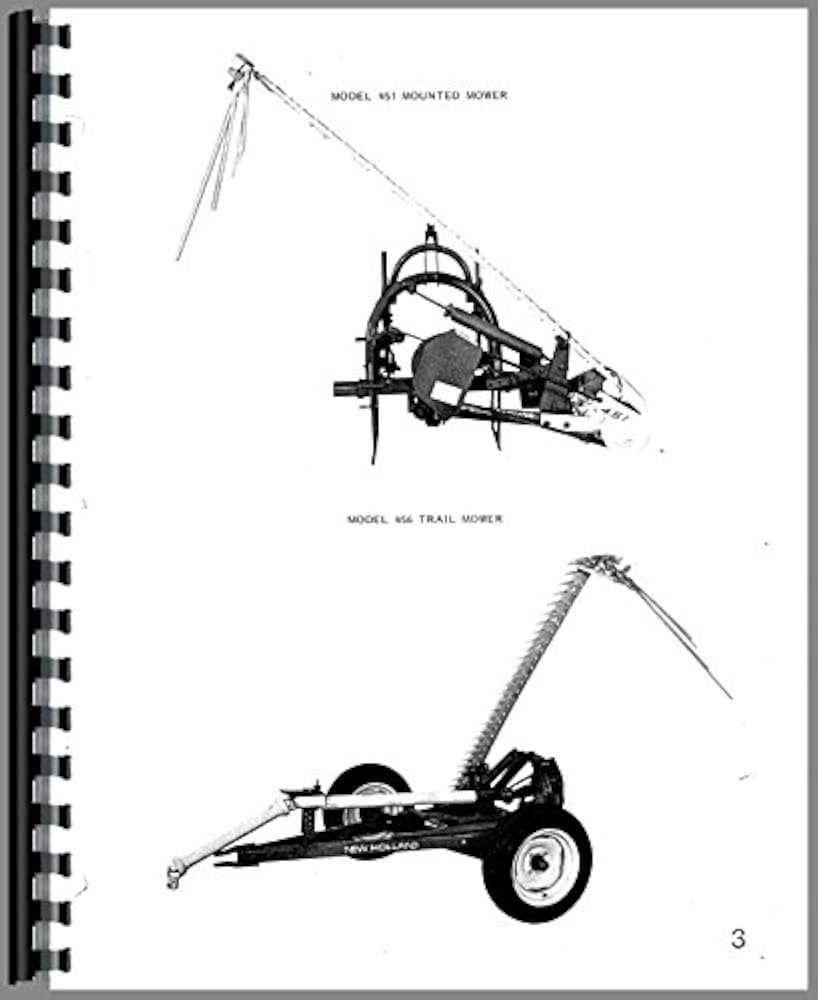

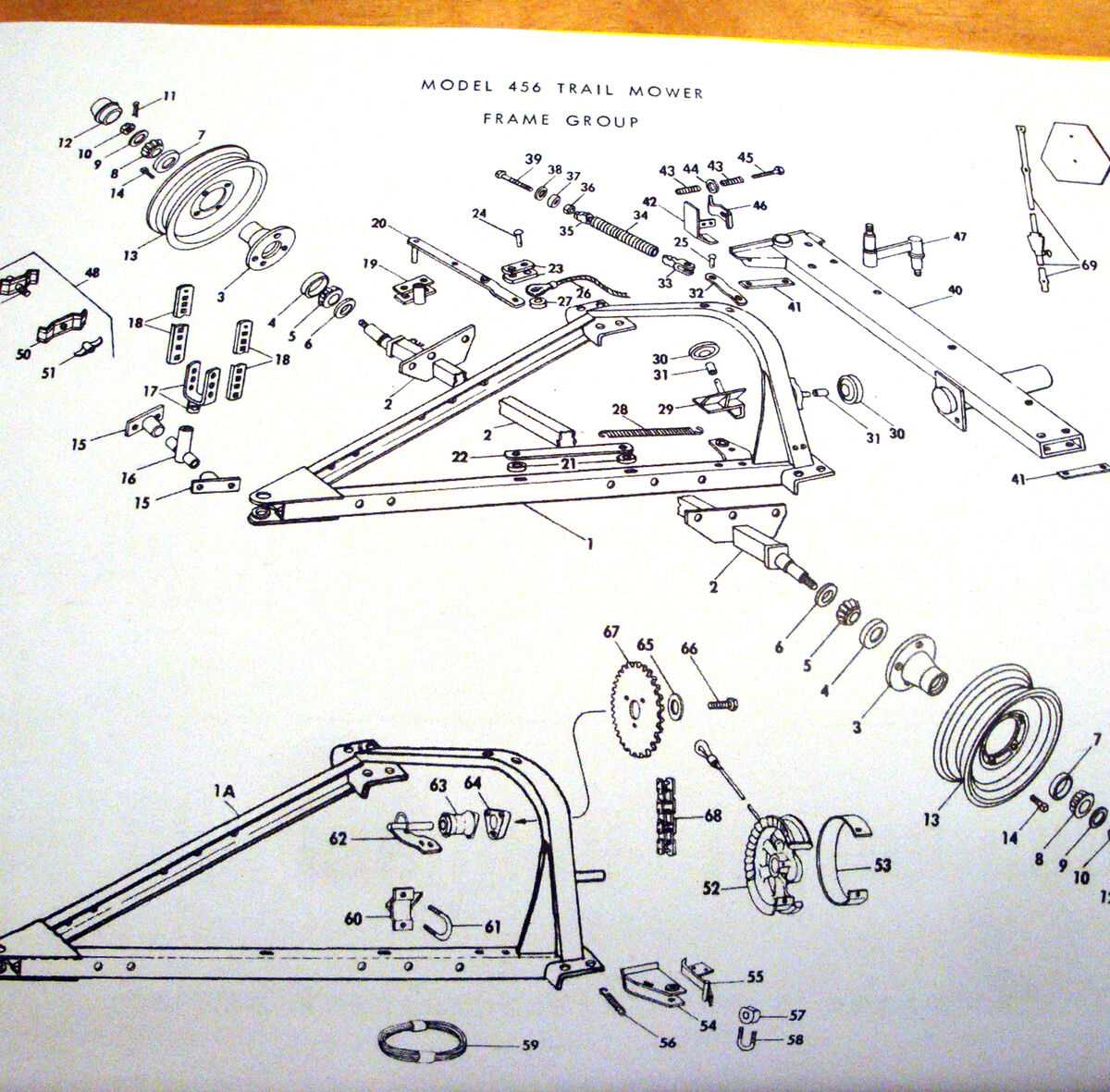

Parts Diagram for New Holland 456 Sickle Mower

For anyone involved in the agricultural sector, comprehending the intricacies of essential machinery is crucial. This article delves into the various elements that constitute a well-known tool used for cutting grass and hay. Each component plays a significant role in the overall efficiency and performance of the machine, ensuring that the tasks are carried out smoothly and effectively.

In this exploration, we will outline the specific elements associated with this agricultural implement, highlighting their functions and interconnections. A clear representation of these elements aids in the maintenance and repair processes, ultimately enhancing the longevity and productivity of the equipment. Whether you are a seasoned operator or a newcomer, understanding these components will contribute to more effective usage and care of the machinery.

By familiarizing yourself with the essential components, you can make informed decisions regarding maintenance and repairs. This knowledge empowers you to optimize the performance of your equipment, ensuring that it meets the demands of your agricultural activities with reliability and precision.

Overview of New Holland 456 Mower

This section provides a comprehensive examination of a versatile agricultural implement designed for efficient cutting and harvesting tasks. Its robust construction and innovative design facilitate optimal performance in various field conditions.

The equipment is renowned for its reliability and efficiency, making it a preferred choice among farmers and agricultural professionals. With user-friendly features, it enhances productivity while ensuring ease of maintenance. Key components play a vital role in its functionality, contributing to a seamless operation that meets the demands of modern farming practices.

Equipped with advanced technology, this implement offers precision in operation, allowing for a consistent cut and reduced crop damage. The combination of durable materials and engineering excellence ensures longevity and effectiveness in the field. Understanding its features can aid users in optimizing their agricultural tasks, leading to improved results and higher yields.

