Comprehensive Guide to Husqvarna Brush Cutter Parts Diagram

For those who enjoy maintaining their outdoor spaces, knowledge of essential tools is crucial. A thorough comprehension of the individual elements that make up your equipment can significantly enhance its efficiency and longevity. This section delves into the various components of a specific type of gardening tool, offering insights into their functions and interrelationships.

Recognizing how each piece works together can empower users to troubleshoot common issues and perform necessary maintenance. Whether you’re replacing a worn-out element or simply seeking to understand how everything fits together, having a clear visual representation can make all the difference.

By familiarizing yourself with the intricate assembly of your device, you not only ensure better performance but also gain the confidence to engage in repairs and upgrades. This guide aims to provide clarity and support as you navigate the various sections of your trimmer, enhancing your overall gardening experience.

Understanding Husqvarna Brush Cutter Components

Familiarizing oneself with the various elements of a gardening tool is crucial for optimal performance and maintenance. Each component plays a significant role in ensuring efficiency and longevity, making it essential for users to understand their functions and interactions.

Key Elements of the Tool

This type of equipment comprises several critical sections that work together seamlessly. Below is a summary of the main elements:

| Component | Description |

|---|---|

| Engine | Powers the device and drives the cutting mechanism. |

| Handle | Provides user control and comfort during operation. |

| Cutting Head | Houses the blades or lines that perform the cutting action. |

| Guard | Protects the user from debris and enhances safety. |

Importance of Each Component

Each segment has a specific purpose that contributes to the overall functionality. Understanding these roles not only aids in troubleshooting but also assists in ensuring proper care and efficient use of the tool.

Importance of Using Original Parts

Using authentic components for maintenance and repairs is crucial for the longevity and performance of any machinery. Genuine replacements are specifically designed to fit and function seamlessly, ensuring optimal operation and reducing the risk of failure. When owners choose original items, they not only protect their investment but also enhance safety and reliability.

Moreover, authentic components often come with warranties and guarantees, providing peace of mind and assurance of quality. Counterfeit or generic alternatives may seem cost-effective initially, but they can lead to increased wear and tear, ultimately resulting in higher repair costs and potential safety hazards. Selecting genuine replacements contributes to overall efficiency and effectiveness, ensuring that the equipment performs at its best over time.

In addition, using original items helps maintain the manufacturer’s specifications and standards, which is essential for preserving performance metrics. This adherence to quality standards supports the machine’s operational integrity and can significantly extend its lifespan, making original parts a wise investment for any user.

Common Issues with Brush Cutters

Operating garden equipment can sometimes lead to unexpected challenges that hinder performance and efficiency. Understanding these common problems can help users maintain their tools effectively and extend their lifespan.

| Issue | Description | Possible Solutions |

|---|---|---|

| Engine Won’t Start | Difficulty in initiating the motor can stem from fuel issues or ignition system failures. | Check fuel quality, replace spark plug, and inspect the ignition coil. |

| Excessive Vibration | High levels of shaking during operation may indicate misalignment or damaged components. | Tighten loose parts and examine the cutting attachment for wear. |

| Overheating | When the machine overheats, it can lead to performance drops and potential damage. | Ensure proper airflow, clean air filters, and avoid prolonged use without breaks. |

| Fuel Leaks | Leaks can pose safety hazards and decrease efficiency. | Inspect fuel lines and connections for cracks and replace any faulty components. |

| Reduced Cutting Performance | A noticeable drop in cutting efficiency often signals dull or damaged cutting tools. | Regularly sharpen or replace cutting elements as needed. |

How to Identify Compatible Parts

Ensuring that you select the correct components for your equipment is crucial for optimal performance and longevity. Identifying suitable replacements can often seem daunting, but with a structured approach, it becomes manageable. Here are some steps to guide you through the process of finding the right fit.

- Refer to the Manual: Always start by consulting the user manual. It contains valuable information about specifications and compatible components.

- Check Model Numbers: Locate the model number of your machine. This number is key to finding matching replacements.

- Consult Manufacturer Resources: Many manufacturers provide online databases or parts catalogs that allow you to search for compatible items by entering your model number.

- Measure Existing Components: If possible, measure the dimensions of the current parts. This will help ensure the new components will fit correctly.

Following these guidelines can significantly ease the process of sourcing the appropriate items for your machinery. Always prioritize quality and compatibility to maintain performance.

Maintenance Tips for Brush Cutters

Proper upkeep is essential for ensuring the longevity and efficiency of your outdoor equipment. Regular maintenance can prevent common issues, enhance performance, and save you from costly repairs. Following a consistent care routine will keep your machine in peak condition, ready for any task.

Regular Cleaning

After each use, it’s crucial to clean the exterior of the equipment thoroughly. Remove any debris, grass, or dirt that may have accumulated. This not only prevents rust but also ensures that all components function correctly. Use a soft brush or cloth to reach tight spots and avoid using high-pressure water, which can damage sensitive parts.

Routine Inspections

Conducting regular inspections is vital to identify wear and tear early. Check the sharpness of cutting tools; dull edges can lead to unnecessary strain on the engine. Additionally, examine all moving components for signs of wear, and ensure that fasteners are tight. Pay special attention to the fuel system and air filters, as they play a critical role in performance.

Emphasizing preventative care will enhance the reliability of your equipment, allowing you to tackle your gardening tasks with ease. Remember that a little attention can go a long way in prolonging the life of your machinery.

