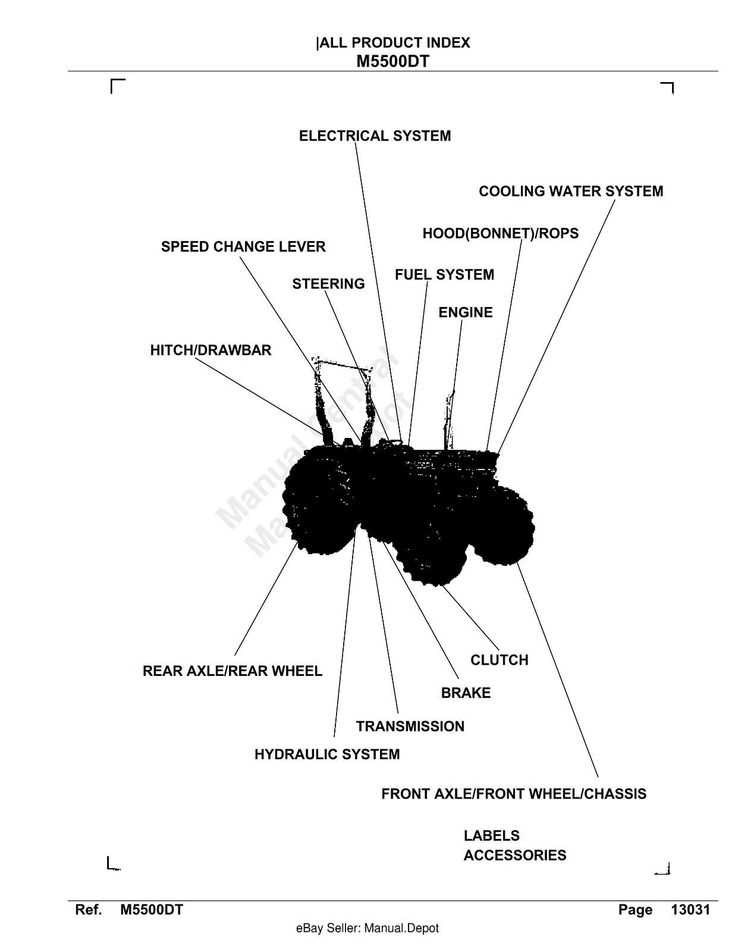

Understanding the Front Axle Parts Diagram for Kubota Tractors

In the world of agricultural machinery, a comprehensive grasp of essential mechanisms is crucial for optimal performance. This section aims to explore the intricacies involved in one vital assembly that plays a significant role in ensuring stability and maneuverability. By breaking down its components, we can uncover the underlying functionality and enhance maintenance practices.

Identifying the elements that contribute to this assembly allows operators and enthusiasts alike to better appreciate their significance. Each component interacts seamlessly to provide the necessary support during operation, making it imperative to recognize their arrangement and purpose.

By delving into this subject, one can achieve a deeper understanding of how these elements work together. The ultimate goal is to equip users with the knowledge required for effective repairs and upkeep, ultimately leading to improved efficiency and longevity of their machinery.

Understanding Kubota Tractor Front Axle

The assembly responsible for steering and load distribution is crucial for efficient operation. This section will explore its components, functionality, and maintenance considerations to ensure optimal performance.

Key Components

- Steering Knuckles

- Spindles

- Bearings

- Supports

- Connecting Rods

Functionality and Maintenance

Regular inspections can prevent wear and enhance durability. Ensure proper lubrication and alignment to maintain seamless operation.