Essential Components of the Mower

The effectiveness of any cutting machine relies heavily on its fundamental elements. Understanding these critical components can enhance performance and maintenance, ensuring optimal operation in various agricultural tasks. Each section plays a pivotal role in the overall functionality, contributing to seamless operation and efficiency.

Cutting Mechanism: This is the primary feature responsible for achieving a clean and precise cut. It typically consists of blades that oscillate or rotate, providing versatility for different types of vegetation. Regular inspection and sharpening are vital for maintaining cutting quality.

Drive System: The power transmission system is crucial for transferring energy from the engine to the cutting mechanism. This includes belts, pulleys, and gears that work together to enable smooth operation. Proper adjustment and lubrication are necessary to prevent wear and ensure longevity.

Frame Structure: The framework serves as the backbone, supporting all other components. It must be robust and durable to withstand the rigors of agricultural work. Reinforced materials are often used to enhance resilience against harsh conditions.

Adjustable Skids: These elements allow for modifications in cutting height, ensuring the user can adapt to various terrains and crop types. Proper adjustment is essential for preventing damage to the machine and promoting healthy growth in the field.

Safety Features: Integrated safety mechanisms are designed to protect the operator and bystanders during operation. This may include shields, emergency stops, and other protective devices that help mitigate risks associated with agricultural machinery.

Importance of Regular Maintenance

Consistent upkeep is crucial for the longevity and efficiency of any machinery. By routinely inspecting and servicing equipment, users can identify potential issues before they escalate into major problems, thus ensuring optimal performance and reducing downtime. Regular attention not only extends the lifespan of the equipment but also enhances its reliability and effectiveness.

Furthermore, adhering to a maintenance schedule can lead to significant cost savings in the long run. Well-maintained machinery tends to consume less fuel and operate more smoothly, which translates to lower operational expenses. Additionally, consistent servicing can improve safety by minimizing the risk of accidents caused by equipment failures.

Ultimately, committing to regular maintenance is an investment in the future productivity and safety of operations. It fosters a proactive approach, allowing users to address minor concerns before they become critical, thereby promoting a seamless and efficient workflow.

Identifying Common Issues

Recognizing frequent problems in agricultural equipment is crucial for maintaining optimal performance and efficiency. By being aware of potential malfunctions, operators can prevent costly downtime and extend the lifespan of their machinery. Below are some typical concerns encountered in this type of equipment.

- Inconsistent Cutting Performance:

This issue may arise due to dull blades or misalignment. Regular inspection and timely sharpening can help address this.

- Excessive Vibration:

Vibration may indicate loose components or imbalanced assemblies. Tightening bolts and ensuring all parts are properly aligned can mitigate this.

- Hydraulic System Problems:

Leaks or insufficient pressure in the hydraulic system can lead to poor operation. Checking for leaks and maintaining proper fluid levels is essential.

- Wear and Tear on Belts:

Belt degradation can result in slippage or complete failure. Regularly examining belts for cracks or fraying and replacing them as needed is advisable.

- Blockages:

Debris accumulation can impede functionality. Regular cleaning and maintenance routines should be established to avoid clogs.

By monitoring these common issues, operators can ensure that their equipment runs smoothly and efficiently, reducing the risk of significant repairs and operational delays.

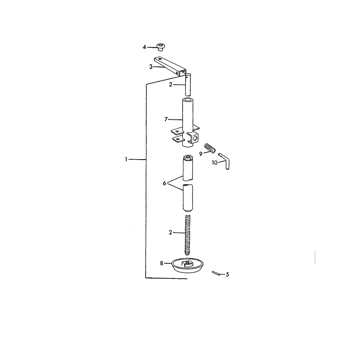

How to Use the Parts Diagram

Understanding the visual representation of components is essential for efficient maintenance and repair of agricultural machinery. This guide will help you navigate the graphical layout, enabling you to identify various elements quickly and accurately. Utilizing this resource can significantly simplify troubleshooting and ordering replacements, ensuring your equipment operates smoothly.

