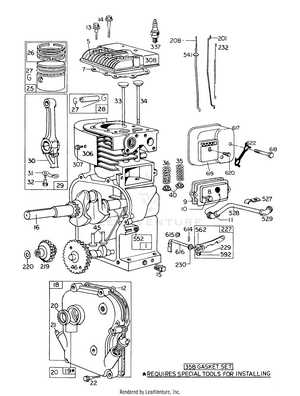

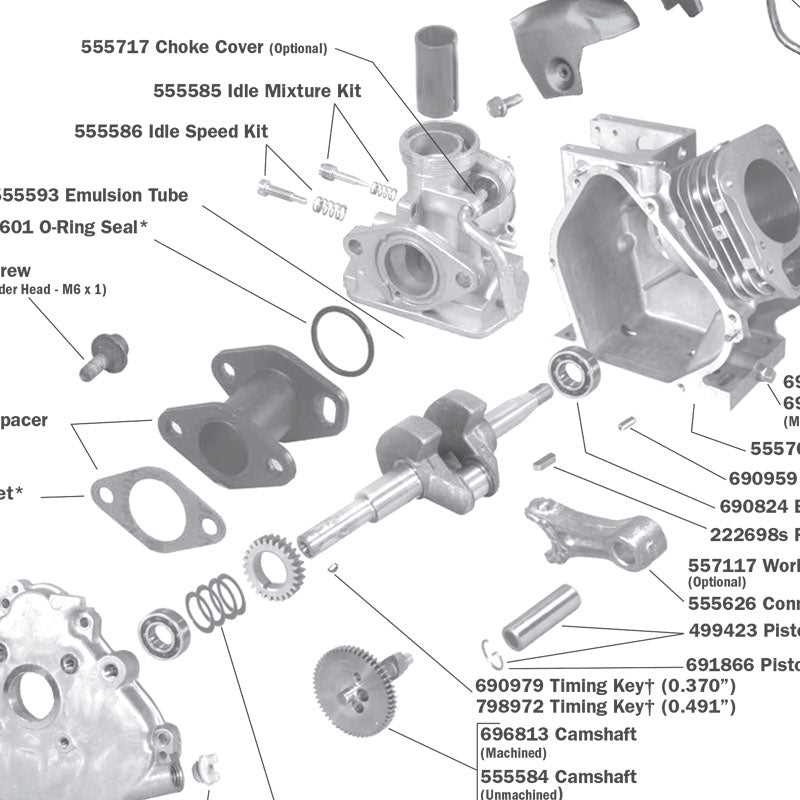

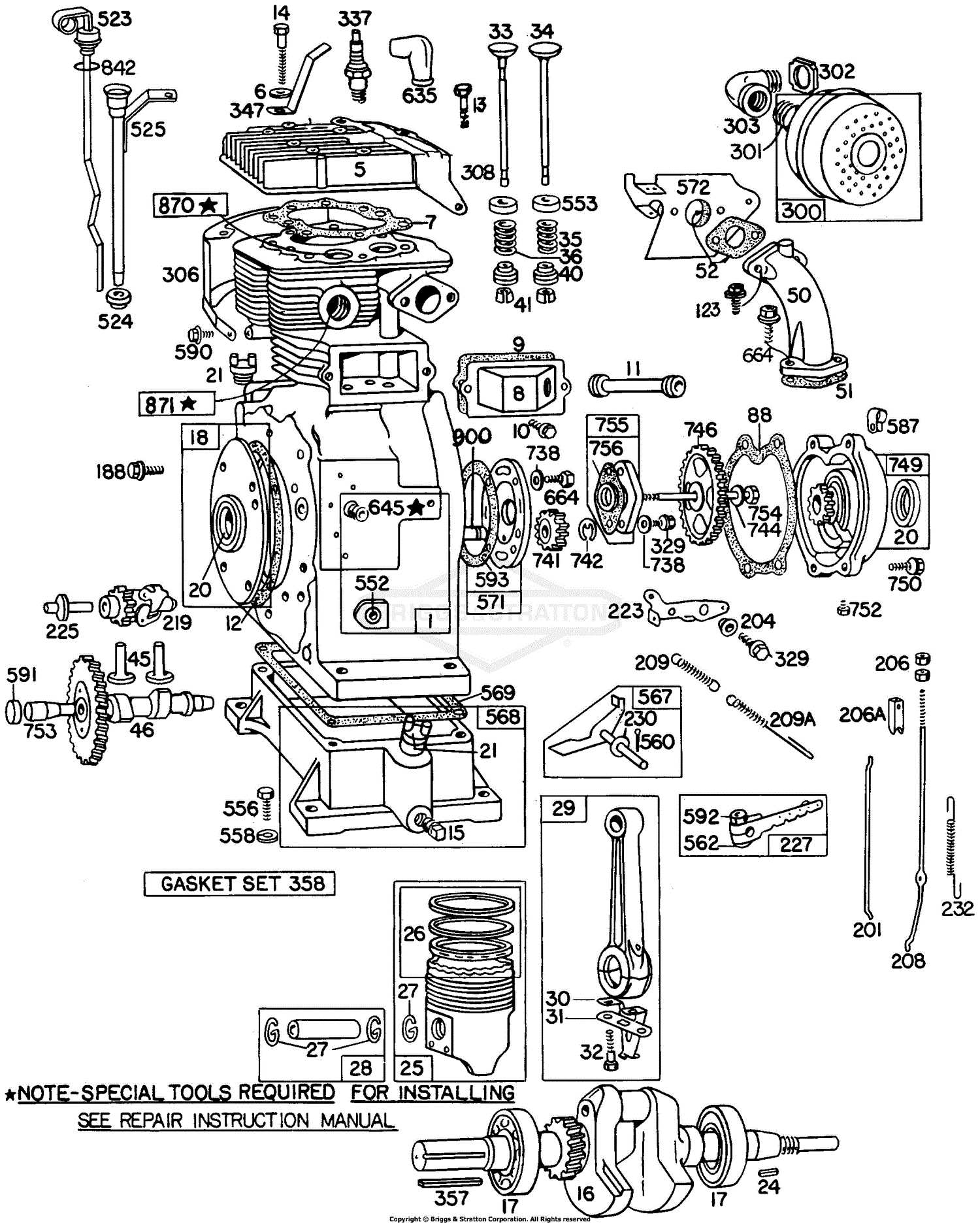

Common Engine Components Explained

This section delves into the essential elements that contribute to the functionality of a small motor. Each component plays a significant role in ensuring optimal performance and reliability. Understanding these vital pieces helps in maintaining efficiency and extending the lifespan of the machinery.

Key Components Overview

Various elements work in unison to facilitate the operation of the unit. Below is a breakdown of some of the most important components:

| Component | Description |

|---|---|

| Cylinder | The chamber where combustion occurs, driving the piston. |

| Piston | A moving piece that converts pressure from combustion into mechanical energy. |

| Crankshaft | Transforms the linear motion of the piston into rotational motion. |

| Camshaft | Controls the timing of the opening and closing of valves. |

| Valves | Regulate the intake of fuel-air mixture and exhaust of combustion gases. |

Functionality and Interaction

Each component’s efficiency directly influences overall performance. For instance, the synchronization between the crankshaft and camshaft is crucial for proper timing, while the integrity of the cylinder affects combustion quality. Regular maintenance of these elements ensures that the entire system operates smoothly, preventing potential failures.

