Comprehensive Guide to John Deere LA105 Parts Diagram

Every efficient lawn care machine consists of various essential elements that work together to ensure optimal performance. Understanding these components is crucial for maintenance and troubleshooting, enabling users to enhance their gardening experience.

By exploring the intricate layout of these mechanical parts, enthusiasts can gain insight into how each piece contributes to the overall functionality. This knowledge empowers owners to identify potential issues and seek appropriate replacements when necessary.

In this section, we will delve into a comprehensive overview of the various sections and functionalities of this particular model, ultimately guiding users in their journey to maintain their equipment effectively.

Understanding John Deere LA105

This section explores a popular lawn care machine, focusing on its essential components and functionality. Gaining insights into its design can enhance user experience and maintenance efficiency.

- Engine Specifications

- Transmission Features

- Cutting Deck Insights

- Steering Mechanism

By understanding these aspects, operators can ensure optimal performance and longevity.

- Regular Maintenance Tasks

- Common Troubleshooting Steps

- Recommended Upgrades

Each element contributes to the overall effectiveness and reliability of the machine, making it crucial for users to delve into these details for the ultimate lawn care experience.

Overview of LA105 Lawn Mower

The LA105 model is designed to offer an efficient and reliable mowing experience, making it a popular choice for homeowners. With its robust features and user-friendly design, it caters to various lawn maintenance needs.

| Feature | Description |

|---|---|

| Engine Power | Strong engine for optimal performance |

| Cutting Width | Generous cutting width for quicker mowing |

| Drive System | Easy-to-use transmission for smooth operation |

| Deck Material | Durable construction for long-lasting use |

| Comfort Features | Ergonomic seating and controls |

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations provide a clear overview, enabling users to identify elements quickly and streamline their work processes. This clarity can lead to enhanced efficiency and reduced downtime.

Enhanced Maintenance Efficiency

Having a visual reference allows technicians to pinpoint specific components without unnecessary guesswork. This precision ensures that tasks are completed swiftly and accurately, minimizing the risk of errors during repairs.

Facilitating Troubleshooting

When issues arise, a visual guide can simplify the diagnostic process. Technicians can easily correlate symptoms with the relevant parts, leading to quicker resolutions and a deeper understanding of the machinery’s overall function.

Key Components of LA105

The efficient operation of a lawn care machine relies heavily on several essential elements. Understanding these components can help in maintenance and troubleshooting, ensuring optimal performance and longevity. Each part plays a vital role in the functionality, from propulsion to cutting mechanisms.

Core Mechanisms

Among the crucial features, the engine stands out as the powerhouse that drives the entire system. Coupled with a robust transmission, it facilitates smooth movement and control. The cutting deck is another integral element, designed to provide precise trimming while maintaining the health of the grass.