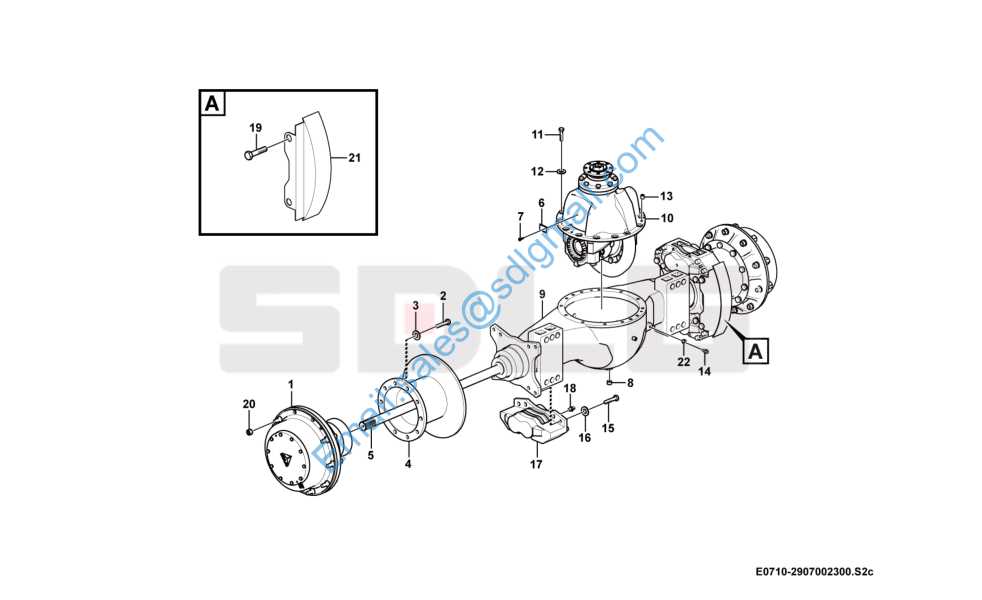

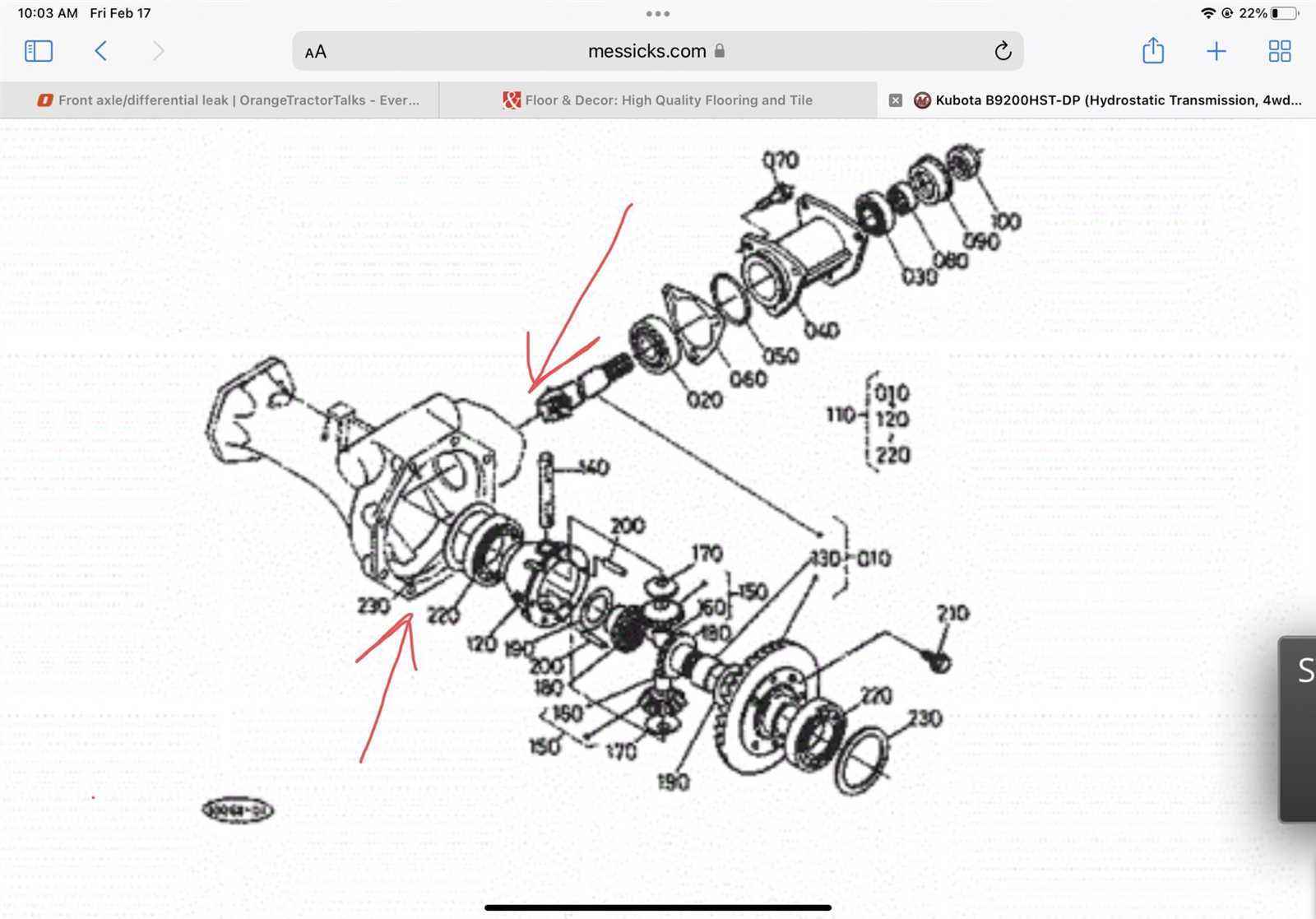

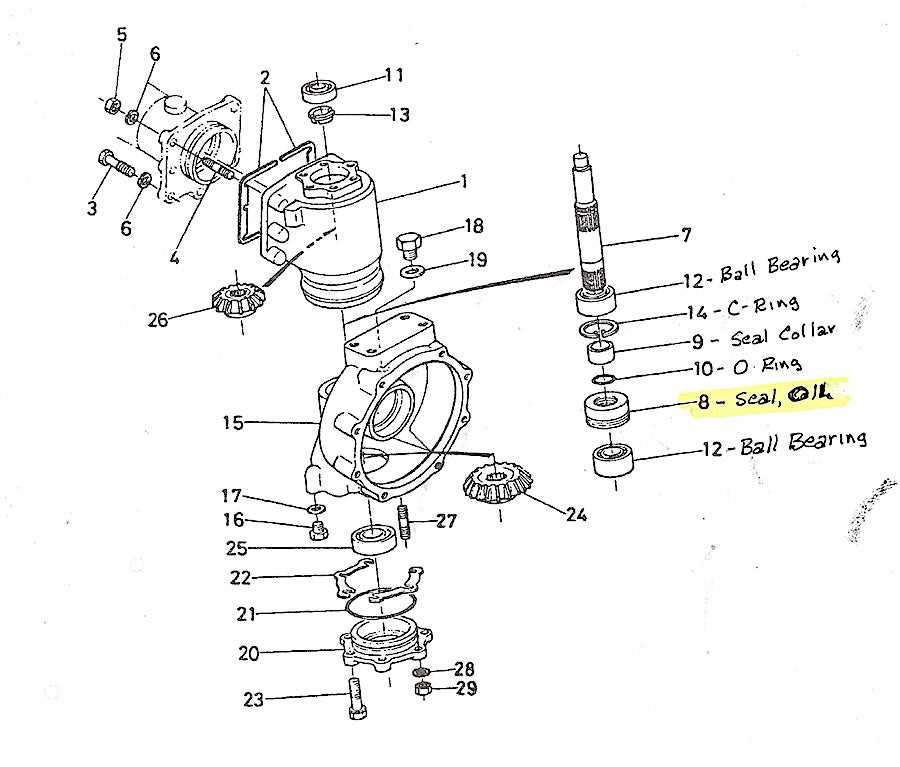

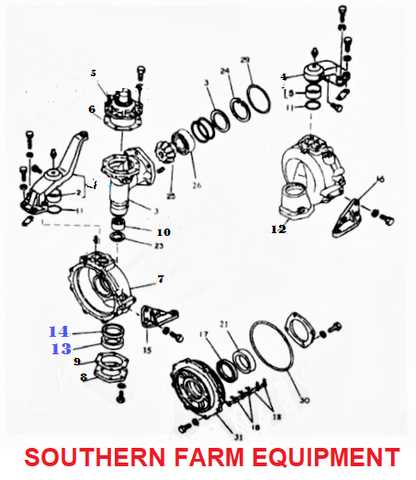

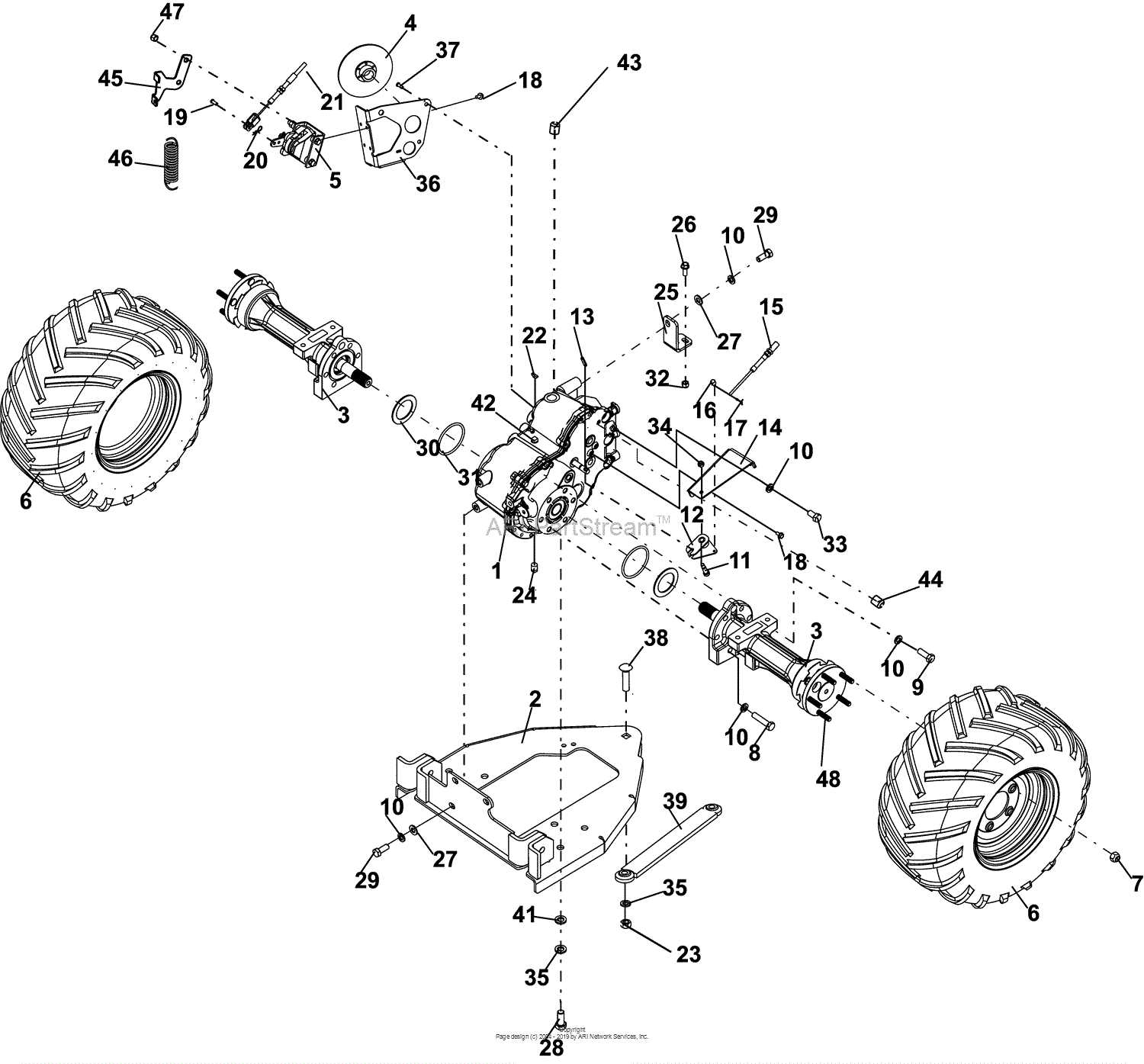

Key Components of the Axle System

The efficiency and functionality of a vehicle’s movement heavily rely on its underlying structure, which encompasses various crucial elements. These components work in harmony to ensure stability, handling, and overall performance during operation.

One essential element is the housing, which protects and supports internal mechanisms while providing a stable foundation. Another vital piece is the differential, allowing for speed variation between wheels during turns, enhancing maneuverability. Additionally, the bearings facilitate smooth rotation and reduce friction, contributing to longevity and ease of use.

