Understanding the Parts Diagram of the Stihl FS 38 Trimmer Head

Maintaining your outdoor equipment is crucial for ensuring its longevity and optimal performance. Within any device designed for precision cutting, a thorough comprehension of its various components is essential for effective upkeep and troubleshooting. Each element plays a significant role in the overall functionality, making it vital to familiarize yourself with them.

This section will delve into the intricate details of the assembly that powers your equipment. By breaking down the various elements and their relationships, you can enhance your understanding and improve your ability to address any issues that may arise during operation. A clear visual representation can greatly aid in this process, allowing users to identify specific components and their functions seamlessly.

Arming yourself with knowledge about these integral components can lead to more efficient use and maintenance of your machinery. Whether you’re looking to replace a worn-out item or simply want to understand how everything fits together, exploring these aspects can make a significant difference in your experience.

Understanding Stihl FS 38 Trimmer Parts

When maintaining your outdoor equipment, familiarity with its components is essential for optimal performance. Each element plays a crucial role in ensuring efficient operation, making it important to comprehend how they interact with one another. By gaining insight into these individual segments, users can effectively troubleshoot issues and enhance the longevity of their equipment.

Key Components Overview

Every machine consists of various essential elements that contribute to its functionality. Understanding these key segments helps users identify potential problems. For instance, the rotational mechanism, which powers the cutting action, relies on precise alignment with other components to function smoothly. Regular checks can prevent wear and extend the device’s lifespan.

Maintenance Tips

To keep your equipment running efficiently, routine maintenance is vital. Always inspect the connections and replace any worn-out elements promptly. Cleaning the exterior and ensuring that all moving parts are lubricated can significantly improve performance. Additionally, consulting the manual for specific recommendations on upkeep can lead to better results and fewer operational issues.

Overview of Trimmer Head Components

This section delves into the various elements that comprise the cutting mechanism, offering insights into their functions and importance. Understanding these components is crucial for effective maintenance and optimal performance.

Key Elements

- Spool: The central part that holds the line, allowing for easy feeding and replacement.

- Line: The cutting material, usually made of nylon, that performs the actual trimming.

- Casing: The outer shell that protects the internal components and provides structural support.

- Cover: The protective element that shields the spool and line from debris.

- Spring: A vital component that ensures the proper tension of the line and allows for automatic feed.

Functionality and Maintenance

Each component plays a pivotal role in the overall functionality of the mechanism. Regular checks and maintenance are essential to ensure these elements work harmoniously, thereby enhancing efficiency and longevity.

- Inspect the spool for wear and tear to prevent line jams.

- Replace the cutting line as needed to maintain effectiveness.

- Ensure the casing is intact to protect against external damage.

