Honda Big Red 250ES 1985 Parts Diagram Overview

This section focuses on the essential components of a well-known all-terrain vehicle from the mid-80s, providing a clear representation of its various elements. Understanding the structure and layout of this vehicle is crucial for enthusiasts and mechanics alike, ensuring proper maintenance and repair.

In the following discussion, we will delve into the intricate assembly of the vehicle, highlighting its key features and the relationships between different components. This knowledge is invaluable for anyone looking to restore or enhance their ride, allowing for informed decisions regarding upgrades and replacements.

Whether you are a seasoned expert or a newcomer to the world of off-road machines, having a comprehensive overview of this model’s architecture will greatly enhance your appreciation and ability to care for it. With clarity and precision, we will outline the essential parts that contribute to its performance and reliability.

1985 Honda Big Red 250ES Overview

This model represents a significant advancement in all-terrain vehicle design, characterized by its durability and versatility. It is engineered for a variety of outdoor activities, making it a preferred choice for both recreational use and work-related tasks. With robust features and reliable performance, this vehicle has earned a strong reputation among enthusiasts.

Key Features

The vehicle is equipped with several notable attributes that enhance its functionality and user experience. Its robust frame supports a powerful engine, ensuring reliable performance across diverse terrains. Additionally, the vehicle incorporates advanced suspension systems that provide comfort and stability, making it suitable for various riding conditions.

Specifications

| Feature | Details |

|---|---|

| Engine Type | Air-cooled, single-cylinder |

| Transmission | Automatic |

| Fuel Capacity | 4.0 gallons |

| Weight | 500 lbs |

| Drive Type | 2WD/4WD |

Key Specifications of the Model

This section provides an overview of the essential characteristics of the all-terrain vehicle, highlighting its performance, capacity, and features that contribute to its functionality and reliability. Understanding these specifications is crucial for enthusiasts and potential users alike.

Performance Features

- Engine Type: Air-cooled, single-cylinder, four-stroke

- Displacement: Approximately 250cc

- Maximum Power Output: Around 15 horsepower

- Transmission: Semi-automatic with a torque converter

- Drive System: Chain-driven

Dimensions and Capacities

- Overall Length: 76 inches

- Overall Width: 46 inches

- Seat Height: 32 inches

- Fuel Tank Capacity: Approximately 3.2 gallons

- Weight: Roughly 460 pounds

These specifications underscore the model’s robust design, making it a reliable option for a variety of outdoor activities.

Common Issues with Big Red 250ES

The model in question has garnered attention for its reliability, yet users often encounter certain recurring challenges. Understanding these common problems can aid owners in maintaining optimal performance and prolonging the lifespan of their vehicle. Addressing these issues proactively can lead to a more enjoyable riding experience.

Engine Performance Problems

One frequent concern involves engine performance, where riders may notice a decline in power or responsiveness. This can stem from various factors, including fuel quality and air filter conditions. Regular maintenance and timely replacement of essential components can significantly enhance engine efficiency and overall performance.

Transmission and Drive Concerns

Transmission issues may also arise, leading to difficulties in shifting gears or engaging the drive system. This problem can often be attributed to worn-out components or improper adjustments. Owners should regularly inspect the transmission fluid levels and consider a thorough examination of the drive mechanism to ensure smooth operation.

Essential Maintenance Tips for Owners

Proper upkeep is vital for ensuring the longevity and performance of your vehicle. Regular attention to key components not only enhances reliability but also contributes to a safer riding experience. By following a systematic maintenance routine, owners can prevent minor issues from escalating into major repairs.

Regular Inspection of Key Components

It is crucial to frequently check essential parts such as brakes, tires, and fluids. This practice helps identify any potential problems early on. Keeping these components in good condition is essential for maintaining safety and performance.

