Comprehensive Guide to John Deere 2038R Parts Diagram

The functionality and efficiency of a compact agricultural machine greatly depend on its individual elements. Familiarizing oneself with the intricate layout of these components is essential for proper maintenance and operation. A thorough examination of these parts can lead to better performance and longevity of the equipment.

In this section, we delve into the specifics of a well-known compact tractor model, exploring its various features and configurations. Recognizing each element and its role allows operators to make informed decisions regarding repairs and upgrades. Understanding how these parts interact enhances the overall user experience and ensures optimal functionality.

Additionally, having access to a comprehensive overview of these components aids in troubleshooting and maintenance tasks. Whether you are a seasoned professional or a novice user, knowing the specifics of your machine’s assembly can save time and resources in the long run. This guide serves as a valuable resource for anyone looking to enhance their knowledge of agricultural machinery.

Understanding the John Deere 2038R

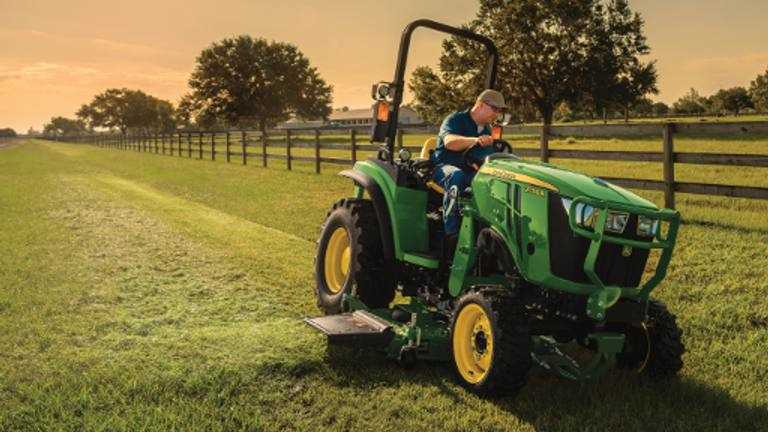

This section delves into the features and functionalities of a compact utility tractor designed for versatility and efficiency in various agricultural and landscaping tasks. Its robust design caters to a wide range of applications, making it a valuable asset for both professionals and enthusiasts.

Equipped with advanced technology, this machine enhances productivity and ensures ease of operation. Its ergonomic layout allows for comfortable handling, enabling users to work for extended periods without fatigue. Additionally, the powerful engine provides reliable performance across different terrains.

| Feature | Description |

|---|---|

| Engine Power | Provides ample horsepower for heavy-duty tasks. |

| Transmission | Offers smooth shifting for optimal control. |

| Hydraulics | Supports various attachments for enhanced functionality. |

| Operator Comfort | Designed with an ergonomic seat and controls for ease of use. |

| Compact Size | Facilitates maneuverability in tight spaces. |

Understanding the essential components and features of this machine allows users to maximize its capabilities and ensure proper maintenance. Whether for farming, gardening, or landscaping, this model stands out as a reliable choice for those seeking efficiency and performance.

Key Features of the 2038R Model

The 2038R model stands out in its category due to a combination of advanced technology and user-friendly design. This machine is engineered to enhance productivity and ensure comfort during operation, making it suitable for a variety of tasks.

One of the notable aspects is its impressive power output, which allows for efficient handling of heavy-duty applications. The compact design enables maneuverability in tight spaces, while the robust construction guarantees durability under challenging conditions.

