Understanding the Parts Diagram of Grundfos MQ3 35

The effective operation of a fluid transfer system relies on the seamless interaction of its individual elements. Each component plays a vital role, ensuring that the entire mechanism functions efficiently and reliably. An in-depth understanding of these elements can greatly enhance maintenance practices and troubleshooting processes.

By exploring the intricate layout and function of these crucial parts, one can gain valuable insights into their interdependencies. This knowledge not only aids in identifying potential issues but also facilitates informed decisions when it comes to repairs and replacements. The clarity of this arrangement can significantly streamline the workflow for technicians and users alike.

Overall, familiarizing oneself with the configuration and functionality of the various elements within a pump system can lead to improved performance and longevity. Such awareness empowers users to optimize their systems and ensures they are well-equipped to handle any challenges that may arise.

This section aims to provide a comprehensive introduction to a specific pump model, highlighting its essential features and functions. Understanding the construction and operation of this device is crucial for users seeking to enhance their knowledge of water distribution systems.

The following key points will be discussed:

- Functionality: An overview of how the device operates, including its role in fluid movement and pressure regulation.

- Key Components: A breakdown of the main elements that make up the system, explaining their purposes and interactions.

- Applications: Insight into the various settings where the pump is utilized, emphasizing its versatility and efficiency.

- Maintenance Tips: Suggestions for proper upkeep to ensure longevity and optimal performance.

By exploring these areas, readers will gain a deeper understanding of the device’s significance and operational nuances, empowering them to make informed decisions related to its use and maintenance.

Key Features of the Pump

The efficiency and reliability of this pumping solution make it an essential component for various applications. Designed with user convenience in mind, it combines advanced technology with ease of operation, ensuring optimal performance in different environments.

High Efficiency: This model operates with exceptional energy efficiency, reducing operational costs while delivering consistent flow rates. Its innovative design minimizes energy consumption, making it an eco-friendly choice for users.

Durability: Built from high-quality materials, this pump is engineered to withstand harsh conditions and provide long-lasting service. Its robust construction ensures reliable performance over time, even in demanding situations.

Compact Design: The compact and lightweight design allows for easy installation and maintenance. It can be seamlessly integrated into various systems without requiring extensive modifications.

Noise Reduction: Equipped with advanced noise-reduction technology, this pump operates quietly, making it suitable for residential and commercial settings where noise levels must be kept to a minimum.

Versatility: Its versatility allows it to be used in a range of applications, from irrigation to domestic water supply. This adaptability makes it a popular choice among professionals in various industries.

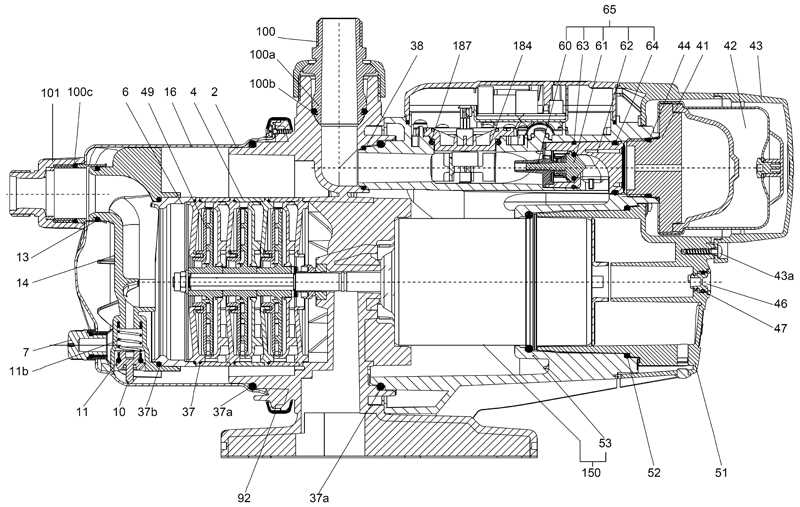

Understanding the Parts Diagram

Grasping the layout of essential components is crucial for effective maintenance and troubleshooting. A visual representation of these elements helps users identify and understand the role of each piece within the system.

In this section, we will explore key features of the schematic representation:

- Component Identification: Each element is labeled clearly, allowing for easy recognition and reference.

- Functional Relationships: The illustration shows how various parts interact with one another, providing insights into the overall operation.

- Maintenance Guidance: Understanding the configuration aids in performing repairs and replacements efficiently.

