Comprehensive Parts Diagram for Stihl MS 441 Chainsaw

In the realm of outdoor equipment, the effective functioning of a high-performance device hinges on its internal structure. Knowing the intricate relationships between various elements can significantly enhance your maintenance efforts and overall understanding of the machinery. Whether you’re a seasoned professional or an enthusiastic hobbyist, a comprehensive grasp of these components can facilitate better troubleshooting and repairs.

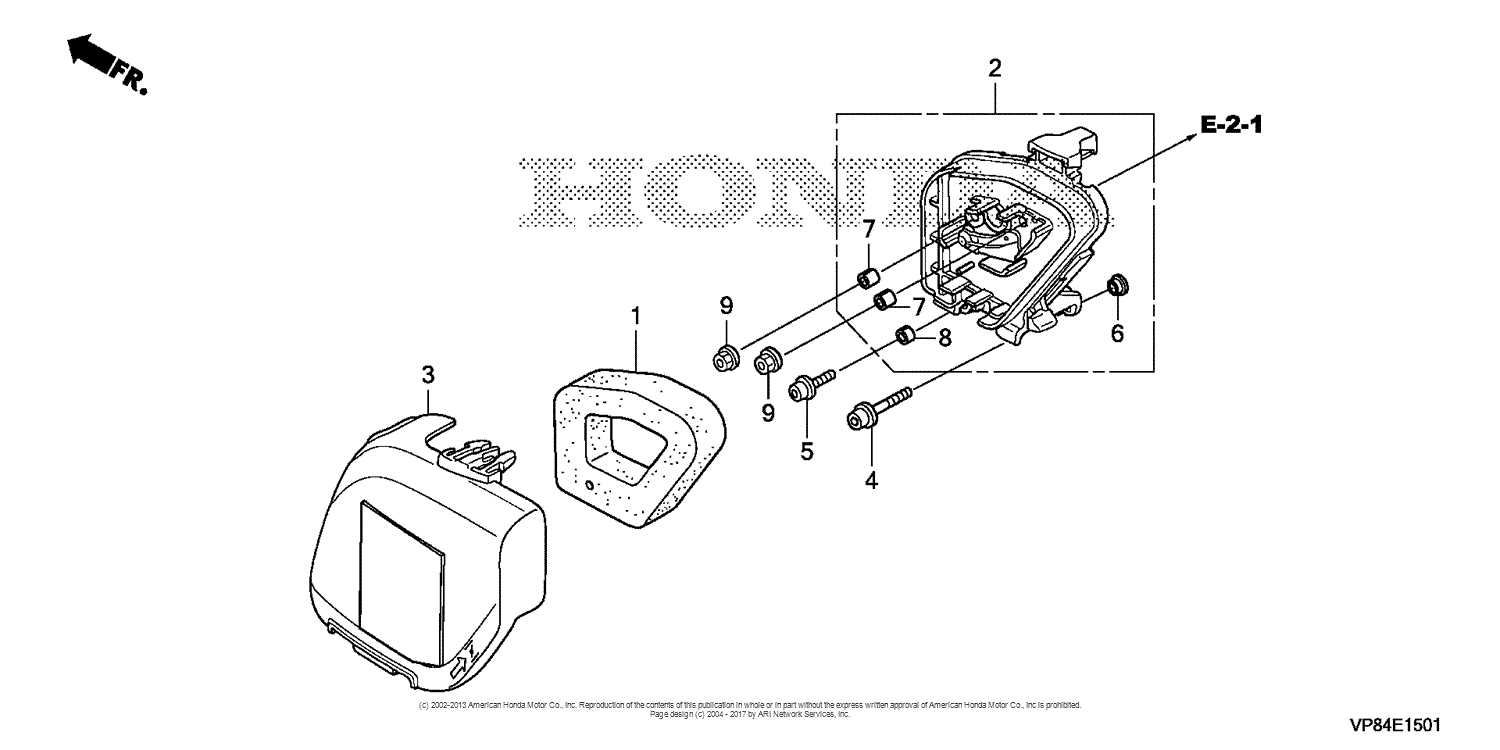

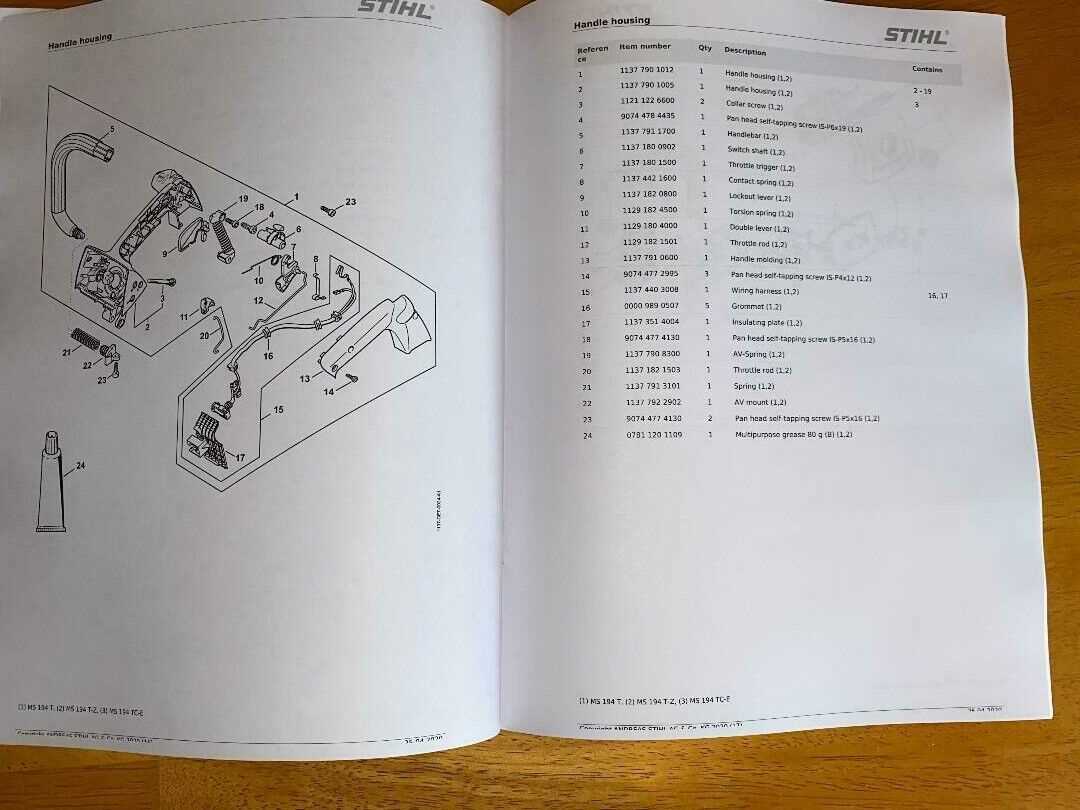

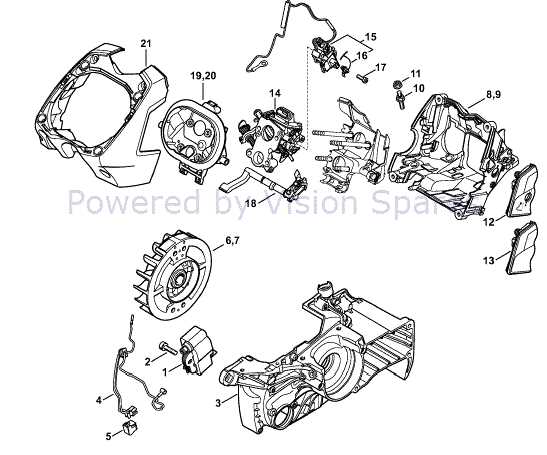

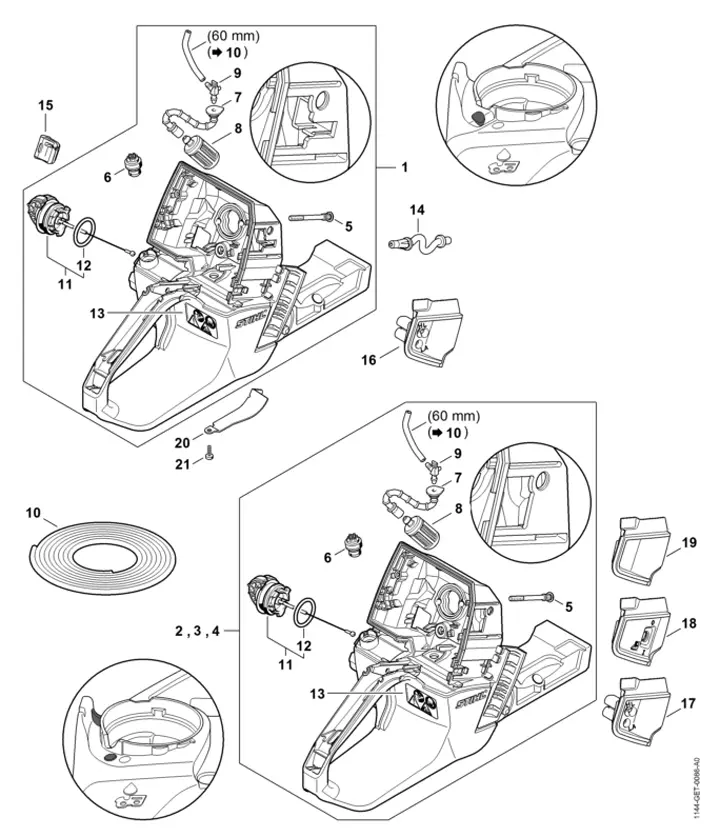

Visual aids play a crucial role in demystifying the complexity of mechanical systems. A clear representation of the individual elements allows users to identify each section with ease. This understanding not only empowers users to carry out routine maintenance but also fosters a deeper appreciation for the engineering behind their tools.

By delving into the specifics of each part, you can ensure your equipment operates at peak efficiency. Regular inspection and knowledge of how components interact can prevent common issues and prolong the lifespan of your investment. Embracing this knowledge equips you to tackle challenges head-on and maintain optimal performance in your outdoor endeavors.

Understanding the Stihl MS 441 Chainsaw

This section delves into the intricacies of a powerful cutting tool, designed for heavy-duty tasks. Its robust construction and advanced features cater to both professional users and dedicated enthusiasts, making it a versatile option for various applications in forestry and landscaping.