Additionally, the ergonomic controls and spacious operator station promote ease of use and reduce operator fatigue, contributing to longer work sessions. The integrated hydraulic system enhances versatility, allowing for seamless attachment of implements.

| Feature | Description |

|---|---|

| Power | High-performance engine for various tasks |

| Compact Design | Efficient operation in confined areas |

| Operator Comfort | Ergonomic controls and spacious seating |

| Hydraulic System | Supports a wide range of attachments |

Importance of Parts Diagrams

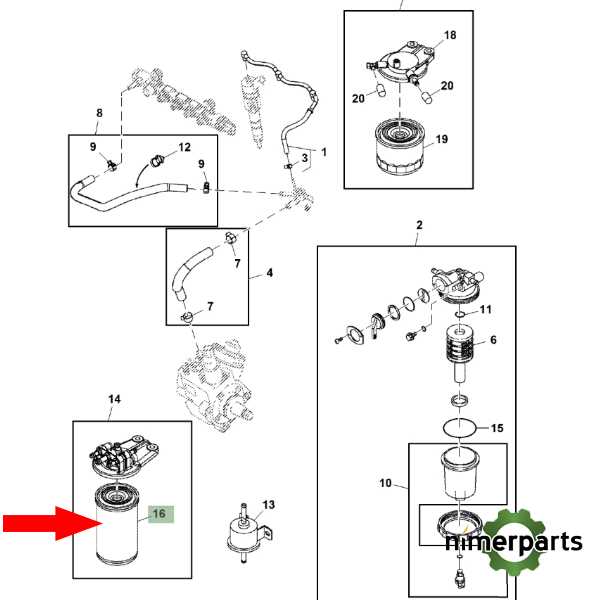

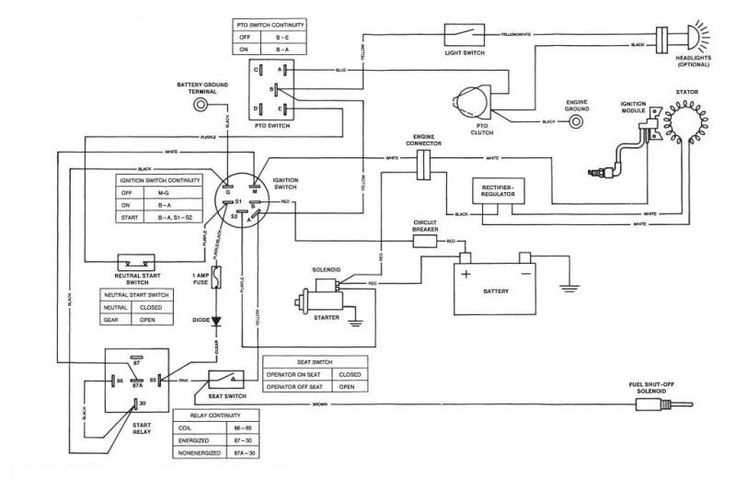

Visual representations of components play a crucial role in understanding the assembly and functionality of machinery. They provide detailed insights that help users identify various elements, ensuring effective maintenance and repair processes. By offering a clear overview, these illustrations assist in the accurate recognition of parts, facilitating efficient troubleshooting and replacement.

Moreover, such visual aids enhance communication among technicians and engineers, allowing for a standardized approach to repairs. They streamline workflows by eliminating ambiguity, ensuring that everyone involved has a consistent reference point. This not only saves time but also reduces the risk of errors during maintenance tasks.

Additionally, familiarizing oneself with these illustrations can significantly extend the lifespan of equipment. Understanding how different components interact encourages proactive maintenance, ultimately leading to improved performance and reliability. Users who are well-versed in these visuals are better equipped to handle repairs, minimizing downtime and enhancing productivity.

How to Read a Parts Diagram

Understanding an illustration that outlines various components of machinery is essential for efficient maintenance and repairs. Such visuals provide a clear representation of each element’s position and function, enabling users to identify and source the necessary items effectively. Mastering this skill can significantly enhance the overall repair process.

Identifying Components

Start by familiarizing yourself with the symbols and notations used in the visual representation. Each component is usually labeled with a specific number or letter, which corresponds to a list detailing its name and specifications. Pay close attention to these labels, as they are crucial for locating the correct items.

Understanding Relationships

Next, analyze how the different elements are connected. Recognizing the relationships between various parts can provide insights into the assembly and disassembly processes. Take note of any arrows or lines that indicate how components interact with one another, as this knowledge is invaluable during repairs or upgrades. By mastering these techniques, you can approach any mechanical task with confidence and precision.