Lastly, the shafts play a significant role in transmitting power from the engine to the wheels, ensuring optimal traction and control on diverse terrains. Understanding these key elements is fundamental for maintaining and optimizing vehicle performance.

Importance of Proper Maintenance

Regular upkeep of machinery plays a crucial role in ensuring optimal performance and longevity. Neglecting this aspect can lead to diminished efficiency, increased downtime, and costly repairs. By adhering to a structured maintenance schedule, operators can prevent unexpected failures and enhance the overall reliability of their equipment.

Consistent maintenance not only extends the life of components but also improves safety. When machines are well-cared for, the risk of accidents caused by malfunctioning parts is significantly reduced. Additionally, routine checks help identify potential issues before they escalate, ensuring a smooth operational flow.

Moreover, investing time in maintenance translates to better productivity. Well-maintained equipment operates at peak performance, allowing for more efficient task completion. In competitive environments, this advantage can be pivotal in achieving business goals.

In conclusion, proper maintenance is essential for maximizing functionality, enhancing safety, and driving productivity. Adopting a proactive approach to care not only protects the investment but also fosters a culture of responsibility and efficiency within operations.

Common Issues with Front Axles

The performance of any machinery heavily relies on its support systems. Various complications can arise that may hinder functionality, leading to operational inefficiencies and increased maintenance costs. Understanding these issues is crucial for effective troubleshooting and prevention.

Typical Problems

Several common challenges can affect the stability and efficiency of these essential components. Wear and tear, misalignment, and inadequate lubrication are among the most frequent issues encountered.

Signs of Trouble

| Issue | Symptoms |

|---|---|

| Excessive Wear | Unusual noises, vibrations |

| Misalignment | Difficulty steering, uneven tire wear |

| Poor Lubrication | Overheating, grinding sounds |

Step-by-Step Repair Process

This section outlines a comprehensive approach to addressing common issues that may arise in machinery’s front support system. By following a structured method, users can effectively diagnose and resolve problems, ensuring optimal performance.

Preparation

- Gather necessary tools and equipment.

- Ensure a clean workspace to facilitate the process.

- Consult the manual for specific instructions related to your model.

Repair Steps

- Identify the problem area through visual inspection.

- Disassemble the components carefully, keeping track of each part.

- Inspect for wear or damage, replacing any faulty items.

- Reassemble the unit, ensuring all connections are secure.

- Test the functionality to confirm successful repairs.

