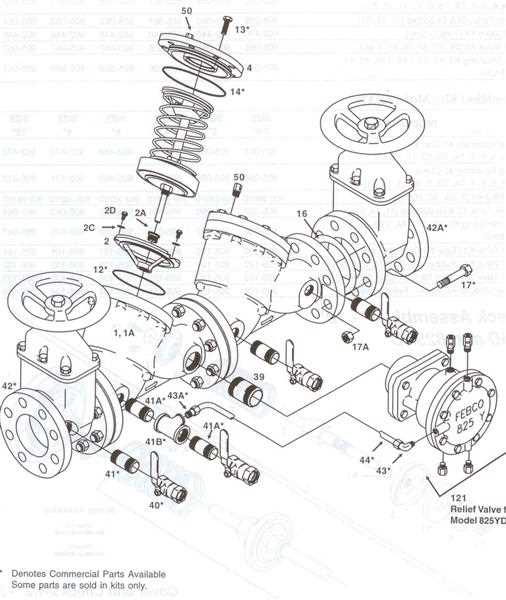

Parts Diagram for Febco 825YA

In the realm of water management, efficient systems are crucial for maintaining optimal flow and pressure. The intricacies of these systems can often be represented through visual aids that highlight each element’s role and interaction. A comprehensive exploration of these visual representations can enhance our understanding of how these mechanisms function.

Through the examination of various illustrations and schematics, we can identify key elements essential for effective operation. These diagrams not only aid in troubleshooting and maintenance but also serve as a guide for installation and replacement. By familiarizing ourselves with each component’s layout and functionality, we can ensure the longevity and reliability of the system.

Additionally, understanding the configuration of these elements can empower users to make informed decisions regarding upgrades and modifications. As we delve deeper into the structure and design of water control mechanisms, we uncover valuable insights that can improve overall efficiency and performance.

Understanding Febco 825YA Components

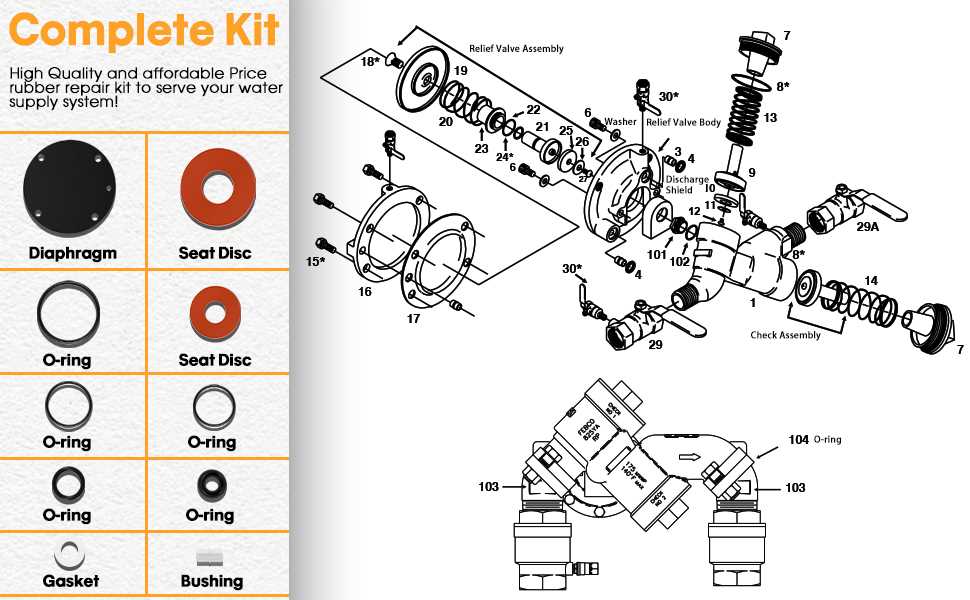

This section aims to provide insights into the various elements that make up a specific water management device. Each component plays a crucial role in ensuring optimal functionality and efficiency. A thorough comprehension of these parts aids in maintenance and troubleshooting, ultimately extending the lifespan of the equipment.

