Understanding the Parts Diagram of Mercury 15 HP Outboard Motor

When it comes to maintaining small marine engines, having a clear understanding of their structure is essential for effective servicing and repairs. Knowing how each element functions in conjunction with others can significantly enhance the longevity and performance of your vessel’s propulsion system. This section delves into the intricate details of a specific 15 horsepower engine, providing a comprehensive overview of its various elements.

The assembly of a marine engine can seem daunting, yet familiarizing oneself with its individual components is vital for any boating enthusiast or technician. Each part plays a crucial role, contributing to the overall efficiency and reliability of the engine. By exploring the arrangement and relationship of these pieces, one can better grasp the mechanics at play.

In this exploration, we will outline the essential components that make up this powerful yet compact engine. With an emphasis on clarity and accessibility, this guide aims to equip you with the knowledge necessary for troubleshooting and maintenance. Understanding how everything fits together will empower you to tackle any issues that may arise on the water.

Understanding Mercury 15 HP Outboard Engines

This section delves into the essentials of small marine propulsion systems, focusing on a specific model known for its reliability and efficiency. These engines are designed for various watercraft, providing power for both leisure and commercial use. By exploring the inner workings and components, users can gain a better appreciation for their functionality and maintenance needs.

Key Features

- Lightweight design for easy handling

- Compact size, making it suitable for smaller vessels

- Fuel-efficient operation for longer excursions

- Durable construction to withstand harsh marine environments

Maintenance Tips

- Regularly check the oil levels and replace as needed.

- Inspect the propeller for damage and clean any debris.

- Examine fuel lines and connections for leaks or wear.

- Ensure that the cooling system is functioning properly.

- Follow the manufacturer’s guidelines for seasonal maintenance.