Step-by-Step Assembly Guide

Assembling outdoor equipment can be a rewarding task that enhances your understanding of the machine and ensures optimal performance. This guide will walk you through the necessary steps to effectively put together your unit, ensuring all components are correctly installed for maximum efficiency.

Required Tools

- Wrench set

- Screwdriver

- Pliers

- Safety gloves

- Owner’s manual

Assembly Steps

- Start by laying out all components on a flat surface. Verify that you have all items listed in the owner’s manual.

- Begin with the main body of the equipment. Attach the handle securely using the screws provided.

- Next, connect the power source following the indicated wiring diagram in the manual. Ensure all connections are tight.

- Install the cutting mechanism, aligning it with the designated slots. Secure it using the locking mechanism.

- Check all fastenings and connections to ensure they are properly tightened.

- Finally, perform a safety check by examining the equipment for any loose parts before operating.

By following these steps carefully, you will be able to assemble your machine efficiently and safely, ready for use in your outdoor tasks.

Tools Needed for Repairs

When it comes to maintaining outdoor equipment, having the right tools at your disposal is essential for effective repairs and upkeep. Properly equipped, you can tackle any issues that arise with confidence and efficiency. The right selection of instruments can make the difference between a simple fix and a time-consuming challenge.

Essential tools include a sturdy set of screwdrivers, wrenches, and pliers to handle various fasteners and components. A torque wrench ensures that parts are secured to the correct specifications, preventing damage during reassembly. Additionally, having a comprehensive socket set can simplify tasks by providing the right fit for different bolts and nuts.

For more intricate repairs, consider specialized tools like a fuel line puller or a carburetor adjustment tool. Safety gear, including gloves and goggles, is equally important to protect yourself during the repair process. By gathering these essential implements, you’ll be well-prepared to address maintenance tasks with ease and precision.

Where to Purchase Spare Parts

Finding replacement components for your outdoor equipment can be essential for maintaining its performance and longevity. Various avenues are available for sourcing these essential items, ensuring you can keep your machine running smoothly.

Authorized Dealers are often the best starting point. They typically offer genuine components that meet the manufacturer’s specifications, ensuring compatibility and quality. Visiting a local dealer allows you to receive expert advice and support.

Online Retailers provide a convenient option for those who prefer shopping from home. Many websites specialize in outdoor equipment, offering a wide range of components. Ensure that you choose reputable sources to guarantee the authenticity of the items.

Local Repair Shops can also be a valuable resource. Many of these establishments keep an inventory of frequently needed components and can assist in identifying the correct items for your machinery. Additionally, they often provide installation services, making the process easier.

Community Forums and discussion groups can serve as informal marketplaces. Enthusiasts and professionals alike may sell spare components, providing opportunities to find rare or discontinued items. Engaging with the community can also lead to recommendations on where to shop.

Consider your specific needs and preferences when deciding where to acquire replacement components. Each option has its benefits, allowing you to choose the most suitable method for maintaining your equipment.

Benefits of Regular Inspections

Conducting routine assessments of outdoor power equipment can significantly enhance its performance and longevity. By identifying potential issues early, users can avoid costly repairs and ensure their tools operate efficiently. Regular evaluations not only contribute to smoother functionality but also promote safety during use.

One of the key advantages of consistent inspections is the prevention of unexpected breakdowns. This proactive approach allows users to address minor concerns before they escalate into major problems. Additionally, routine checks help maintain optimal performance, ensuring that the equipment runs smoothly and effectively for longer periods.

| Benefit | Description |

|---|---|

| Cost Savings | Early detection of issues reduces repair expenses and extends the life of the machinery. |

| Enhanced Safety | Regular checks help identify wear and tear, minimizing the risk of accidents during operation. |

| Improved Efficiency | Well-maintained equipment performs better, resulting in increased productivity and effectiveness. |

| Environmental Impact | Efficient tools consume less fuel and produce fewer emissions, contributing to sustainability. |

In conclusion, routine inspections serve as a vital practice for maintaining outdoor machinery. By prioritizing these assessments, users can enjoy enhanced performance, safety, and overall satisfaction with their tools.