Key Elements of the Assembly

The assembly comprises several key elements, each designed to perform distinct functions. Understanding these elements can facilitate better handling and care of the device, ensuring reliable performance in various applications.

| Component Name | Function |

|---|---|

| Inlet Valve | Regulates water flow into the system. |

| Outlet Valve | Controls the discharge of water. |

| Spring | Maintains pressure and supports valve operation. |

| Diaphragm | Helps in sealing and regulating flow within the device. |

| Body | Houses all components and provides structural integrity. |

Maintenance and Care

Proper maintenance of each part is essential for ensuring the longevity and efficiency of the unit. Regular inspections and timely replacements of worn components can prevent potential failures and enhance overall performance.

Overview of Febco 825YA Design

This section provides a comprehensive understanding of the structure and functionality of a specific model used in irrigation and plumbing systems. Designed for reliability and efficiency, this device plays a crucial role in maintaining water flow and preventing backflow in various applications. The construction of the unit highlights innovative engineering principles aimed at enhancing performance while ensuring ease of maintenance.

Key Features and Components

The device is characterized by several essential features that contribute to its effectiveness. A robust body made from durable materials ensures longevity, while the innovative sealing mechanism prevents leaks and maintains optimal pressure. Additionally, the incorporation of a filtration system aids in keeping water free from contaminants, thus enhancing the overall quality of the fluid being transported.

Applications and Benefits

This particular model is versatile and can be employed in a range of settings, from residential gardens to commercial irrigation systems. Its ability to function efficiently under various conditions makes it a valuable asset for both professionals and DIY enthusiasts. Furthermore, the straightforward design facilitates easy installation and troubleshooting, minimizing downtime and maintenance costs.

Key Features of Febco 825YA

The device is engineered for efficient water flow management, showcasing a range of innovative characteristics that enhance its performance in various applications. Its design emphasizes reliability and durability, making it suitable for both residential and commercial environments.

Robust Construction: Built with high-quality materials, this model ensures longevity and resistance to wear, which is crucial for sustaining optimal functionality over time.

Efficient Operation: Featuring advanced technology, the device minimizes water wastage while providing consistent performance, thus contributing to effective resource management.

Easy Maintenance: The thoughtful design allows for straightforward maintenance procedures, enabling users to keep the system in peak condition with minimal effort.

Versatile Applications: This unit can be utilized in a variety of settings, including irrigation systems and industrial processes, demonstrating its adaptability to different operational demands.

Integrated Safety Features: Equipped with safety mechanisms, it ensures the protection of the system against potential malfunctions, enhancing user confidence in its operation.

User-Friendly Interface: The intuitive controls and indicators facilitate ease of use, allowing operators to manage the system efficiently without extensive training.

Importance of Accurate Parts Diagram

Having a precise visual representation of components is crucial for effective maintenance and repair processes. Such illustrations help technicians identify individual elements and understand their interconnections, leading to efficient troubleshooting and replacements.

Enhancing Understanding

A clear representation of components plays a vital role in enhancing comprehension among users. It allows for:

- Quick identification of specific elements

- Understanding the overall system configuration

- Facilitating communication between technicians and clients

Improving Efficiency

An accurate visual reference can significantly improve operational efficiency by:

- Reducing the time spent searching for components

- Minimizing errors during assembly or disassembly

- Streamlining the ordering process for replacements

In summary, precise illustrations are essential for ensuring smooth operations and effective repairs, ultimately leading to enhanced productivity and reduced downtime.

Identifying Each Component in Diagram

Understanding the various elements within a technical schematic is crucial for effective maintenance and troubleshooting. Each segment serves a distinct purpose, contributing to the overall functionality of the assembly. By recognizing these individual components, users can enhance their comprehension of the system’s operation.