Equipped with an efficient engine, this model offers exceptional performance while ensuring user comfort. The innovative design minimizes vibrations and optimizes handling, allowing for extended usage without fatigue. Understanding its components is essential for effective maintenance and troubleshooting.

| Component | Description |

|---|---|

| Engine | High-performance motor providing ample power for demanding tasks. |

| Guide Bar | Durable bar designed to accommodate various cutting lengths. |

| Chain | Precision-engineered for efficient cutting and longevity. |

| Fuel System | Optimized for easy starts and reliable operation. |

| Air Filtration | Advanced system ensuring cleaner air intake and better performance. |

Familiarity with these elements not only enhances the user experience but also aids in prolonging the lifespan of the tool. Proper care and understanding of each feature contribute significantly to achieving optimal results in any project.

Overview of Chainsaw Components

The effective operation of a cutting tool relies on a variety of essential elements, each playing a critical role in performance and efficiency. Understanding these components can enhance maintenance practices and troubleshooting efforts.

Key components typically include the following:

- Engine: The heart of the equipment, providing the necessary power to perform cutting tasks.

- Guide Bar: This long metal piece supports the cutting chain and directs the cutting action.

- Cutting Chain: Equipped with teeth designed for slicing through wood, its sharpness is vital for efficiency.

- Clutch: Engages and disengages the chain from the engine, allowing for safe handling.

- Air Filter: Keeps debris out of the engine, ensuring optimal airflow and performance.

- Fuel System: Comprises the fuel tank and lines, delivering power to the engine.