Identifying Components

Begin by familiarizing yourself with the layout of the visual reference. Each item is typically numbered or labeled, making it easier to locate specific elements. Pay attention to the legend or key, which provides crucial information about each section. This step is vital for recognizing which components require attention or replacement during servicing.

Ordering Replacements

Once you have identified the necessary components, the next step is to acquire replacements. Use the corresponding numbers or labels from the visual reference when contacting suppliers or searching online. This practice not only streamlines the ordering process but also helps ensure that you receive the correct items, minimizing delays in your machinery’s operation.

Replacement Parts: What You Need

Ensuring the functionality of your equipment involves understanding the essential components that may require substitution over time. Identifying these elements is crucial for maintaining optimal performance and extending the lifespan of your machine. This section will guide you through the critical components and considerations when looking for replacements.

Common Components for Substitution

- Belts and Chains: Vital for the transfer of power and motion.

- Blades: Essential for cutting efficiency and precision.

- Bearings: Important for smooth operation and reducing friction.

- Gearboxes: Necessary for transmitting torque and speed effectively.

Where to Find Quality Replacements

- Authorized Dealers: Ensure compatibility and quality assurance.

- Online Retailers: Convenient access to a wide range of options.

- Local Parts Stores: Immediate availability for urgent needs.

- Manufacturer’s Website: Direct source for original specifications and recommendations.

Tools Required for Repairs

Proper maintenance and repair of agricultural equipment necessitate the use of specific implements and tools. Having the right instruments on hand not only streamlines the process but also ensures safety and efficiency during repair tasks. This section outlines the essential tools needed to facilitate repairs effectively.

Basic Hand Tools

For routine repairs, a selection of hand tools is indispensable. Commonly used items include wrenches, screwdrivers, and pliers. These tools are crucial for loosening and tightening various components, ensuring that connections are secure and functional.

Specialized Equipment

In addition to basic hand tools, certain specialized instruments may be required for more intricate repairs. For example, a torque wrench is vital for applying the correct amount of force when securing bolts, while diagnostic tools can help identify underlying issues within the machinery. Investing in high-quality, reliable tools will contribute to a more efficient repair process and extend the lifespan of the equipment.

Step-by-Step Repair Guide

This section offers a comprehensive approach to restoring and maintaining agricultural machinery, focusing on essential techniques and best practices. By following these steps, you can effectively address common issues and enhance the longevity of your equipment.

Begin by gathering all necessary tools and safety equipment. Ensure that you have a clean workspace to facilitate the repair process. Familiarize yourself with the machinery components and their functions, as this knowledge will aid in identifying problems accurately.

Next, carefully inspect the unit for any visible damage or wear. Pay attention to critical areas that may require immediate attention. Document your findings to create a clear plan of action. If parts need replacement, consult reliable sources for the correct specifications and compatible components.

Once you have a solid understanding of the issues, proceed with disassembly. Take your time and label each component as you remove it to ensure correct reassembly later. Use appropriate techniques to avoid causing further damage during this process.

After disassembling, clean all parts thoroughly to remove dirt and debris. Inspect each component for signs of wear and tear. Replace any damaged pieces with high-quality alternatives to maintain optimal performance.

As you reassemble the unit, follow your earlier documentation to ensure accuracy. Tighten all connections securely but avoid overtightening, which can cause additional stress on components. Conduct a final inspection to ensure everything is in place before testing the machinery.

Finally, after reassembly, run the equipment to verify that it operates smoothly. Monitor for any unusual sounds or behaviors, and make adjustments as needed. Regular maintenance and timely repairs will help extend the lifespan of your machinery.

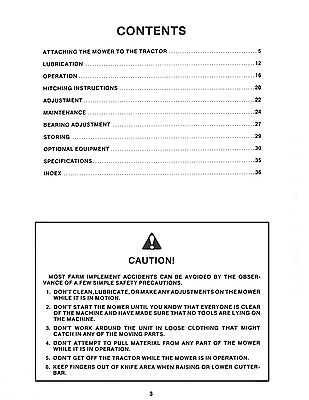

Safety Precautions While Working

Ensuring a secure work environment is crucial for preventing accidents and injuries when operating agricultural machinery. Familiarizing oneself with essential safety measures not only protects the individual but also promotes efficient task execution. This section outlines vital precautions to consider before and during operations.