Supportive Elements

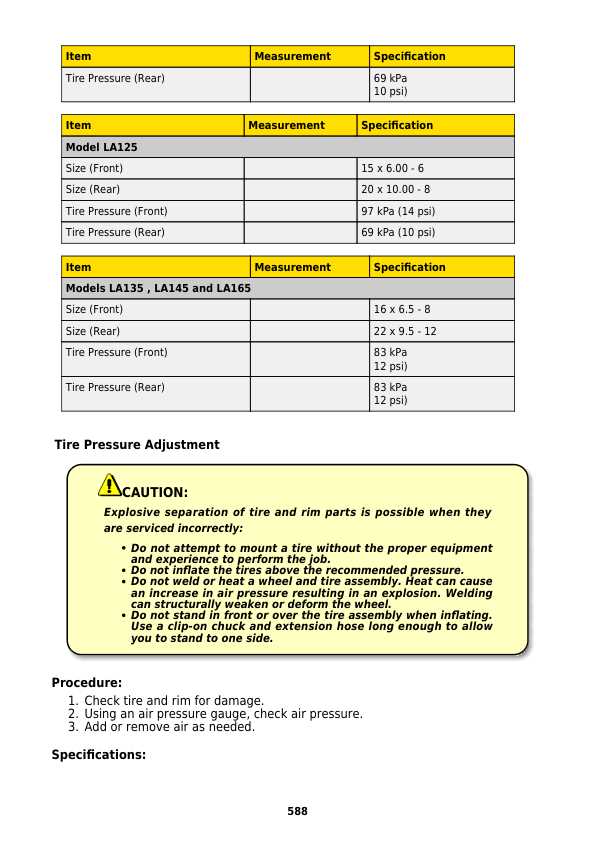

Other supportive components include the battery, which supplies necessary electrical power, and the fuel system, responsible for efficient energy consumption. Additionally, wheels and tires contribute to stability and maneuverability, enhancing the user experience.