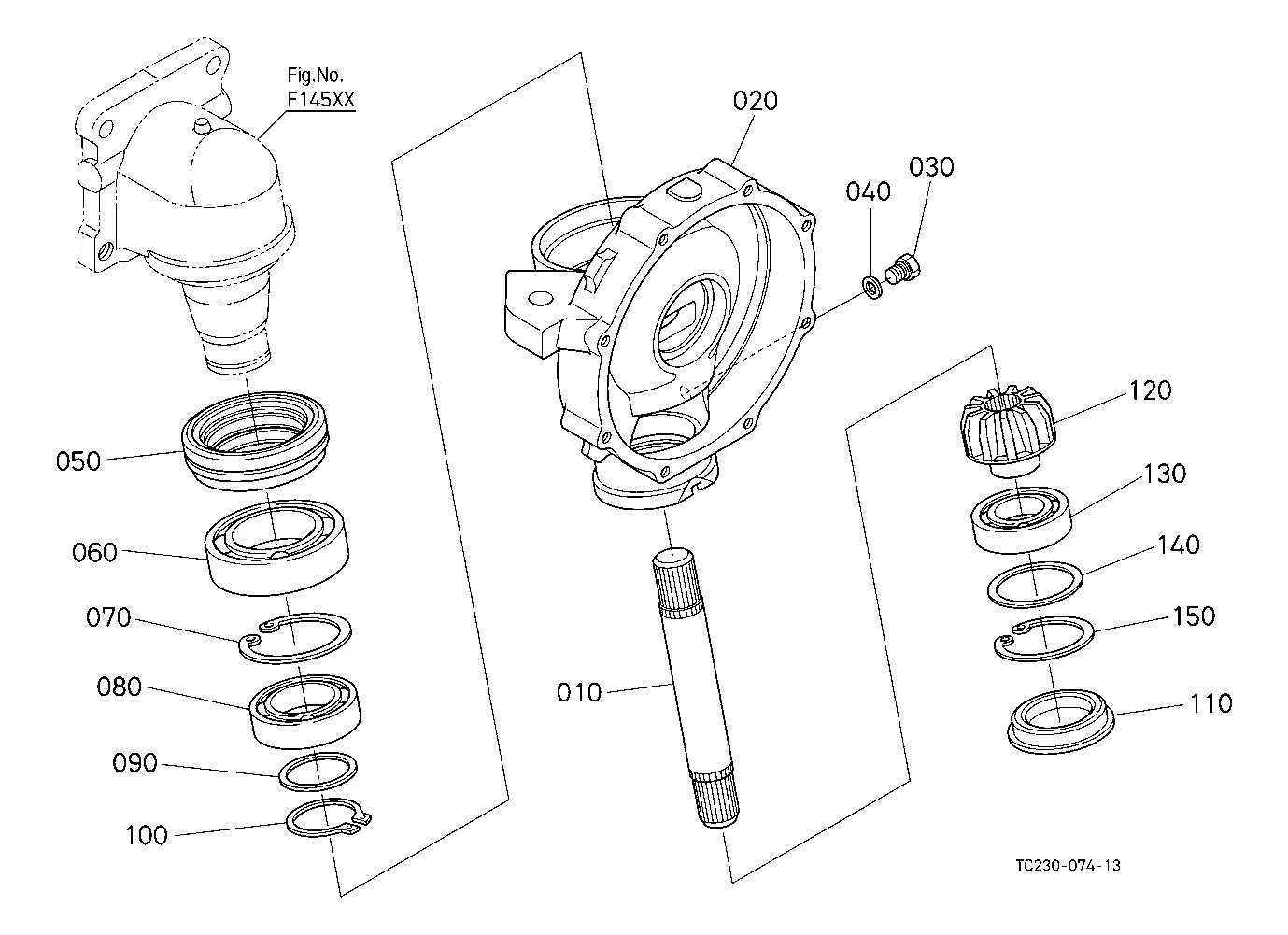

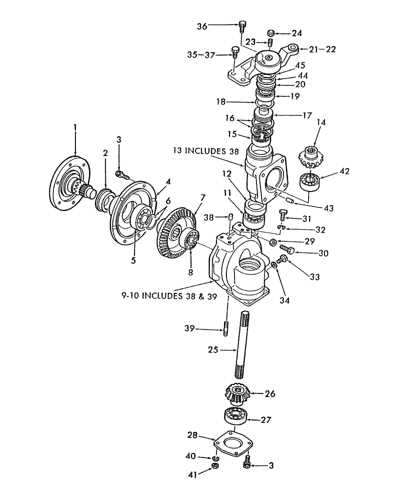

Diagram Interpretation for Beginners

Understanding technical illustrations can be essential for effective maintenance and repair. This guide will help novices grasp the basic elements of these visual aids, enabling better comprehension of machinery components and their functions.

