Comprehensive Parts Diagram for Stihl 028 AV Super Chainsaw

The functionality of any cutting instrument relies heavily on its internal components and their precise arrangement. Each element plays a critical role in ensuring efficient performance and longevity. For enthusiasts and professionals alike, having a clear understanding of these components is essential for optimal maintenance and repair.

When delving into the intricacies of such equipment, one can discover how the design and interaction of various elements contribute to the overall effectiveness of the tool. Identifying each part and its purpose can ultimately enhance the user experience, allowing for smoother operation and reduced wear over time.

In this section, we will explore the essential elements of a widely-used cutting device, breaking down its anatomy to reveal the synergy between its parts. By gaining insights into the specific functions and relationships of these components, users can achieve greater mastery and care of their equipment.

Understanding Stihl 028 AV Super Chainsaw

This section aims to provide a comprehensive overview of a powerful cutting tool designed for various applications in forestry and landscaping. By examining its key features and components, users can appreciate its capabilities and operational efficiency. This device is celebrated for its durability and performance, making it a preferred choice among both professionals and hobbyists.

Key Features

The tool is equipped with advanced technology that enhances cutting precision and user comfort. Its lightweight construction ensures ease of handling, while the robust engine delivers impressive power. Additionally, the ergonomic design contributes to reduced fatigue during prolonged use, allowing for greater productivity.

Maintenance Considerations

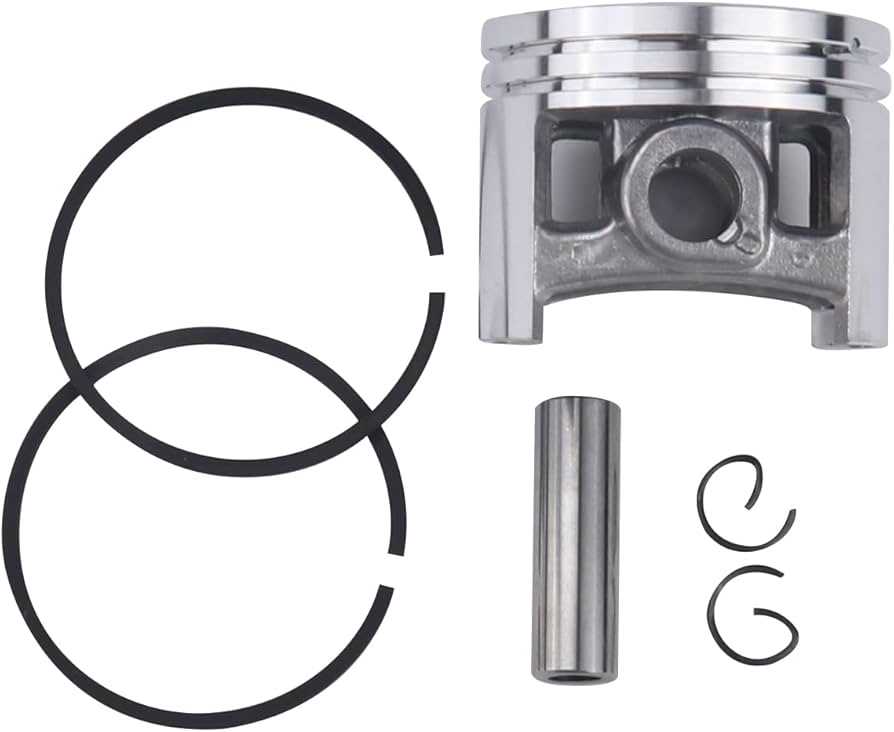

Essential Components of the Chainsaw

Understanding the fundamental elements of a cutting tool is crucial for effective operation and maintenance. Each component plays a vital role in ensuring optimal performance, safety, and durability. A well-designed assembly not only enhances efficiency but also contributes to the overall longevity of the equipment.

Key Functional Parts

Among the primary functional components, the motor stands out as the powerhouse, providing the necessary energy for cutting tasks. The cutting bar and chain work in tandem to achieve precision and speed, making them essential for any heavy-duty operation. Additionally, the handle and throttle mechanism enable the user to maintain control and adjust the speed, ensuring both comfort and safety during use.