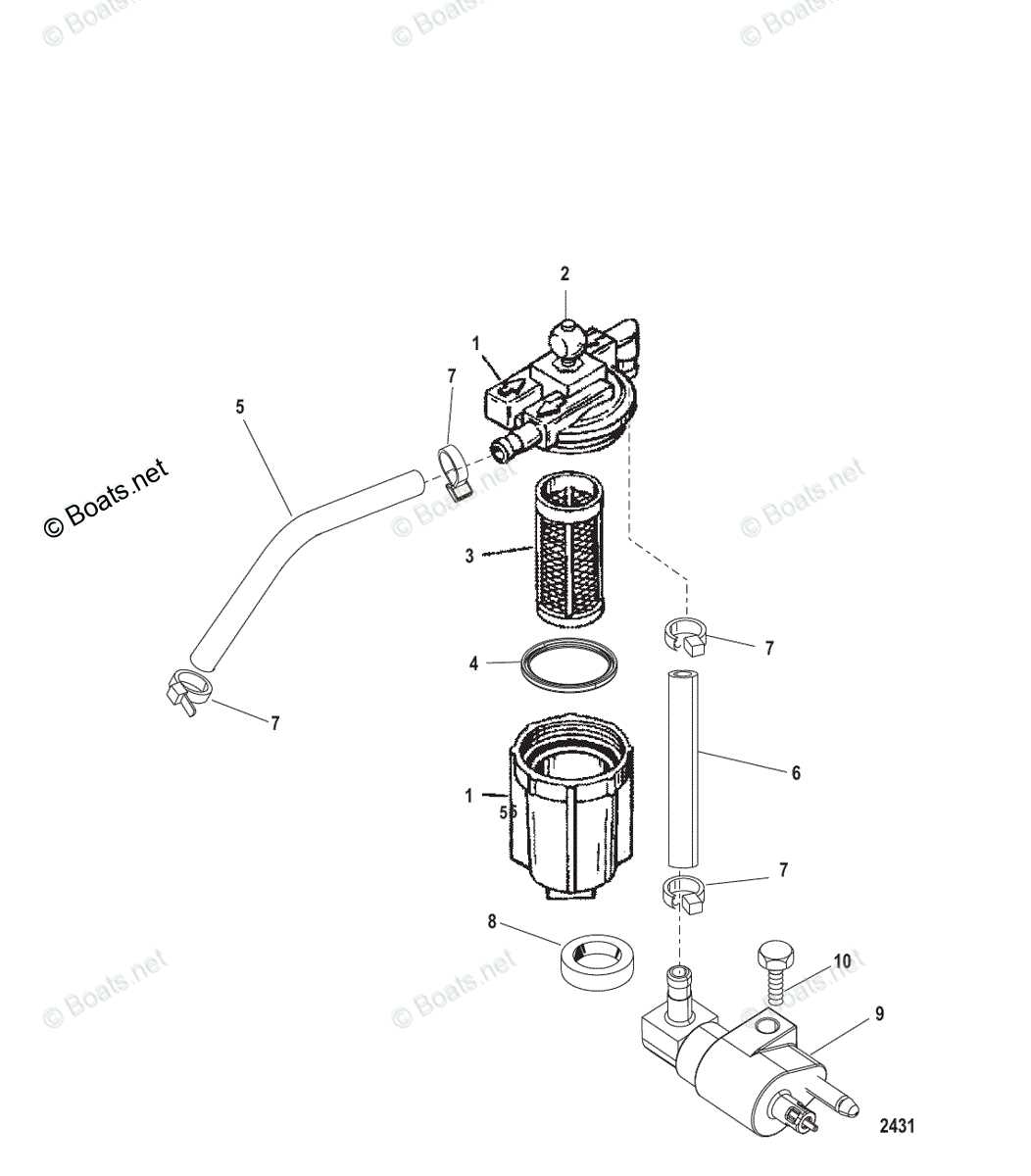

Importance of Parts Diagrams

Understanding the intricacies of mechanical systems is essential for effective maintenance and repair. Visual representations play a crucial role in this process, offering clear insights into the assembly and functionality of various components. By utilizing these illustrations, individuals can easily identify specific elements and their relationships within the overall structure.

Firstly, such visuals enhance communication between technicians and users, ensuring everyone is on the same page regarding what needs to be fixed or replaced. Secondly, these representations aid in troubleshooting by allowing users to pinpoint issues quickly, reducing downtime and increasing efficiency. Moreover, they serve as valuable educational tools, helping novices grasp the complexities of the machinery they are working with.

In summary, the role of these illustrations is indispensable, streamlining repair processes and facilitating a deeper understanding of mechanical systems.

