Comprehensive Guide to Stihl TS350 Parts Diagram

In the world of power equipment, mastering the intricacies of machinery is essential for optimal performance and longevity. A comprehensive breakdown of a tool’s structure allows users to identify individual elements and understand their functions. This knowledge not only enhances maintenance practices but also aids in troubleshooting common issues.

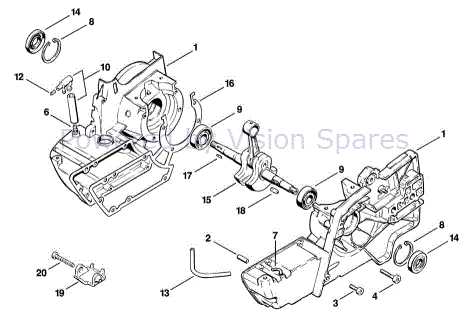

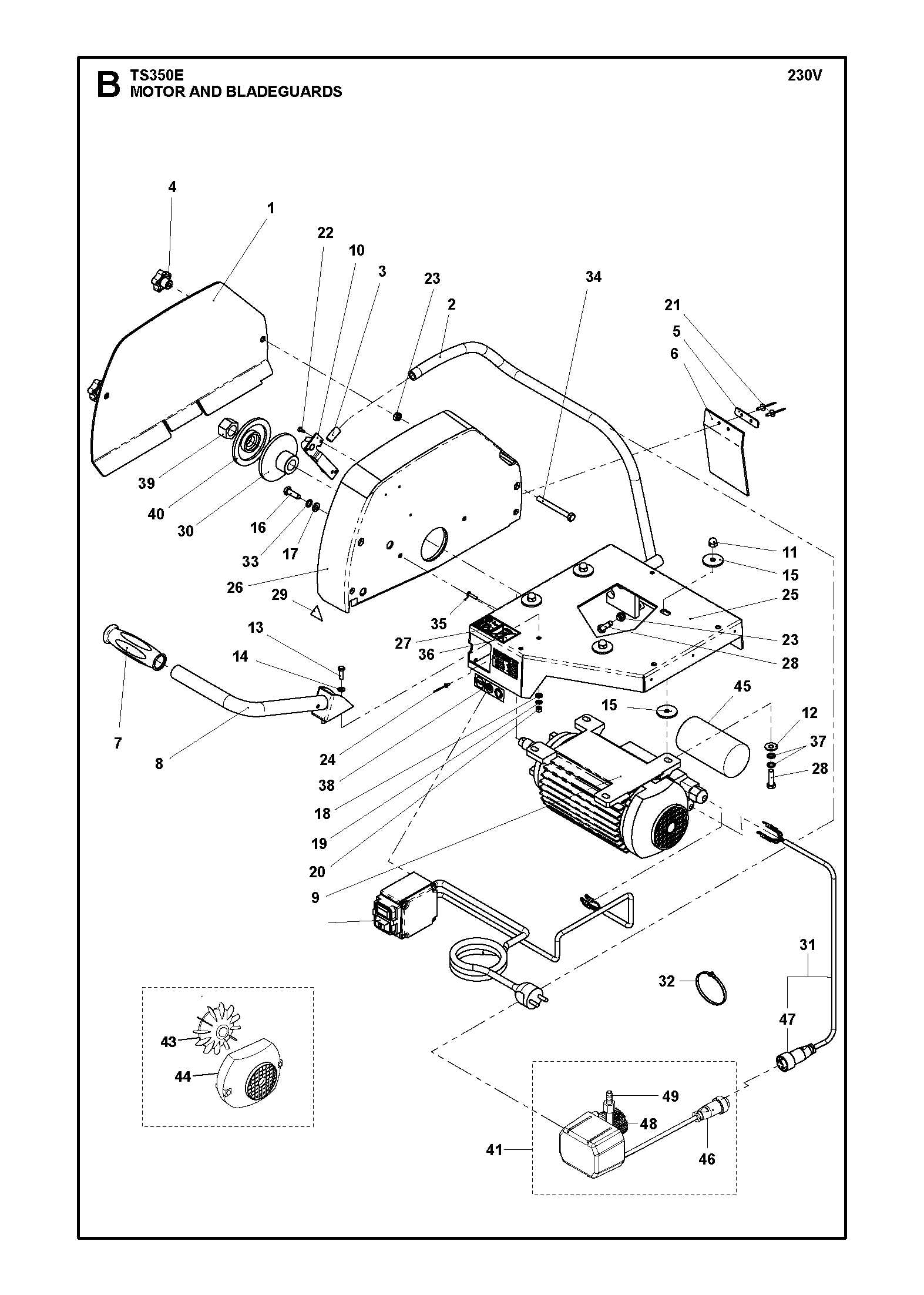

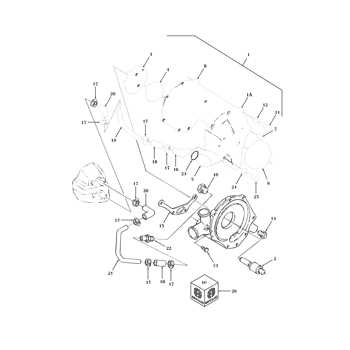

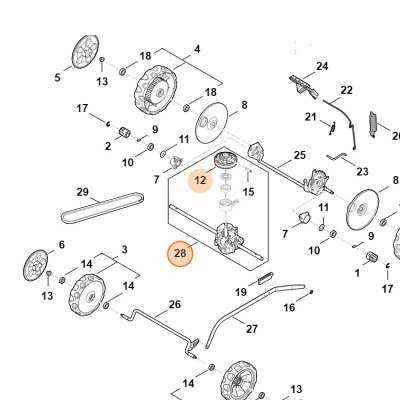

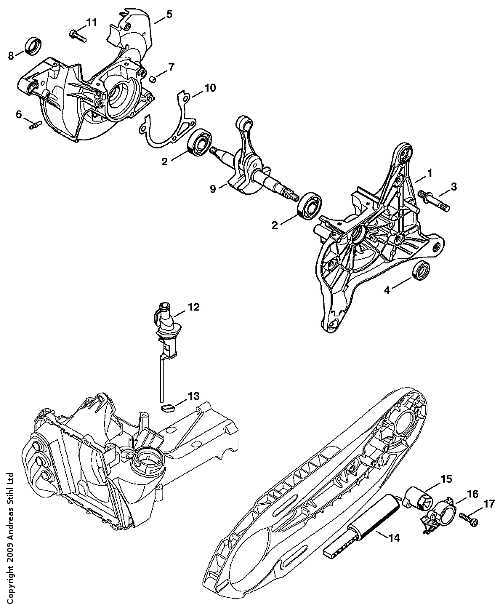

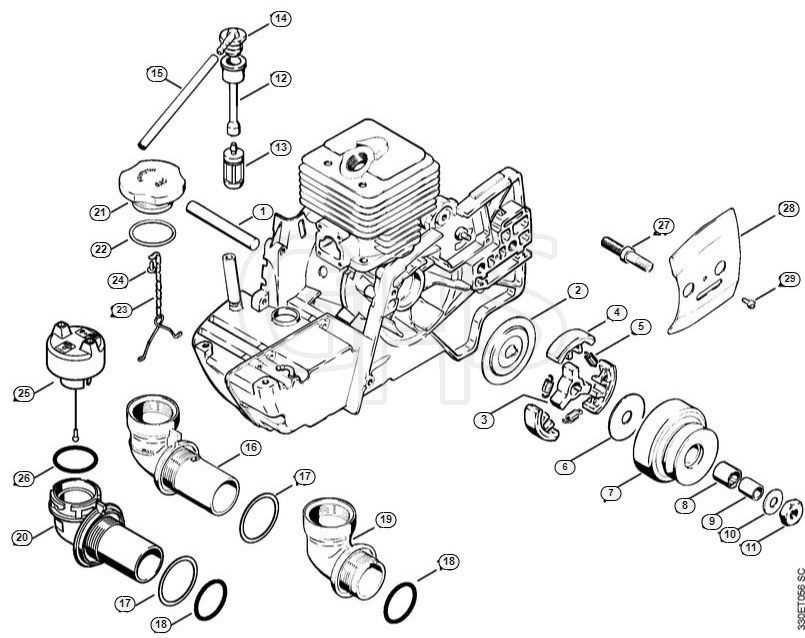

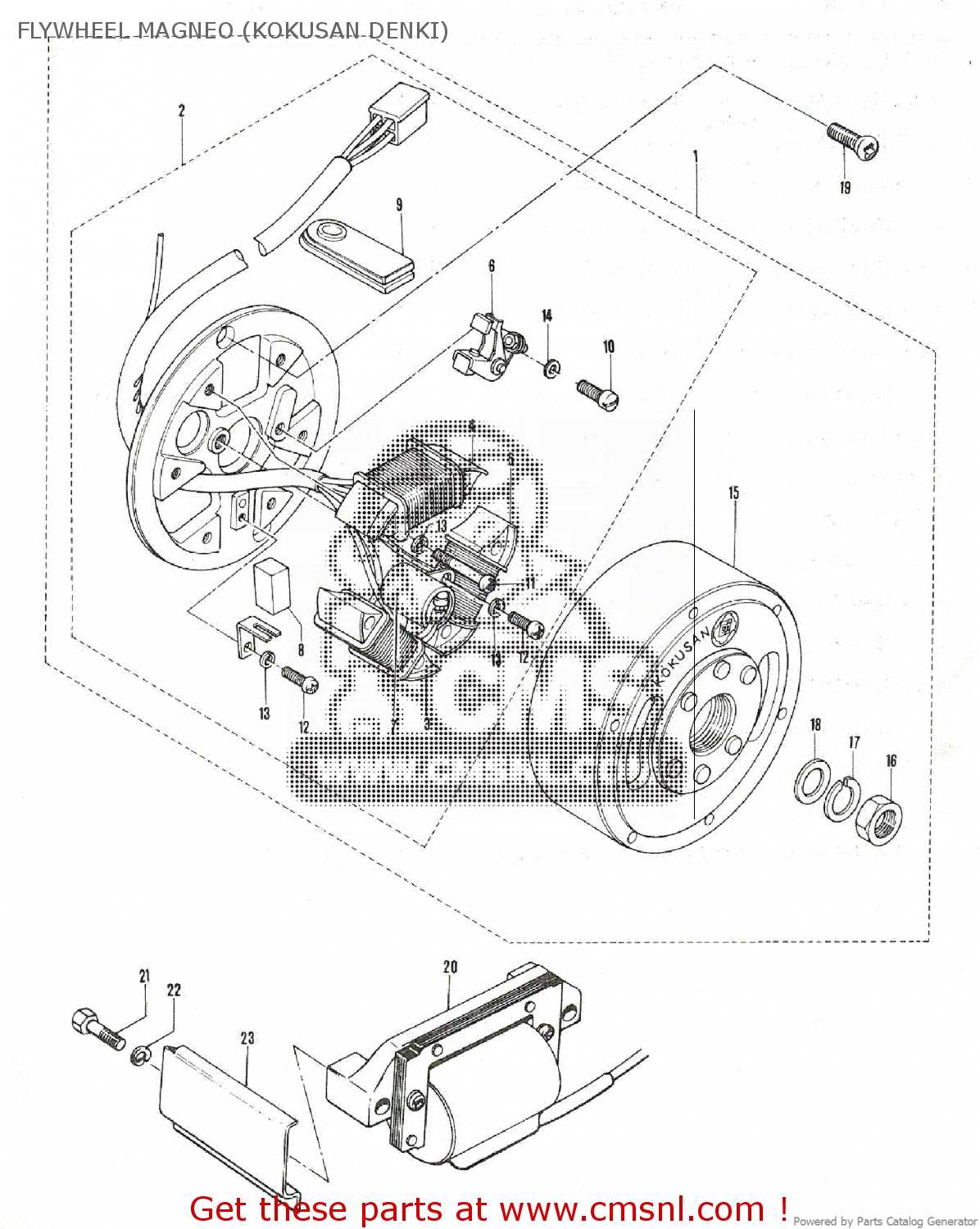