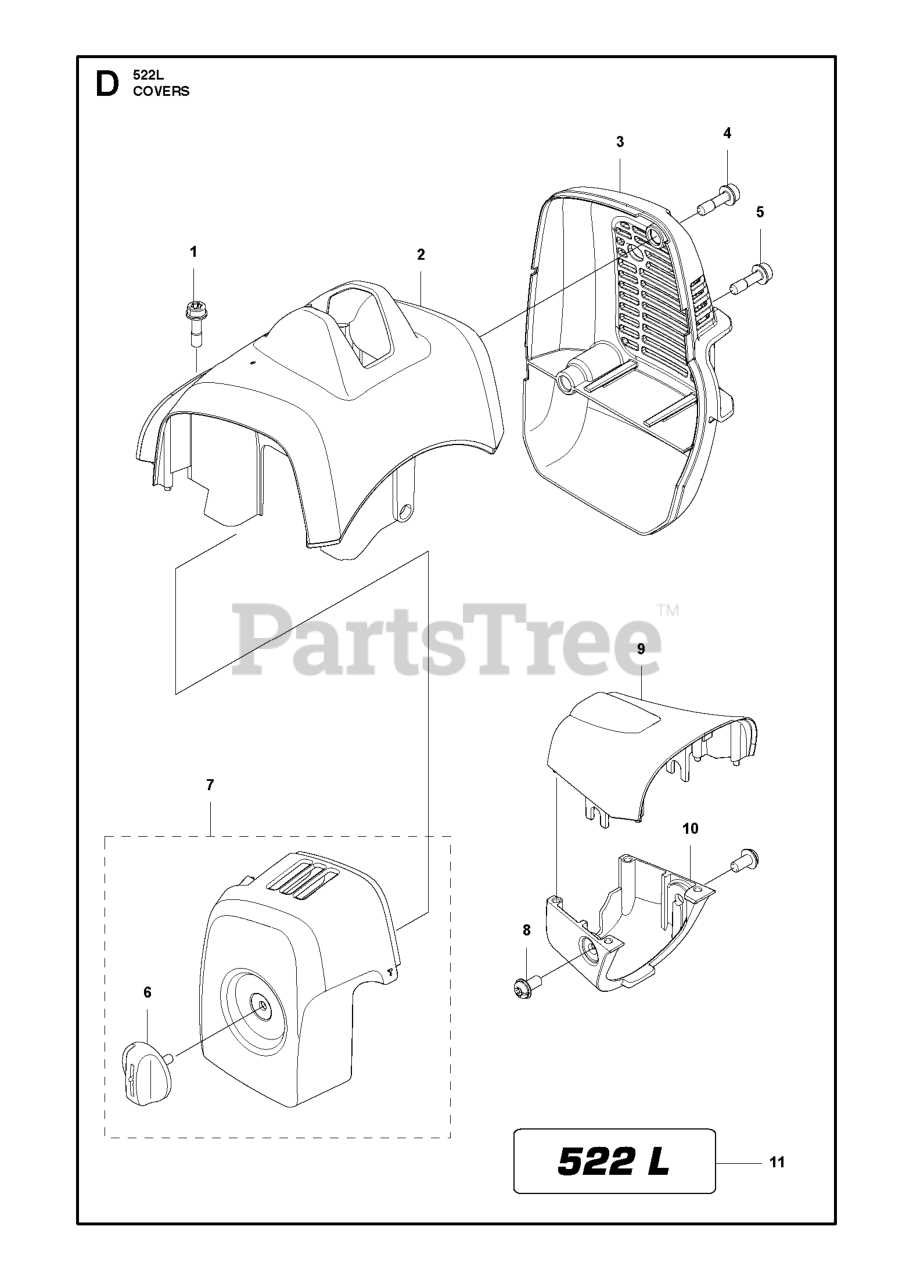

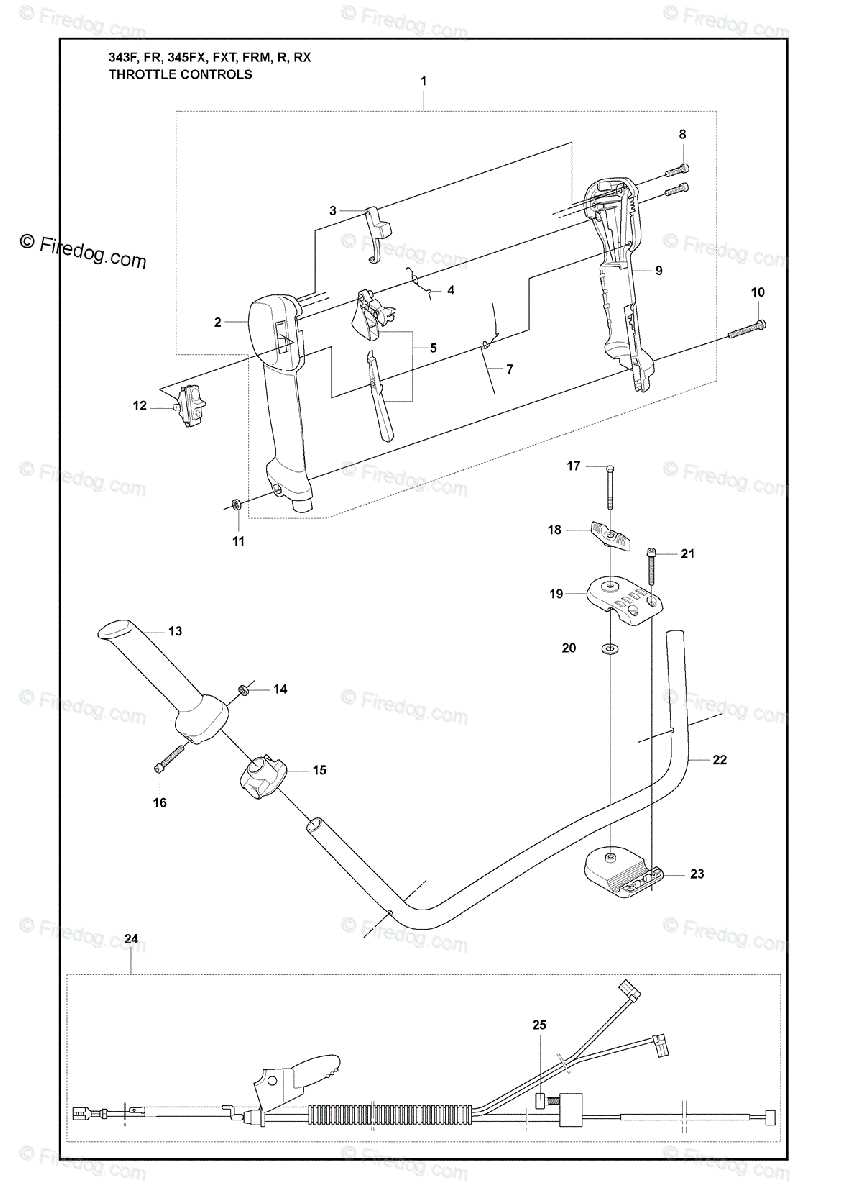

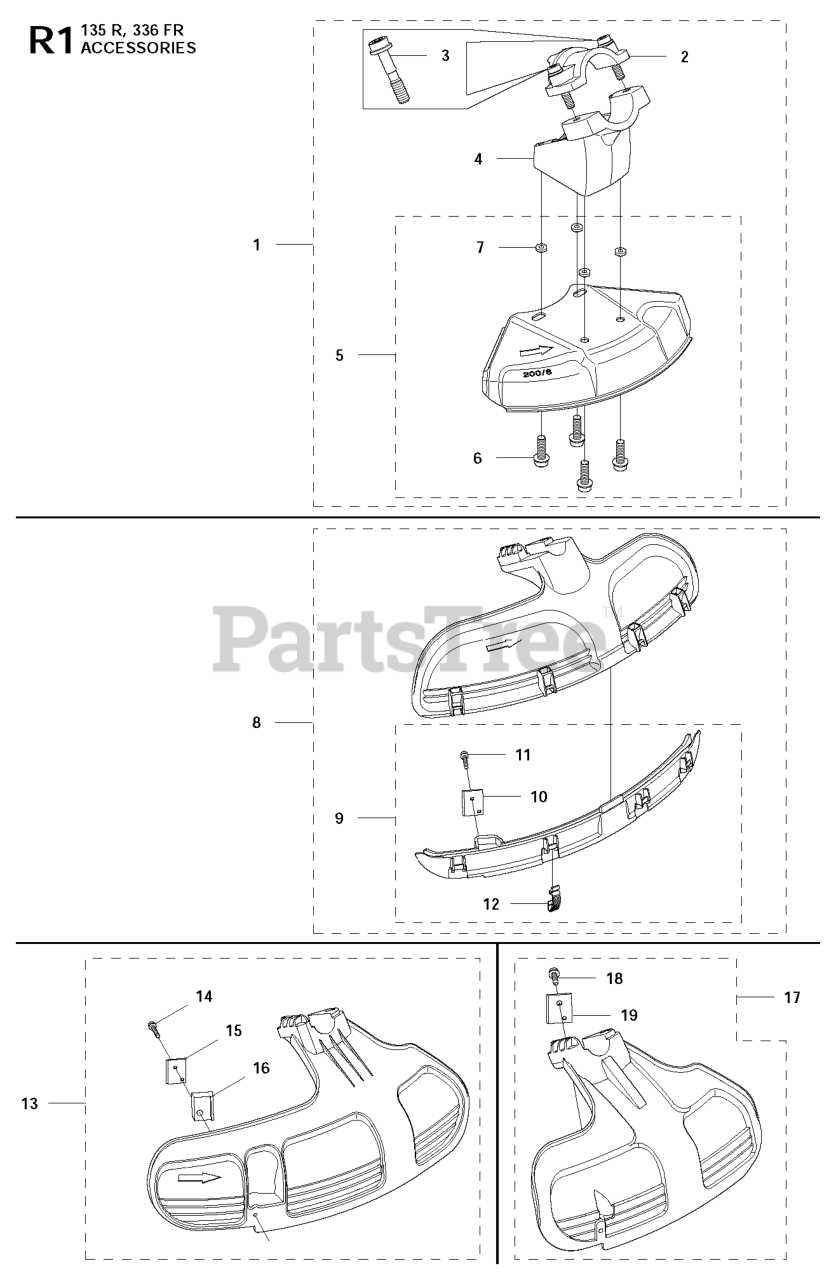

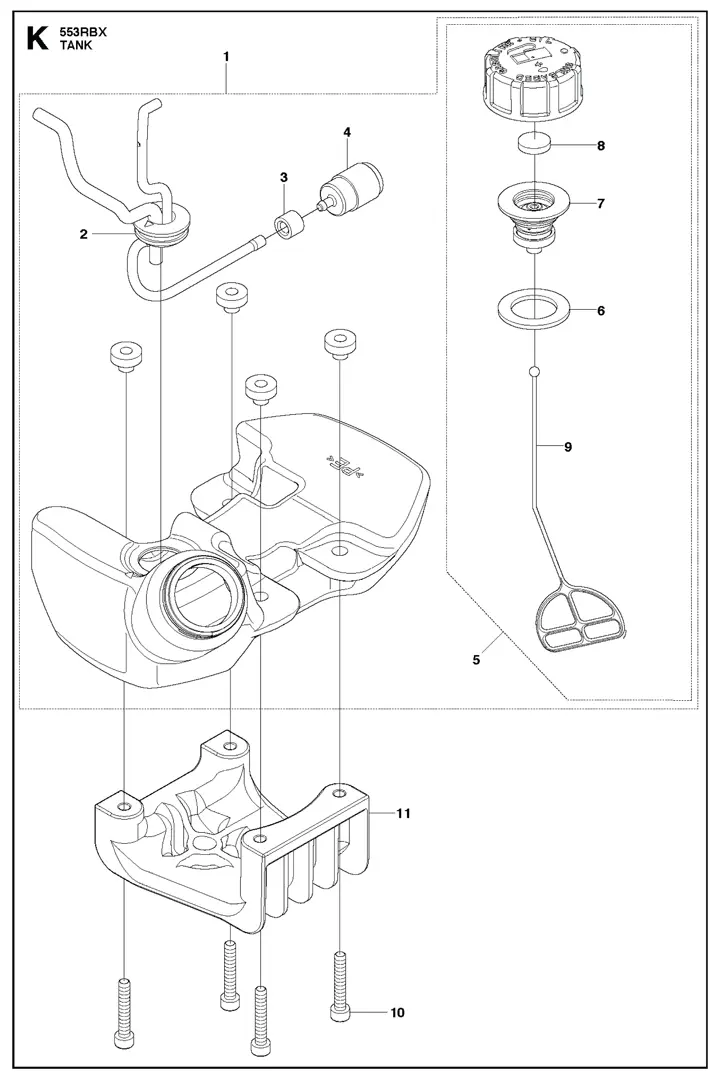

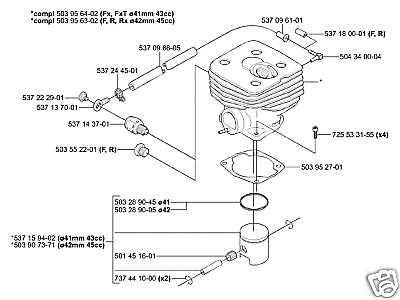

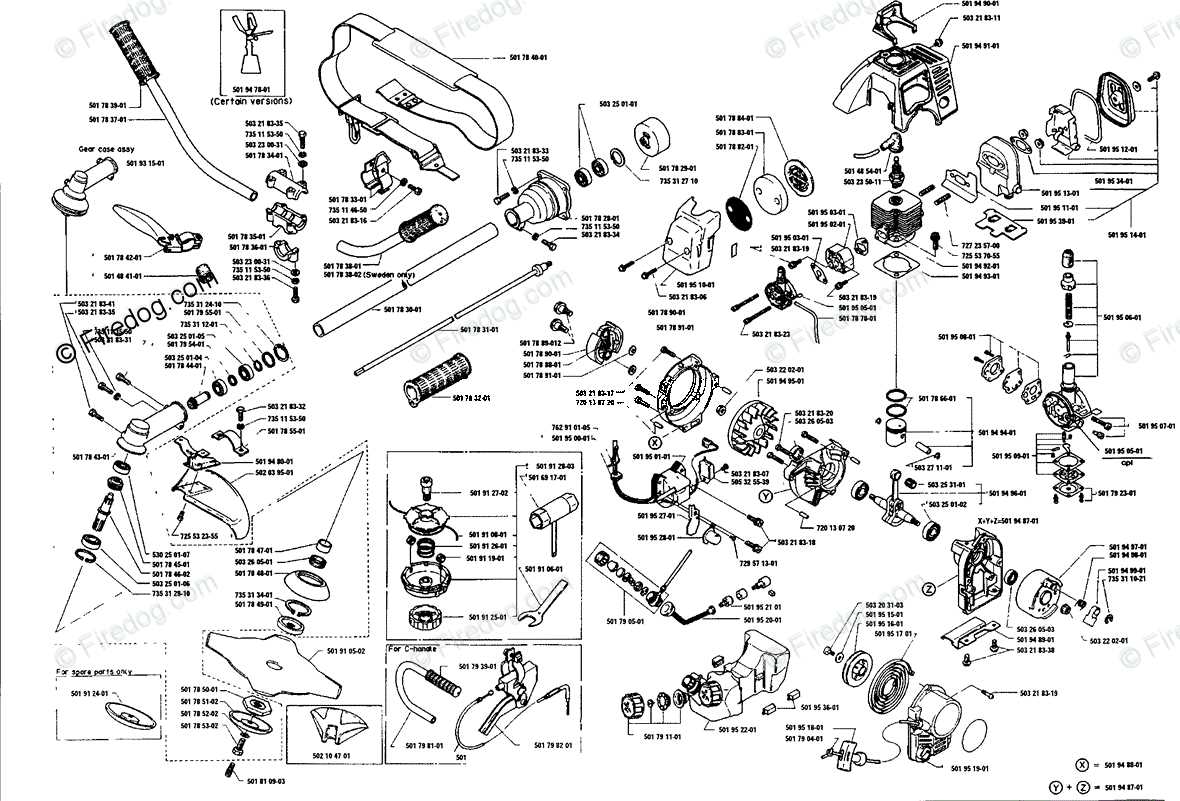

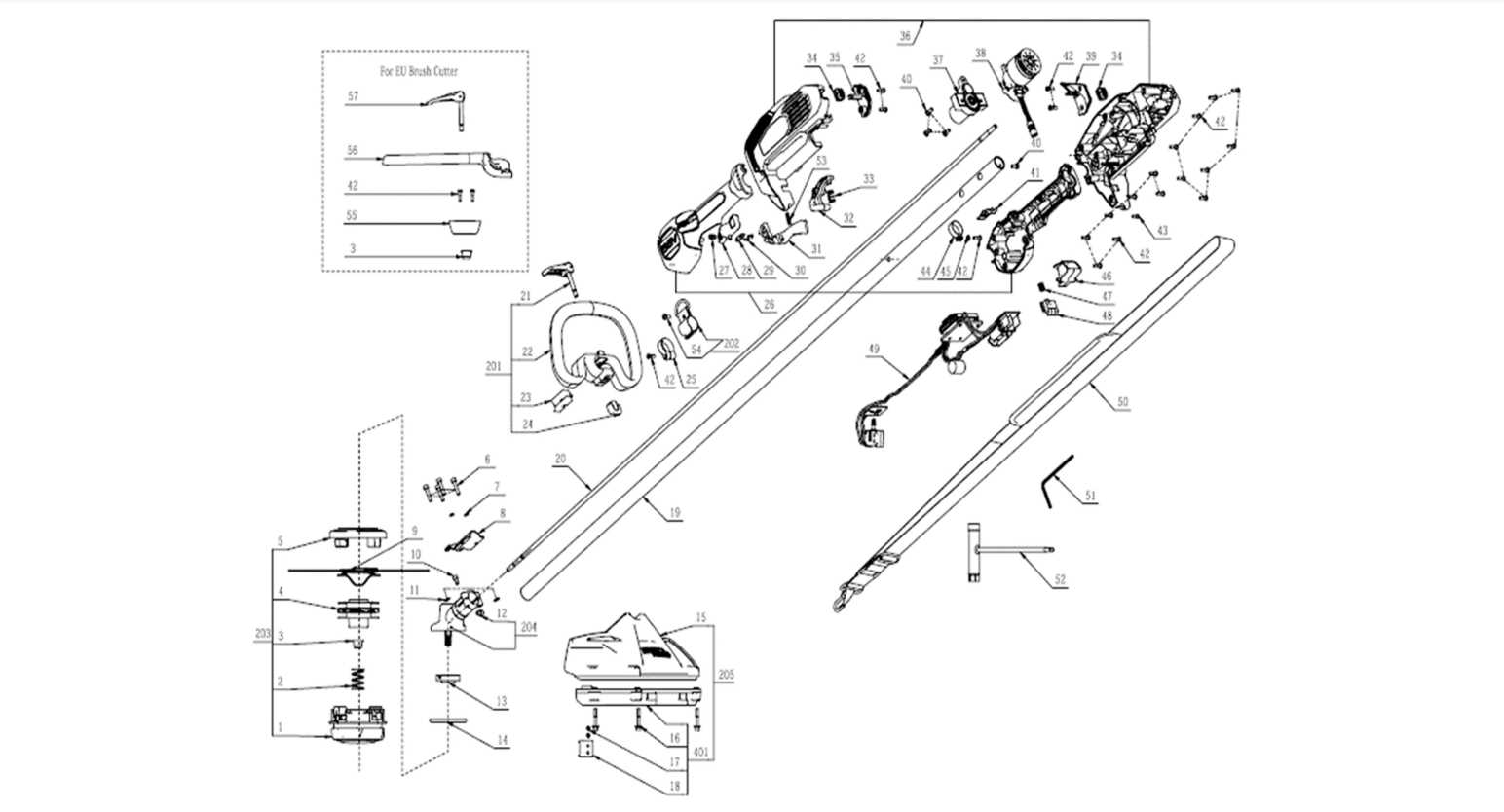

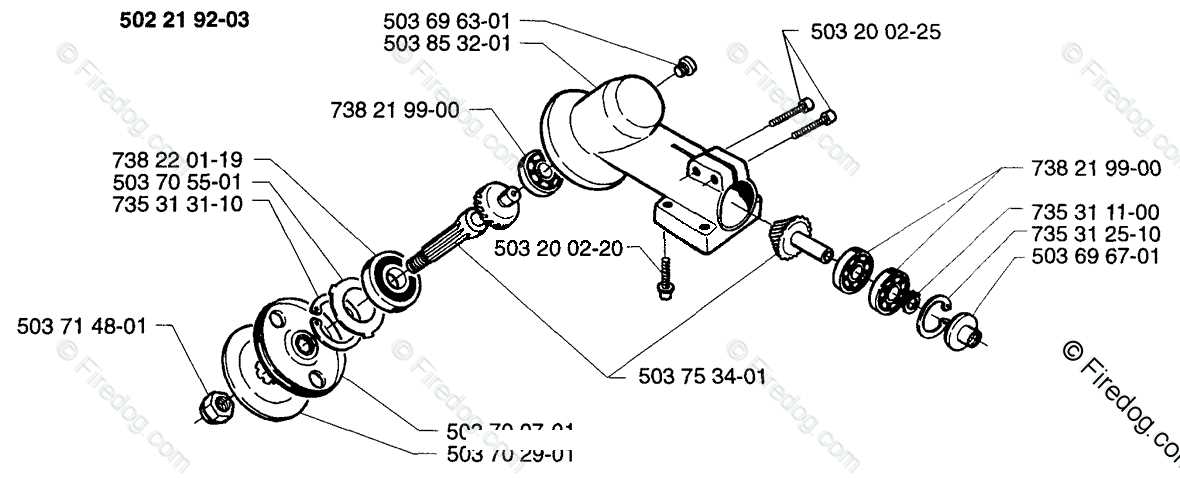

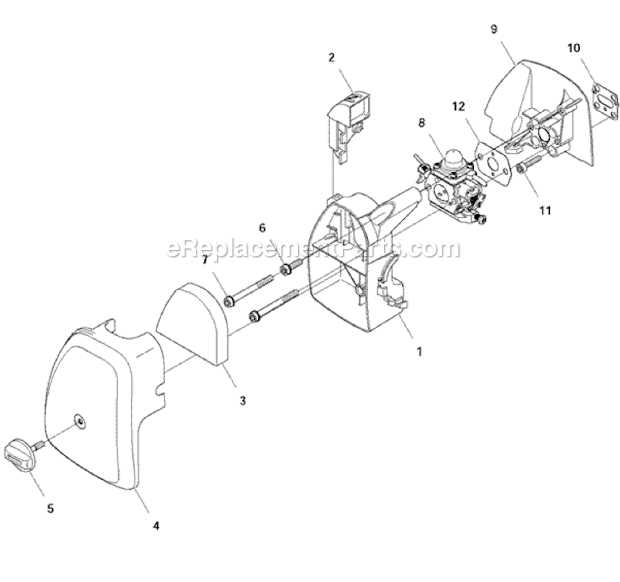

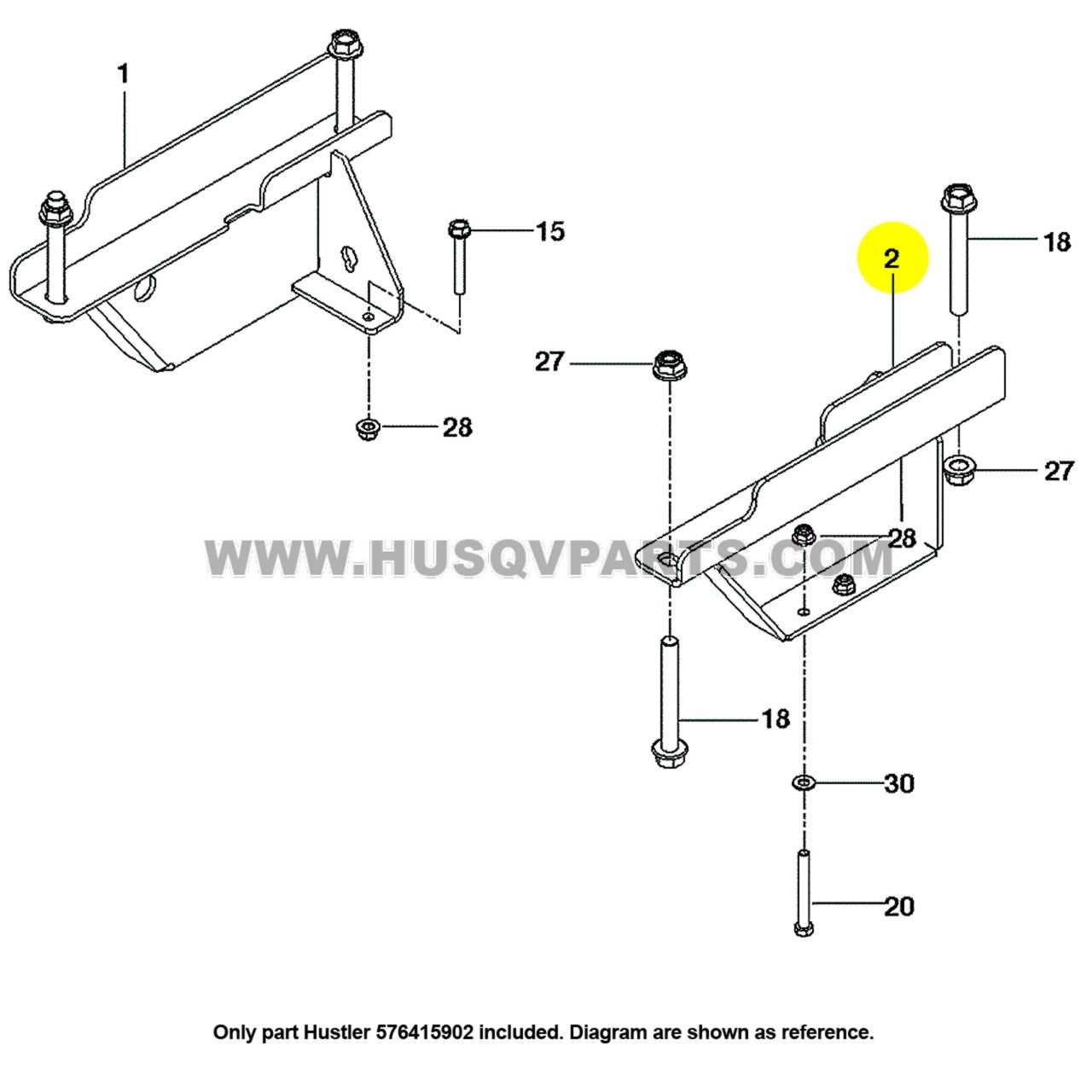

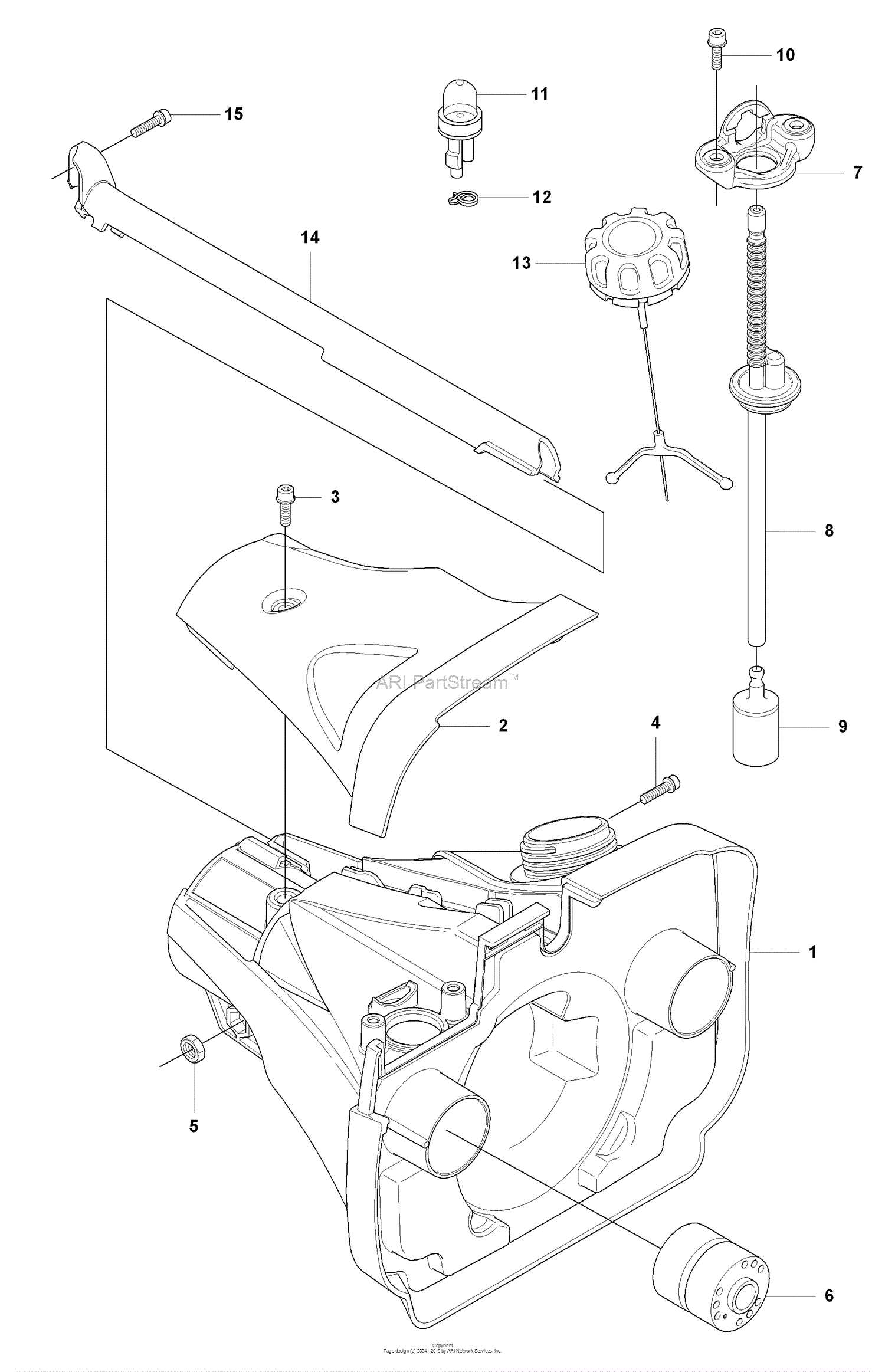

Understanding the Parts Diagram

Comprehending the visual representation of components is essential for effective maintenance and