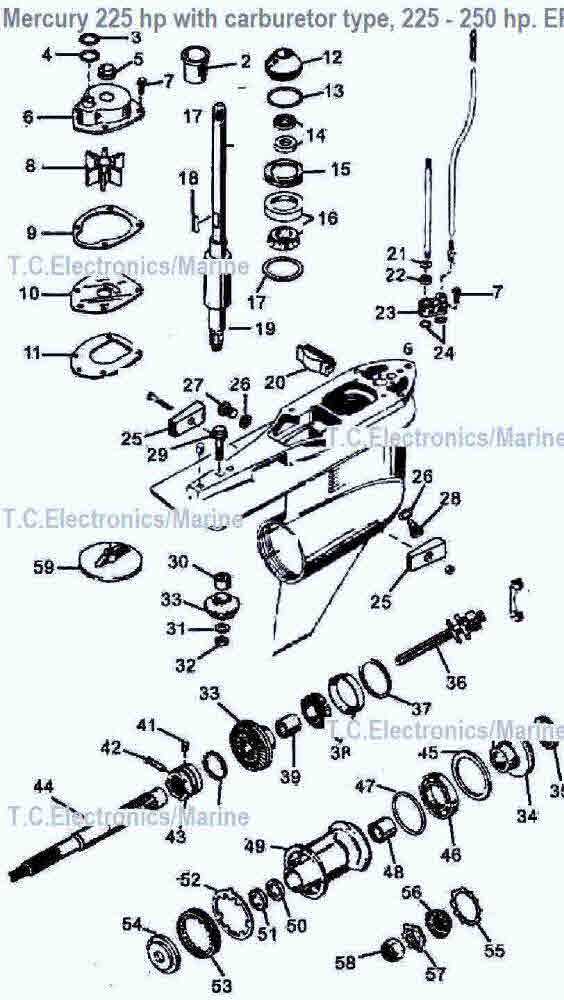

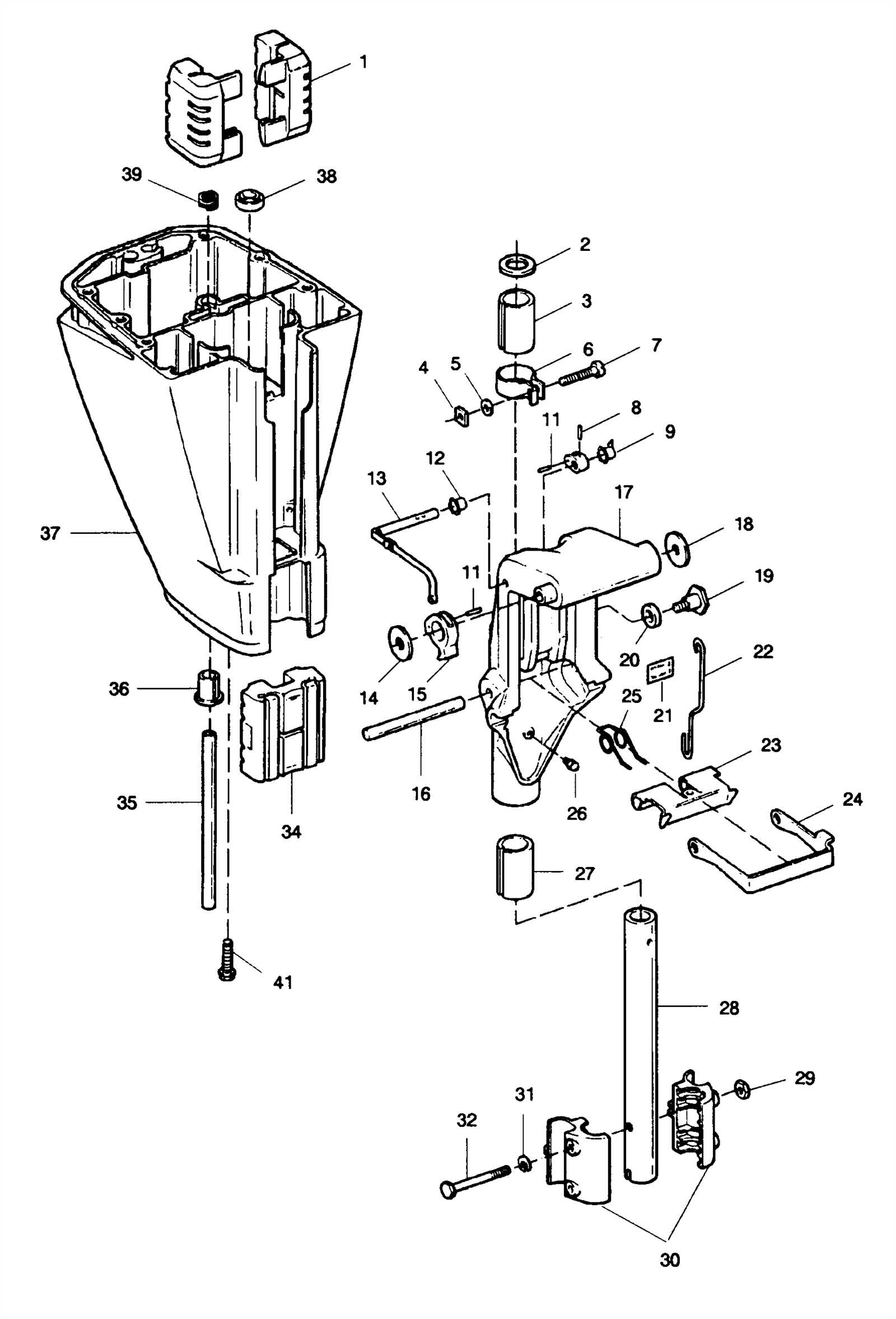

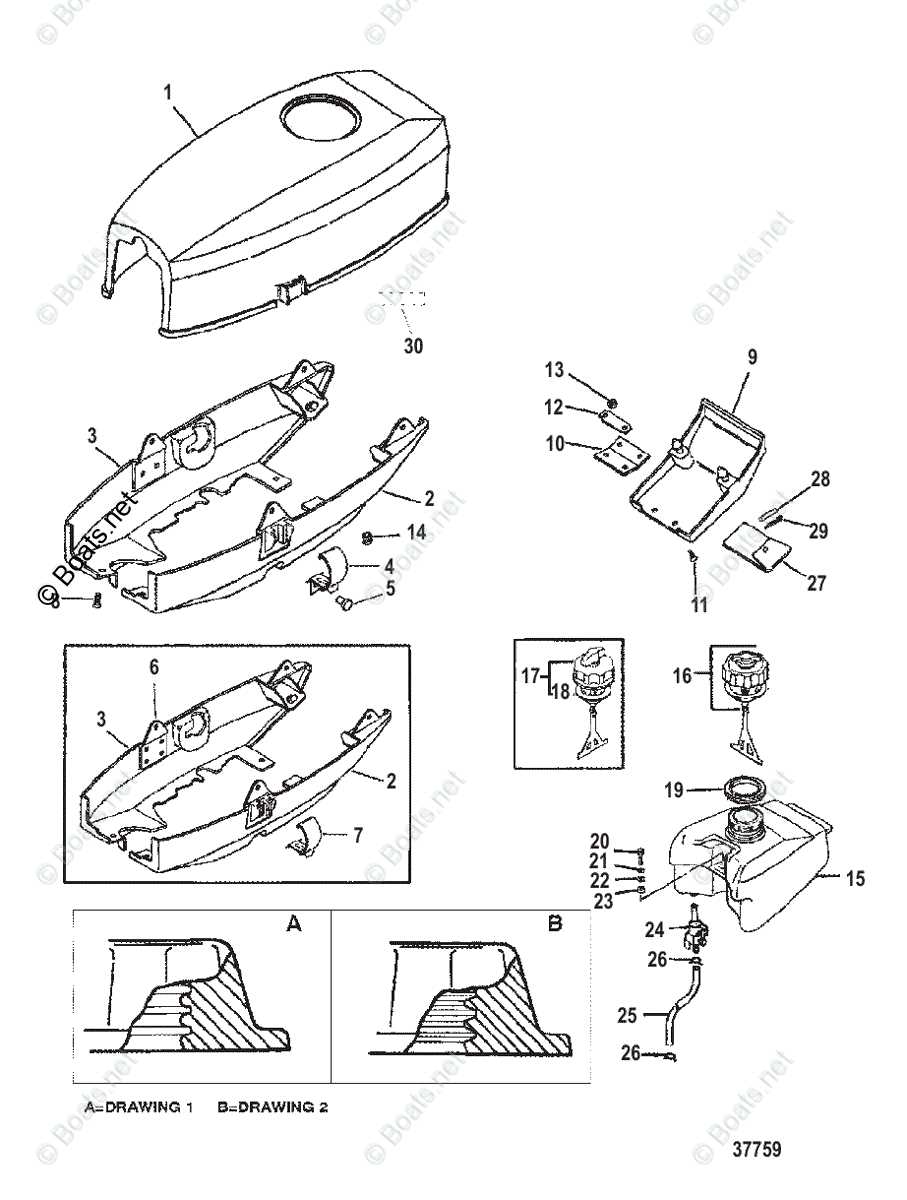

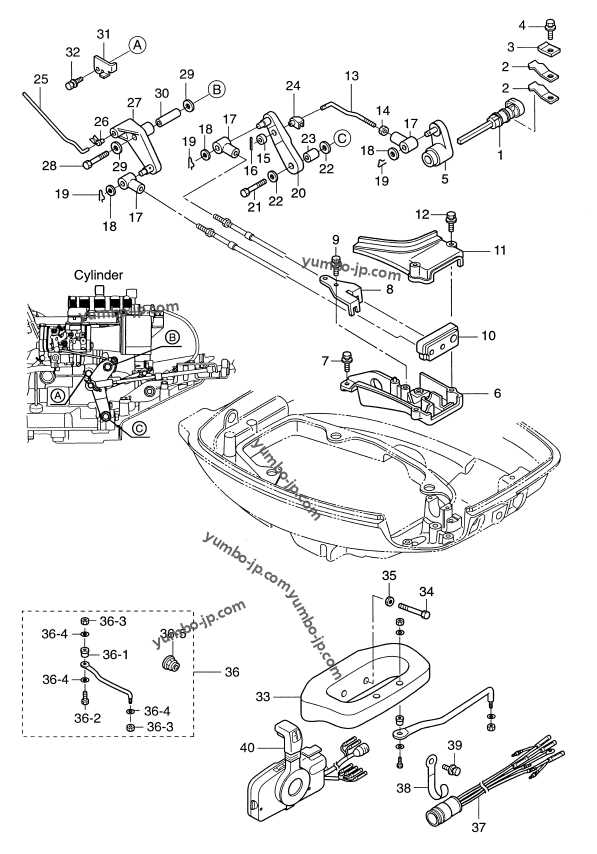

Common Components of the Engine

The functionality of a marine propulsion system relies heavily on several key elements that work in harmony. Understanding these fundamental components is essential for maintenance and troubleshooting. Each part plays a distinct role in ensuring optimal performance and reliability.