- Troubleshooting Assistance: Familiarity with the layout enables quicker diagnosis of issues, leading to timely resolutions.

By familiarizing oneself with this schematic representation, users can enhance their understanding of the system, leading to improved performance and longevity.

Main Components Explained

This section delves into the essential elements of a specific pumping unit, emphasizing their roles and interactions within the system. Understanding these components is crucial for effective maintenance and operation.

Motor: The driving force behind the unit, the motor converts electrical energy into mechanical energy. It powers the pump, enabling fluid movement through the system.

Impeller: This rotating component plays a vital role in the fluid dynamics of the system. By imparting kinetic energy to the liquid, it facilitates efficient transport from the inlet to the discharge.

Diffuser: Positioned after the impeller, the diffuser helps to convert the kinetic energy of the fluid into pressure, ensuring a steady and regulated flow. Its design is crucial for optimal performance.

Pressure Switch: This safety device monitors the pressure within the system and automatically controls the operation of the motor. It prevents potential damage by ensuring that pressure levels remain within safe limits.

Check Valve: A critical component for maintaining system integrity, the check valve prevents backflow, ensuring that the fluid flows in one direction. This feature is essential for preventing contamination and ensuring efficiency.

In conclusion, each element of this unit contributes significantly to its overall functionality. A comprehensive understanding of these components enhances the ability to troubleshoot and optimize performance.

Importance of Each Part

Understanding the significance of every component within a pump system is crucial for ensuring optimal functionality and longevity. Each element plays a specific role that contributes to the overall performance and efficiency of the unit. Recognizing these roles allows for better maintenance practices and informed troubleshooting.

Key components and their importance include:

- Motor: The heart of the system, providing the necessary power for operation. Its efficiency directly affects energy consumption.

- Impeller: Essential for fluid movement, the design and material of the impeller influence flow rates and pressure generation.

- Seal: Prevents leaks and maintains pressure within the unit, ensuring reliable operation and protecting other parts from damage.

- Housing: Provides structural integrity and protection for internal components, safeguarding them from external factors.

- Control System: Regulates the operation, allowing for adjustments in response to varying demands, thus enhancing efficiency.

By appreciating the function of each component, users can make informed decisions regarding maintenance and repairs, leading to improved performance and reduced downtime.

Common Issues and Solutions

When dealing with water pumping systems, several challenges may arise that can affect performance and efficiency. Identifying these common problems and implementing effective solutions can help ensure optimal functionality and longevity of the equipment.

- Insufficient Pressure:

This issue can stem from various factors, such as blockages in the system or a malfunctioning pressure switch. To resolve this, check for any obstructions in the intake or discharge lines and inspect the pressure switch for proper operation.

- Noisy Operation:

Unusual sounds during operation may indicate wear and tear or misalignment. Regular maintenance and inspection of components can help identify the source of the noise. Lubrication or realignment may be necessary to rectify this problem.

- Frequent Cycling:

If the pump turns on and off frequently, it might be due to a leaking pipe or a faulty pressure switch. Inspect all connections for leaks and replace the pressure switch if needed to maintain consistent operation.

- Overheating:

Excessive heat can lead to system failure. This may occur due to inadequate ventilation or continuous operation without breaks. Ensure proper airflow around the unit and allow for regular downtime to cool.

- Low Flow Rate:

A decrease in the flow rate may indicate a clogged filter or a malfunctioning impeller. Regularly clean or replace filters and check the impeller for damage or obstruction to maintain optimal flow.

By being aware of these common issues and implementing timely solutions, users can significantly enhance the reliability and efficiency of their water pumping systems.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment requires regular upkeep and attention to detail. Proper maintenance practices not only enhance performance but also prevent potential issues that could lead to costly repairs. Implementing a systematic approach to care can greatly contribute to the durability and efficiency of your system.

Regular Inspection

Frequent examinations of your device are essential. Look for signs of wear and tear, leaks, or any unusual noises. Addressing minor issues promptly can prevent them from escalating into significant problems. Schedule inspections at regular intervals to keep your machinery in top condition.

Proper Cleaning

Maintaining cleanliness is crucial for optimal functionality. Dust and debris can hinder performance and lead to overheating. Make it a habit to clean the exterior and interior components regularly, ensuring that all filters and vents are free from obstructions. This simple practice can significantly enhance the efficiency and lifespan of your equipment.

How to Identify Replacement Parts

Identifying the necessary components for replacement can be a straightforward process when approached methodically. Understanding the key aspects of the system you are working with is essential for ensuring compatibility and functionality.