The components are typically labeled and arranged systematically, allowing for straightforward identification. Familiarizing oneself with the common symbols and notations used in these illustrations is essential. This knowledge not only aids in identifying the specific parts but also facilitates a deeper insight into how they interact within the larger mechanism.

When examining the layout, pay attention to features such as valves, seals, and connectors. Each item plays a vital role in ensuring optimal performance. A careful study of their positions and connections can reveal important information about the system’s flow dynamics and operational efficiency.

In addition, cross-referencing the schematic with the corresponding documentation can provide further clarification. Detailed descriptions and specifications often accompany the visual representations, offering valuable context for each element. By engaging with both the diagram and the supplemental materials, users can achieve a comprehensive understanding of the entire assembly.

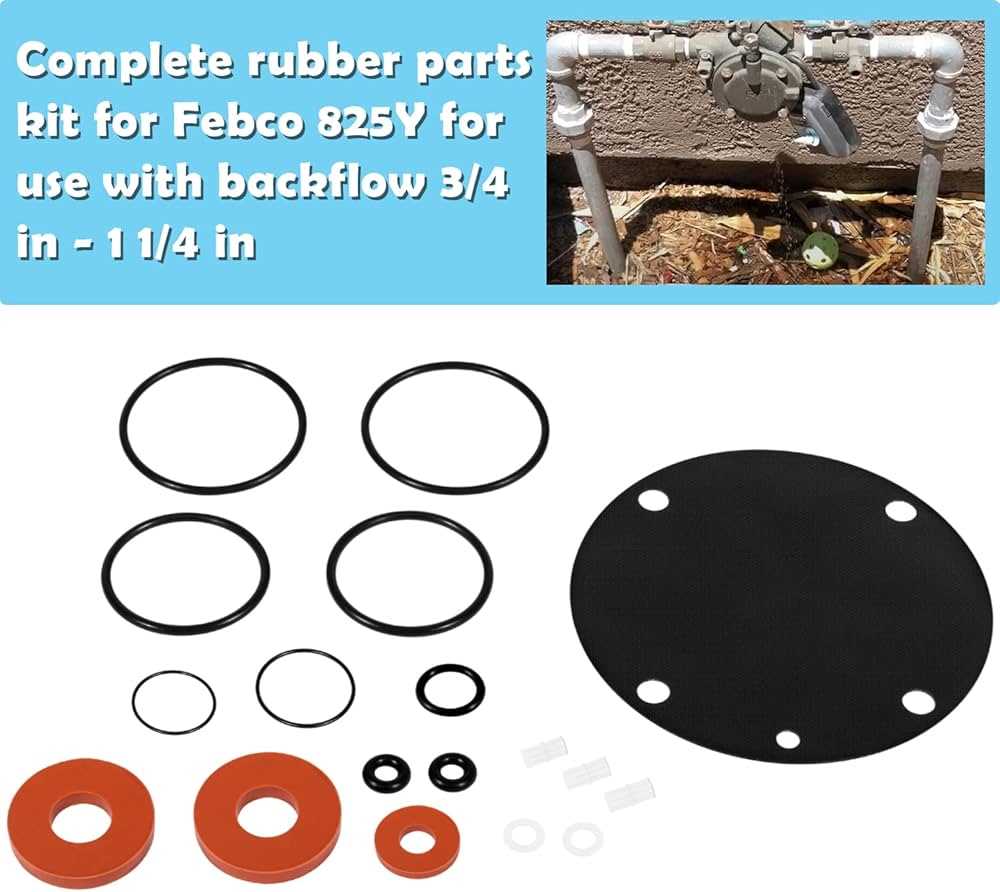

Common Issues with Febco 825YA

When dealing with backflow preventers, users may encounter various challenges that can affect performance and efficiency. Understanding these potential problems can help in timely diagnosis and repair, ensuring that the system operates effectively.

Frequent Leakage Problems

One of the most common concerns is leakage. Over time, wear and tear on seals and internal components can lead to unwanted water flow, compromising the device’s primary function. Regular maintenance and inspections can help identify these issues early.

