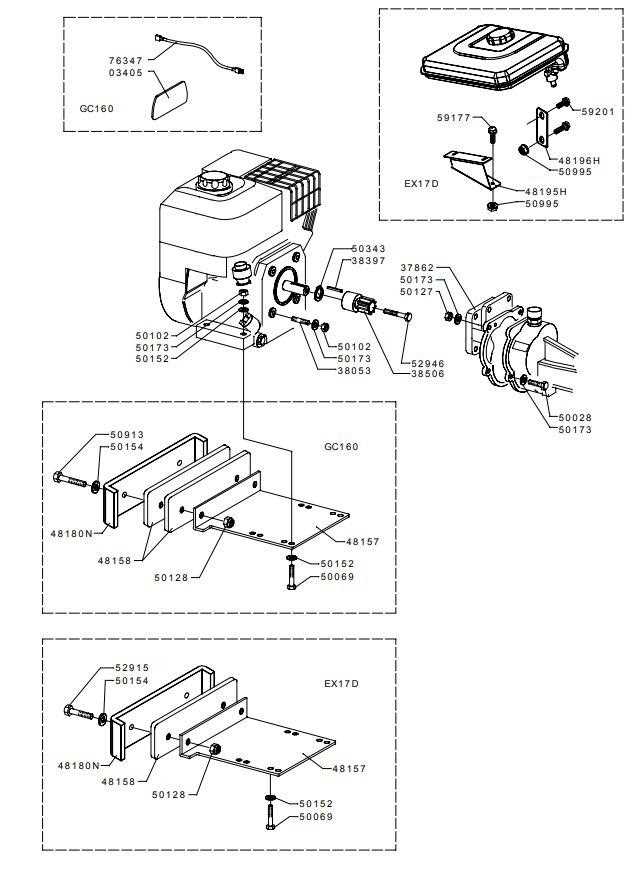

Honda GC160 Parts Diagram Overview

Understanding the intricate layout of engine components is crucial for effective maintenance and repair. A clear representation of these elements aids in identifying their specific functions and interconnections, which is essential for troubleshooting and optimizing performance.

Visual aids can significantly enhance comprehension by providing a structured overview of how various elements work together. This knowledge is not only beneficial for seasoned mechanics but also empowers enthusiasts to engage in DIY repairs with confidence.

Moreover, familiarity with the arrangement of engine parts facilitates the procurement of replacement components, ensuring that repairs are timely and efficient. By delving into the specifics of engine assembly, one can appreciate the engineering that contributes to reliable operation.

This section highlights the distinctive characteristics of a popular small engine model, showcasing its design and functionality. The engine’s specifications and components contribute to its performance, making it suitable for various applications.

| Feature | Description |

|---|---|

| Power Output | Generates a reliable output suitable for light to moderate tasks. |

| Engine Type | Four-stroke cycle, known for efficiency and lower emissions. |

| Cylinder Configuration | Single-cylinder design enhances simplicity and compactness. |

| Fuel Type | Utilizes gasoline, providing convenience in refueling. |

| Starting System | Equipped with a recoil starter for easy ignition. |

| Cooling System | Air-cooled system helps maintain optimal operating temperature. |

