Comprehensive Guide to Ford Dana 44 Front Axle Parts Diagram

In the realm of automotive engineering, the intricacies of a vehicle’s drivetrain play a pivotal role in its performance and durability. Every element within this system is designed to work in harmony, ensuring optimal functionality under various conditions. This exploration delves into the specific elements that contribute to the strength and reliability of one of the most critical assemblies found in many vehicles.

The arrangement of these vital components can significantly influence the overall efficiency and handling of the automobile. By examining their structure and interrelationships, enthusiasts and professionals alike can gain valuable insights into how to maintain and enhance the performance of their machines. This section aims to provide clarity on the arrangement and function of these crucial mechanical elements.

Whether you are a seasoned mechanic or a curious owner, understanding the layout and function of each component is essential for effective maintenance and troubleshooting. A comprehensive overview of these features will not only empower you with knowledge but also assist in making informed decisions regarding upgrades and repairs.

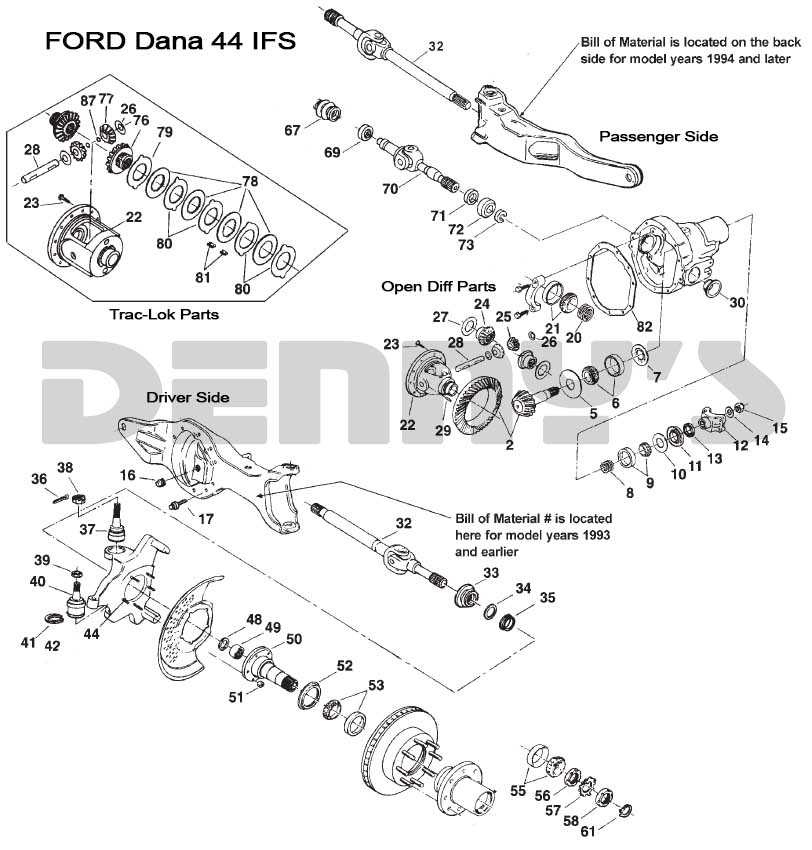

Overview of Ford Dana 44 Axle

This section provides an in-depth look at a robust assembly commonly found in off-road vehicles and trucks. Known for its strength and reliability, this component is essential for delivering power to the wheels while maintaining stability and control in various terrains.

Key Features

The assembly is designed to handle significant loads, making it a favorite among enthusiasts who demand durability and performance. Its configuration allows for smooth engagement and disengagement, ensuring efficient operation under different driving conditions. Additionally, it typically incorporates advanced materials that enhance its longevity.

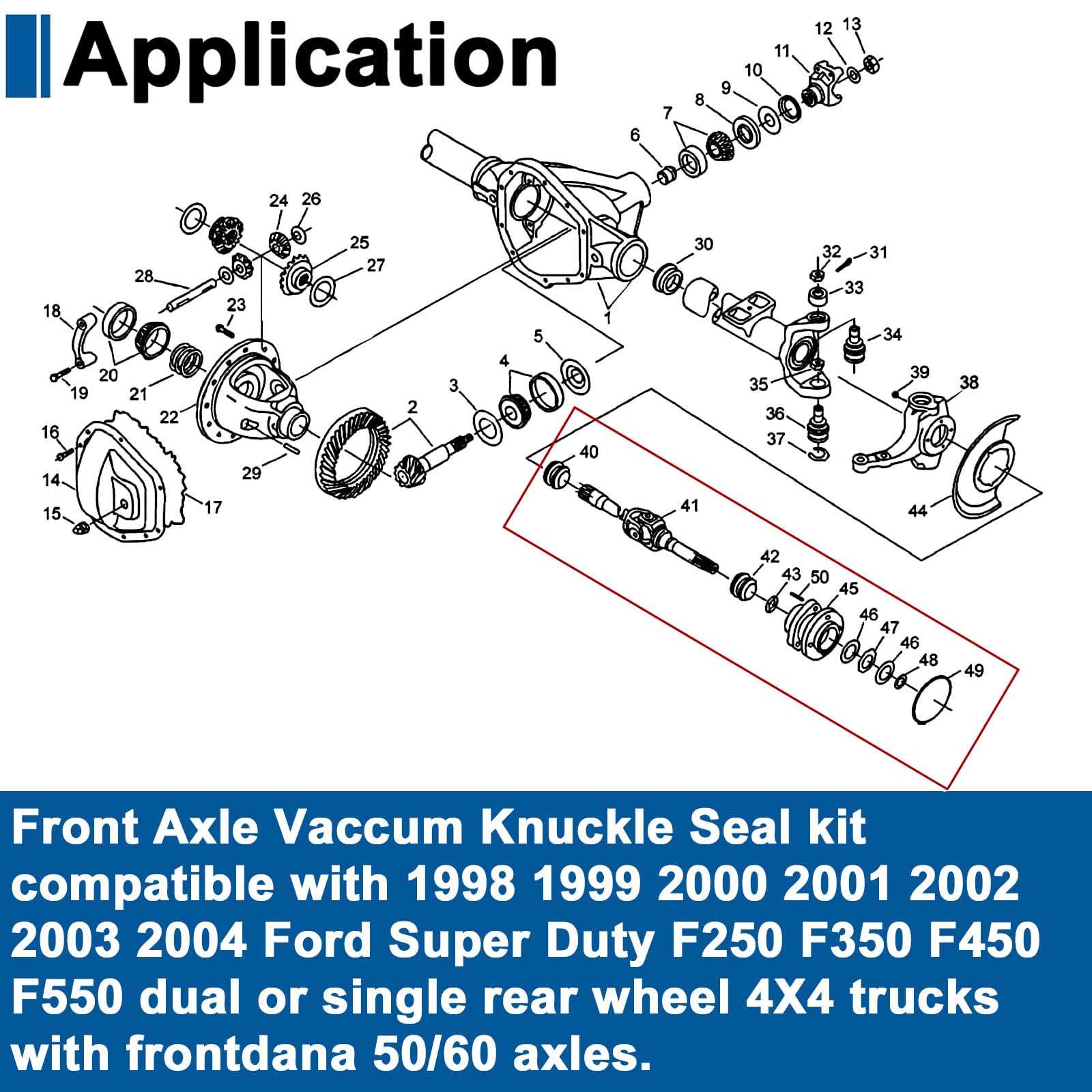

Applications

This assembly is prevalent in a variety of vehicles, particularly those built for rugged use. Whether navigating rocky landscapes or tackling muddy trails, its design supports superior traction and maneuverability. Many aftermarket upgrades are available, allowing users to tailor the setup to their specific needs and preferences.

