Understanding the Parts Diagram of Stihl MSA 120 C

When it comes to maintaining and operating your electric cutting equipment, having a clear understanding of its internal mechanisms is essential. Each unit comprises various elements that work in harmony to deliver optimal performance. Familiarity with these components not only aids in effective troubleshooting but also ensures longevity and reliability in usage.

In this section, we will delve into the intricate layout of the various sections and parts that make up your tool. By breaking down each component, you’ll gain insights into their functions and how they contribute to the overall efficiency of the equipment. This knowledge empowers users to perform routine maintenance and make informed decisions during repairs.

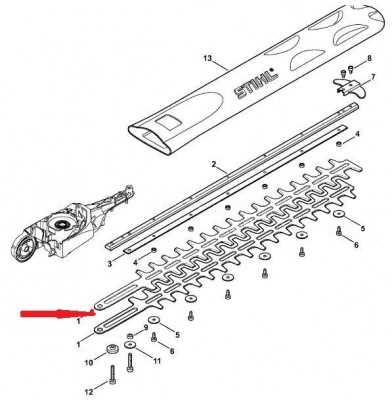

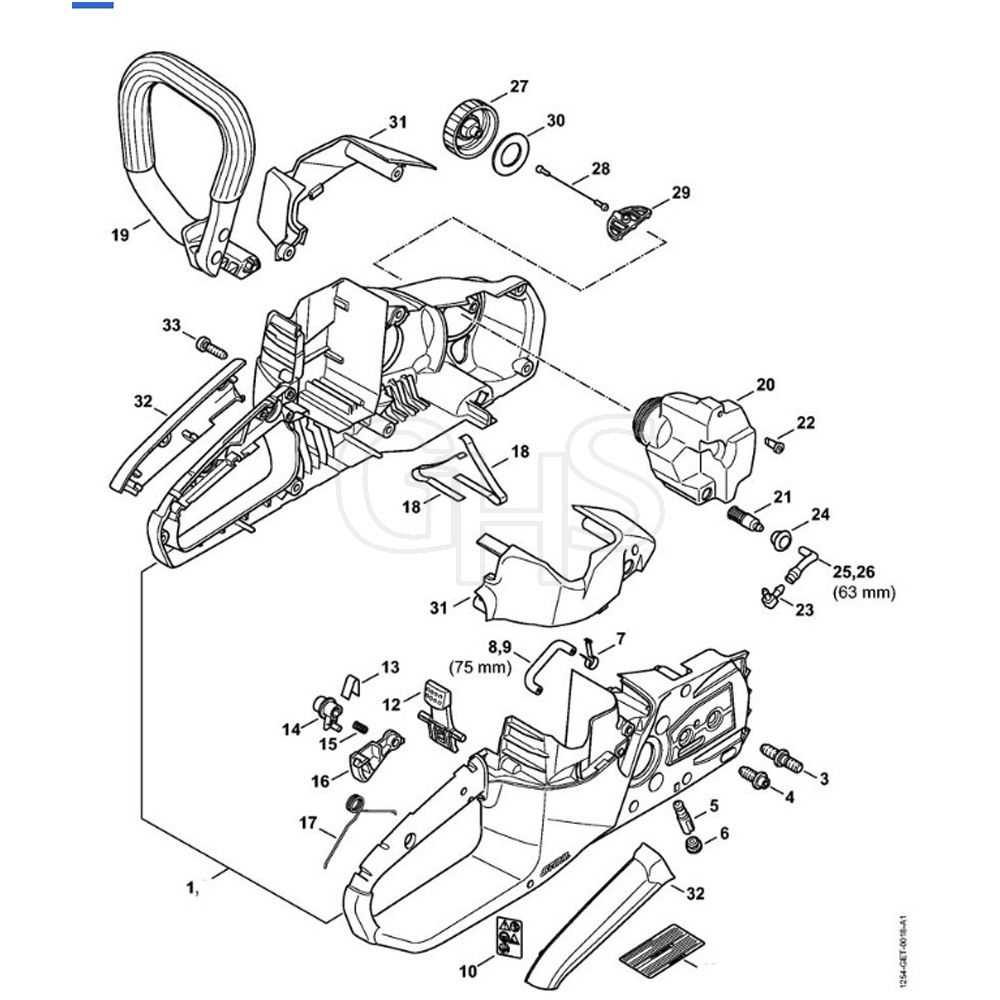