Each of these elements works in harmony, contributing to the overall functionality of the tool. Proper knowledge of their roles can assist users in maintaining their equipment effectively and prolonging its lifespan.

Key Features of the MS 441

This powerful tool is designed for professionals and enthusiasts alike, offering a blend of efficiency, durability, and advanced technology. Its robust build and innovative features make it a reliable choice for various cutting tasks, ensuring optimal performance in challenging conditions.

Powerful Engine

Equipped with a high-performance engine, this model delivers exceptional power while maintaining fuel efficiency. The advanced design reduces emissions, making it an eco-friendly option for users who prioritize environmental responsibility.

User-Friendly Design

The ergonomic design enhances comfort during extended use, with features such as an anti-vibration system that minimizes operator fatigue. Additionally, the easy-access air filter and tool-free chain tensioning facilitate quick maintenance, ensuring the tool remains in peak condition.

Durability and reliability are at the core of this machine, making it a valuable addition to any collection.

Importance of Proper Maintenance

Ensuring the longevity and optimal performance of any power tool hinges on regular upkeep and care. Maintenance not only enhances functionality but also significantly reduces the risk of malfunctions, leading to safer operation. Understanding the critical aspects of care can help users maximize the efficiency of their equipment.

Routine checks are essential for identifying potential issues before they escalate. This proactive approach can prevent unexpected breakdowns and costly repairs. Regular inspections of the equipment’s components, including the engine and cutting mechanisms, ensure that everything operates smoothly and efficiently.