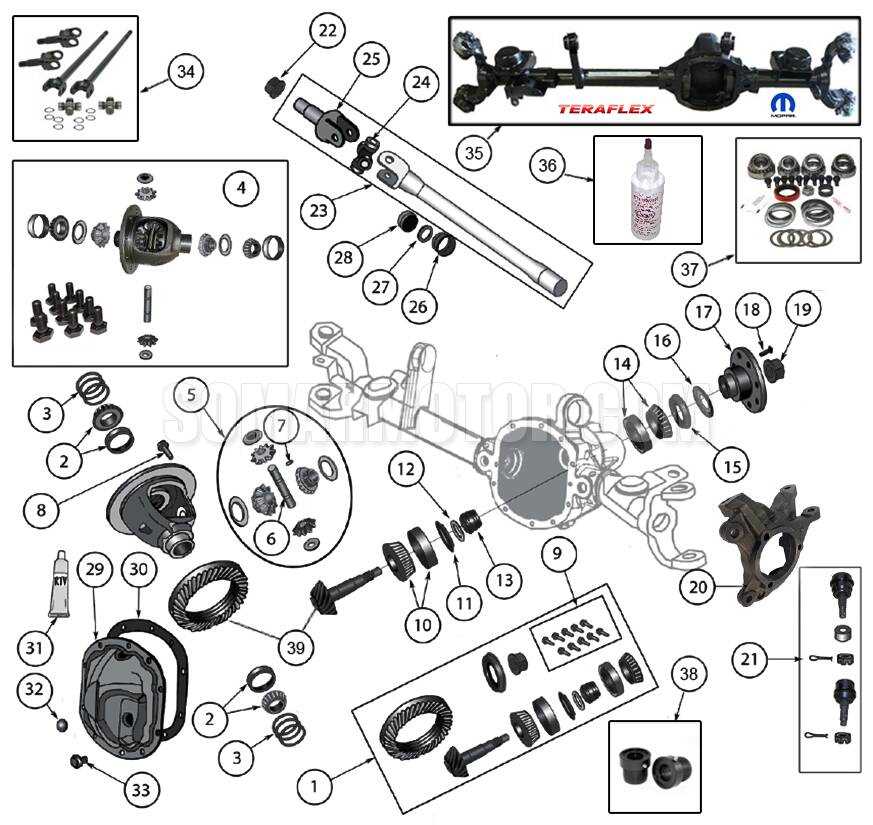

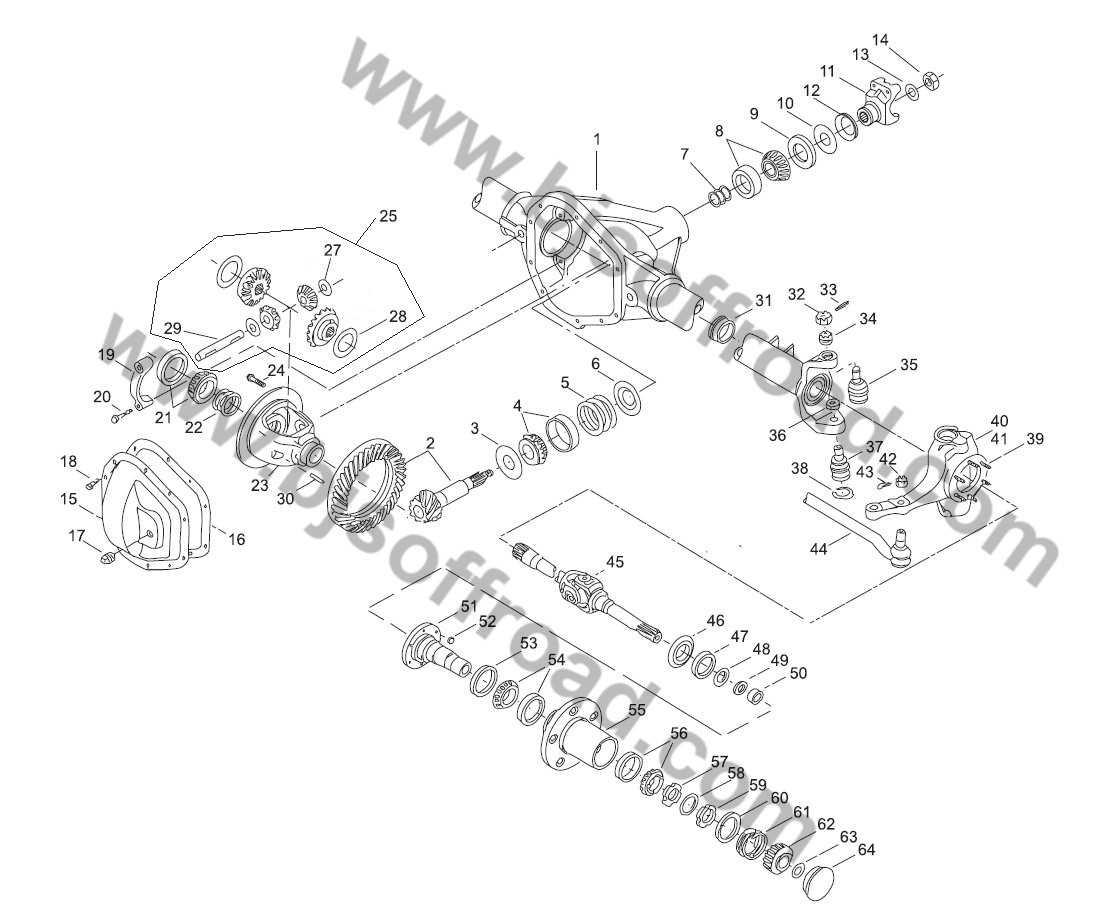

Key Components of the Axle System

The functionality of a vehicle’s drivetrain relies heavily on a robust assembly of essential elements that work in harmony. Understanding these components provides insight into how power is transferred from the engine to the wheels, ensuring optimal performance and stability.