| Component | Function |

|---|---|

| Engine | Powers the machine |

| Transmission | Controls movement |

| Cutting Deck | Facilitates grass trimming |

| Battery | Supplies electrical power |

| Fuel System | Manages energy consumption |

| Wheels and Tires | Ensures stability |

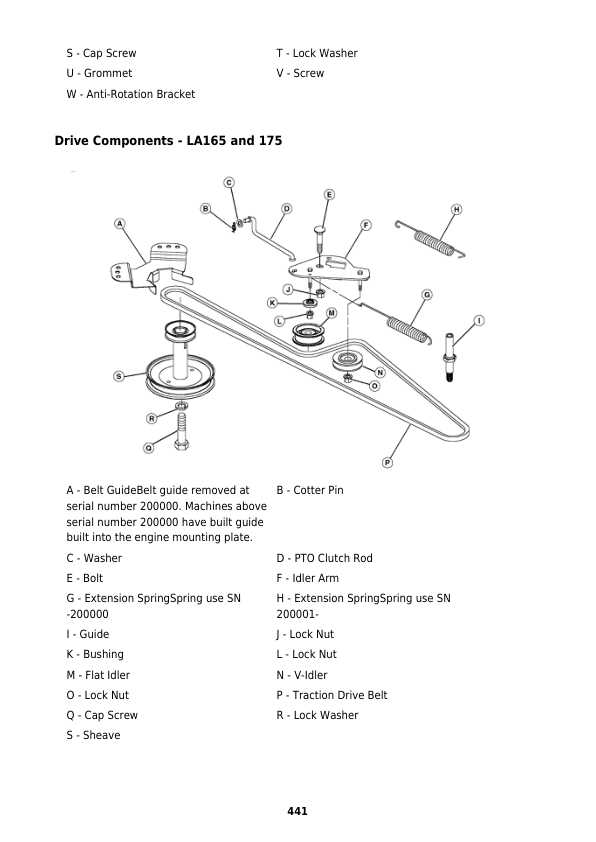

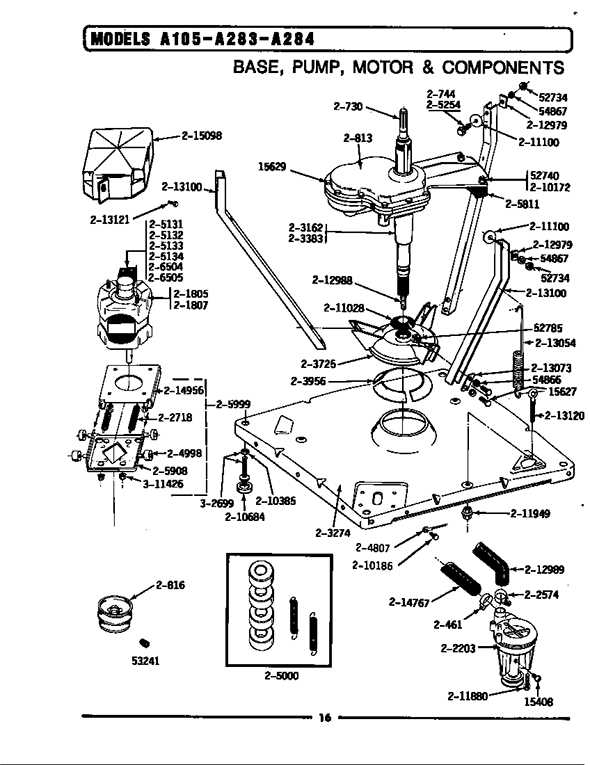

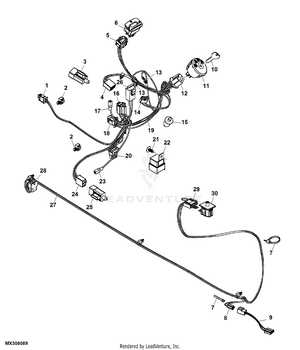

How to Read Parts Diagrams

Understanding assembly illustrations is essential for effective maintenance and repair. These visual aids provide crucial information, enabling users to identify components and their relationships within machinery.

First, familiarize yourself with the overall layout. Components are often numbered or labeled, making it easier to track their positions and functions. Next, pay attention to accompanying legends or notes that offer additional context, clarifying any symbols or terms used in the illustration.

Finally, practice locating specific elements within the drawing, cross-referencing them with your equipment. This hands-on approach will enhance your ability to interpret future visuals accurately.

Common Replacement Parts for LA105

Maintaining your equipment is essential for optimal performance and longevity. Various components may need to be replaced over time due to wear and tear. Identifying these elements can help you keep your machine running smoothly and efficiently.

| Component | Description |

|---|---|

| Battery | Provides the necessary power to start the engine and run electrical systems. |

| Blades | Critical for effective cutting; dull or damaged blades can reduce performance. |

| Air Filter | Prevents dirt and debris from entering the engine, ensuring optimal airflow. |

| Fuel Filter | Removes impurities from fuel, protecting the engine and enhancing efficiency. |

| Spark Plug | Essential for igniting the fuel-air mixture, influencing engine performance. |

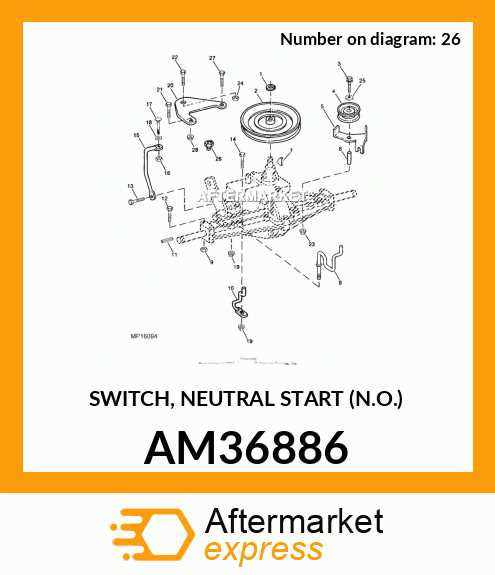

Identifying Part Numbers Easily

Locating the correct identifiers for components can significantly enhance maintenance efficiency and ensure proper replacements. Understanding how to navigate through reference materials is essential for any equipment owner or technician.

Utilizing Reference Guides

- Consult manufacturer manuals for comprehensive lists.

- Use online resources for up-to-date information.

- Engage with forums and communities for shared insights.

Visual Recognition Techniques

- Familiarize yourself with common shapes and sizes.

- Note any specific markings or labels on components.

- Keep a list of frequently needed identifiers for quick access.