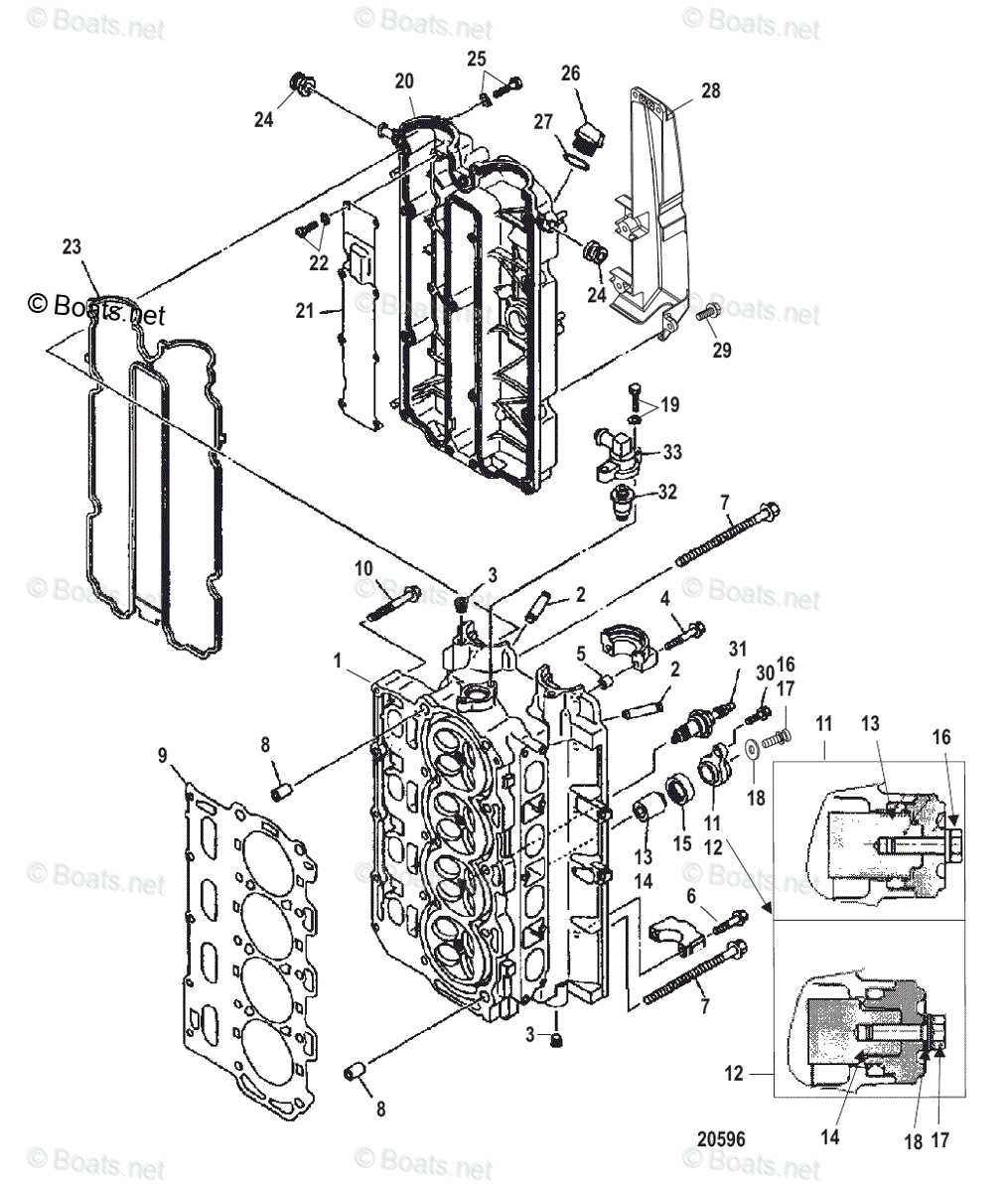

Powerhead serves as the heart of the mechanism, housing critical elements like the cylinders and combustion chamber. It is responsible for generating the power needed to propel the vessel.