Moreover, cleaning and lubricating parts as needed play a vital role in maintaining performance. Dust, debris, and old oil can accumulate, hindering functionality and potentially causing damage. By keeping everything clean, users can enhance the lifespan of their tools and maintain consistent performance.

Lastly, adhering to the manufacturer’s guidelines for maintenance schedules and procedures is crucial. Following these recommendations helps ensure that the tool remains in peak condition, thus maximizing productivity and safety during use. Prioritizing maintenance ultimately leads to better results and a more satisfying experience with the equipment.

Common Issues with the MS 441

Every tool may encounter challenges over time, and this particular model is no exception. Users often report a range of problems that can affect performance and reliability. Understanding these common issues is essential for effective maintenance and ensuring optimal operation.

Starting Difficulties: One frequent complaint is related to the difficulty in starting the engine. This can stem from issues such as a faulty ignition system, fuel delivery problems, or a clogged air filter. Regular checks and timely replacements can help mitigate these issues.

Power Loss: Users might experience a noticeable decrease in power during operation. This can be caused by several factors, including dull cutting tools, incorrect fuel mixtures, or blockages in the exhaust system. Ensuring that all components are in good condition is vital for maintaining peak performance.

Overheating: Another common issue is overheating, which can lead to severe damage if not addressed promptly. Causes may include insufficient lubrication, a malfunctioning cooling system, or extended use without breaks. Monitoring temperature and taking necessary precautions can prevent overheating.

Vibration Issues: Excessive vibration during use can also be a concern. This may result from unbalanced cutting tools or worn-out dampers. Regular inspections and maintenance can help reduce vibrations and enhance user comfort.

Fuel Leaks: Fuel leaks pose safety hazards and can affect performance. Common sources include worn gaskets, damaged fuel lines, or improperly sealed components. Addressing leaks immediately is crucial for both safety and efficiency.

By staying aware of these potential problems, users can take proactive steps to maintain their equipment, ensuring longevity and reliability in their tasks.

Identifying Replacement Parts

When maintaining a powerful cutting tool, understanding how to identify necessary components is crucial for optimal performance. Proper knowledge of each element allows for timely replacements, ensuring longevity and efficiency in operation.

To effectively determine the components that need replacement, consider the following steps:

- Consult the User Manual: Always start with the manual specific to your model. It provides essential information regarding components and their functions.

- Inspect Visually: Regularly check for wear and damage. Look for signs such as cracks, rust, or excessive wear on various parts.

- Use Online Resources: Many websites offer detailed descriptions and images to help identify specific components. This can be particularly helpful for visual reference.

Here are some common elements that may require attention:

- Guide bar

- Drive links

- Chain tensioner

- Air filter

- Fuel lines

By following these guidelines, you can ensure that your tool remains in peak condition, ready to tackle any task at hand.

Where to Find Diagrams Online

Locating detailed illustrations and schematics for specific tools and machinery can significantly enhance maintenance and repair efforts. Several online resources offer a wealth of information that can guide users through the intricacies of their equipment. Below are some recommended avenues to explore for these valuable resources.

Official Manufacturer Websites

- Many brands provide official manuals and breakdowns on their websites.

- Look for sections dedicated to customer support or downloads.

- Search for specific models to access tailored information.

Online Retailers and Marketplaces

- Websites that sell tools often include user manuals and diagrams in their product listings.

- Check customer reviews and Q&A sections for additional insights.

- Some platforms may have user-uploaded content that can be helpful.

Utilizing these resources will streamline the repair process and ensure that you have the right information at your fingertips.

How to Use the Parts Diagram

A visual representation of components is an invaluable resource for anyone looking to maintain or repair their equipment. Understanding how to interpret this guide can enhance your efficiency and ensure that you are using the right elements for your machine.

Here are some key steps to effectively utilize this visual guide:

- Familiarize Yourself with the Layout: Begin by understanding the overall structure. Identify major sections and how components are grouped together.

- Identify Key Components: Focus on the parts relevant to your task. Look for labels and numbers that correspond to specific elements.

- Cross-Reference with Manuals: Use this visual tool alongside your equipment’s manual. This will provide additional context and details about each component.

- Make a Parts List: As you identify the components you need, compile a list. This will help streamline your shopping process.

- Consult Online Resources: If you have questions about certain parts, online forums and manufacturer websites can offer valuable insights.

By following these steps, you can maximize the effectiveness of the visual representation, ensuring that you have the knowledge and tools necessary for successful maintenance or repairs.