Support and Safety Features

Safety features, such as the chain brake and safety throttle, are critical for preventing accidents and injuries. These elements are designed to minimize risks while maximizing user protection. Other support components, including the air filter and fuel system, contribute to the efficiency of the engine and overall functionality, ensuring that the tool operates smoothly and effectively in various conditions.

Diagram Overview: Stihl 028 AV Parts

This section provides a comprehensive look at the components of a popular model, highlighting their arrangement and function within the machine. Understanding these elements is essential for effective maintenance and repairs.

Key Components

- Engine Assembly

- Fuel System

- Ignition System

- Bar and Chain Assembly

- Handle and Housing

Importance of Each Element

- The engine assembly drives the overall performance.

- Fuel system ensures optimal power delivery.

- Ignition system is crucial for starting and operation.

- Bar and chain assembly determine cutting efficiency.

- Handle and housing contribute to user safety and comfort.

Common Issues with Chainsaw Parts

When operating power cutting tools, various components may encounter problems that affect performance and safety. Understanding these common issues can help in maintaining efficiency and prolonging the lifespan of the equipment.

- Fuel System Failures:

- Clogged fuel lines due to debris or old fuel.

- Faulty fuel filters that restrict flow.

- Issues with the carburetor leading to poor fuel mixture.

- Ignition Troubles:

- Worn-out spark plugs causing ignition failure.

- Malfunctioning ignition coils leading to inconsistent starts.

- Bad connections in the wiring harness that interrupt power.

- Bar and Chain Problems:

- Excessive wear on the guide bar due to improper lubrication.

- Dull chain teeth resulting in inefficient cutting.

- Chain tension that is too loose or too tight, affecting operation.

- Safety Mechanism Failures:

- Malfunctioning chain brake that may not engage.

- Defective throttle triggers leading to unexpected acceleration.

- Worn hand grips that compromise control.

Regular maintenance and inspections can mitigate these issues, ensuring reliable performance and safety during use.

Maintenance Tips for Longevity

Ensuring the extended life of your outdoor power equipment requires consistent care and attention. Implementing regular maintenance practices not only enhances performance but also prevents costly repairs.

Regular Cleaning: Keep the exterior and components free from debris and residues. Cleanliness prevents overheating and facilitates better operation.

Oil Levels: Regularly check and maintain proper lubrication. Adequate oil reduces friction, prolonging the lifespan of critical parts.

Chain Tension: Monitor the tension to prevent slippage or damage. Properly adjusted tension ensures efficient cutting and minimizes wear.

Inspection: Frequently examine all components for signs of wear or damage. Early detection of issues can save time and money.

Storage: Store equipment in a dry, protected environment. Proper storage minimizes exposure to elements that can cause deterioration.

By following these tips, you can maximize the performance and durability of your essential tools, ensuring they serve you well for years to come.

How to Identify Genuine Parts

Ensuring the authenticity of components for your equipment is crucial for optimal performance and longevity. Recognizing authentic items can significantly enhance efficiency and reduce the risk of malfunctions. By understanding the characteristics of genuine offerings, users can make informed choices and safeguard their investments.

1. Examine Packaging: Authentic items often come in high-quality packaging that includes clear branding and product information. Look for any signs of tampering or poor quality.

2. Check Serial Numbers: Genuine components typically have unique serial numbers that can be verified with the manufacturer. Always cross-reference these codes.

3. Evaluate Build Quality: Authentic items are made from durable materials and exhibit precise craftsmanship. Pay attention to details like finishing and weight.

4. Research Vendors: Purchase from reputable dealers and official distributors. Check reviews and ratings to ensure reliability.

5. Consult Documentation: Refer to manuals or official guides that outline specifications and features of authentic offerings to distinguish them from imitations.

By following these guidelines, users can effectively navigate the market and ensure they select only the most reliable and authentic components for their equipment.

Replacing Worn-Out Components

Maintaining the efficiency of your cutting tool often requires timely substitution of aged or damaged elements. Identifying and addressing these issues can significantly enhance performance and prolong the lifespan of the equipment.