Pressure Fluctuations

Another prevalent issue is inconsistent pressure levels within the system. This can result from blockages or improper installation, which may cause fluctuations that affect water supply. Monitoring pressure and conducting routine checks can prevent these complications from escalating.

Maintenance Tips for Febco 825YA

Regular upkeep is essential for ensuring optimal performance and longevity of your backflow prevention device. By adhering to a few straightforward practices, you can maintain its efficiency and prevent potential issues from arising. This section provides key recommendations to help you keep your equipment in excellent condition.

Routine Inspection

Conduct regular checks to identify any signs of wear or damage. Look for leaks, corrosion, or unusual noises during operation. Early detection of problems can save time and costs associated with major repairs.

Cleaning and Lubrication

Ensure that all components are free from dirt and debris, as these can impede functionality. Regularly clean the device according to the manufacturer’s instructions. Additionally, apply appropriate lubricants to moving parts to ensure smooth operation and prevent rusting.

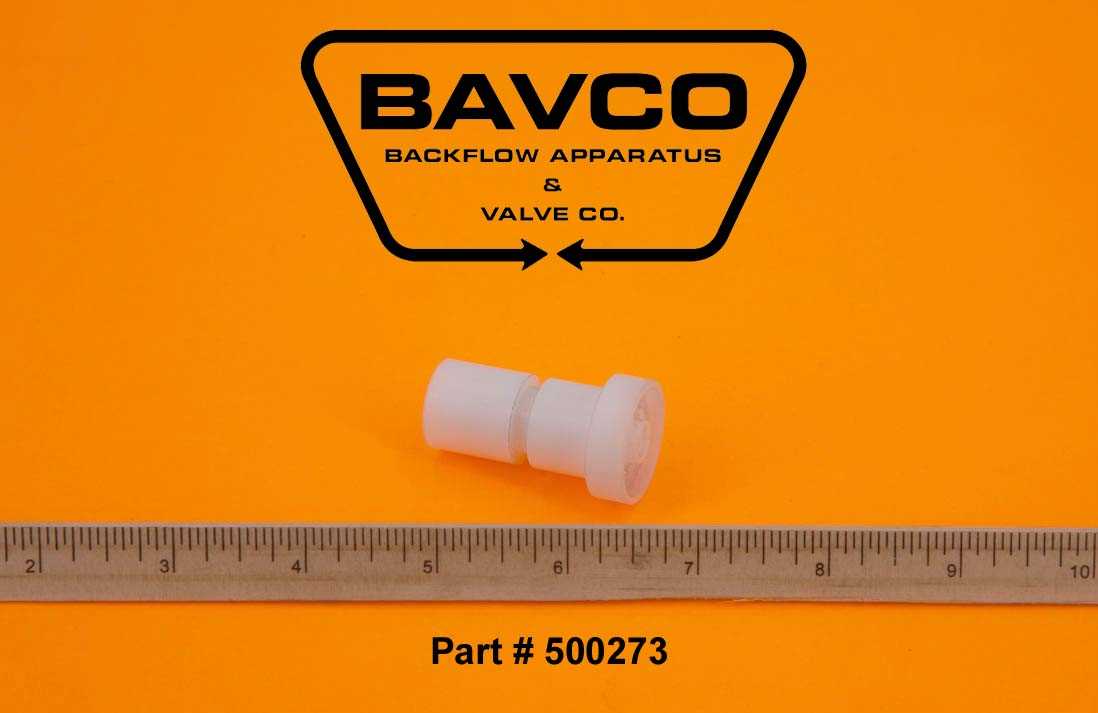

How to Order Replacement Parts

When it comes to maintaining your equipment, acquiring suitable components is crucial for ensuring optimal performance. Whether you’re dealing with leaks or system inefficiencies, knowing how to effectively procure necessary items can save time and effort.