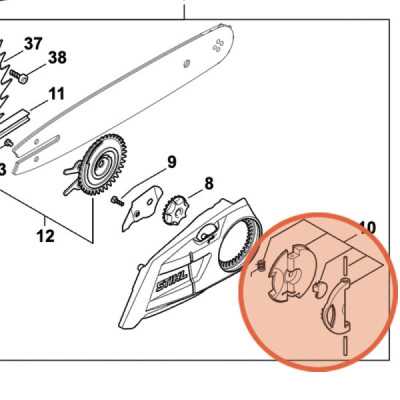

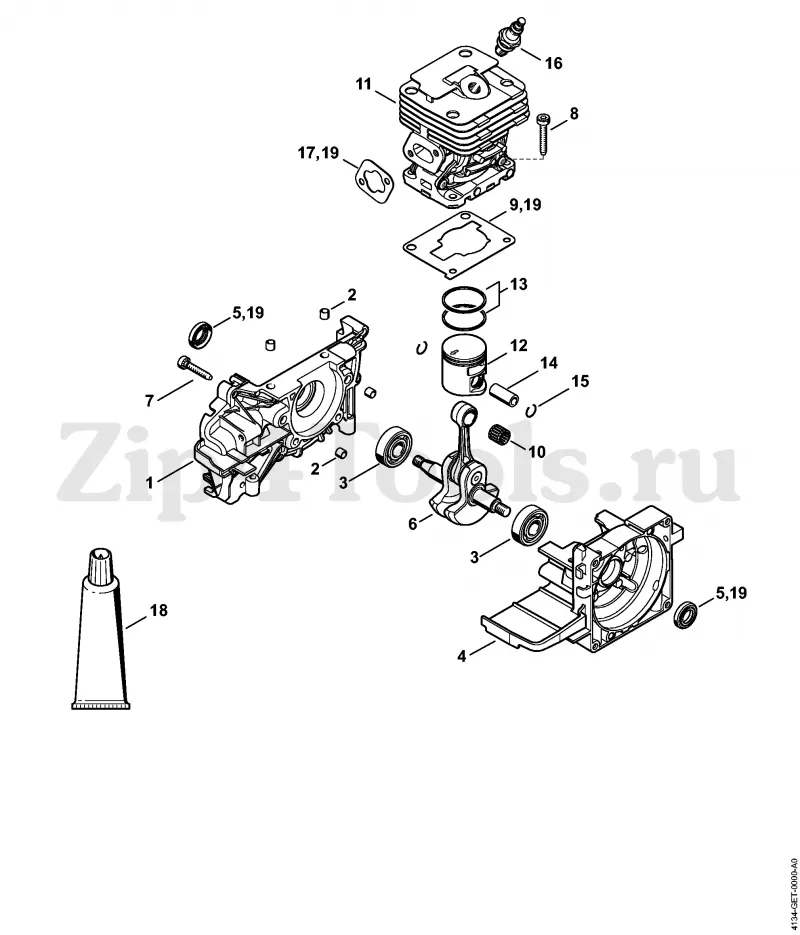

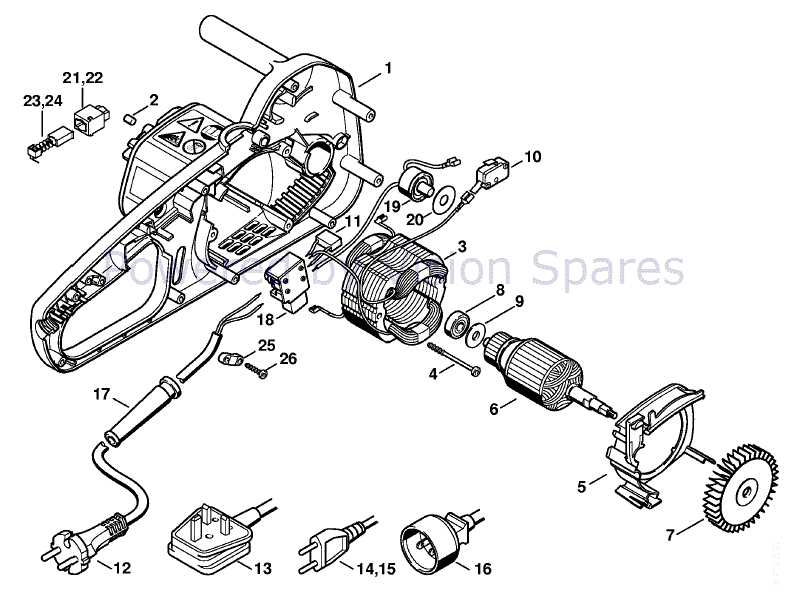

Moreover, visual representations can greatly enhance your comprehension of how different parts interact. Such illustrations serve as valuable guides, helping you to pinpoint specific areas when performing inspections or replacements. As you navigate through the complexities of your tool’s structure, you will discover how a thorough understanding can transform your experience from daunting to manageable.

Understanding Stihl MSA 120 C

This section delves into the key features and functionality of a popular battery-operated chainsaw model, highlighting its design, usability, and performance. Ideal for homeowners and professionals alike, this tool combines efficiency with ease of use, making it suitable for various cutting tasks.