repair. These illustrations serve as a valuable tool for identifying various elements, their functions, and their interconnections within the machine.

By analyzing such illustrations, users can:

- Quickly locate specific components

- Understand the assembly and disassembly process

- Identify potential wear points and maintenance needs

- Facilitate troubleshooting by pinpointing issues

Familiarity with the layout can significantly enhance the efficiency of repairs. The organized presentation allows for easier reference during both routine inspections and more extensive overhauls.

- Start by identifying the main sections of the illustration.

- Examine the labels and numbers associated with each component.

- Use the visual guide to match physical elements with their corresponding functions.

With practice, interpreting these visual guides will become a seamless part of maintaining the equipment, leading to improved performance and longevity.

Tips for Troubleshooting Performance Issues

When encountering difficulties with outdoor equipment, it’s essential to systematically identify and resolve potential problems. By focusing on specific components and conducting thorough checks, you can restore optimal functionality and enhance overall efficiency.

Check Fuel Quality

Fuel plays a critical role in the operation of your machinery. Stale or contaminated fuel can lead to poor performance. Always ensure you use fresh, high-quality fuel and consider draining and replacing any old gasoline that may have been sitting in the tank for an extended period.

Inspect Air Filter and Spark Plug

The air filter and spark plug are vital for maintaining engine performance. A clogged air filter can restrict airflow, while a worn spark plug may fail to ignite the fuel mixture effectively. Regularly clean or replace these components to prevent performance degradation and ensure smooth operation.

Safety Precautions While Repairing

When engaging in maintenance or repair tasks, adhering to safety guidelines is essential to prevent accidents and ensure a smooth workflow. Proper preparation and awareness of potential hazards can significantly reduce the risk of injury and equipment damage.

Preparation Steps

Before starting any repair activity, it’s important to equip yourself with the right knowledge and tools. Familiarize yourself with the equipment’s manual and gather all necessary tools to avoid interruptions during the process.

Personal Protective Equipment (PPE)

Wearing appropriate protective gear is crucial. This includes gloves, goggles, and sturdy footwear to safeguard against sharp components and flying debris. Additionally, ensure that your workspace is clear of hazards to maintain a safe environment.

| Safety Equipment | Purpose |

|---|---|

| Gloves | Protect hands from cuts and abrasions |

| Goggles | Shield eyes from debris and dust |

| Sturdy Footwear | Prevent foot injuries from heavy items |

| Ear Protection | Reduce noise exposure |