Here are some steps to facilitate the ordering process:

- Identify the Required Component:

Before making a purchase, ascertain the specific element you need. This may involve consulting the user manual or any available documentation.

- Check Compatibility:

Ensure that the selected item is compatible with your existing setup. This might include verifying dimensions, specifications, and model numbers.

- Find a Reputable Supplier:

Research vendors who specialize in the distribution of these components. Look for those with positive reviews and reliable customer service.

- Place Your Order:

Once you’ve identified a supplier, proceed to place your order. Be sure to provide accurate details to avoid any delays.

- Keep Records:

Maintain documentation of your purchases, including invoices and confirmation emails, for future reference and warranty purposes.

Following these steps will help streamline the process of obtaining necessary replacements and ensure that your equipment continues to function efficiently.

Comparing Febco 825YA with Other Models

When evaluating different backflow prevention devices, it is crucial to understand how various models perform in terms of efficiency, reliability, and features. This analysis will delve into the distinctions between a specific unit and other competing variants available in the market, highlighting their unique functionalities and design choices.

One significant aspect to consider is the construction materials used in these devices. While some models may utilize more durable materials to withstand harsh environmental conditions, others might focus on lightweight designs for easier installation and maintenance. Additionally, performance metrics such as flow rates and pressure capabilities can vary, affecting suitability for different applications.

Moreover, user-friendliness is another factor that sets these devices apart. Certain models may offer advanced features such as automated monitoring systems or simplified maintenance protocols, enhancing convenience for users. In contrast, other units may prioritize cost-effectiveness, appealing to budget-conscious consumers.

Lastly, it is important to assess customer feedback and reliability ratings, as they provide valuable insights into long-term performance and satisfaction. By comparing these characteristics, users can make informed decisions tailored to their specific needs and preferences.

Installation Guidelines for Febco 825YA

Proper setup is crucial for the optimal performance of any irrigation control device. This section provides essential instructions for the installation process, ensuring that users can effectively integrate the unit into their existing systems. Following these guidelines will help prevent common issues and enhance the longevity of the equipment.

Preparation Steps

Before beginning the installation, it is essential to gather all necessary tools and components. Ensure that the workspace is clean and free from debris to facilitate a smooth operation. Additionally, review the manufacturer’s specifications and requirements to confirm compatibility with the surrounding system. Taking the time to prepare adequately will minimize complications during the installation process.

Installation Process

Begin the installation by securely mounting the unit according to the outlined specifications. Make sure to connect all relevant pipes and fittings, ensuring that there are no leaks or loose connections. After the initial setup, conduct a thorough inspection to confirm that everything is in place. Finally, test the device to verify its functionality and adjust settings as necessary to optimize performance.

Frequently Asked Questions

This section addresses common inquiries regarding a specific model of backflow preventers. It aims to provide clarity and assist users in understanding various aspects related to its functionality, maintenance, and components.

Common Inquiries

- What are the primary functions of this type of device?

- How can I determine if my unit requires servicing?

- What steps should I take for routine maintenance?

- Where can I find replacement components for my system?

Maintenance and Troubleshooting

- Inspect the unit regularly for signs of wear or damage.

- Ensure that all connections are secure to prevent leaks.

- Follow manufacturer guidelines for cleaning and servicing.

- If issues arise, consult the user manual for troubleshooting steps.

Resources for Further Information

Accessing comprehensive resources is essential for understanding components and their configurations in any complex system. This section provides a selection of references that can enhance your knowledge and support troubleshooting efforts.

| Resource Type | Description | Link |

|---|---|---|

| Manufacturer’s Manual | Official documentation containing detailed information about product specifications and installation guidelines. | View Manual |

| Online Forums | Community discussions where users share experiences, solutions, and advice related to various models and applications. | Join Forum |

| Technical Support | Direct assistance from experts who can provide insights and solutions for specific inquiries. | Contact Support |

| Educational Videos | Video tutorials that visually demonstrate installation, maintenance, and repair processes. | Watch Videos |