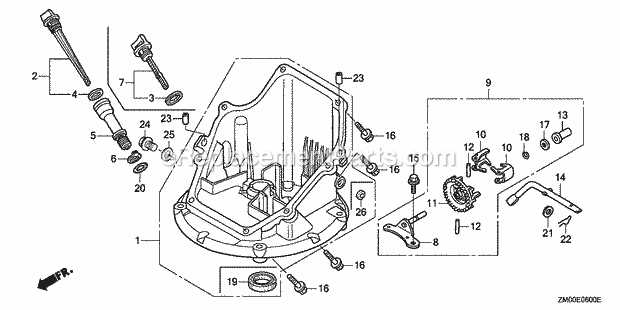

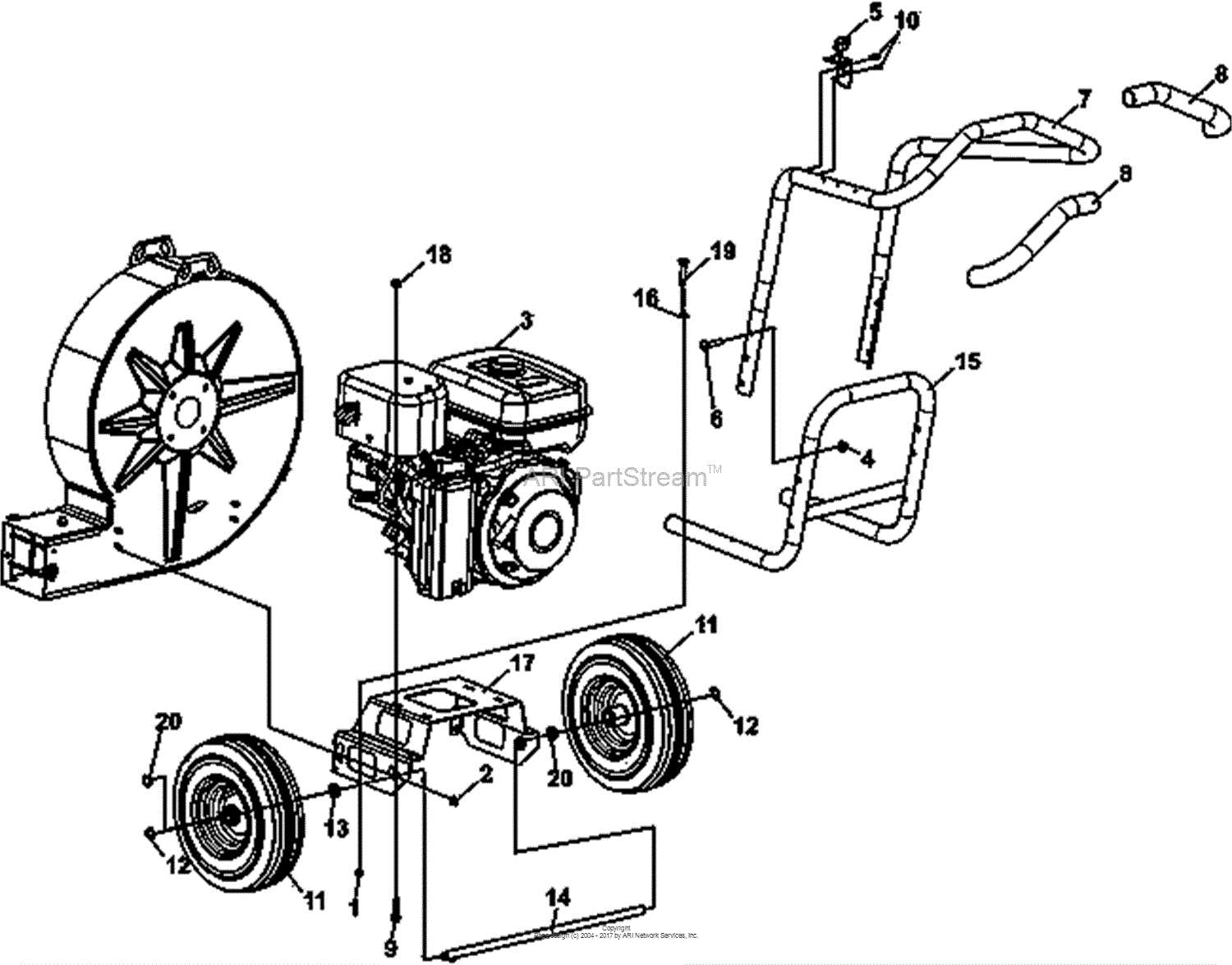

Essential Components Breakdown

This section provides a comprehensive overview of the crucial elements that contribute to the functionality of small engines. Understanding these components is vital for maintenance and effective operation.

- Engine Block: The core structure housing various parts, ensuring durability and strength.

- Piston: A moving element that compresses fuel and air, playing a crucial role in generating power.

- Crankshaft: Converts the linear motion of the piston into rotational motion, driving the output shaft.

- Camshaft: Regulates the opening and closing of the intake and exhaust valves, critical for engine timing.

- Fuel Tank: Stores fuel required for combustion, essential for operation.

- Carburetor: Mixture of fuel and air is prepared for combustion, influencing engine performance.

- Ignition System: Responsible for initiating combustion, ensuring the engine runs smoothly.

- Exhaust System: Expels gases produced during combustion, contributing to efficient engine operation.

Familiarity with these components aids in troubleshooting and enhances the overall understanding of engine mechanics.