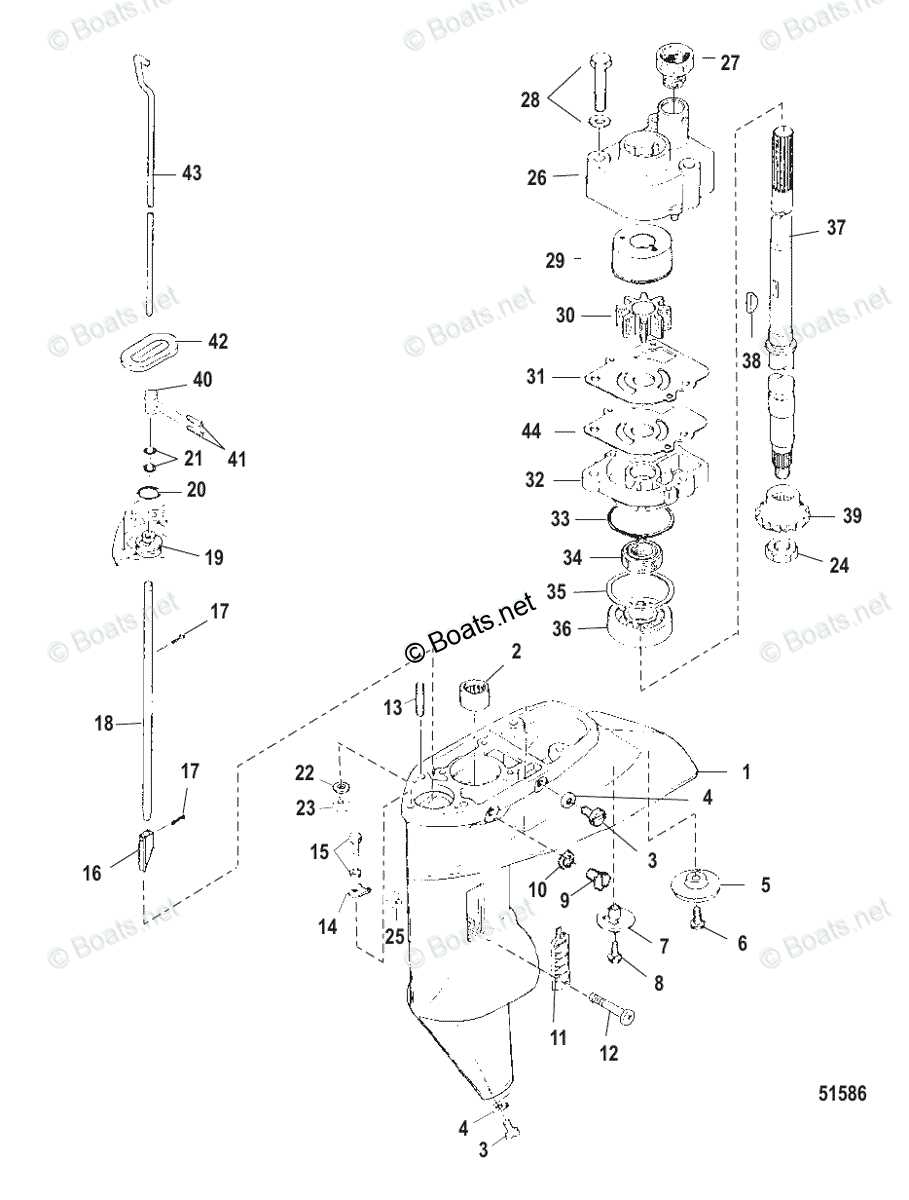

Lower Unit contains the gearbox and propeller shaft, which are crucial for transmitting the power generated in the powerhead to the propeller. This unit also includes the water pump, essential for cooling the engine during operation.

Fuel System comprises various elements like the carburetor or fuel injection system, which mix air and fuel in the correct proportions for efficient combustion. A well-functioning fuel system is vital for smooth performance.

Ignition System includes components such as spark plugs and coils, which are responsible for initiating the combustion process. Timely ignition ensures that the engine operates at its peak performance.

Electrical System powers various accessories and supports the ignition system. It includes the battery, wiring, and switches, all of which are essential for reliable operation.

By familiarizing oneself with these integral components, users can better appreciate the mechanics of their propulsion system and ensure it remains in excellent working condition.

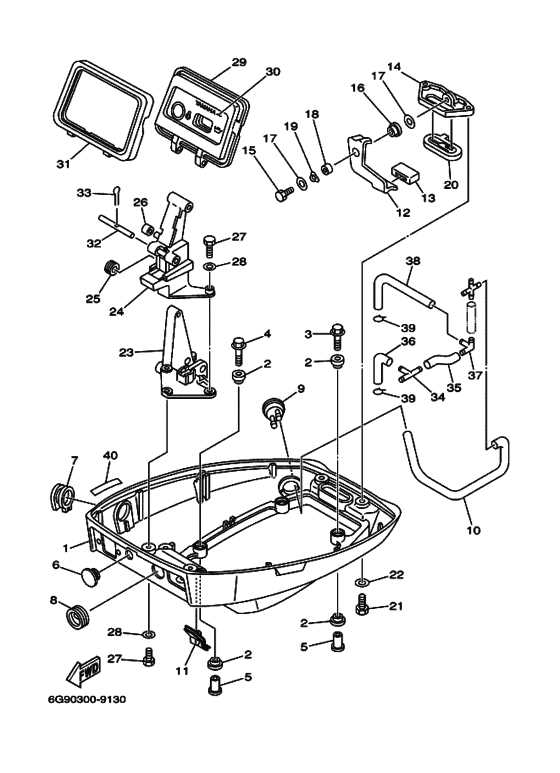

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for anyone looking to maintain or repair machinery. These visual guides provide an organized view of various elements, allowing users to identify and locate each piece effectively. Familiarity with the layout and symbols used in these representations can greatly simplify the process of troubleshooting or sourcing replacements.

Key Components of a Schematic

When examining a visual guide, there are several key elements to consider. Typically, these include reference numbers, component names, and their respective positions. Recognizing how these parts are interconnected can aid in comprehension and facilitate easier assembly or disassembly.

Tips for Interpretation

To effectively navigate a schematic representation, follow these tips:

| Tip | Description |

|---|---|

| Start with the Legend | Check for a key that explains symbols and numbering. |

| Identify Groups | Look for clusters of components that work together. |

| Use Reference Numbers | Locate parts by their assigned numbers for quick identification. |

| Note Relationships | Pay attention to how components connect and interact. |

With practice, reading these representations becomes an intuitive process, enabling effective maintenance and repair strategies for any machinery.