Fluid Changes and Levels

Monitoring and replacing fluids, including oil and coolant, is a necessary part of vehicle maintenance. Ensuring that all fluid levels are optimal helps to prevent overheating and engine wear. Regularly scheduled changes will enhance efficiency and prolong the lifespan of the engine.

| Maintenance Task | Frequency |

|---|---|

| Brake Inspection | Every 1,000 miles |

| Tire Rotation | Every 3,000 miles |

| Oil Change | Every 2,500 miles |

| Coolant Level Check | Monthly |

Parts Availability for Honda ATVs

When it comes to off-road vehicles, ensuring the availability of components is crucial for maintenance and repair. Owners often seek reliable sources for high-quality replacements and enhancements to keep their machines running smoothly.

Various retailers specialize in aftermarket and OEM solutions, catering to a wide range of models. Many enthusiasts find it beneficial to explore both online and local options to compare prices and quality. Additionally, forums and community groups can provide valuable insights into trusted suppliers and recommendations for hard-to-find items.

With the right resources, keeping these recreational vehicles in optimal condition becomes a manageable task. Regular maintenance not only extends the life of the vehicle but also enhances performance during outdoor adventures.

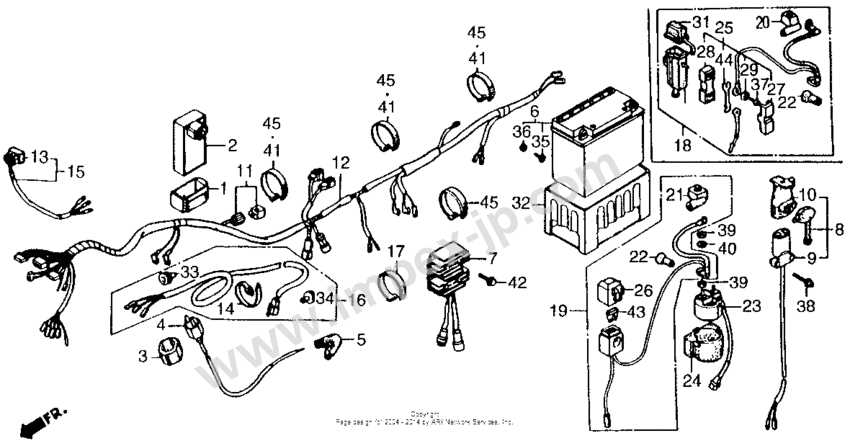

Understanding the Electrical System Layout

The electrical framework of an all-terrain vehicle plays a crucial role in its overall performance and functionality. By comprehending the arrangement and connections of the electrical components, users can enhance their knowledge of the vehicle’s operation and maintenance. This section will delve into the essential elements of the electrical system, outlining how each component interacts to ensure optimal performance.

Key Components of the Electrical System

The electrical system consists of various parts that work in harmony. Understanding these components can aid in troubleshooting and maintenance tasks. The main elements include the battery, wiring harness, ignition system, and lighting. Each plays a significant role in ensuring the vehicle runs smoothly.

Wiring Layout Overview

A clear understanding of the wiring layout is vital for effective diagnostics and repairs. The wiring harness connects all electrical components, facilitating the flow of current throughout the system. Below is a simplified representation of the wiring connections.

| Component | Description |

|---|---|

| Battery | Stores electrical energy for starting and powering the vehicle. |

| Ignition System | Generates the spark needed to ignite the fuel-air mixture. |

| Wiring Harness | Bundled wires connecting all electrical components. |

| Lighting System | Illuminates the path and enhances visibility during operation. |

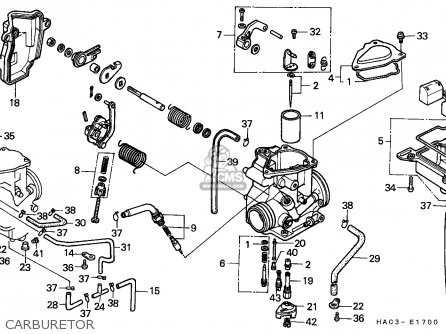

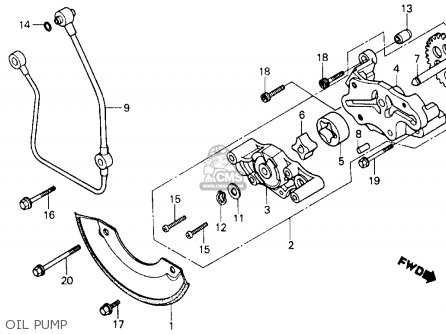

Detailed Engine Components Breakdown

This section provides a comprehensive overview of the various components that make up the engine of a specific all-terrain vehicle. Understanding these elements is crucial for both maintenance and repair, ensuring optimal performance and longevity of the machine. Each part plays a vital role in the overall functionality, from the power generation to the transmission of energy to the wheels.