Common Parts for the 2038R

The efficient operation of compact tractors relies on various essential components that enhance performance and durability. Understanding these elements can help ensure that the machinery runs smoothly and effectively, minimizing downtime and maintenance costs.

Key Components

One of the most crucial elements includes the engine assembly, which provides the necessary power for all functions. Additionally, the transmission system plays a vital role in controlling speed and torque, making it indispensable for optimal performance.

Maintenance Essentials

Regular upkeep is vital for the longevity of any machine. Filters, belts, and hydraulic fluids should be monitored and replaced as needed to maintain efficiency. Utilizing high-quality replacements not only prolongs the lifespan but also ensures consistent operation during demanding tasks.

For those seeking to enhance their compact tractor experience, focusing on these fundamental elements is essential for achieving peak productivity.

Maintenance Tips for Longevity

Proper upkeep of machinery is essential for ensuring its optimal performance and extending its lifespan. Regular maintenance not only enhances efficiency but also reduces the likelihood of unexpected breakdowns. Implementing a few straightforward practices can significantly contribute to the durability and reliability of your equipment.

Regular Inspection

Conducting routine checks is crucial for identifying potential issues before they escalate. Focus on the following areas:

- Fluid levels: Check oil, coolant, and hydraulic fluids regularly.

- Belts and hoses: Inspect for wear and tear, ensuring they are not frayed or cracked.

- Battery: Monitor connections and clean terminals to prevent corrosion.

Scheduled Servicing

Adhering to a servicing schedule helps maintain peak performance. Consider these recommendations:

- Follow the manufacturer’s maintenance guidelines for service intervals.

- Replace filters, such as air and oil, according to the suggested timeline.

- Lubricate moving parts to minimize friction and prevent wear.

By integrating these maintenance strategies into your routine, you can significantly enhance the longevity of your machinery, ensuring it operates smoothly for years to come.

Identifying Parts by Number

Understanding the identification of components is essential for effective maintenance and repair of machinery. Each item within the system is assigned a unique identifier, allowing for efficient tracking and ordering. This process not only streamlines repairs but also ensures that the correct replacements are sourced.

To facilitate the identification process, consider the following steps:

- Refer to the owner’s manual, which typically includes a comprehensive list of identifiers.

- Utilize online resources and official websites dedicated to equipment support.

- Examine the machinery itself, as many components will have the identifier stamped or printed directly on them.

- Contact a local dealer or service center for assistance in locating the correct identifiers.

Utilizing these strategies will help ensure that you can accurately identify and acquire the necessary components for optimal functionality.

Where to Find Replacement Parts

Finding suitable components for your machinery is crucial for maintaining optimal performance. Numerous sources are available to help you locate the necessary items, whether for routine maintenance or repairs. Understanding where to search can save you time and ensure you acquire high-quality replacements.

Authorized Dealers

One of the most reliable options for sourcing components is through authorized dealers. These outlets provide genuine items that meet the manufacturer’s specifications. Additionally, you can benefit from expert advice and support.

Online Retailers

Another convenient option is to explore various online retailers. Numerous websites specialize in providing machinery components, often offering competitive pricing and a wide selection. Make sure to verify the credibility of the retailer before making a purchase.

| Source Type | Advantages | Considerations |

|---|---|---|

| Authorized Dealers | Genuine products, expert support | Higher prices, limited locations |

| Online Retailers | Convenient shopping, wide selection | Verify retailer credibility, shipping times |

| Local Repair Shops | Personalized service, immediate availability | Limited stock, variable quality |

Cost Considerations for Repairs

When it comes to maintaining equipment, financial aspects play a crucial role in decision-making. Understanding the expenses associated with repairs can help owners budget effectively and avoid unexpected costs. Properly assessing the condition of machinery and its components is essential for determining whether to repair or replace parts.