Key Replacement Parts for Maintenance

Regular upkeep is essential for ensuring optimal performance and longevity of marine engines. A selection of critical components plays a vital role in maintaining functionality and addressing common wear issues. Understanding these key elements helps in efficient troubleshooting and enhances the overall reliability of the machinery.

| Component | Description | Importance |

|---|---|---|

| Fuel Filter | Removes impurities from fuel to prevent engine damage. | Critical for maintaining clean fuel flow. |

| Impeller | Circulates water for cooling the engine. | Essential to prevent overheating. |

| Spark Plug | Ignites the air-fuel mixture for combustion. | Key for starting and efficient operation. |

| Thermostat | Regulates engine temperature. | Prevents overheating and maintains efficiency. |

| Gear Oil | Lubricates internal components to reduce friction. | Vital for smooth operation and longevity. |

Identifying and replacing these essential components not only enhances performance but also minimizes the risk of unexpected breakdowns. Regular inspections and timely replacements can lead to a more reliable and enjoyable boating experience.

Identifying Engine Model Variations

Understanding the distinctions between different models of a motor is crucial for effective maintenance and repair. Each variant can possess unique characteristics, impacting performance and compatibility with specific components. Recognizing these differences allows enthusiasts and technicians to make informed decisions when sourcing necessary items or troubleshooting issues.

Key Characteristics to Consider

- Year of Manufacture: Variations often arise from changes made in specific production years, affecting specifications and designs.

- Horsepower Rating: The power output can vary, influencing the type of tasks the engine can handle.

- Model Number: Each engine typically has a unique identifier that can reveal important details about its specifications.

- Fuel Type: Different engines may require various fuel compositions, impacting efficiency and performance.

Resources for Identification

- Manufacturer Manuals: These documents often provide detailed specifications and diagrams that can aid in identifying model variations.

- Online Forums: Communities dedicated to motor enthusiasts can be invaluable for advice and shared experiences regarding specific models.

- Parts Retailers: Websites specializing in engine components often allow you to search by model number, facilitating easier identification.

By focusing on these aspects, individuals can more effectively discern the unique traits of their motors, ensuring proper care and optimization of performance.

Tips for Ordering Parts Online

When purchasing components online, it’s essential to approach the process with careful consideration and preparation. The vast selection available can be overwhelming, but with the right strategies, you can ensure a smooth and efficient experience.

1. Verify Compatibility: Before placing an order, confirm that the item you intend to buy is suitable for your specific model. Referencing the manufacturer’s specifications can help avoid potential mismatches.

2. Research Reliable Suppliers: Take the time to find trustworthy vendors. Look for reviews and ratings to gauge the reliability of the seller. A reputable source will often provide detailed descriptions and specifications.

3. Check Return Policies: Understand the return and exchange policies of the seller. In case the item doesn’t meet your expectations or is incompatible, it’s important to know your options for returning or exchanging it.

4. Compare Prices: Prices can vary significantly between different retailers. Don’t settle for the first option; take the time to compare prices to ensure you’re getting the best deal possible.

5. Look for Warranty Information: A solid warranty can provide peace of mind. Ensure that the item comes with a guarantee against defects or issues, as this can save you money in the long run.

6. Utilize Customer Support: Don’t hesitate to reach out to customer service with any questions. They can provide valuable assistance and help clarify any uncertainties you may have.

By following these tips, you can navigate the online purchasing landscape more effectively, ensuring that you receive the correct items promptly and with minimal hassle.

Tools Needed for Repairs

When undertaking maintenance tasks, having the right equipment is essential for ensuring efficiency and accuracy. The appropriate instruments not only simplify the process but also enhance the quality of the repairs. Below is a list of necessary tools that will help you tackle various repair jobs effectively.

| Tool | Description |

|---|---|

| Socket Set | Essential for loosening and tightening bolts and nuts, providing versatility for different sizes. |

| Screwdrivers | A variety of flathead and Phillips screwdrivers are crucial for accessing screws in tight spaces. |

| Wrenches | Used for gripping and turning nuts and bolts, available in adjustable and fixed sizes. |

| Pliers | Useful for holding, bending, and cutting wires or small components during repairs. |

| Torque Wrench | Ensures that fasteners are tightened to the correct specifications, preventing damage from over-tightening. |

| Multimeter | Allows for testing electrical systems and components, ensuring proper functionality. |

| Cleaning Supplies | Include brushes and solvents to maintain cleanliness and optimal performance of parts. |

Typical Issues with Mercury Outboards

When operating a marine propulsion system, users may encounter various challenges that affect performance and reliability. Understanding these common problems can help ensure smoother operation and prolong the lifespan of the equipment.