Major Engine Elements

The primary components of the engine include the following:

| Component | Description |

|---|---|

| Cylinder Head | The upper part of the engine that houses the combustion chamber and facilitates air intake and exhaust gas exit. |

| Piston | A cylindrical piece that moves up and down within the cylinder, converting fuel energy into mechanical work. |

| Crankshaft | This component converts the linear motion of the piston into rotational motion, driving the vehicle. |

| Camshaft | Controls the opening and closing of the engine valves, ensuring proper timing for combustion. |

Auxiliary Components

In addition to the major parts, several auxiliary elements support the engine’s operation:

| Component | Description |

|---|---|

| Fuel Injector | Delivers the precise amount of fuel into the combustion chamber for optimal performance. |

| Oil Pump | Circulates engine oil to lubricate moving parts, reducing friction and preventing overheating. |

| Ignition System | Provides the spark necessary to ignite the air-fuel mixture in the combustion chamber. |

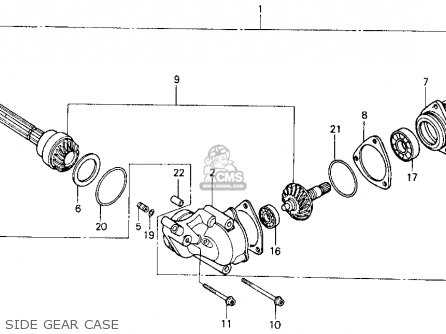

Transmission and Gear System Insights

The transmission and gear mechanisms play a crucial role in the overall functionality of off-road vehicles. They are designed to ensure optimal power delivery from the engine to the wheels, allowing for efficient movement across various terrains. Understanding these systems provides valuable insights into performance enhancement and maintenance practices.

Overview of Transmission Components

A well-designed transmission system consists of various components that work in harmony to transmit power. Key elements include the gearbox, clutch, and driveshaft. Each part serves a specific function, contributing to the smooth operation and longevity of the vehicle.

| Component | Function |

|---|---|

| Gearbox | Regulates gear ratios to match speed and torque requirements. |

| Clutch | Engages and disengages the engine from the transmission, allowing for smooth shifting. |

| Driveshaft | Transfers power from the transmission to the wheels, facilitating movement. |

Maintenance Tips for Optimal Performance

Regular maintenance of the transmission and gear system is essential for ensuring peak performance. Key practices include checking fluid levels, inspecting for leaks, and replacing worn components. Adhering to these guidelines can significantly extend the lifespan of the vehicle’s transmission.

Suspension Parts and Functions Explained

The suspension system is a vital component of any vehicle, ensuring a smooth ride and optimal handling. It is designed to absorb shocks from uneven surfaces and maintain contact between the tires and the ground. This section will delve into the various components of the suspension system and their specific roles in enhancing performance and comfort.

- Shock Absorbers: These elements are crucial for dampening the impact of bumps and irregularities on the road. They control the oscillation of the springs and prevent excessive bouncing.

- Springs: Springs support the weight of the vehicle and absorb shocks. They come in various types, including coil, leaf, and air springs, each serving different applications.

- A-arms: A-arms, or control arms, connect the wheel assembly to the vehicle’s chassis. They allow for up and down movement while keeping the wheels aligned.

- Struts: Struts combine the functions of shock absorbers and structural support. They help maintain the vehicle’s alignment and support the suspension system.

- Stabilizer Bar: Also known as an anti-roll bar, this component reduces body roll during cornering. It enhances stability by distributing weight evenly across the vehicle.

Each of these components works together to create a cohesive suspension system. Understanding their functions can help in diagnosing issues and improving the overall performance of the vehicle.