Key Features

This model boasts a lightweight design that enhances maneuverability, allowing users to tackle both small and medium-sized jobs with confidence. Its advanced battery technology ensures longer run times, while the low noise levels contribute to a more pleasant working environment. Additionally, the integrated safety features help to prevent accidents, making it a reliable choice for users of all skill levels.

Maintenance and Care

Key Features of the Chainsaw

This powerful tool is designed to provide efficiency and precision for various cutting tasks. Its lightweight construction ensures ease of handling, while advanced technology enhances performance and safety, making it suitable for both professionals and enthusiasts.

One of the standout attributes is the battery-operated system, offering convenience without the hassle of cords or fuel. This feature allows for quiet operation, reducing noise pollution in residential areas. Additionally, the ergonomic design minimizes user fatigue during extended use.

The innovative cutting mechanism ensures smooth and quick performance, capable of tackling a variety of materials with ease. Safety features, including automatic chain brakes and low kickback bars, further enhance user protection, allowing for confident operation even in challenging conditions.

Importance of Parts Diagram

Understanding the layout and components of a device is crucial for efficient maintenance and repair. A visual representation detailing each element not only enhances comprehension but also aids in troubleshooting issues effectively. When users have access to such resources, they can more easily identify problems and find appropriate solutions.

One key advantage of having a visual guide is that it simplifies the process of reassembly after disassembly. Knowing where each part fits can prevent mistakes and save time, which is essential for both amateur and professional users.

Moreover, this type of reference can be invaluable when ordering replacements or upgrades. By clearly displaying the components, users can ensure they procure the correct items, thereby improving the longevity and performance of their equipment.

Overall, visual aids are indispensable tools that promote a deeper understanding of machinery and foster better care practices.

How to Read Parts Diagrams

Understanding schematics can greatly enhance your ability to maintain and repair equipment. These visual representations offer a clear overview of components, their arrangement, and how they interact with each other. Familiarizing yourself with these illustrations is crucial for effective troubleshooting and parts replacement.

To read these schematics effectively, consider the following steps:

- Familiarize Yourself with Symbols: Each illustration uses specific symbols to represent different components. Knowing what each symbol stands for is essential.

- Identify Major Sections: Diagrams are often divided into major sections, such as the engine, drive system, and control elements. Start by identifying these areas to navigate more easily.

- Follow the Flow: Understand how components are interconnected. This flow can indicate the operation sequence and help pinpoint issues.

- Reference the Legend: Many illustrations include a legend or key that explains the symbols and part numbers. Always refer to this for clarification.

- Cross-Check with Manuals: Use operational manuals to supplement your understanding of the schematic. These documents often provide additional context and instructions.

By following these guidelines, you’ll enhance your ability to interpret these valuable tools, leading to more efficient maintenance and repairs.

Common Replacement Parts Explained

Understanding the essential components of power tools is crucial for maintaining optimal performance. Various elements may require attention over time due to wear and tear, ensuring that the tool operates efficiently and safely. This section delves into the most frequently replaced items, providing insights into their functions and importance.

Battery Systems

Battery systems are vital for the operation of cordless tools. Over time, batteries can lose capacity or fail to hold a charge, necessitating replacement. Choosing a high-quality battery ensures longer run times and better tool performance, making this a key component for users.