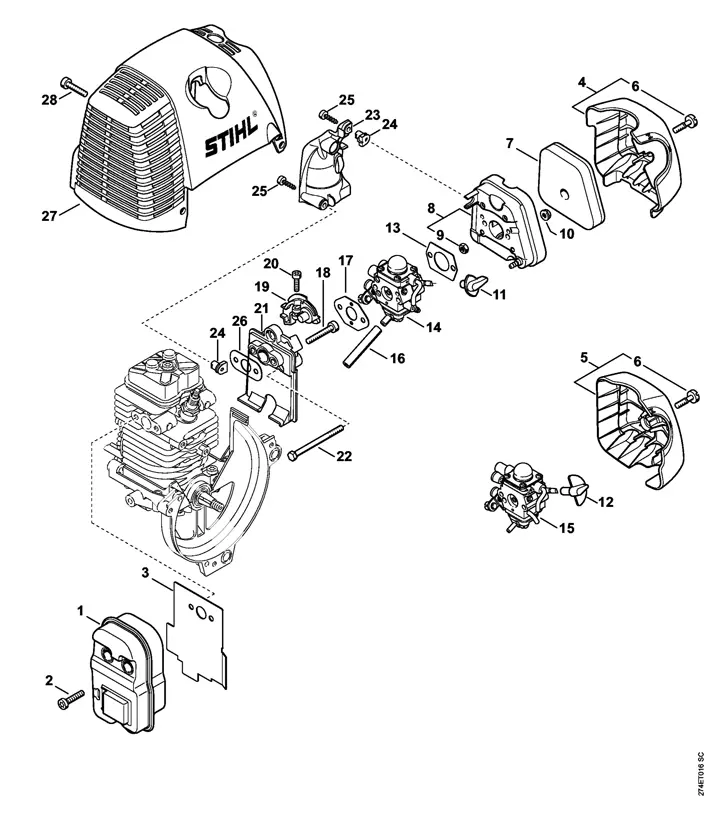

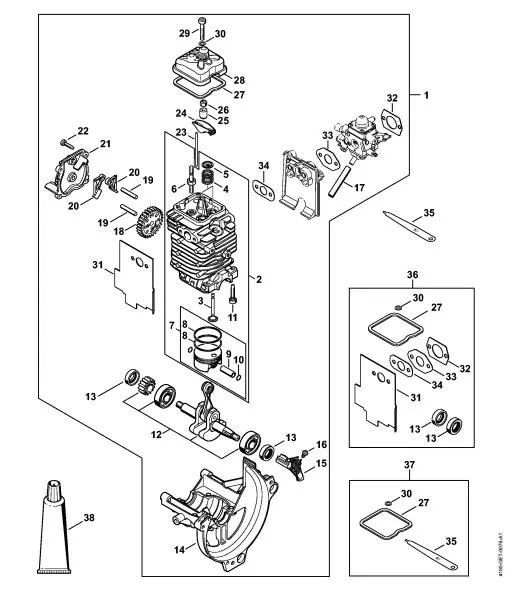

How to Read Parts Diagrams

Understanding technical illustrations is essential for anyone looking to maintain or repair equipment. These visual aids provide valuable insights into the components of a machine, helping users identify and locate specific elements. Knowing how to interpret these visuals can significantly enhance the efficiency of your repair process.

Here are key steps to effectively read these illustrations:

- Familiarize Yourself with the Symbols: Each illustration typically includes a variety of symbols representing different components. Recognizing these symbols is crucial for accurate interpretation.

- Follow the Numbering System: Most diagrams will include a numbering system that corresponds to a list of parts. Always refer to this list to understand what each number represents.

- Identify the Assembly Order: Pay attention to how parts are arranged in the illustration. This can help you understand the sequence in which components should be assembled or disassembled.

- Check for Notes and Annotations: Many visuals include additional notes or annotations that provide extra context or instructions. These can offer insights into specific assembly techniques or precautions.

- Compare with Your Equipment: If possible, have the actual machine nearby while consulting the illustration. This allows for direct comparison and can aid in identifying parts more easily.

By mastering these steps, you’ll be better equipped to navigate technical illustrations, leading to more successful maintenance and repair efforts.

Common Issues with Trimmer Heads

Maintaining garden tools can sometimes be challenging, especially when it comes to the components that facilitate cutting. Users often encounter several prevalent issues that can hinder performance and efficiency. Understanding these problems can help in effective troubleshooting and prolonging the lifespan of your equipment.

Line Jamming

One of the most frequent complaints is line jamming. This occurs when the cutting material becomes entangled or fails to dispense properly. Factors contributing to this issue include improper winding of the line or using the wrong type of material. Regular checks can prevent these complications, ensuring smooth operation.

Inconsistent Cutting Performance

Inconsistent performance can be frustrating, often resulting in uneven trimming. This may be caused by wear and tear on components or insufficient power. Additionally, using the wrong speed settings can lead to subpar results. Regular maintenance and adjustments are crucial for achieving optimal functionality.

Replacement Parts for Stihl FS 38

Ensuring optimal performance of your equipment involves understanding the various components that may require replacement over time. This section outlines essential elements that contribute to the functionality of your model, helping you maintain efficiency and extend its lifespan.

- Line spool

- Cutting line

- Drive shaft

- Gear assembly

- Cover

- Spring

- Connector

Each of these components plays a crucial role in the overall operation. Regular inspections and timely replacements can prevent unexpected breakdowns and enhance the user experience.

- Identify the component needing attention.

- Consult the user manual for specific guidelines.

- Purchase high-quality replacements from a trusted source.

- Follow proper installation procedures to ensure durability.

By proactively managing these elements, you can keep your equipment running smoothly and efficiently, ensuring that it meets your cutting needs effectively.

Tools Required for Trimmer Repair

Proper maintenance and repair of outdoor equipment necessitate specific tools that ensure efficient and safe handling. Understanding the essential instruments can significantly streamline the repair process and enhance the longevity of your equipment.

Below is a list of the basic tools typically required for effective repairs:

| Tool | Description |

|---|---|

| Screwdriver Set | Variety of sizes and types (flathead and Phillips) for loosening or tightening screws. |

| Wrench Set | Includes both open-end and socket wrenches to accommodate different bolt sizes. |

| Replacement Blades or Line | Essential for maintaining cutting efficiency, ensuring that the device performs optimally. |

| Pliers | Useful for gripping and manipulating small components during the repair process. |

| Fuel Mix Container | For preparing and storing the correct fuel mixture, which is critical for operation. |

| Protective Gear | Includes gloves and safety glasses to ensure safety while working on equipment. |

Equipping yourself with the right tools can make the repair process smoother, helping you get back to maintaining your garden or lawn in no time.

Step-by-Step Assembly Guide

This guide provides a comprehensive approach to assembling essential components for efficient operation. Following these steps will ensure that everything is put together correctly for optimal performance.

-

Begin by gathering all necessary components and tools. Ensure that you have the following items:

- Assembly unit

- Fastening elements

- Protective gear

- Instruction manual

-

Start with the base component. Position it on a stable surface to facilitate assembly.

-

Next, attach the central element. Align it carefully with the designated points and secure it using the provided fasteners.

-

Incorporate any additional attachments as outlined in your manual. Make sure each piece clicks into place firmly.

-

Once all components are connected, double-check each connection for security and stability. This step is crucial for safe operation.

-

Finally, perform a brief inspection of the assembled unit. Look for any irregularities or loose parts before usage.