Preparation Before Use

- Inspect equipment thoroughly for any signs of wear or damage.

- Ensure that all guards and safety devices are in place and functioning properly.

- Read the manufacturer’s instructions to understand the specific safety requirements.

- Wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

During Operation

- Maintain a safe distance from moving parts while the machinery is in use.

- Stay alert and focused to respond quickly to any unexpected situations.

- Do not allow unauthorized personnel near the working area.

- Keep hands and feet clear of all operational components.

By adhering to these precautions, operators can significantly reduce the risk of incidents and ensure a safer working environment.

Where to Buy Replacement Parts

Finding the right components for agricultural machinery can be crucial for maintaining optimal performance and efficiency. Whether you are looking to repair or upgrade your equipment, there are several avenues to explore when sourcing these essential elements. It’s important to choose suppliers who offer quality items and reliable service to ensure your machinery operates smoothly.

Local dealers often carry a selection of components suitable for various models. Visiting these stores can provide you with the advantage of speaking directly with knowledgeable staff, who can offer recommendations based on your specific needs. Additionally, they may have access to specialized items that are not widely available.

Online marketplaces are another excellent option for obtaining the necessary components. Websites dedicated to agricultural equipment usually provide detailed catalogs, allowing you to search for specific items based on model specifications. Be sure to read customer reviews and check the reputation of the seller to ensure a satisfactory transaction.

Moreover, auction sites and classified ads can yield great finds at competitive prices. These platforms often list both new and used items, giving you the flexibility to choose according to your budget. Always verify the condition and compatibility of used components before purchasing.

Lastly, consider connecting with online forums and communities dedicated to agricultural machinery. Fellow enthusiasts and professionals can share insights on where to find quality items and may even have recommendations for lesser-known suppliers who offer great deals.

Customer Reviews and Feedback

This section focuses on the opinions and experiences of users regarding a specific agricultural tool. Customer insights can provide valuable information about the efficiency, durability, and overall performance of the equipment. Understanding user perspectives helps potential buyers make informed decisions and highlights areas for improvement.

Positive Experiences

Many users appreciate the reliability and functionality of this machine. They frequently mention its ability to handle various tasks with ease, making it a favorite among farmers. One customer noted, “This implement has significantly improved my workflow, allowing me to complete jobs much faster than before.” The ease of use and low maintenance requirements also receive high praise.

Areas for Improvement

While feedback is largely positive, some users have pointed out a few challenges. A common concern is the availability of replacement components, which can sometimes be difficult to source. As one reviewer stated, “I love the performance, but finding parts when needed can be a hassle.” Addressing these issues could enhance user satisfaction and encourage more people to choose this equipment.

Comparing New Holland Models

This section aims to analyze various models produced by the manufacturer, highlighting key features and differences. Understanding these variations can assist users in making informed decisions based on their specific needs and applications.

Key Features to Consider

- Design and Build Quality

- Performance and Efficiency

- Maintenance Requirements

- Compatibility with Attachments

- Cost of Ownership

Popular Models Overview

-

Model A: Known for its robust construction and efficiency in various conditions.

-

Model B: Offers enhanced maneuverability and is favored for smaller fields.

-

Model C: Combines power with advanced technology for optimal performance.

-

Model D: A cost-effective option that balances functionality with affordability.

By evaluating these models based on the highlighted features, potential buyers can select the most suitable equipment for their agricultural tasks.

Resources for Further Information

For those seeking to enhance their understanding and knowledge regarding specific equipment and its components, numerous valuable resources are available. These materials can provide in-depth insights, technical guidance, and expert advice, catering to both novices and seasoned professionals in the field.

Online Forums and Communities

Engaging with online forums and communities dedicated to agricultural machinery can be highly beneficial. Platforms such as discussion boards and social media groups allow enthusiasts to share experiences, troubleshoot issues, and exchange tips related to maintenance and operation.

Manufacturer Websites and Manuals

Visiting the official websites of manufacturers can offer access to a wealth of resources, including user manuals, assembly instructions, and maintenance guides. These documents are often crucial for ensuring proper handling and care of equipment.