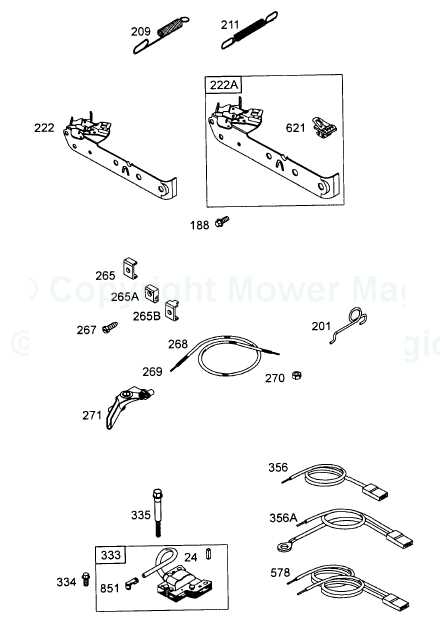

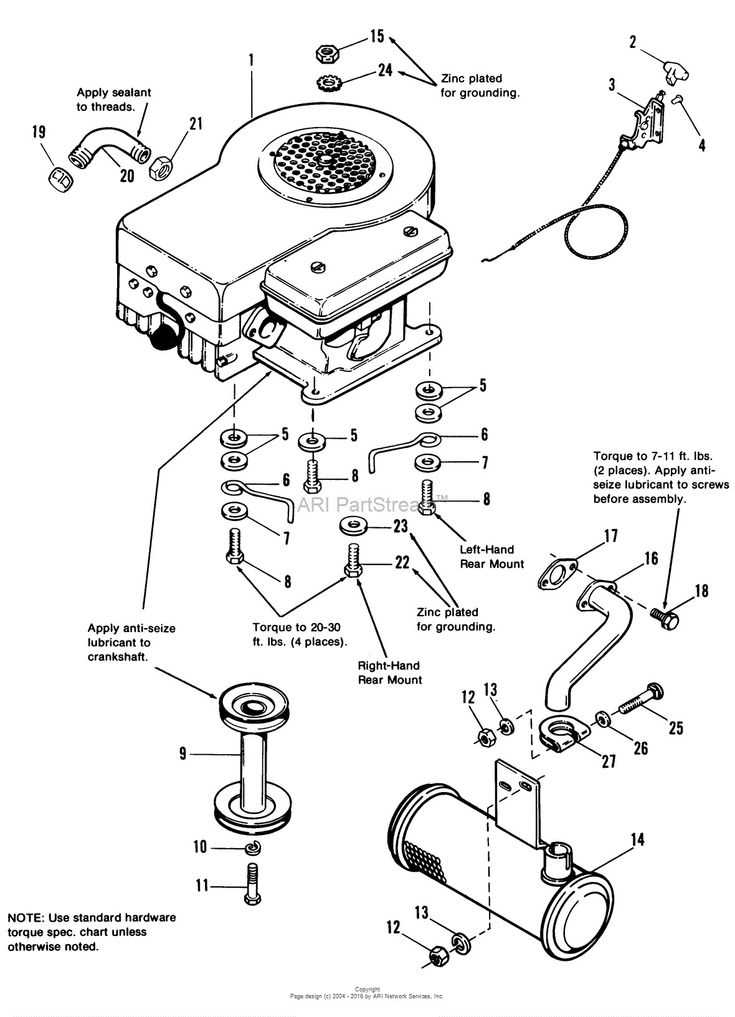

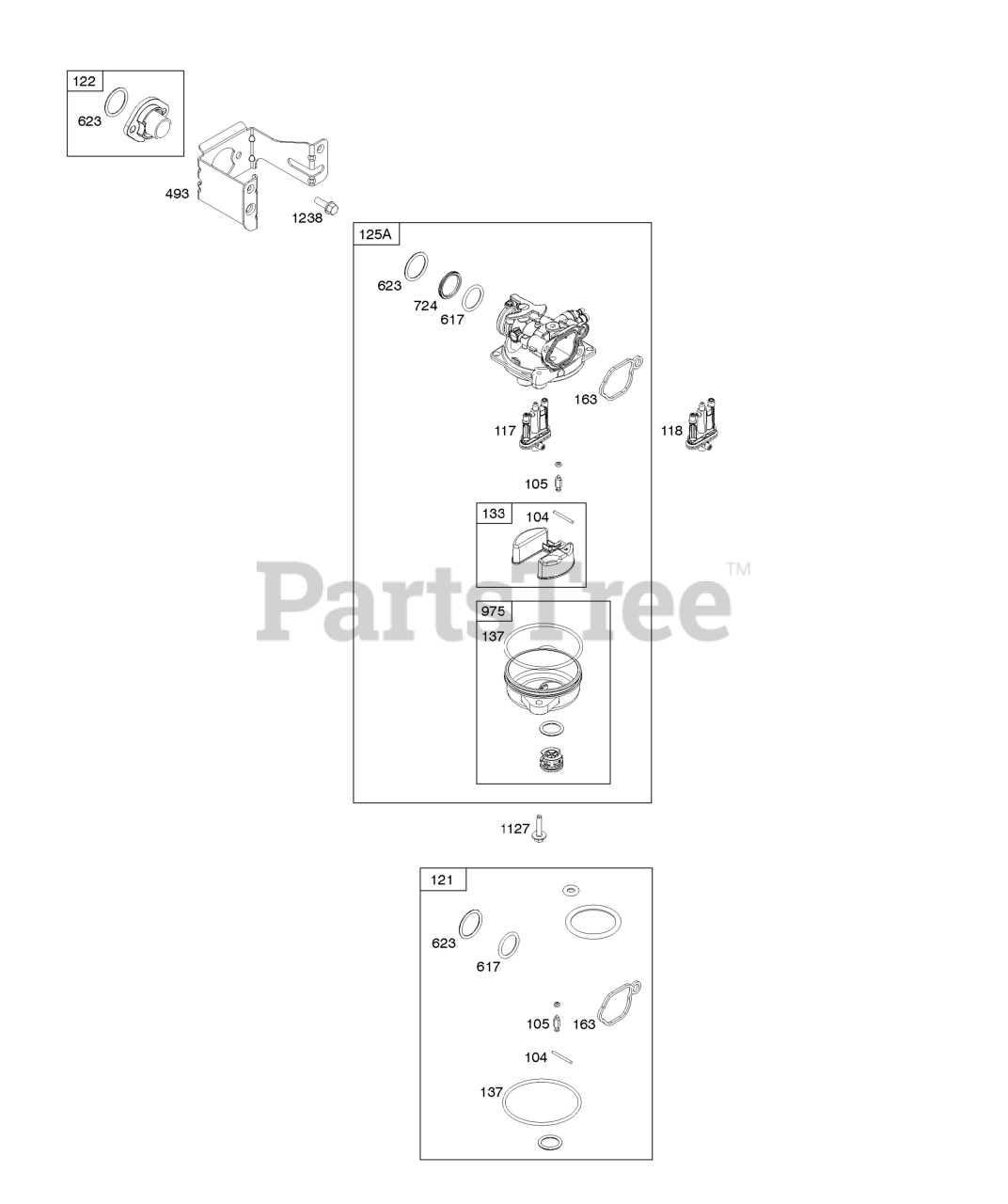

How to Read a Parts Diagram

Understanding a schematic representation is essential for effective maintenance and repair tasks. These illustrations provide a visual guide to the components involved, allowing users to identify and locate specific elements efficiently. Familiarity with the layout and symbols used in these representations can significantly enhance the repair process.

Key Elements of the Illustration

When examining a schematic, it’s important to recognize the main components, their relationships, and the connections between them. Typically, the following elements are included:

| Element | Description |

|---|---|

| Labels | Designations that indicate the names or numbers of various components. |

| Connections | Lines or arrows that show how different parts interact with each other. |

| Legend | A key that explains the symbols and markings used within the representation. |

Tips for Effective Interpretation

To enhance your ability to read these illustrations, consider the following strategies:

- Familiarize yourself with common symbols and their meanings.

- Start by identifying the main components before looking at the finer details.

- Refer to the accompanying legend to clarify any confusing elements.

Identifying Engine Model Numbers

Recognizing specific model identifiers is crucial for understanding the specifications and requirements of small motor units. These unique designations provide essential information for maintenance, repairs, and replacements, ensuring compatibility and performance. Knowing how to locate and interpret these numbers simplifies the process of sourcing necessary components or troubleshooting issues.

Typically, the model number can be found on a label or stamped on the housing. This information is often accompanied by a type number and a code that indicates the manufacturing date. Understanding the placement of these identifiers is vital, as they can vary depending on the design. Look for these labels on the side or rear of the unit, ensuring you have a clear view to accurately read the details.