By following these steps methodically, you will achieve a well-assembled unit ready for effective performance.

Maintenance Tips for Longevity

Ensuring the durability and performance of your outdoor equipment requires regular care and attention. By following specific maintenance practices, you can extend the lifespan of your machinery, keeping it in optimal condition for years to come.

Regular Cleaning

After each use, it’s essential to remove debris and grass clippings that can accumulate. This not only helps maintain efficiency but also prevents corrosion and damage. Utilize a brush or cloth to wipe down surfaces, ensuring that no residue is left behind.

Check and Replace Worn Components

Routine inspection of all essential elements is vital. Look for signs of wear or damage, particularly in parts that experience significant stress. Replacing any worn components promptly can prevent further issues and ensure smooth operation. Additionally, refer to the manufacturer’s guidelines for recommended replacement intervals.

By implementing these straightforward practices, you can significantly enhance the longevity of your outdoor equipment, ensuring it remains reliable and effective throughout its life cycle.

Identifying Worn Parts in Use

Regular maintenance of gardening equipment is crucial for ensuring optimal performance. Over time, various components may experience wear and tear, affecting efficiency and effectiveness. Recognizing these worn elements can help prolong the lifespan of your tools and enhance their functionality.

When inspecting your equipment, look for signs of damage or deterioration. This may include fraying, cracking, or other visible defects. Additionally, listening for unusual noises during operation can indicate that something is not functioning correctly.

| Component | Signs of Wear | Recommended Action |

|---|---|---|

| String | Fraying or thinning | Replace immediately |

| Drive shaft | Excessive play or wobbling | Inspect for damage, replace if necessary |

| Guard | Cracks or breaks | Replace to ensure safety |

| Handle | Loose fittings or cracks | Tighten or replace |

By conducting regular inspections and addressing issues promptly, you can maintain your equipment in peak condition, ensuring it operates efficiently for years to come.

Where to Buy Replacement Parts

Finding quality components for your gardening tools is essential for maintaining their performance and longevity. Whether you’re looking for original or compatible items, there are several avenues to explore that cater to different needs and budgets.

Online Retailers

Numerous e-commerce platforms offer a vast selection of components. Websites such as Amazon, eBay, and specialized outdoor equipment sites often provide detailed listings, customer reviews, and competitive pricing. Ensure you check the seller’s ratings and return policies before making a purchase.

Local Hardware Stores

Your neighborhood hardware store can be a valuable resource. Many carry a variety of components and can assist you in finding exactly what you need. Additionally, local shops may provide personalized service and advice based on your specific tools.

Differences Between Trimmer Models

When exploring various models of garden maintenance tools, it’s essential to recognize the key distinctions that can impact performance and usability. Each variant is designed with specific features that cater to different needs and preferences, ensuring that users can find the ideal option for their tasks.

- Engine Type: Models may vary in their engine configurations, including two-stroke and four-stroke engines, affecting power output and fuel efficiency.

- Weight and Maneuverability: The weight of each unit can influence ease of use, particularly during extended periods of operation.

- Cutting Width: Different models offer various cutting widths, which can affect the efficiency of work and suitability for certain tasks.

- Handle Design: Ergonomics play a significant role, with some designs offering adjustable or loop handles for better control.

- Line Feed Mechanism: Variations in how the cutting line is advanced can impact convenience and operational efficiency.

- Durability and Build Quality: Material choices may differ, influencing longevity and resistance to wear under challenging conditions.

Understanding these differences allows users to make informed choices based on their specific gardening needs, ensuring optimal performance and satisfaction with their selected tool.

Customer Reviews of Stihl FS 38

This section explores user feedback on the popular gardening tool, highlighting various experiences and opinions. Reviews reflect a mix of satisfaction and concerns, providing valuable insights for potential buyers.

Positive Feedback

- Many users appreciate the lightweight design, making it easy to maneuver for extended periods.

- The power and efficiency received high praise, with many noting its effectiveness in tackling thick grass and weeds.

- Several customers highlighted the straightforward assembly process, allowing quick setup and use.

Constructive Criticism

- Some reviewers mentioned issues with durability over time, expressing concerns about wear and tear.

- A few users found the noise level higher than expected, which could be a drawback for residential areas.

- Others suggested improvements in the vibration control for a more comfortable experience during use.

Safety Precautions During Repairs

Ensuring personal safety while conducting maintenance or repairs is paramount. Following specific guidelines can significantly reduce the risk of injury and enhance the efficiency of the task. Proper preparation and awareness of potential hazards play a crucial role in a successful repair process.

Personal Protective Equipment

Wearing appropriate personal protective gear is essential. Always use safety goggles to protect your eyes from debris and dust. Gloves should be worn to safeguard your hands from sharp edges and chemicals. Additionally, sturdy footwear will help prevent foot injuries in case of dropped tools or equipment.

Work Environment Safety

Maintaining a clean and organized workspace is vital. Ensure that the area is well-lit and free from obstacles that could cause tripping. Before starting any repair, disconnect the power source to prevent accidental activation. Being aware of your surroundings can help you identify potential dangers and work more effectively.