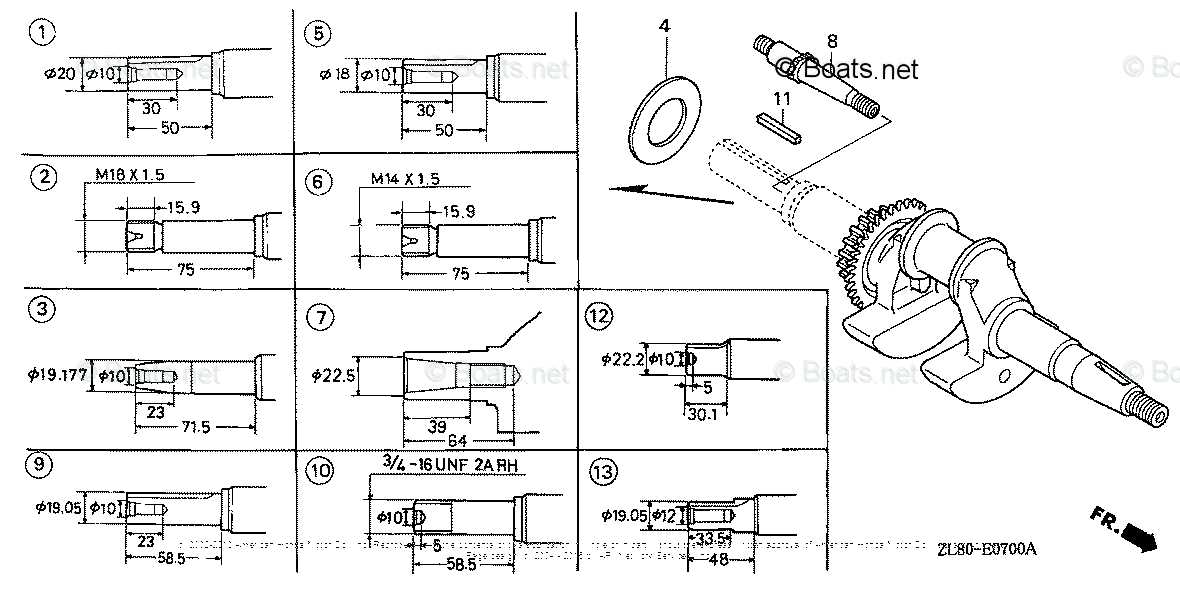

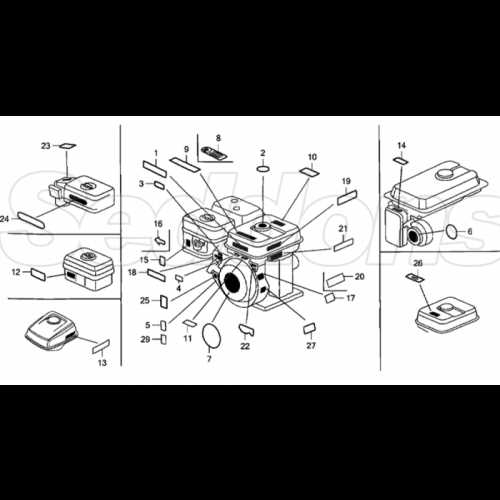

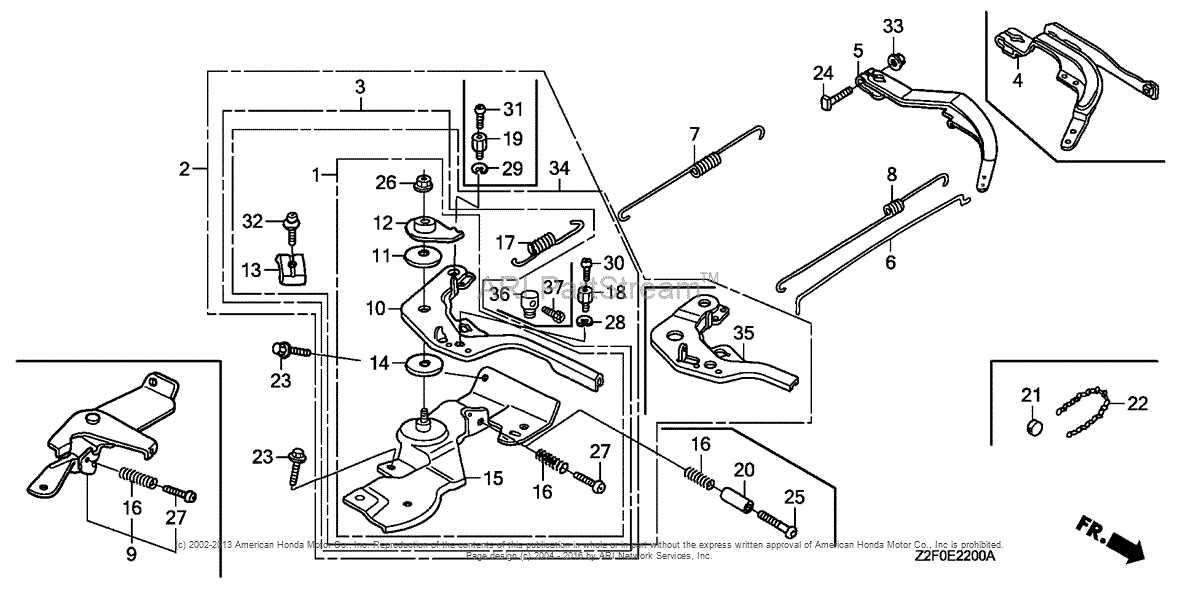

Identifying Engine Assembly Parts

Understanding the various components of an engine assembly is crucial for effective maintenance and repair. Each element plays a significant role in the overall functionality, and recognizing them can simplify troubleshooting and enhance efficiency during service tasks.

Common Components Overview

The engine assembly consists of several key elements, each with its specific purpose. Familiarity with these components allows for better identification and resolution of issues that may arise during operation.

| Component | Description |

|---|---|

| Cylinder Head | Houses valves and spark plugs, sealing the combustion chamber. |

| Piston | Moves up and down within the cylinder, converting combustion energy into mechanical work. |

| Crankshaft | Transforms linear motion of the piston into rotational motion. |

| Connecting Rod | Links the piston to the crankshaft, facilitating motion transfer. |

Importance of Component Knowledge

Being aware of these components aids in diagnosing performance issues and planning for repairs. It enhances the ability to communicate effectively with service professionals and can lead to more informed decisions regarding maintenance and parts replacement.

Maintenance and Repair Guidelines

This section provides essential recommendations for upkeep and restoration of small engines, ensuring optimal performance and longevity. Following systematic procedures can prevent common issues and enhance reliability.

Regular inspections are crucial to identify potential problems early. Key areas to focus on include:

| Component | Maintenance Task | Frequency |

|---|---|---|

| Air Filter | Clean or replace | Every 25 hours of operation |

| Oil | Change | Every 50 hours of operation |

| Spark Plug | Inspect and replace | Every 100 hours of operation |

| Fuel System | Check for leaks and cleanliness | Before each use |

| Cooling System | Clean fins and ensure airflow | Every season |