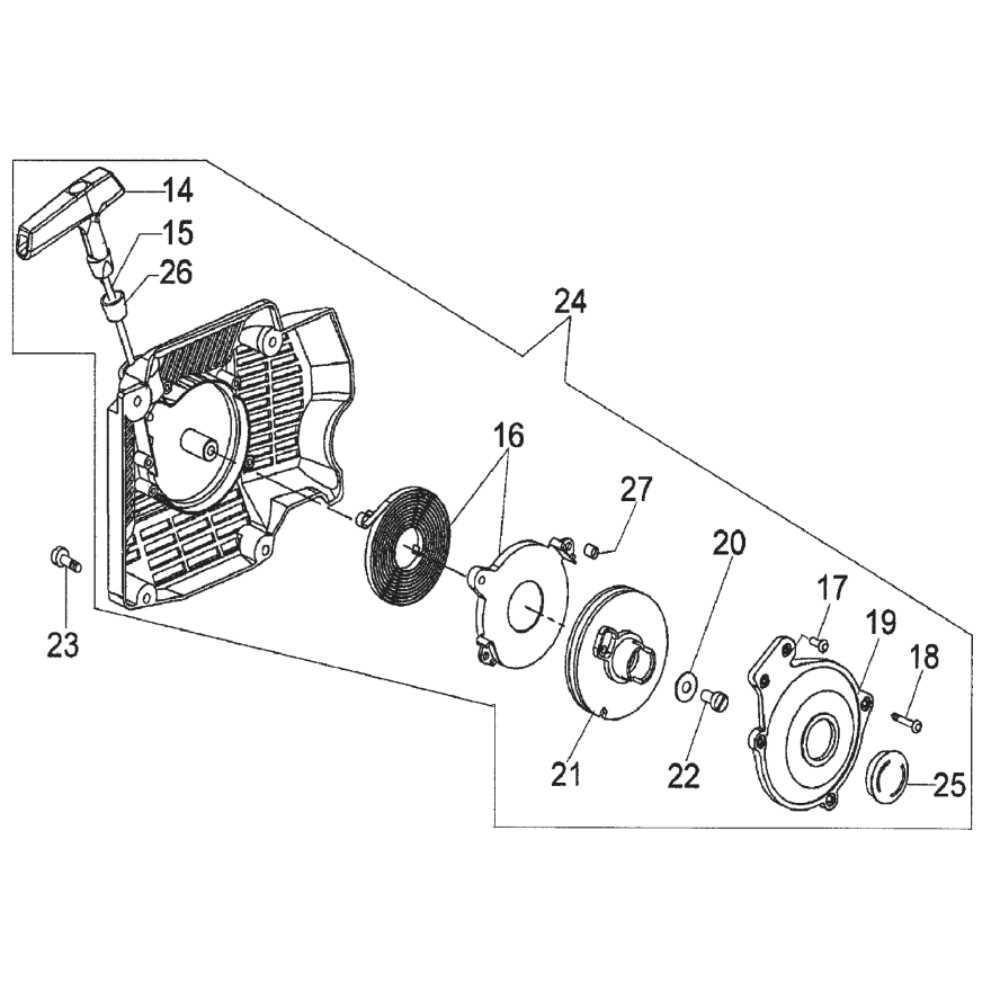

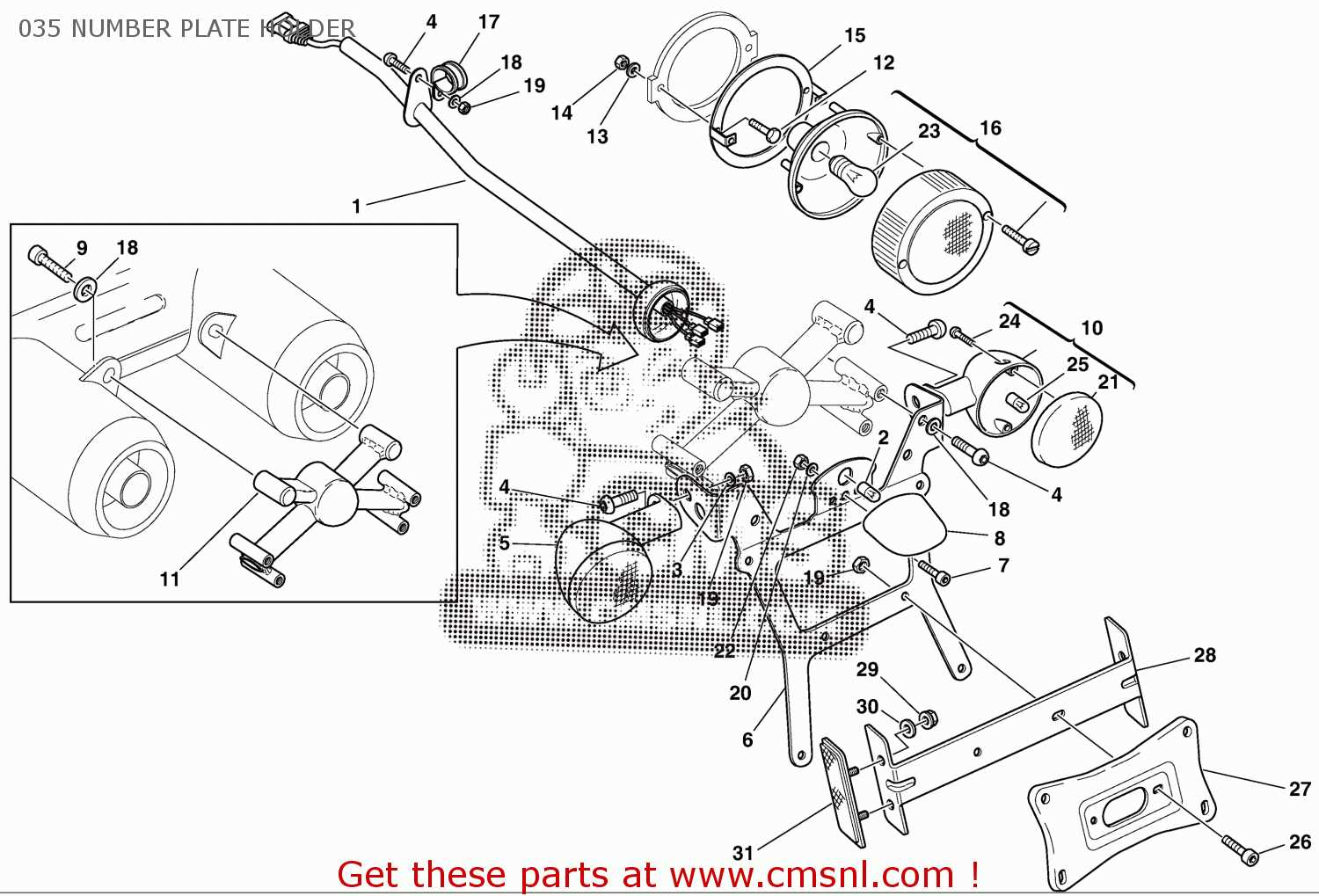

Visual representations of these components serve as invaluable resources for both novices and seasoned users. By examining detailed illustrations, one can grasp the relationships between various parts, facilitating easier assembly and disassembly. Such resources empower users to take control of their equipment’s upkeep, ensuring that every element is in peak condition.

Moreover, a thorough comprehension of a tool’s inner workings can lead to improved efficiency and effectiveness during operation. Recognizing how each segment contributes to the overall functionality transforms the user’s approach, making