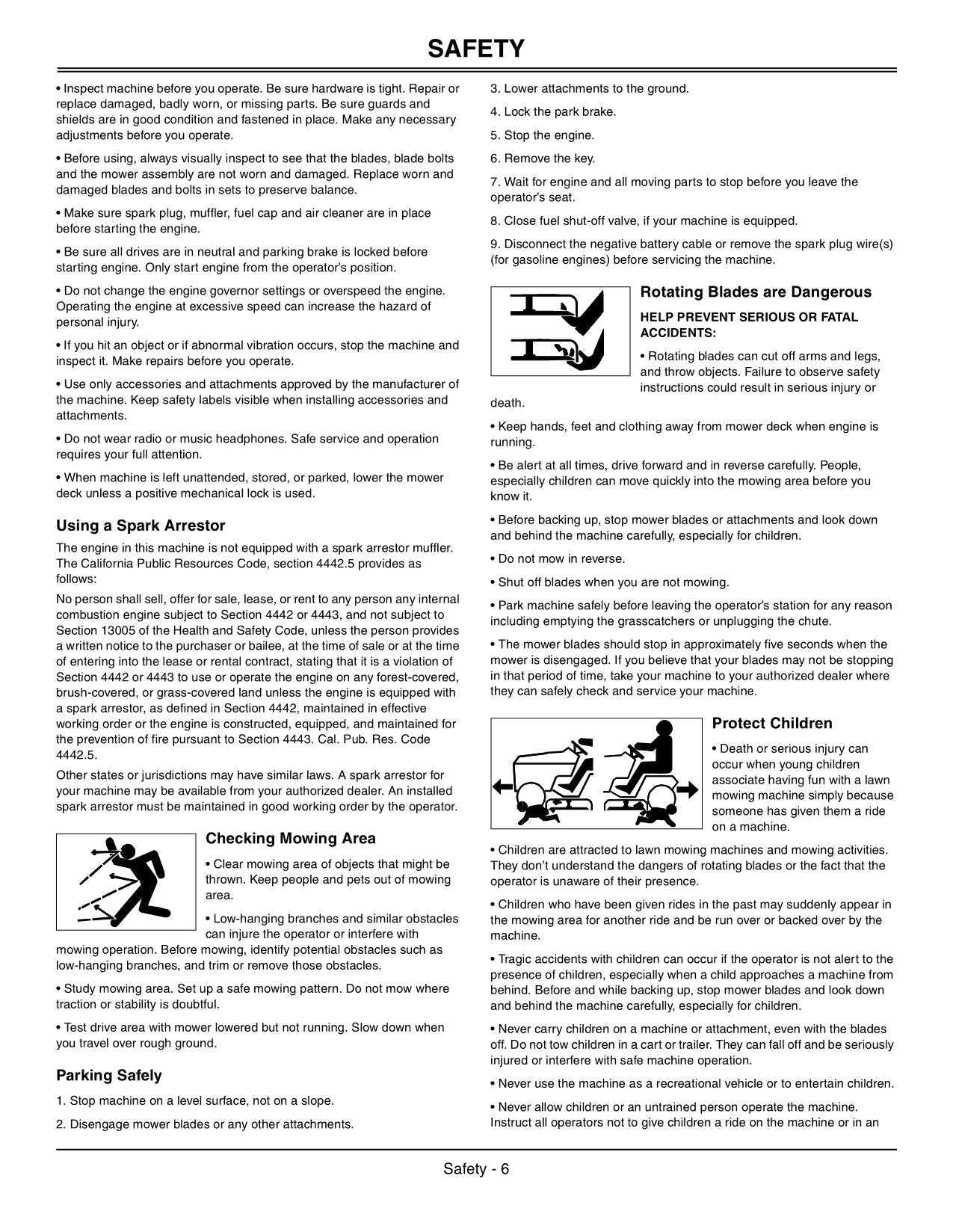

Maintenance Tips for LA105 Parts

Proper upkeep is essential for ensuring longevity and optimal performance of your lawn equipment. Regular attention to various components not only enhances functionality but also prevents potential breakdowns. Implementing a systematic approach to maintenance can save time and resources in the long run.

Here are some key maintenance practices to consider:

| Component | Maintenance Task | Frequency |

|---|---|---|

| Blades | Sharpen and clean | Every 20-25 hours of use |

| Oil | Change and check level | Every 50 hours of use |

| Air Filter | Inspect and clean/replace | Every season or as needed |

| Battery | Check charge and clean terminals | Monthly |

| Tires | Check pressure and inspect for wear | Monthly |

Following these guidelines can significantly improve the reliability and efficiency of your equipment. Consistent maintenance not only enhances performance but also prolongs the life of your machinery, making it a worthwhile investment.