Main Elements

Each section of the assembly plays a critical role, contributing to the overall efficiency and durability. Below are some of the primary elements that make up this intricate system:

| Component | Function |

|---|---|

| Housing | Encloses and protects internal components, maintaining structural integrity. |

| Gear Set | Facilitates power distribution and alters torque based on driving conditions. |

| Drive Shafts | Transmits rotational force from the engine to the wheels. |

| Bearings | Minimize friction and support rotating elements for smoother operation. |

Additional Components

Beyond the main elements, several auxiliary components enhance performance and reliability. Each part is designed to withstand varying loads and stresses, ensuring a seamless driving experience.

| Component | Function |

|---|---|

| Seals | Prevent fluid leaks and protect internal components from contaminants. |

| Brackets | Provide mounting points for various elements, ensuring stability and alignment. |

| Universal Joints | Allow for flexibility in movement while maintaining power transfer. |

Understanding Axle Functionality

The essential role of a rotating shaft assembly in a vehicle’s drivetrain cannot be overstated. This component is crucial for transmitting power from the engine to the wheels, enabling movement and ensuring stability. Understanding its design and mechanics enhances knowledge of vehicle performance and maintenance.

Key Components of the System

- Housing: The outer shell that protects internal components and contains lubricant.

- Shafts: The main rotating elements that transfer torque to the wheels.

- Bearings: Support structures that reduce friction and wear during rotation.

- Seals: Prevent leakage of lubricants and entry of contaminants.

Functionality in Motion

This assembly operates through a series of interconnected parts that work harmoniously. As the engine generates power, the rotational force is transferred through the shaft, engaging the wheels. This interaction allows for efficient handling and maneuverability, especially on various terrains.

- Power generation from the engine.

- Transmission of torque through the assembly.

- Engagement of wheel mechanisms for movement.

- Ensuring stability and control during driving.

A solid grasp of these fundamentals is vital for anyone involved in vehicle maintenance or restoration, as it lays the groundwork for understanding performance upgrades and repairs.

Common Issues with Dana 44 Axles

The robust design of certain vehicle components often encounters various challenges over time. Understanding these issues can help in identifying potential problems before they escalate, ensuring smooth operation and longevity of the assembly.

Frequent Problems

- Worn Bearings: Bearings can deteriorate due to excessive load or lack of lubrication, leading to increased noise and eventual failure.

- Seals Leaking: Seals may degrade, causing fluid loss which can result in inadequate lubrication and overheating.

- Gear Wear: Over time, the gears can show signs of wear, affecting performance and leading to costly repairs.

- Incorrect Alignment: Misalignment can lead to uneven tire wear and handling issues, impacting overall vehicle stability.

Maintenance Tips

- Regularly check and replace lubricants to ensure proper functioning.

- Inspect seals for any signs of wear or damage.

- Monitor for unusual noises that may indicate bearing issues.

- Perform alignment checks periodically, especially after heavy use.

Maintenance Tips for Optimal Performance

Ensuring that your vehicle’s components operate smoothly requires regular upkeep and attention. Implementing a consistent maintenance routine not only enhances performance but also extends the lifespan of crucial systems. By focusing on key areas, you can prevent wear and tear, minimize breakdowns, and enjoy a safer driving experience.

Regular Inspections

Conducting frequent evaluations of essential elements is vital. Look for signs of wear, leaks, or unusual noises that could indicate potential issues. Pay close attention to lubricated areas and ensure that all components are properly aligned. Early detection of problems can save time and resources in the long run.

Fluid Checks and Changes

Maintaining appropriate fluid levels is crucial for optimal function. Regularly check the quality and quantity of lubricants, ensuring they are clean and at recommended levels. Consider changing fluids at intervals specified in your maintenance manual to promote efficient operation and reduce friction among moving parts. Investing in high-quality lubricants can also provide added protection against wear and enhance overall performance.

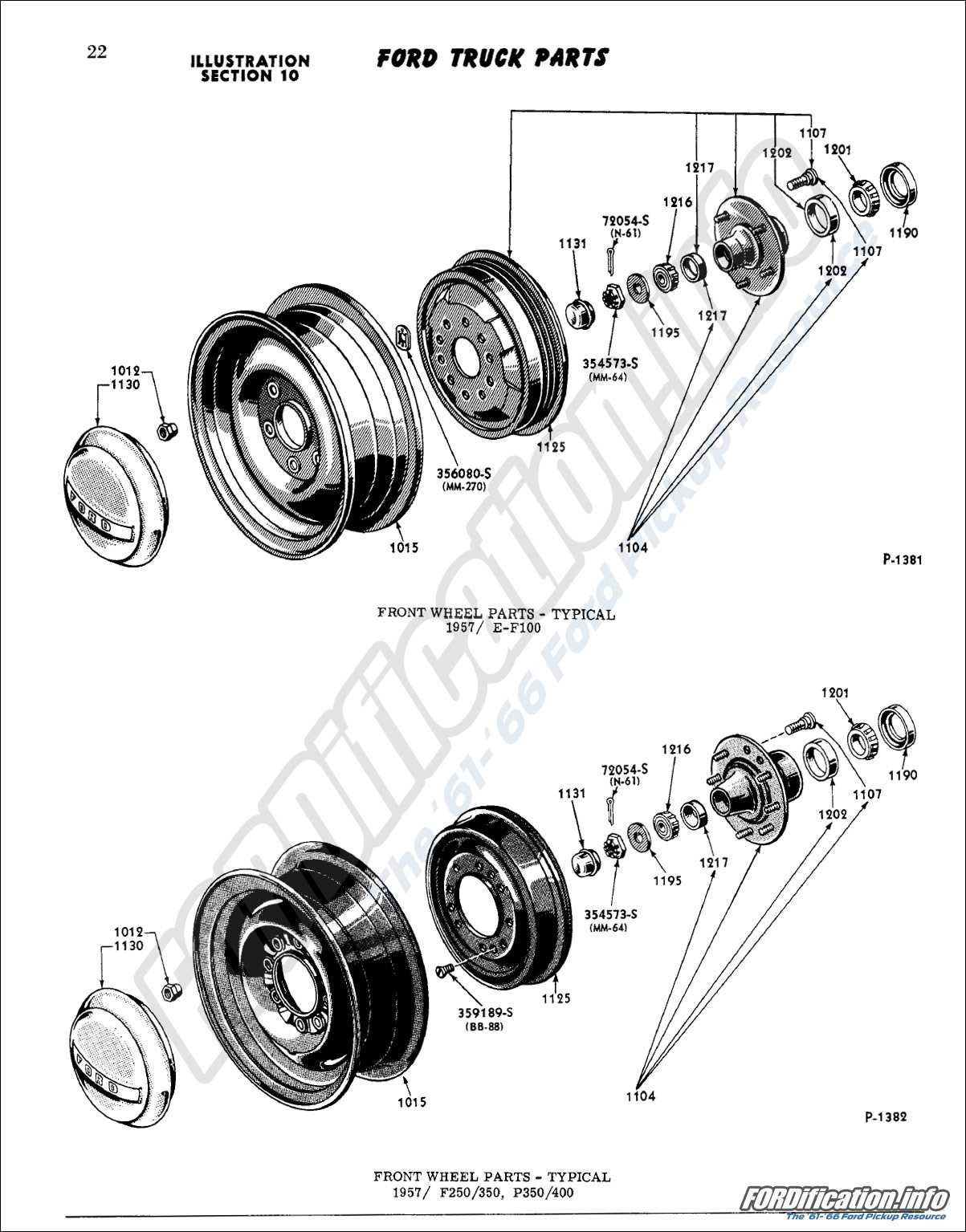

Parts Replacement and Upgrades

Ensuring optimal performance and longevity of your vehicle often involves timely replacements and thoughtful enhancements of its essential components. Upgrading specific elements not only improves functionality but can also boost reliability and overall driving experience. This section focuses on the common replacements and potential upgrades for enhancing the durability and efficiency of your assembly.