When approaching an illustration, consider the following key aspects:

- Symbols: Familiarize yourself with common icons representing various elements.

- Labels: Pay attention to annotations that clarify specific parts and their roles.

- Connections: Observe how different components are linked, indicating their interrelationships.

To effectively interpret these visuals, follow these steps:

- Start with a general overview of the illustration.

- Identify the main components using the symbols and labels.

- Analyze how these elements interact within the system.

By mastering these techniques, you will gain confidence in deciphering technical visuals and enhance your understanding of machinery operations.

Choosing Quality Replacement Parts

Selecting high-quality components is crucial for maintaining the longevity and efficiency of any machinery. When faced with the need for replacements, understanding the importance of durability and performance can significantly impact the functionality of the equipment. Investing in reliable elements not only ensures optimal operation but also contributes to reducing long-term maintenance costs.

Factors to Consider

When searching for suitable replacements, several factors should be evaluated. First and foremost, material quality plays a vital role in the performance of the item. Look for components made from robust materials that can withstand wear and tear. Additionally, compatibility with existing machinery is essential; ensure that the new parts match the specifications of your equipment to avoid any operational issues.

Where to Source

It’s advisable to obtain components from reputable suppliers. Authorized dealers and manufacturers often provide a warranty or guarantee, which adds a layer of protection to your investment. Furthermore, checking customer reviews and ratings can offer insights into the reliability and performance of the products offered. By prioritizing quality and sourcing from trustworthy vendors, you can ensure your machinery operates at its best for years to come.

Tools Required for Front Axle Work

When undertaking maintenance or repairs on your machinery’s suspension system, having the right tools is essential for efficiency and effectiveness. Proper equipment not only facilitates the process but also ensures safety and precision.

- Wrenches: Various sizes are necessary for loosening and tightening bolts.

- Sockets: Ratchet sets with different socket sizes help access hard-to-reach areas.

- Torque wrench: Ensures bolts are tightened to manufacturer specifications.

- Pry bars: Useful for adjusting components into place.

- Jack stands: Provide stability when lifting the machinery for inspection or repair.

In addition to these, having a reliable toolkit with essential hand tools is recommended for any unexpected tasks that may arise during the process.

Safety Precautions During Repairs

When performing maintenance on heavy machinery, it is crucial to prioritize safety to prevent accidents and ensure effective repairs. Adopting proper practices not only protects the technician but also prolongs the life of the equipment.

Here are some essential safety measures to consider:

- Personal Protective Equipment (PPE): Always wear appropriate gear, including gloves, safety goggles, and steel-toed boots.

- Work Environment: Keep the workspace clean and well-lit to reduce the risk of tripping and ensure visibility.

- Equipment Stability: Ensure that the machinery is securely supported before starting any repairs to prevent unexpected movement.

- Follow Manufacturer Guidelines: Refer to the service manual for specific instructions and safety warnings related to the equipment.

- Use Proper Tools: Utilize the correct tools for the job to avoid injury and damage to the components.

By adhering to these safety protocols, individuals can minimize risks and perform repairs more efficiently, contributing to a safer working environment.

Performance Impact of Front Axle Condition

The state of the steering mechanism plays a crucial role in the overall functionality and efficiency of agricultural machinery. A well-maintained system ensures optimal handling and maneuverability, which directly affects productivity and safety during operations.

Resources for Further Learning

Expanding your knowledge on machinery components is essential for both enthusiasts and professionals. There are numerous materials available that provide insights into various elements, their functionalities, and maintenance practices.

Books and Manuals

Consulting specialized literature can offer in-depth explanations and illustrations. Look for manuals that cover specific machinery systems, as they often include troubleshooting tips and maintenance guidelines.

Online Forums and Communities

Engaging in online platforms dedicated to machinery can enhance your understanding through shared experiences. Participate in discussions to gain practical advice and learn from seasoned users.