Tools Needed for Repairs

Proper maintenance and repair of your equipment require a selection of essential instruments. Having the right tools not only simplifies the process but also ensures that tasks are completed efficiently and safely. This section will outline the necessary implements that will aid in restoring your machinery to optimal working condition.

1. Screwdrivers: A set of both flathead and Phillips screwdrivers is crucial for loosening and tightening various screws throughout the device.

2. Wrenches: Adjustable wrenches and socket sets are needed for handling nuts and bolts, allowing for easy assembly and disassembly.

3. Pliers: Needle-nose pliers can be especially useful for gripping small components and reaching tight spaces.

4. Tuning Tools: Specific gauges and tuning devices ensure accurate adjustments, particularly for performance and efficiency improvements.

5. Cleaning Supplies: Brushes and cleaning solvents are essential for maintaining the cleanliness of parts and preventing debris buildup that can hinder performance.

6. Safety Gear: Always prioritize safety by wearing gloves, goggles, and hearing protection during any repair work to minimize the risk of injury.

Equipping yourself with these tools will facilitate a smoother repair experience, helping you maintain the longevity and effectiveness of your machinery.

Step-by-Step Repair Guide

This section aims to provide a comprehensive approach to restoring functionality to your cutting tool. By following a systematic method, you can effectively troubleshoot and fix various issues that may arise during use. Each step will guide you through identifying problems and implementing solutions, ensuring your equipment operates smoothly once again.

Tools and Materials Needed

- Screwdriver set

- Wrench set

- Replacement components

- Lubricating oil

- Cleaning cloths

- Protective gloves

Repair Steps

- Safety First: Ensure the device is completely powered off and disconnected from any power source.

- Disassemble: Carefully remove the outer casing using the appropriate screwdriver, taking note of where each screw belongs.

- Inspect Components: Check for any visible wear or damage to internal parts such as the motor, blade assembly, and air filter.

- Replace Defective Parts: If any component is damaged, carefully remove it and install a new one, ensuring it is securely fitted.

- Reassemble: Once all necessary replacements have been made, reattach the outer casing, making sure all screws are tightened properly.

- Final Check: Before testing, inspect all connections and ensure everything is in its rightful place.

- Test the Equipment: Reconnect to power and perform a test run to verify that the tool is functioning correctly.

By adhering to this guide, you can effectively address common issues and maintain your equipment in optimal condition.

Safety Tips for Chainsaw Maintenance

Proper upkeep of your cutting tool is crucial not only for its performance but also for your safety. Regular maintenance can prevent accidents and ensure that the equipment operates smoothly. Adhering to certain guidelines while servicing your tool can significantly reduce risks associated with its use.

| Tip | Description |

|---|---|

| Wear Protective Gear | Always use appropriate safety equipment, such as gloves, goggles, and hearing protection, to safeguard against potential injuries. |

| Check for Damage | Inspect your equipment regularly for any signs of wear or damage. Replace any worn or broken components immediately to maintain safety. |

| Keep the Area Clear | Ensure that your workspace is free from obstacles and clutter. A clean area minimizes the risk of accidents during maintenance or operation. |

| Follow Manufacturer Instructions | Consult the manufacturer’s manual for specific maintenance guidelines. Adhering to these recommendations can help prevent mishaps. |

| Maintain Sharpness | A dull blade can cause more accidents than a sharp one. Regularly sharpen the cutting edge to ensure efficient operation and reduce strain. |

| Store Properly | When not in use, store your equipment in a dry, secure place. Proper storage protects it from damage and reduces the risk of unauthorized use. |

Upgrading Your Chainsaw Components

Enhancing the performance of your cutting tool can lead to significant improvements in efficiency and effectiveness. By focusing on key components, you can transform a standard machine into a powerhouse, allowing for smoother operation and extended lifespan. This process involves assessing various elements that contribute to overall functionality and selecting high-quality upgrades that suit your needs.

Identifying Essential Upgrades

Start by evaluating the crucial components that can be improved. Common areas include the engine, bar, and chain. Upgrading the engine can provide more power and reduce wear over time. Additionally, opting for a longer or wider bar can enhance cutting capacity, while a sharper or more durable chain ensures cleaner cuts and less effort during operation.

Benefits of Quality Enhancements

Investing in superior upgrades can lead to remarkable advantages. Enhanced performance allows for quicker task completion, while increased durability minimizes the frequency of replacements, ultimately saving you money. Furthermore, a well-maintained and upgraded tool not only performs better but also improves safety, providing peace of mind during use.