Common Replacement Components

Regular maintenance is key to avoiding unexpected failures. Here are some crucial components that may require replacement over time:

- Bearings: Essential for smooth rotation and load distribution.

- Seals: Prevent fluid leaks and protect internal mechanisms from contaminants.

- Spindles: Support the weight of the vehicle and ensure proper wheel alignment.

- U-joints: Allow for flexibility in movement while transmitting torque.

- Hubs: Facilitate wheel attachment and rotation, critical for overall stability.

Potential Upgrades for Enhanced Performance

Investing in upgrades can significantly improve performance and handling characteristics. Consider these options:

- Heavy-Duty Bearings: Increase load capacity and durability.

- Aftermarket Hubs: Offer improved engagement and disengagement for better off-road capability.

- Performance U-joints: Designed to withstand higher torque and provide enhanced flexibility.

- Upgraded Seals: Better protection against dirt and moisture, extending component life.

- Adjustable Spindles: Allow for fine-tuning of alignment for better handling.

By keeping these components in mind for both replacement and upgrade, you can significantly enhance your vehicle’s performance and reliability on various terrains.

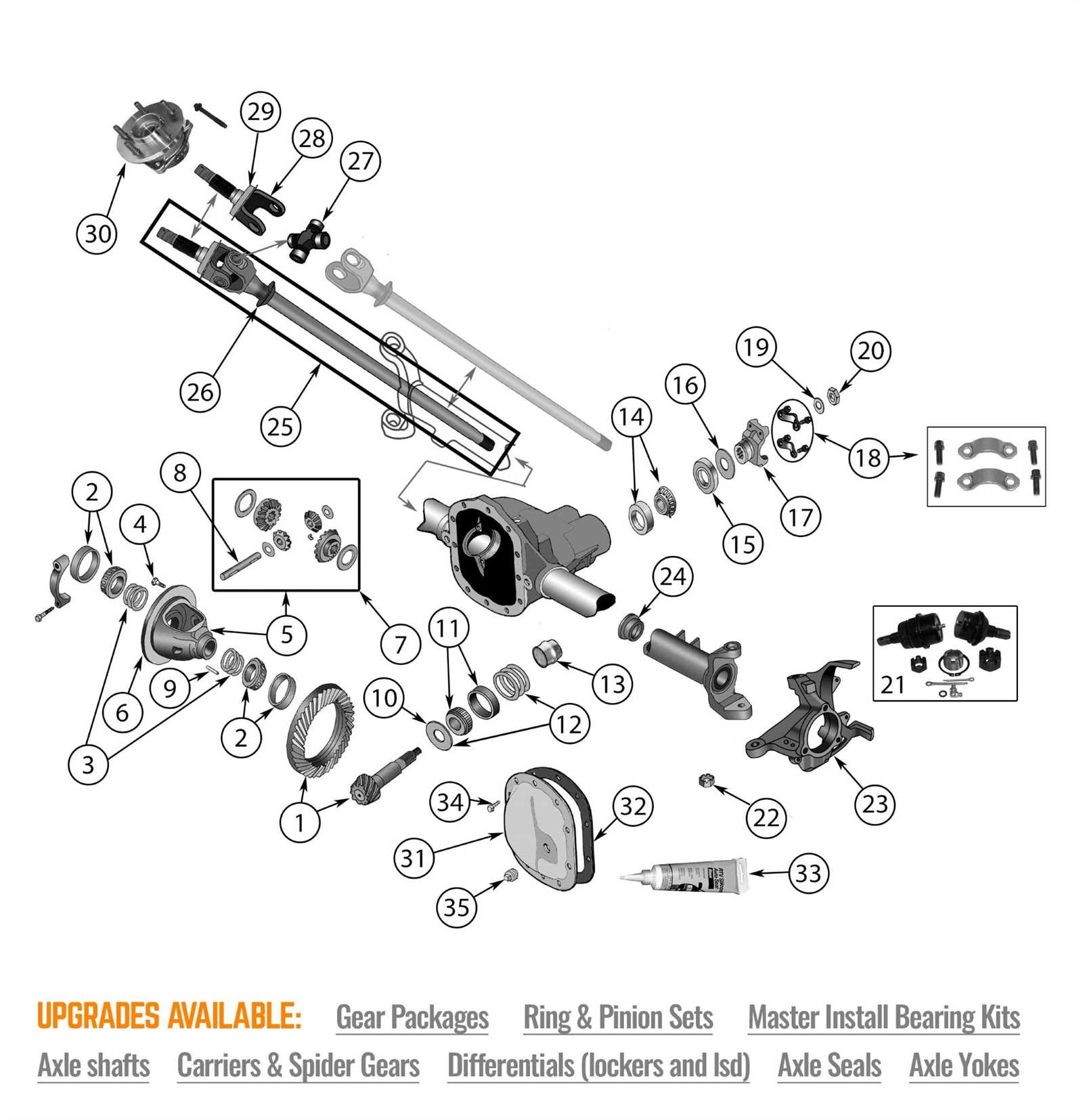

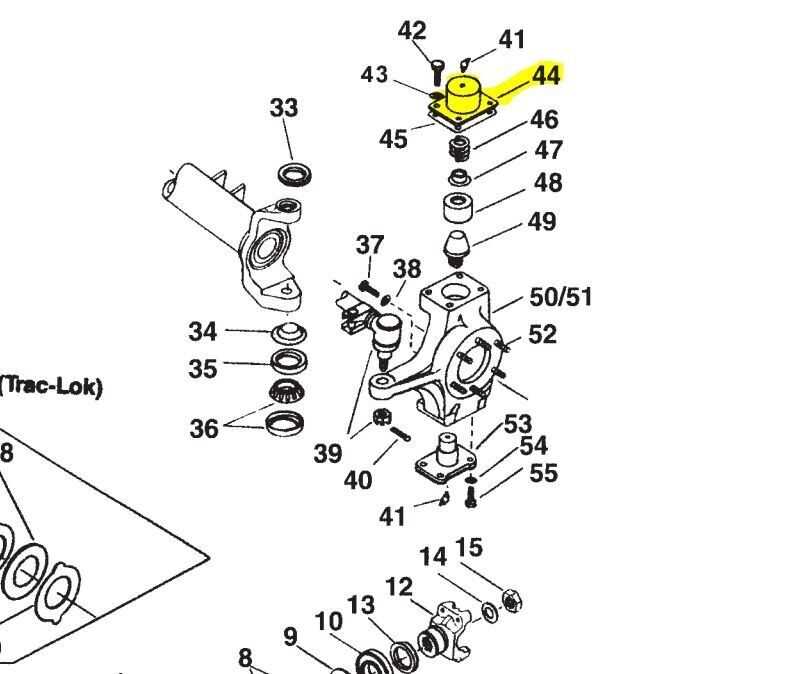

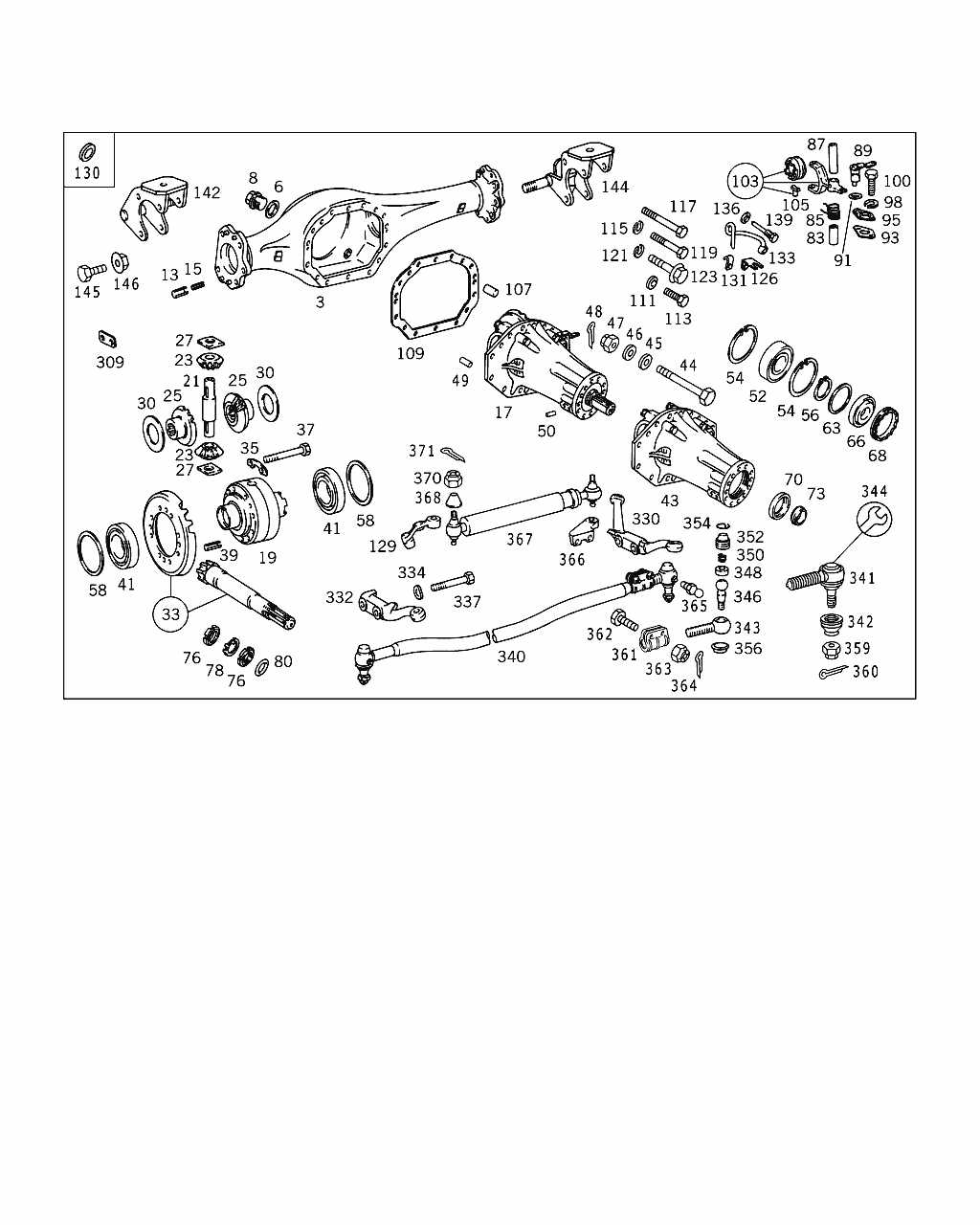

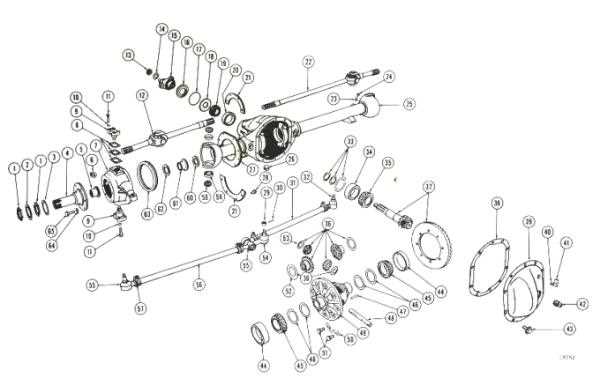

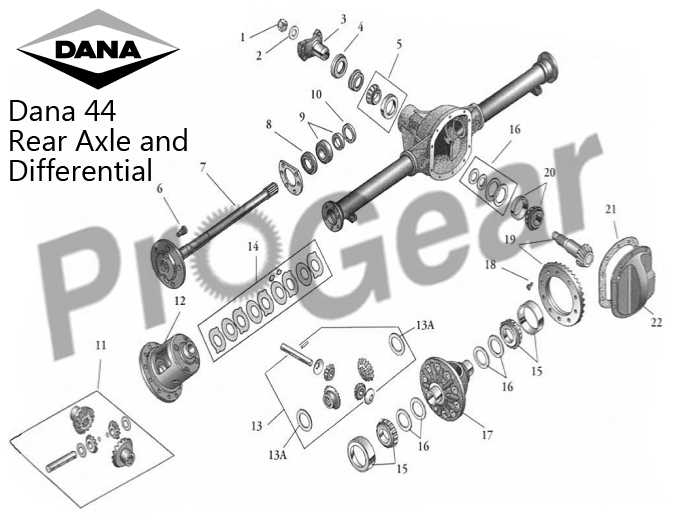

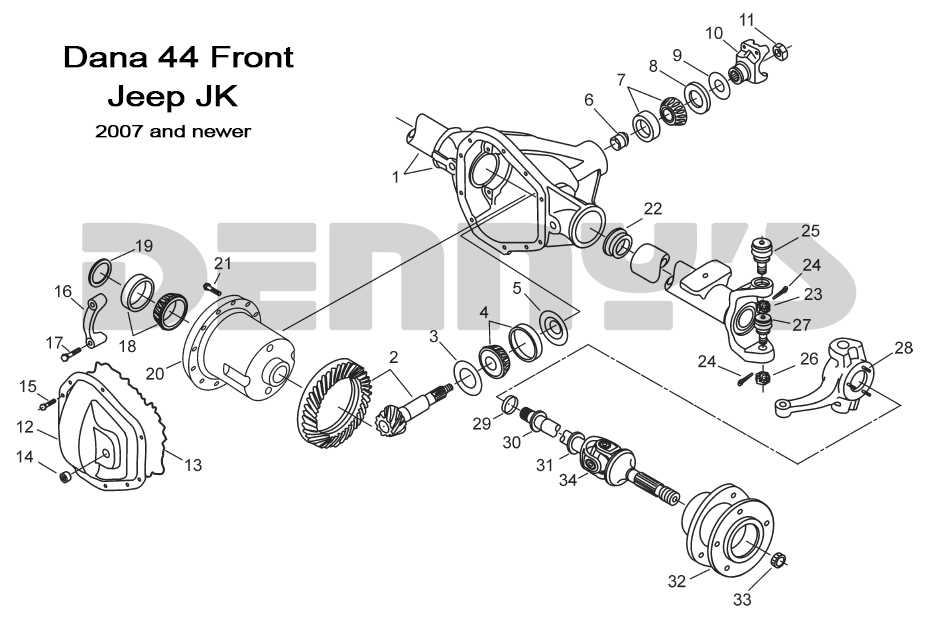

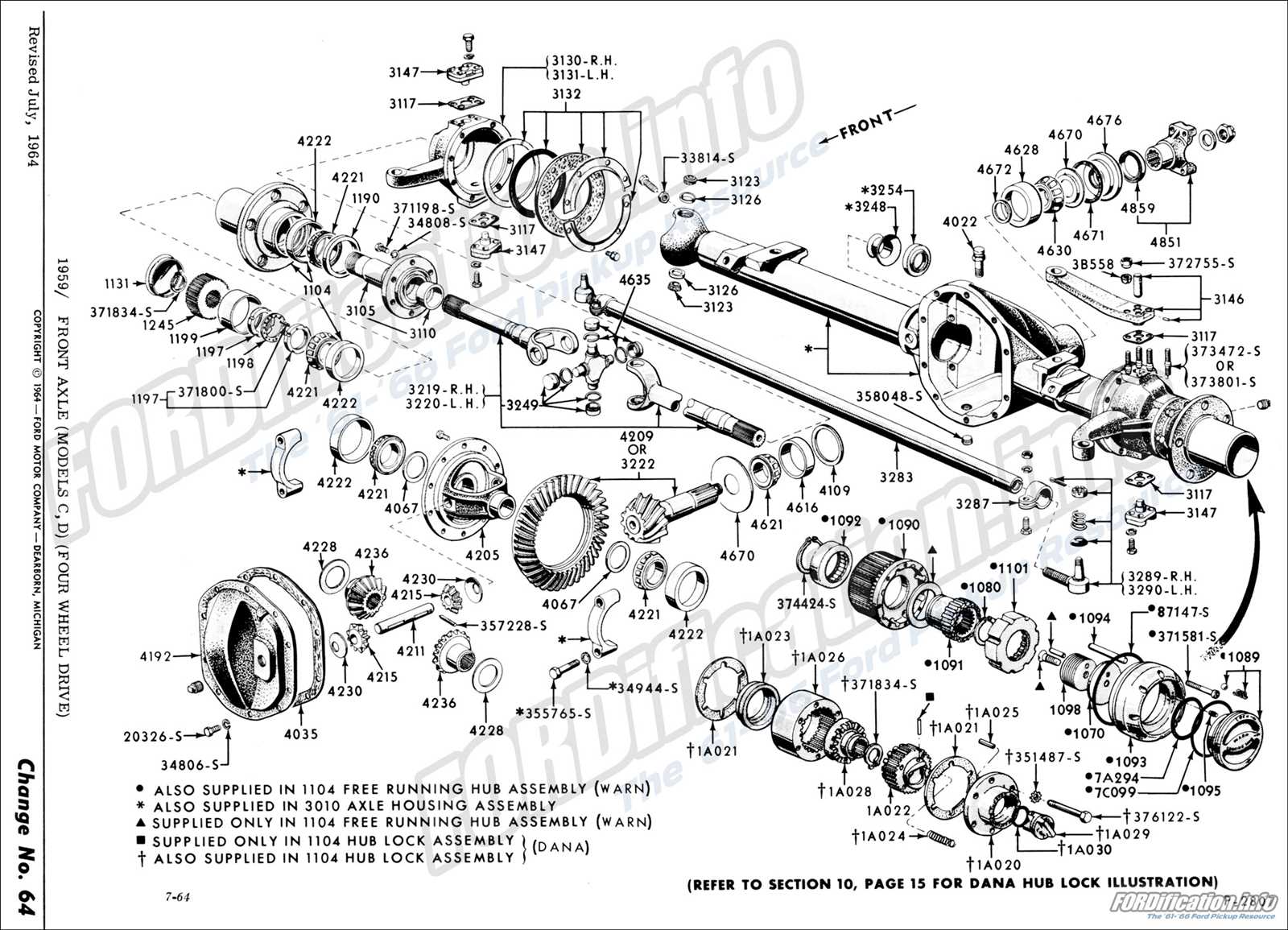