Where to Find Diagrams Online

Locating detailed illustrations and schematics for machinery components can enhance maintenance and repair processes. Various online resources provide access to these invaluable visual guides, ensuring users can efficiently address their equipment needs.

| Resource | Description |

|---|---|

| Manufacturer’s Website | Official sites often offer comprehensive resources, including service manuals and schematics. |

| Online Forums | Community-driven platforms where enthusiasts share insights and diagrams. |

| Parts Retailers | Specialized retailers often feature diagrams as part of their listings for easy reference. |

| DIY Websites | Sites dedicated to do-it-yourself repairs often provide guides and relevant visuals. |

Ordering Genuine John Deere Parts

When it comes to maintaining your equipment, sourcing authentic components is crucial for optimal performance and longevity. Ensuring that you choose the right suppliers can make a significant difference in the reliability and efficiency of your machinery.

Here are some key points to consider when placing an order for original components:

| Factor | Description |

|---|---|

| Quality Assurance | Genuine components are manufactured to meet strict quality standards, ensuring compatibility and durability. |

| Warranty Protection | Using authentic items typically maintains your warranty coverage, protecting your investment. |

| Availability | Authorized dealers usually have access to a wide range of items, making it easier to find what you need. |

| Expert Support | Purchasing from recognized sources often includes access to knowledgeable staff who can provide assistance and advice. |

Choosing authentic components is not just about compliance; it’s about ensuring your equipment performs at its best, keeping you productive and efficient in your tasks.

DIY Repairs Using Parts Diagrams

Understanding how to tackle repairs on your machinery can save time and money. Utilizing visual references can significantly enhance the repair process, enabling you to identify necessary components quickly and accurately. This approach empowers you to perform maintenance tasks with confidence and precision.

Benefits of Visual References

Visual references simplify complex repairs by breaking them down into manageable sections. They allow you to familiarize yourself with the arrangement of various elements, ensuring you have the right tools and replacement items ready before starting your work. This method not only streamlines the repair process but also helps in preventing errors.

Steps for Effective DIY Repairs

Begin by obtaining a visual reference tailored to your specific machinery. Carefully study the illustration to understand the placement of each component. Gather all necessary tools and parts, then follow a systematic approach to disassemble and replace the required elements. Always keep safety in mind to ensure a smooth and successful repair experience.

Comparing Aftermarket vs. OEM Parts

When it comes to maintaining and repairing machinery, the choice between original components and their alternative counterparts can significantly impact performance and longevity. Understanding the differences between these options is essential for making informed decisions that affect both functionality and budget.

Quality and Reliability

Original components are often manufactured to the exact specifications set by the original equipment manufacturer. This means they generally offer:

- Higher reliability and durability

- Better compatibility with existing systems

- Potentially longer warranty periods

On the other hand, alternative options can vary in quality. Factors to consider include:

- Brand reputation and reviews

- Materials used in manufacturing

- Quality control processes

Cost Considerations

One of the most significant factors influencing the choice is cost. Typically, original components come at a premium price, while alternatives may be more budget-friendly. However, it’s important to evaluate:

- The potential for additional repairs if alternatives fail prematurely

- Long-term savings through enhanced performance of original parts

- Impact on resale value if the equipment is well-maintained with quality components

Ultimately, the decision should be based on a careful assessment of both immediate needs and future implications, ensuring that the chosen option aligns with the overall maintenance strategy.

Resources for Troubleshooting LA105

When facing issues with your mowing equipment, having the right resources can significantly streamline the troubleshooting process. This section provides essential tools and references to help you identify and resolve common problems effectively.

Online Forums and Communities

Engaging with online communities can be beneficial. Here are some platforms where enthusiasts and experts share their experiences:

- Reddit: Look for subreddits dedicated to gardening and lawn care.

- Facebook Groups: Join groups focused on lawn equipment maintenance.

- Dedicated Forums: Many websites host forums specifically for equipment troubleshooting.

Maintenance Manuals and Guides

Consulting maintenance manuals can provide valuable insights. Consider the following resources:

- Manufacturer’s Website: Download official manuals and troubleshooting guides.

- YouTube Tutorials: Search for video demonstrations on common repair tasks.

- Local Libraries: Check for books on lawn care machinery maintenance.