Once the identifiers are located, decoding them allows users to access manuals and guides tailored to that specific model. This not only aids in efficient repairs but also enhances the overall lifespan of the motor. Therefore, taking the time to properly identify these designations can save significant effort and resources in the long run.

Finding Replacement Parts Easily

Locating suitable components for machinery can be a daunting task. However, with the right approach and resources, this process can be streamlined significantly. Understanding where to look and what to consider ensures you can obtain the necessary items quickly and efficiently.

Utilizing Online Resources

The internet offers a plethora of platforms dedicated to providing detailed listings of various items. By searching for specific models or specifications, you can find a wide range of options that suit your needs. Many websites also offer customer reviews, helping you make informed choices.

Local Retailers and Suppliers

Visiting local shops can be beneficial, as you can physically inspect the goods before purchasing. Additionally, knowledgeable staff can assist you in identifying what you need based on your requirements. Building relationships with local suppliers can also lead to better deals and exclusive offers.

| Source Type | Advantages |

|---|---|

| Online Stores | Wide selection, convenient comparisons, user reviews |

| Local Shops | Personal assistance, immediate availability, ability to inspect |

| Manufacturer Websites | Authentic goods, accurate specifications, warranty information |

Maintenance Tips for Ensuring Durability

Proper maintenance is crucial to maximize the lifespan and efficiency of your small combustion apparatus. Regular upkeep not only enhances performance but also prevents premature wear and costly repairs.