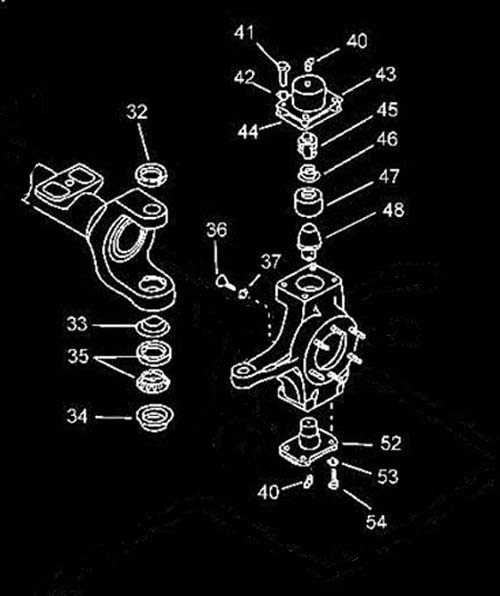

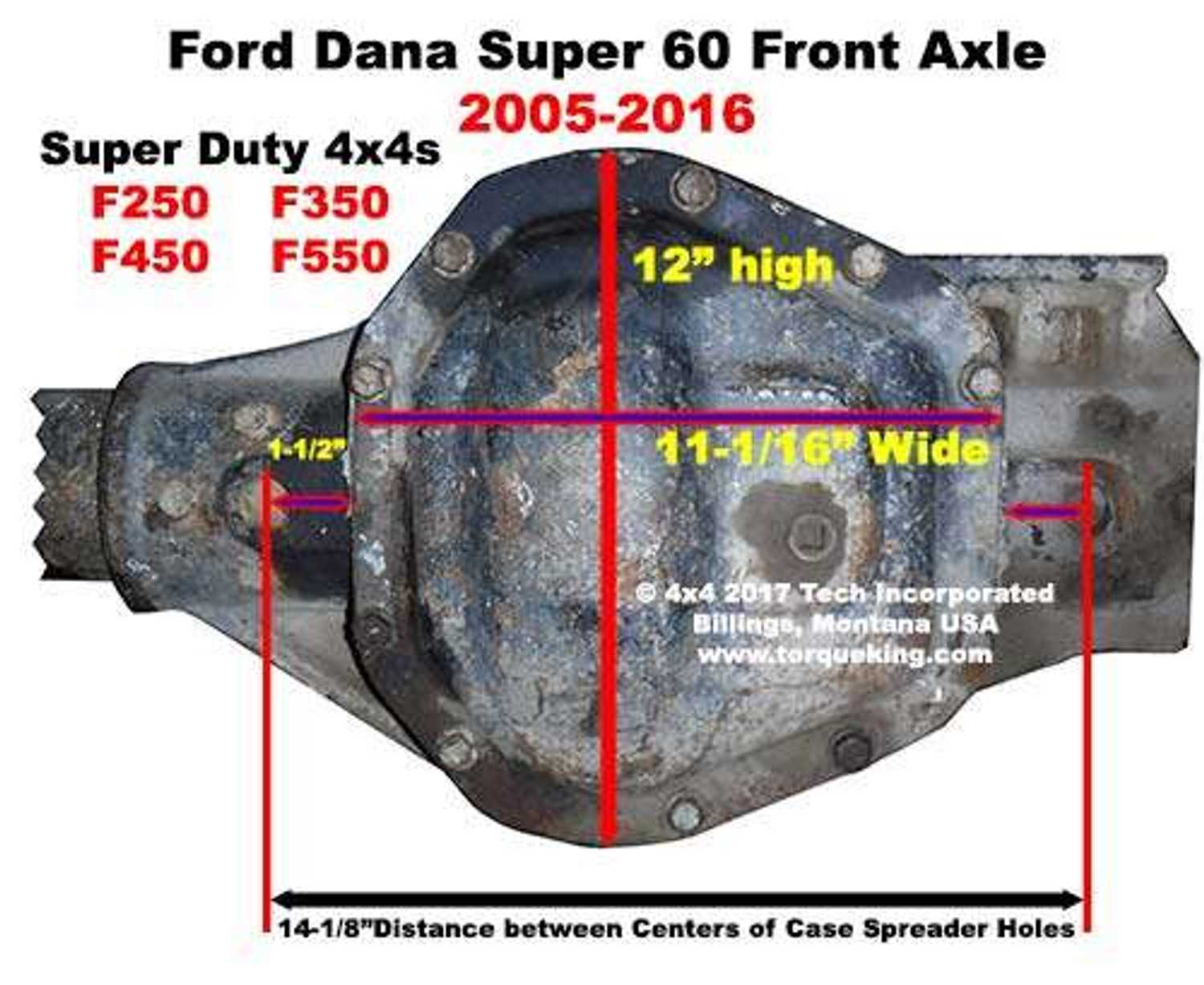

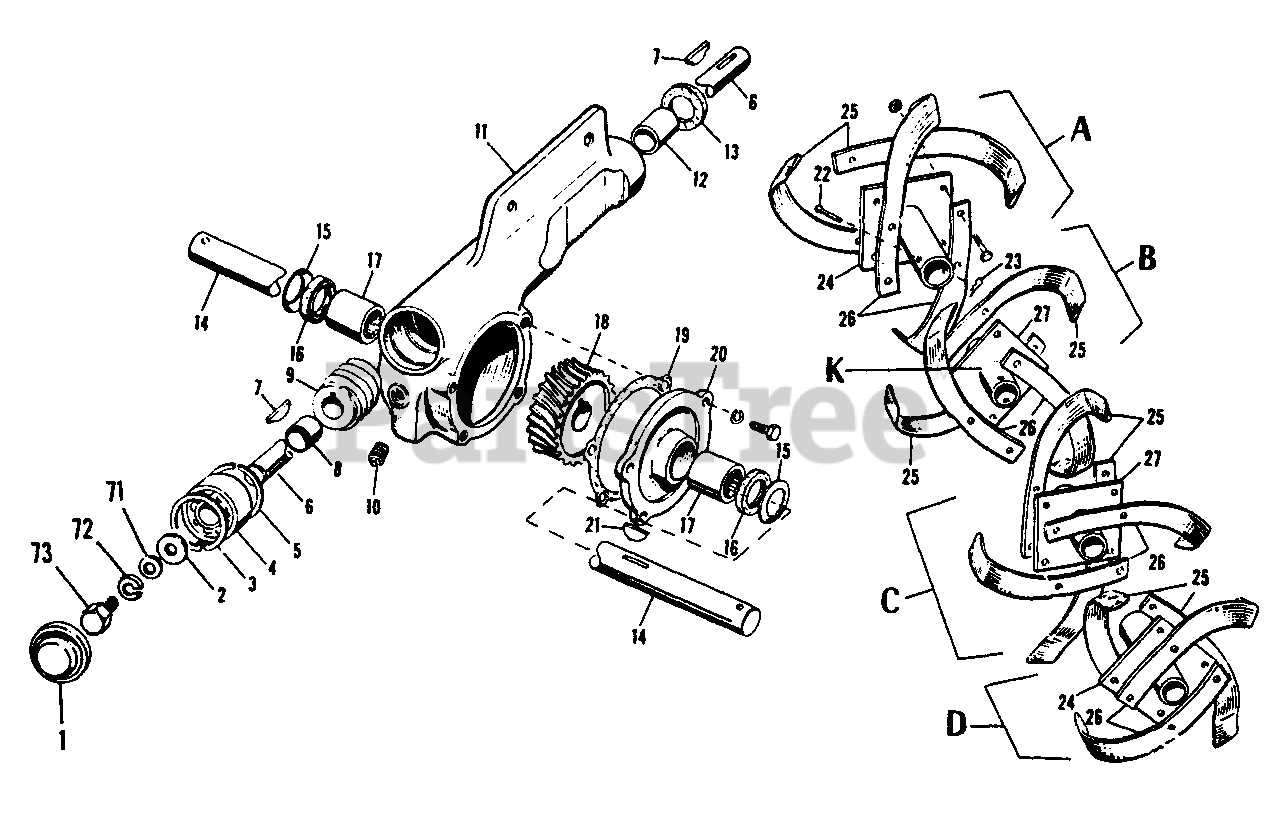

How to Read Parts Diagrams

Understanding visual representations of mechanical components is essential for effective maintenance and repair. These illustrations serve as guides, highlighting various elements and their relationships within an assembly. Grasping how to interpret these visuals can significantly enhance your ability to diagnose issues and identify necessary replacements.