Regular inspections are essential for spotting signs of wear. Look for components that show signs of damage, such as cracks or excessive wear. Taking immediate action to replace these parts can prevent further complications and ensure optimal functionality.

When sourcing new components, always choose quality replacements that meet the manufacturer’s specifications. Proper installation is crucial; follow guidelines to ensure a secure fit and maintain overall safety during operation. Frequent maintenance not only keeps the equipment running smoothly but also provides peace of mind for users.

Tools Needed for Repairs

To effectively perform maintenance and repairs on mechanical devices, having the right instruments is crucial. This section outlines essential tools that will facilitate the repair process and ensure optimal functionality.

Essential Instruments

- Wrenches: Various sizes for loosening and tightening components.

- Screwdrivers: Flathead and Phillips types for different screws.

- Pliers: For gripping and manipulating small parts.

- Torque Wrench: Ensures screws are tightened to the correct specifications.

Specialized Equipment

- File: For smoothing rough edges and surfaces.

- Measuring Tools: Rulers or calipers for precise measurements.

- Lubricants: Necessary for maintaining moving parts.

- Safety Gear: Gloves and goggles for personal protection during repairs.

Exploring Aftermarket Options

When maintaining or enhancing outdoor power tools, many users consider alternative components. These aftermarket selections often provide cost-effective solutions while ensuring compatibility and performance. Delving into these options can uncover a variety of benefits, including improved efficiency and extended durability.

Choosing the right replacements is essential for optimal functioning. Below is a comparison of key aftermarket offerings:

| Component | Aftermarket Brand | Benefits |

|---|---|---|

| Bar | Brand A | Enhanced durability and lighter weight |

| Chain | Brand B | Superior cutting efficiency and longer life |

| Air Filter | Brand C | Improved filtration and engine performance |

Ultimately, exploring these alternatives can lead to valuable upgrades, enhancing the overall experience and functionality of your equipment.

Assembly Instructions for Parts

Proper assembly is crucial for optimal performance and longevity of your equipment. Following a systematic approach ensures each component fits securely, contributing to overall functionality.

Preparation Steps

- Gather all necessary tools and components.

- Clean the workspace to avoid contamination.

- Review the manual for specific instructions.

Assembly Process

- Start with the base unit, ensuring it is stable.

- Attach the main body components, aligning them carefully.

- Secure all fasteners, checking for tightness.

- Install any additional accessories as per the guidelines.

- Conduct a final inspection for completeness and alignment.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial for both the individual performing the work and the equipment being serviced. Proper precautions help to minimize the risk of accidents and injuries, creating a safer environment for all involved.

Before beginning any repair, always wear appropriate protective gear, including gloves, goggles, and hearing protection. This helps shield against potential hazards like flying debris or sharp objects. Additionally, ensure that the workspace is clean and well-lit to prevent slips and falls.

It’s essential to disconnect the power source or remove the fuel before starting any disassembly. This step prevents accidental starts that could lead to severe injuries. Familiarize yourself with the user manual and any specific instructions related to the equipment to understand its components and their functions better.

Keep tools organized and in good condition. Using the right tools for each task not only enhances efficiency but also reduces the risk of mistakes that can result in injury. Always double-check that the equipment is securely positioned to avoid unintended movements during the repair process.

Lastly, if you’re uncertain about any procedure, don’t hesitate to seek professional assistance. Understanding your limits is key to ensuring a safe and successful repair experience.

Expert Advice on Troubleshooting

Tackling mechanical issues requires a methodical approach. Understanding the common problems can significantly streamline the repair process, ensuring your equipment operates effectively.

- Identify Symptoms: Begin by noting any unusual sounds or performance drops.

- Check Fuel Quality: Old or contaminated fuel can lead to inefficient operation.

- Inspect the Air Filter: A clogged filter restricts airflow, impacting performance.

- Examine the Spark Plug: Ensure it’s clean and properly gapped for optimal ignition.

By systematically addressing these areas, you can delve deeper into the root cause of the issue and implement the ultimate solution effectively.