1. Routine Inspection and Cleaning

- Regularly examine and cleanse essential components to remove debris and deposits that can hinder functionality.

- Inspect filters, valves, and connections to ensure they are intact and functioning optimally.

2. Lubrication and Fluid Checks

- Apply appropriate lubricants to moving parts to reduce friction and prevent mechanical strain.

- Regularly check oil levels and replace fluids as recommended by the manufacturer to maintain optimal operation.

Following these maintenance tips will help extend the service life of your equipment, ensuring reliable performance over time.

Troubleshooting Common Engine Issues

When faced with operational difficulties, identifying the root cause is crucial for effective resolution. This section will guide you through typical problems encountered, enabling you to pinpoint issues swiftly and take appropriate corrective actions.

Below are some prevalent challenges and their potential solutions:

- Starting Problems:

- Check fuel levels and ensure the quality is adequate.

- Inspect the ignition system for faults or wear.

- Verify the battery condition if applicable.

- Unusual Noises:

- Listen for grinding or knocking sounds that may indicate internal wear.

- Check for loose components that may be rattling during operation.

- Examine the exhaust for signs of blockage.

- Overheating:

- Ensure the cooling system is functioning correctly and not blocked.

- Examine oil levels and condition; low or dirty oil can cause excess heat.

- Inspect air intake areas for obstructions.

- Loss of Power:

- Check for air filter clogs that could restrict airflow.

- Inspect the fuel system for blockages or leaks.

- Examine spark plugs for wear or fouling.

By systematically addressing these issues, you can enhance performance and prolong the lifespan of your machine. Always remember to consult your user manual for specific guidance related to your model.

Resources for Engine Repair Manuals

Access to comprehensive resources is essential for anyone looking to maintain or restore small power units. These materials provide invaluable insights and guidance, ensuring that repairs are performed effectively and efficiently. Whether you’re a seasoned technician or a DIY enthusiast, having the right references can make all the difference in your project’s success.

Online Databases

Numerous online platforms offer extensive collections of manuals and guides. Websites dedicated to machinery repair often feature downloadable PDFs, complete with detailed instructions and illustrations. Utilizing these databases can streamline your repair process, allowing for quick access to vital information.

Printed Manuals

For those who prefer physical copies, printed guides are widely available. Many manufacturers publish official manuals that contain specifications, troubleshooting tips, and step-by-step procedures. Investing in a hard copy can be beneficial, providing a reliable resource that can be referenced easily in your workshop.

In conclusion, whether opting for digital or printed materials, having the right resources at your fingertips is crucial for successful repairs. Engage with trusted sources to ensure your projects are handled with care and expertise.

Comparing Different Engine Models

When evaluating various power unit configurations, it’s essential to consider their unique features and specifications. Each variant is designed with specific applications in mind, leading to distinct performance characteristics and operational efficiencies. By understanding these differences, users can make informed decisions tailored to their requirements.

Performance Metrics: Different configurations offer varying horsepower ratings, torque outputs, and fuel efficiencies. Assessing these metrics can help determine which model best suits particular tasks, whether for residential use or industrial applications.

Durability and Maintenance: The longevity of these power sources can vary significantly based on design and materials used. Some models may require more frequent upkeep, while others are built for extended operation with minimal intervention. Evaluating maintenance needs is crucial for long-term reliability.

Technological Advancements: Innovations in engineering have led to improved efficiency and reduced emissions in modern designs. Understanding the technological differences can aid in selecting a model that aligns with environmental standards and personal values.

By analyzing these aspects, users can effectively compare different options and choose the most suitable unit for their specific applications.

Upgrading Your Engine: What to Know

Improving the performance of your machinery can significantly enhance its efficiency and lifespan. Whether you’re looking to boost power or increase reliability, understanding the essentials of enhancements is crucial. This section covers vital considerations and tips to ensure a successful upgrade.

Assess Your Current Setup

Before embarking on any modifications, evaluate the existing configuration thoroughly. Identify the areas that require improvement and determine your specific goals. This will guide you in selecting appropriate enhancements that align with your objectives, whether it’s enhanced output or greater fuel efficiency.

Selecting Quality Components

When upgrading, the quality of the components you choose is paramount. Opt for reliable manufacturers known for their durability and performance. Investing in high-quality parts not only ensures a smoother operation but also prolongs the overall life of your machinery. Research and compare various options to find the best fit for your needs.