Braking System and Components Overview

The braking system is a crucial component of any vehicle, ensuring safety and control during operation. It consists of various elements that work together to slow down or stop the vehicle effectively. Understanding the components involved in the braking mechanism is essential for maintenance and troubleshooting.

The primary parts of the braking system include the brake pads, rotors, and calipers. Brake pads create friction against the rotors to decelerate the wheels. The rotors, attached to the wheel hub, rotate with the wheels, while the calipers house the brake pads and are activated by hydraulic pressure.

Additionally, the brake lines and master cylinder play vital roles in the system. The master cylinder generates hydraulic pressure that travels through the brake lines to the calipers, ensuring that the pads engage the rotors when the brake pedal is pressed. Regular inspection of these components can help maintain optimal performance and extend the lifespan of the braking system.

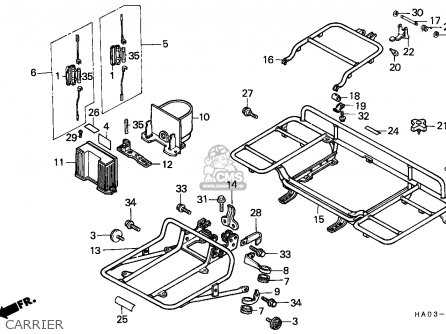

Bodywork and Frame Diagram Analysis

This section delves into the structure and exterior components of a classic utility vehicle, focusing on the layout and interconnection of various elements. Understanding how these components interact is crucial for maintenance and restoration efforts. The analysis emphasizes the importance of each section in ensuring the overall functionality and durability of the machine.

The frame serves as the backbone, providing stability and support for all attached elements. An examination of the outer coverings reveals not only aesthetic features but also practical roles in protecting internal mechanisms from environmental factors. The synergy between the frame and bodywork is essential for optimal performance, affecting handling and ride quality.

In the context of repairs, recognizing the location of fasteners and attachment points can simplify disassembly and reassembly processes. Additionally, identifying areas susceptible to wear or damage allows for proactive maintenance. Each segment, from the chassis to the panels, contributes to the vehicle’s reliability and operational efficiency.

Helpful Resources for Repair Manuals

Finding the right guidance for maintenance and troubleshooting can significantly enhance the longevity of your equipment. A variety of resources are available to assist users in understanding their machinery and effectively carrying out repairs. Utilizing these tools can simplify the process, ensuring a smoother experience for both novice and experienced users alike.

Online Platforms

Numerous websites offer extensive databases of repair manuals and instructional guides. These platforms often feature community forums where users can share experiences, ask questions, and provide insights into specific issues. Popular sites may include manufacturers’ official pages, online retailers, and dedicated forums that focus on equipment maintenance.

Printed Manuals and Literature

For those who prefer tangible resources, printed manuals are invaluable. Many manufacturers provide hard copies of their manuals, often available for purchase or free download. Additionally, local libraries or bookstores may carry guides that cover a wide range of machinery. Utilizing these resources can offer detailed illustrations and step-by-step instructions, making repairs more accessible.

Finding Replacement Parts and Suppliers

Locating suitable replacements for your vehicle can be a challenging but essential task for maintaining its performance and longevity. Understanding where to find quality components and reputable vendors is crucial for ensuring that your machine runs smoothly and efficiently.

Start by exploring local dealers, as they often carry a range of components that are compatible with your vehicle model. These dealers typically have knowledgeable staff who can assist you in identifying the right items and may even provide insights into the best maintenance practices.

Online marketplaces are another valuable resource for sourcing necessary items. Websites dedicated to automotive parts usually have extensive inventories, including both new and used options. Always check customer reviews and seller ratings to gauge reliability before making a purchase.

Another effective method is to join enthusiast forums and social media groups dedicated to your vehicle type. These communities can be great sources of information, offering recommendations for trustworthy suppliers and even suggestions for alternative parts that may offer better performance or durability.

Lastly, consider reaching out to specialized salvage yards or recycling centers. These facilities often have older models available, allowing you to find rare components at a fraction of the cost. Always verify the condition of used items before purchasing to ensure they meet your standards.