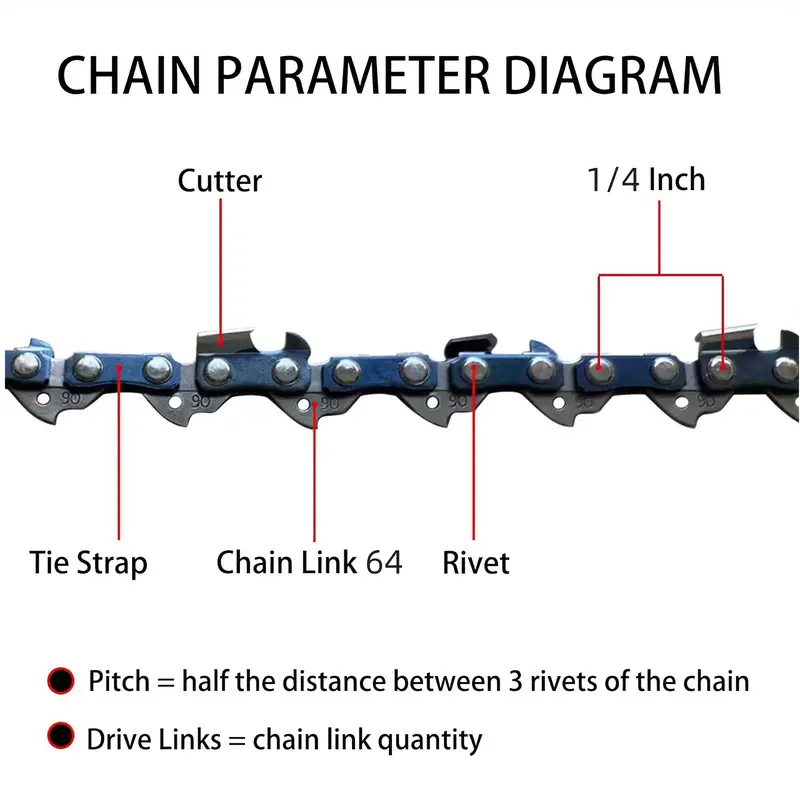

Cutting Blades

Cutting blades are essential for achieving clean and precise cuts. Dull or damaged blades can hinder effectiveness and lead to safety issues. Regular inspection and timely replacement of these components can enhance both performance and safety during use.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended life and optimal performance of your power tools. Regular attention not only prevents unexpected breakdowns but also enhances efficiency, making tasks easier and more enjoyable. Following a few straightforward practices can significantly improve the durability of your equipment.

| Maintenance Task | Frequency | Tips |

|---|---|---|

| Clean the exterior | After each use | Use a soft cloth and mild detergent to remove dirt and debris. |

| Check the battery | Monthly | Inspect for any signs of wear or damage; store in a cool, dry place. |

| Sharpen the blades | As needed | Ensure clean cuts and reduce strain on the motor; use a sharpening tool. |

| Inspect for loose components | Every few uses | Ensure all screws and bolts are tight to avoid operational issues. |

| Replace worn parts | As needed | Use genuine replacements to maintain performance and safety standards. |

By adhering to these guidelines, you can significantly extend the lifespan of your equipment, ensuring reliable performance for years to come.

Tools Required for Repairs

When undertaking maintenance tasks, having the right instruments at your disposal is crucial for effective repairs. This not only ensures efficiency but also enhances safety throughout the process. Understanding the necessary equipment can make a significant difference in achieving successful outcomes.

Basic Tools

Essential tools such as screwdrivers, wrenches, and pliers form the foundation of any repair kit. These instruments enable you to access and adjust various components with ease. Additionally, a set of measuring tools can assist in ensuring accuracy during the process.

Specialized Equipment

For more complex repairs, specialized gear like torque wrenches and chain sharpeners may be required. These tools allow for precise adjustments and maintenance, ensuring optimal performance and longevity of the equipment. Investing in quality instruments pays off in the long run, enhancing both effectiveness and reliability.

Where to Find Authentic Parts

Ensuring the longevity and optimal performance of your equipment relies heavily on sourcing genuine components. Authentic items are crafted to meet specific standards, providing reliability and efficiency. This section explores the best avenues for obtaining these essential elements.

Official Retailers

Authorized dealers offer a wide range of certified components, ensuring you receive high-quality replacements. These retailers often have knowledgeable staff who can assist in identifying the correct items for your model.

Online Marketplaces

Reputable e-commerce platforms also stock genuine components, often accompanied by customer reviews and ratings. Look for sellers with a history of positive feedback to guarantee authenticity and service quality.

Comparing Models in Stihl Range

When exploring different models within a renowned lineup, it’s essential to understand their unique features and intended uses. Each variant offers distinct advantages tailored to various tasks and preferences.

- Power and Efficiency: Evaluate the power output and efficiency of each model.

- Weight and Portability: Consider the weight for ease of use and transportation.

- Battery Life: Look at battery duration and charging times for uninterrupted operation.

- Cutting Capacity: Assess the cutting width and depth for different applications.

By examining these factors, users can make informed decisions that best suit their needs, ultimately enhancing their experience with these tools.

Safety Precautions While Repairing

Ensuring safety during maintenance and repair tasks is crucial to prevent injuries and equipment damage. By adhering to proper guidelines, individuals can create a secure environment that fosters effective work practices.

Personal Protective Equipment

Wearing appropriate personal protective gear is essential. This includes gloves, goggles, and hearing protection to shield against potential hazards. Make sure all equipment is in good condition before starting repairs.

Work Environment Safety

Maintain a clean and organized workspace to minimize risks. Ensure that all tools are easily accessible and properly stored after use. Additionally, always work in a well-ventilated area to avoid exposure to harmful fumes.

Customer Reviews and Feedback

This section highlights the experiences and opinions of users regarding the product in question. Customer insights play a crucial role in understanding the strengths and weaknesses of the item, offering valuable perspectives that can assist potential buyers in making informed decisions.

Many users praise its lightweight design and ease of use, emphasizing how it simplifies tasks in both professional and residential settings. Feedback often mentions the device’s efficiency, allowing for quick and effective work, which is particularly appreciated by those managing larger projects.

However, some reviews point out limitations, such as battery life under heavy usage. Customers express the need for more robust options for prolonged tasks, highlighting the importance of durability in demanding situations. Overall, the shared experiences create a comprehensive overview for future users to consider.