Common Challenges

- Fuel System Problems

- Electrical Failures

- Cooling System Issues

- Mechanical Wear

Symptoms and Solutions

- Fuel System Problems:

- Symptoms: Stalling, poor acceleration, or difficulty starting.

- Solution: Check for clogged filters, inspect fuel lines, and ensure the fuel is fresh.

- Electrical Failures:

- Symptoms: Inconsistent performance or no response when starting.

- Solution: Test the battery, inspect connections, and check the ignition system.

- Cooling System Issues:

- Symptoms: Overheating or low water pressure.

- Solution: Examine the water pump, clear obstructions, and verify the intake is functioning.

- Mechanical Wear:

- Symptoms: Unusual noises or vibration during operation.

- Solution: Regularly inspect moving parts, replace worn components, and perform routine maintenance.

By being aware of these typical issues and their solutions, users can enhance their experience and ensure their marine propulsion systems operate efficiently.

How to Troubleshoot Engine Problems

Identifying issues within a motor can be a daunting task, yet a systematic approach can simplify the process. By focusing on common symptoms and methodically assessing each component, you can efficiently diagnose the root of the problem and apply the necessary fixes. This guide will provide insights into common issues and practical steps for troubleshooting.

Common Symptoms and Initial Checks

Begin by observing the engine’s behavior. Unusual sounds, poor performance, or failure to start are clear indicators of potential issues. Check the fuel system for blockages or contamination, as well as ensuring there is an adequate supply of fresh fuel. Examine the ignition system for any signs of wear or damage, as faulty spark plugs or coils can lead to misfiring or stalling.

Systematic Troubleshooting Steps

Once initial symptoms are noted, proceed with a step-by-step diagnosis. Start with the electrical components, ensuring all connections are secure and free from corrosion. Next, inspect the air intake and exhaust for any restrictions. If the problem persists, it may be necessary to delve into the mechanical aspects, such as examining compression levels and checking for leaks in gaskets or seals. Keeping a detailed log of your findings can also aid in identifying patterns and resolving recurring issues.

Where to Find Genuine Parts

When it comes to maintaining your marine engine, sourcing authentic components is crucial for optimal performance and longevity. Quality elements not only ensure proper functionality but also enhance safety while navigating waters. Knowing where to find reliable sources can save you time and money in the long run.

Authorized Dealers

One of the best ways to secure genuine components is through authorized retailers. These establishments are certified to sell original items and often provide warranties, ensuring peace of mind with every purchase. You can visit their physical locations or explore their online platforms for a comprehensive selection.

Online Marketplaces

Reputable online platforms also offer a wide range of authentic components. Look for sellers with high ratings and positive feedback from previous customers. Always check for authenticity guarantees and return policies to protect your investment. Additionally, forums and community groups related to marine activities can provide recommendations on trustworthy online shops.

Cost Considerations for Repairs

When it comes to maintaining small marine engines, understanding the financial implications of repairs is crucial. Costs can vary significantly based on the nature of the issue, the availability of components, and whether you opt for professional assistance or choose to tackle the repairs yourself. Being aware of these factors can help you budget effectively and make informed decisions.

Labor vs. DIY Repairs

One of the first decisions to consider is whether to hire a technician or perform the work independently. Professional services often come with labor costs that can escalate quickly, especially if the repairs are complex. Conversely, do-it-yourself repairs may save money, but they require a certain level of expertise and may involve purchasing specialized tools. Weighing these options can impact the overall expense of the maintenance process.

Parts Acquisition

The expense of replacement components is another vital factor. Prices can fluctuate based on brand, quality, and availability. While opting for original equipment may guarantee reliability, aftermarket options can offer significant savings. It’s essential to research and compare prices from various suppliers to ensure you are making a cost-effective choice without compromising quality.

Maintenance Tips for Longevity

Ensuring the durability and reliability of your marine engine requires regular attention and care. Proper maintenance not only enhances performance but also extends the lifespan of your equipment. Following a consistent routine will help prevent issues before they arise and keep your engine operating smoothly.

Regular Inspections

- Check for any signs of wear and tear on external components.

- Inspect fuel lines and connections for leaks.

- Examine electrical connections for corrosion or damage.

Scheduled Servicing

- Change the oil and filter as recommended by the manufacturer.

- Replace spark plugs to ensure efficient combustion.

- Flush the cooling system to remove debris and prevent overheating.

By incorporating these practices into your maintenance routine, you can significantly enhance the longevity of your marine engine, ensuring reliable performance for many seasons to come.