Key Components of Visual Representations

Typically, these illustrations will include labels, numbers, and a legend, which provide critical information about each item depicted. Familiarizing yourself with these elements is crucial for accurate interpretation.

| Element | Description |

|---|---|

| Labels | Indicate the names or codes of specific components. |

| Numbers | Represent quantities or specific parts in the assembly. |

| Legend | Explains symbols or color codes used in the illustration. |

Tips for Effective Interpretation

To effectively utilize these visuals, start by examining the legend to understand any symbols. Next, follow the numbered sequence to comprehend the assembly order. Taking notes on the components and their functions can also aid in recalling details during repairs or replacements.

Tools Needed for Repairs

When it comes to undertaking maintenance or repair work on your vehicle’s suspension system, having the right equipment is essential for achieving optimal results. A well-equipped workshop can significantly streamline the process, making it easier to address issues efficiently and safely.

Essential Tools

Here’s a list of vital tools that will help you tackle various tasks involved in the repair process:

| Tool | Purpose |

|---|---|

| Socket Set | Used for loosening and tightening bolts and nuts. |

| Torque Wrench | Ensures that fasteners are tightened to the manufacturer’s specifications. |

| Pry Bar | Helps in removing stubborn components and applying leverage. |

| Jack Stands | Provides secure support for the vehicle when lifted. |

| Impact Wrench | Speeds up the process of loosening tight bolts. |

Safety Equipment

In addition to the essential tools, don’t forget to equip yourself with safety gear. This includes gloves, goggles, and protective clothing to ensure your well-being while working on your vehicle.

Comparing Dana 44 to Other Axles

When it comes to off-road performance and durability, various assemblies are often assessed to determine their suitability for specific applications. Understanding the strengths and weaknesses of different configurations can help enthusiasts make informed decisions regarding upgrades or replacements.

Strength and Durability

One of the primary considerations when evaluating different configurations is their strength and durability. Key factors include:

- Material Quality: The composition and thickness of components can significantly impact performance under stress.

- Design Features: Elements such as ring and pinion size, as well as housing design, contribute to overall robustness.

- Load Capacity: Different designs can handle varying loads, influencing their suitability for heavy-duty use.

Weight and Size

Another important aspect is the weight and dimensions of the assemblies. Variations can lead to differences in handling and fuel efficiency:

- Overall Weight: Lighter configurations may enhance maneuverability but could compromise strength.

- Footprint: The size can affect installation compatibility and ground clearance.

- Modifications: Some setups may require more extensive alterations to fit specific vehicles.

By analyzing these characteristics, enthusiasts can choose the most appropriate configuration to meet their off-road needs, balancing performance, durability, and compatibility. Each assembly has its unique advantages that cater to different styles and requirements.

Assembly Process of Dana 44 Parts

The assembly of crucial components in a heavy-duty vehicle system is essential for ensuring optimal performance and longevity. This process involves meticulous attention to detail and a thorough understanding of each element’s function within the overall structure. Proper assembly techniques contribute significantly to the reliability and efficiency of the mechanism.

Initially, gather all necessary components, ensuring they are clean and free from debris. This preparation phase is vital as contaminants can affect the fit and functionality of the assembly. Begin by placing the primary housing securely, followed by the installation of critical internal elements. Alignment is key during this step to guarantee smooth operation.

Next, utilize the appropriate lubricants on moving parts to minimize friction and wear. This practice not only enhances performance but also extends the lifespan of each component. After lubrication, carefully position the additional elements, making certain that they fit snugly and securely.

Once everything is in place, proceed to tighten all fasteners according to the manufacturer’s specifications. Torque settings are crucial; over-tightening can lead to deformation, while under-tightening may result in component failure. Conduct a final inspection to ensure everything is assembled correctly and securely.

In conclusion, the assembly of these vital components requires precision, proper technique, and a comprehensive understanding of the mechanical system. Following these guidelines will lead to a well-functioning setup, capable of handling rigorous demands.

Identifying Genuine vs. Aftermarket Parts

Understanding the distinction between authentic and alternative components is crucial for maintaining the integrity and performance of your vehicle. This knowledge helps ensure reliability and longevity, as each category presents unique characteristics that can impact overall functionality.

Key Differences

- Quality: Authentic components are typically manufactured to higher standards, ensuring better durability and performance.

- Cost: Alternative options often come at a lower price point, but this may come at the expense of quality.

- Warranty: Genuine items usually come with a warranty, providing peace of mind regarding their longevity.

- Fitment: Authentic components are designed to fit perfectly, whereas alternatives may require adjustments.

Identifying Features

- Examine the packaging: Genuine components often come in branded packaging with clear labeling.

- Check for serial numbers: Authentic items usually have identifiable serial numbers or stamps.

- Assess material quality: Feel and inspect the materials used; genuine components are often made from superior materials.

- Research suppliers: Purchase from reputable sources to avoid counterfeit products.

Custom Modifications for Off-Roading

Enhancing vehicles for rugged terrain involves a variety of tailored adjustments that boost performance and durability. These modifications can significantly improve traction, stability, and overall driving experience in challenging environments. From upgrading suspension systems to installing specialized tires, each change contributes to better handling and capability.

Suspension Upgrades: One of the most critical areas for off-road enhancement is the suspension. Upgrading to a high-performance setup can provide increased ground clearance and improved articulation. This allows the vehicle to navigate over rocks, logs, and other obstacles with ease. Consider adjustable shock absorbers and reinforced springs for optimal results.

Tire Selection: The choice of tires is paramount when tackling off-road challenges. Opt for all-terrain or mud-terrain tires that offer superior grip and durability. Larger diameter tires can enhance ground clearance, reducing the risk of damage while traversing uneven surfaces.

Protective Gear: Installing protective elements such as skid plates and bumpers can safeguard vital components from impacts and debris. These accessories not only shield the vehicle but also contribute to a rugged aesthetic that reflects its capabilities.

Gear Ratios: Adjusting gear ratios can improve torque delivery, making it easier to climb steep inclines or navigate through tricky sections. This modification allows for better control and enhances overall vehicle performance in off-road conditions.

Ultimately, customizing a vehicle for off-roading is about creating a machine that can handle the demands of adventure while providing reliability and comfort. Each modification should be carefully considered to ensure it aligns with the intended use and enhances the overall driving experience.

Resources for Further Learning

Expanding your knowledge about vehicle components can greatly enhance your understanding and maintenance capabilities. Numerous resources are available that cover various aspects of automotive assemblies, offering insights into their design, functionality, and repair techniques.

Online Communities

Joining forums and social media groups dedicated to automotive enthusiasts can provide a wealth of information. Members often share their experiences, tips, and troubleshooting advice, fostering a collaborative learning environment. Engaging with others who share similar interests can also lead to valuable networking opportunities.

Educational Websites and Tutorials

There are countless websites that offer tutorials, articles, and videos focused on mechanical systems. Websites like HowStuffWorks and Car and Driver provide detailed explanations and guides, making complex concepts more accessible. Additionally, platforms like YouTube host countless instructional videos that demonstrate repair processes and modifications step-by-step.