Evaluating Repair Costs

Repair costs can vary significantly based on several factors, including the complexity of the issue, labor rates, and the price of replacement components. It is vital to gather quotes from multiple service providers to ensure competitive pricing. Additionally, considering the age and overall condition of the machinery can influence whether investing in repairs is financially sound.

Long-term Financial Impact

Investing in repairs may initially seem costly, but it can lead to long-term savings by extending the life of the equipment and preventing future breakdowns. Regular maintenance and timely repairs can also enhance performance, contributing to overall productivity. Analyzing the potential return on investment can guide owners in making informed choices about repairs versus replacements.

Upgrades Available for 2038R

Enhancements for this versatile machine can significantly boost its performance and functionality. Upgrading specific components allows operators to tailor their equipment to better suit diverse tasks and improve overall efficiency.

Performance Enhancements

One popular upgrade is the installation of high-efficiency engines, which provide greater power output while maintaining fuel economy. Additionally, implementing advanced hydraulic systems can enhance lifting capabilities, enabling users to handle heavier loads with ease.

Comfort and Usability Features

To improve the user experience, various comfort upgrades are available, such as ergonomic seating and climate control options. These modifications ensure that operators can work for extended periods without fatigue. Furthermore, integrating modern display systems can provide real-time data, enhancing operational awareness and safety.

By considering these enhancements, owners can maximize the potential of their machinery, making it more efficient and comfortable for everyday use.

Comparison with Similar Models

This section explores the similarities and differences among compact utility tractors within the same category. Understanding these variations can assist potential buyers in making informed decisions based on their specific requirements and preferences.

When evaluating tractors in this segment, key factors such as engine power, hydraulic capacity, and transmission options often come into play. Competitors in this range may offer comparable horsepower but differ in features like loader compatibility and lift height. Some models might excel in fuel efficiency, while others may provide enhanced comfort with superior ergonomics.

Additionally, the availability of attachments and aftermarket accessories can significantly influence a buyer’s choice. While one model may have a robust lineup of compatible implements, another may offer a more streamlined design suited for specific tasks. Ultimately, assessing these attributes helps potential users determine which machine aligns best with their operational needs.

Owner Experiences and Testimonials

This section highlights the feedback and experiences of individuals who have utilized their machinery, focusing on their insights regarding performance, reliability, and overall satisfaction. Owners often share valuable information that can assist potential buyers in making informed decisions.

Positive Feedback

- Many users appreciate the ease of operation, stating that the controls are intuitive and straightforward.

- Several testimonials highlight the machine’s versatility, noting its ability to handle various tasks effectively.

- Owners frequently mention the comfort of the operator station, which enhances productivity during extended use.

Areas for Improvement

- Some users suggest enhancements in certain features for increased efficiency.

- A few testimonials express a desire for additional accessories to expand functionality.

- Occasional feedback points out the need for clearer maintenance instructions in the user manual.

Resources for Further Learning

For those interested in expanding their knowledge about agricultural machinery and its components, numerous valuable resources are available. Engaging with these materials can provide insights into maintenance, operation, and the intricacies of various models.

Online Forums: Participating in specialized forums can connect you with enthusiasts and experts. These communities often share experiences, troubleshooting tips, and practical advice.

Manufacturer Websites: Many manufacturers offer extensive resources on their websites, including manuals, how-to guides, and technical specifications. These documents can be essential for understanding specific machinery features.

Video Tutorials: Platforms like YouTube host numerous tutorials that cover a wide range of topics, from basic maintenance procedures to complex repairs. Visual learning can be particularly effective for grasping detailed processes.

Books and Manuals: Reference books and user manuals are excellent for in-depth study. They typically provide comprehensive information about machinery systems, best practices, and safety protocols.

Local Workshops: Attending workshops or seminars conducted by professionals can enhance practical skills. These hands-on experiences allow for direct interaction and learning from industry experts.

Utilizing these resources will deepen your understanding and improve your ability to manage and maintain agricultural equipment effectively.