Proper tools and safety gear should be utilized when performing maintenance tasks. Consult the operational manual for specific guidelines related to your equipment model to ensure accurate and effective maintenance practices.

Common Issues and Solutions

Various mechanical units often encounter specific challenges that can hinder their performance. Understanding these common problems and their corresponding solutions can greatly enhance efficiency and longevity.

| Issue | Description | Solution |

|---|---|---|

| Starting Problems | The engine fails to start, which can be caused by fuel or spark plug issues. | Check the fuel level and replace the spark plug if necessary. |

| Overheating | Excessive heat can lead to performance decline or damage. | Ensure adequate cooling by cleaning the air filter and checking coolant levels. |

| Unusual Noises | Strange sounds may indicate loose components or internal wear. | Tighten loose parts and inspect for wear; replace worn components as needed. |

| Vibration Issues | Excessive vibrations can signal misalignment or unbalanced components. | Check alignment and balance of rotating parts; adjust or replace as required. |

| Fuel Leaks | Leaks can lead to reduced efficiency and safety hazards. | Inspect fuel lines and connections; replace damaged parts immediately. |

Parts Replacement Procedures

Maintaining the efficiency and performance of your engine involves timely replacement of worn components. Following systematic procedures ensures that the process is straightforward and minimizes potential issues during assembly.

Begin by gathering the necessary tools and replacement components. Ensure your workspace is clean and organized to prevent the loss of any small items. Safety precautions should be your priority, including wearing gloves and protective eyewear.

Next, refer to the specific guidelines for disassembling the engine. This usually involves removing the outer casing and carefully detaching any connected elements. Handle all components with care to avoid damage, particularly sensitive parts.