Step-by-Step Guide

- Review the User Manual: Start by consulting the user manual, which typically includes information on component specifications and identification.

- Check Model Numbers: Locate the model number on the device; this will help narrow down the specific items needed.

- Use Visual References: Utilize diagrams or images available online to compare the components visually.

- Note Compatibility: Ensure that the replacement items are compatible with your specific model, as variations can exist.

Where to Find Replacement Items

- Authorized Dealers: Visit authorized retailers for original components that meet the manufacturer’s specifications.

- Online Marketplaces: Explore reputable online platforms where various items may be available.

- Local Hardware Stores: Check with local suppliers that may stock compatible alternatives.

Installation Guidelines for MQ3 35

This section outlines essential steps for setting up the water pump efficiently. Proper installation is crucial for optimal performance and longevity. Following these guidelines will help ensure a successful installation process.

Before beginning the installation, gather all necessary tools and components. It is advisable to review the manufacturer’s instructions thoroughly and ensure that the working environment is safe and suitable for the task.

| Step | Description |

|---|---|

| 1 | Prepare the installation site by ensuring adequate space and accessibility for maintenance. |

| 2 | Connect the intake pipe securely to the designated inlet, ensuring a watertight seal to prevent leaks. |

| 3 | Attach the discharge pipe to the outlet, ensuring it is oriented correctly for optimal water flow. |

| 4 | Install the pump in a level position to reduce vibrations and wear during operation. |

| 5 | Make electrical connections following local electrical codes and ensure all wiring is properly insulated. |

| 6 | After installation, perform a system check to confirm that there are no leaks and that the pump operates smoothly. |

Adhering to these guidelines will facilitate a smooth installation and help achieve optimal functionality of the pump system. Regular maintenance should follow to ensure continued performance.

Frequently Asked Questions

This section aims to address common inquiries related to the operation and maintenance of a specific pump model. By providing clear and concise answers, users can better understand the device’s functionality and troubleshoot potential issues effectively.

Common Issues and Solutions

Many users encounter similar challenges while using their pumps. Below are some frequent problems along with suggested solutions:

| Issue | Possible Solution |

|---|---|

| Pump does not start | Check the power supply and ensure all connections are secure. |

| Unusual noises during operation | Inspect for any loose parts or debris inside the unit. |

| Low pressure output | Verify that there are no blockages in the inlet and outlet pipes. |

| Frequent cycling | Ensure that the pressure switch is properly adjusted. |

Maintenance Tips

To ensure optimal performance and longevity of the pump, consider the following maintenance practices:

- Regularly check for leaks in connections and hoses.

- Clean filters and screens to prevent clogs.

- Inspect seals and gaskets for wear and replace as necessary.

- Store the unit in a dry, protected environment during off-seasons.

Comparing MQ3 35 with Other Models

This section focuses on the evaluation of a specific water pump model in relation to its counterparts in the market. By analyzing various aspects such as efficiency, performance, and features, users can make informed decisions when selecting the right pump for their needs.

The following table summarizes key characteristics of the selected model alongside other comparable pumps:

| Model | Power (kW) | Flow Rate (l/min) | Max Pressure (bar) | Weight (kg) |

|---|---|---|---|---|

| Model A | 1.5 | 50 | 5.5 | 12 |

| Model B | 1.1 | 40 | 4.5 | 10 |

| Model C | 1.2 | 45 | 5.0 | 11 |

| Target Model | 1.0 | 38 | 4.0 | 9 |

Through this comparison, it’s evident that each pump has distinct advantages and limitations. Users should consider factors such as application requirements and budget when choosing the most suitable option.

Where to Purchase Spare Parts

Finding reliable sources for replacement components is crucial for maintaining equipment functionality and longevity. Various options are available, each catering to different needs and preferences.

Here are some common avenues to explore when seeking quality replacements:

- Authorized Dealers: Purchasing from certified sellers ensures compatibility and quality assurance. They typically offer a wide range of genuine replacements.

- Online Retailers: E-commerce platforms provide convenience and accessibility. Be sure to check customer reviews and ratings before making a purchase.

- Local Supply Stores: Visiting nearby hardware or plumbing stores can be beneficial. Local shops often have knowledgeable staff who can assist in finding the right components.

- Manufacturer’s Website: Many manufacturers have online catalogs showcasing their products. This is a reliable way to find specific items directly from the source.

When selecting a supplier, consider factors such as pricing, availability, and shipping options to make an informed decision.