Once disassembled, inspect each component for wear and tear. Identify which elements require replacement and procure suitable replacements. Using original or high-quality alternatives is recommended for optimal performance.

During reassembly, follow the reverse order of disassembly. Make sure all parts are securely fastened and aligned correctly. It is essential to double-check that no tools or materials are left inside the engine.

Finally, conduct a thorough test after the replacement to ensure everything operates as intended. Regular checks will help maintain the longevity of your machinery.

Tools Needed for Repair Work

Effective maintenance and repair require specific instruments to ensure efficiency and accuracy. Having the right tools on hand can significantly simplify the process and enhance the overall experience.

Here is a list of essential tools that are typically necessary for conducting repairs:

- Wrenches: Various sizes to accommodate different bolts and nuts.

- Screwdrivers: A set of flathead and Phillips screwdrivers for different screw types.

- Socket Set: For easy access to hard-to-reach areas.

- Torque Wrench: To apply the correct amount of force to fasteners.

- Pliers: For gripping and bending materials.

- Oil Filter Wrench: Specialized tool for removing oil filters.

- Measuring Tools: Such as calipers or tape measures for precise measurements.

- Work Gloves: To protect hands while working.

Utilizing these tools can help facilitate a smoother repair process and contribute to successful outcomes.

Where to Buy Genuine Parts

Finding authentic components for your engine can be essential for ensuring optimal performance and longevity. Whether you are conducting maintenance or making repairs, sourcing reliable replacements is crucial. Below are several options for acquiring high-quality components that meet your needs.

| Source | Description | Website |

|---|---|---|

| Authorized Dealers | Visit your local authorized dealers for genuine replacements. They offer the assurance of quality and compatibility. | Visit Site |

| Online Retailers | Many reputable online platforms specialize in engine components. Look for customer reviews to gauge reliability. | Visit Site |

| Manufacturer’s Website | Directly purchasing from the manufacturer ensures you receive authentic products. Check their site for available options. | Visit Site |

| Local Repair Shops | Many repair shops have access to genuine components. Inquire about their suppliers for reliable sourcing. | Visit Site |

Online vs. Local Suppliers

When sourcing components for machinery, customers often face a choice between online retailers and local vendors. Each option presents distinct advantages and challenges, impacting both availability and convenience.

Online suppliers offer:

- Wider selection of items

- Convenience of shopping from home

- Potentially lower prices due to competition

- Access to customer reviews for informed decisions

Conversely, local vendors provide:

- Immediate access to products without shipping delays

- Personalized service and expert advice

- The opportunity to inspect items before purchase

- Support for local businesses

Ultimately, the decision between online and local suppliers depends on individual preferences, specific needs, and the importance of factors like speed and customer service.

Understanding Warranty Policies

Warranty policies are essential for ensuring customer satisfaction and protecting investments in products. These policies outline the coverage provided by manufacturers, detailing what is included and the conditions under which repairs or replacements may occur. Familiarizing oneself with these terms can significantly enhance the overall ownership experience.

Key Elements of Warranty Coverage

When reviewing warranty documents, pay attention to the duration of coverage, specific components included, and any limitations that may apply. Most warranties offer a clear timeframe during which repairs or replacements are guaranteed, usually contingent upon proper maintenance and usage. Understanding these aspects helps users make informed decisions when it comes to their equipment.

Claiming Warranty Benefits

To successfully claim warranty benefits, it is crucial to keep receipts and documentation of purchases. Manufacturers often require proof of purchase to validate warranty claims. Additionally, following maintenance guidelines outlined in the warranty documentation can prevent disputes and ensure that coverage remains intact. Being proactive in understanding these policies not only safeguards investments but also facilitates a smoother resolution process in case of issues.

Aftermarket Parts Considerations

When seeking alternatives for components, it’s essential to evaluate various factors that can influence performance and durability. These considerations often determine whether an aftermarket replacement will effectively meet the needs of your engine. Understanding the balance between cost and quality is crucial in making an informed choice.

Several aspects should be taken into account when exploring these options:

| Factor | Importance | Notes |

|---|---|---|

| Compatibility | High | Ensure the part fits your engine model accurately. |

| Quality | Medium | Research reviews and brand reputation for reliability. |

| Warranty | Medium | Check for guarantees that cover defects or failures. |

| Price | High | Balance affordability with quality to avoid future costs. |

| Performance | High | Consider how the part affects overall engine function. |