them more adept at handling repairs and modifications. With this foundational knowledge, one can confidently navigate the challenges of equipment maintenance.

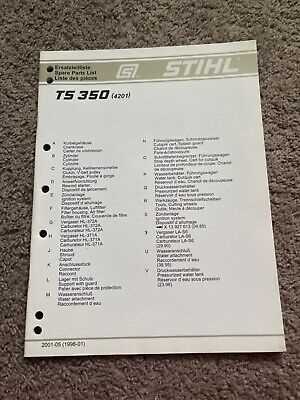

Understanding the Stihl TS350 Model

This section aims to provide a comprehensive overview of a specific cutting tool, emphasizing its design, functionality, and the essential components that contribute to its efficiency. The intricate engineering behind this machine makes it a valuable asset for various applications, particularly in construction and landscaping.

| Feature | Description |

|---|---|

| Engine Type | Powerful two-stroke engine ensuring high performance |

| Blade Size | Standardized size suitable for various cutting tasks |

| Weight | Lightweight design for improved maneuverability |

| Durability | Constructed with high-quality materials for longevity |

| Applications | Ideal for cutting concrete, brick, and other tough materials |

Understanding these features allows users to appreciate the ultimate capabilities of this remarkable tool, enabling them to utilize it effectively in their projects.

Importance of Parts Diagrams

Visual representations of components play a crucial role in maintenance and repair tasks. They provide an organized way to understand the relationships and functions of various elements within a machine. By simplifying complex assemblies, these illustrations help users identify and locate specific items efficiently, enhancing the overall repair process.

Benefits of Visual Representations

- Enhanced Clarity: Diagrams break down intricate systems into understandable segments, making it easier for users to grasp how different parts interact.

- Time Efficiency: Quickly locating components saves valuable time during maintenance, allowing for quicker repairs and less downtime.

- Reduced Errors: Having a clear reference minimizes the risk of misplacing or incorrectly assembling components.

Applications in Maintenance

- Facilitating troubleshooting by highlighting potential failure points.

- Assisting in inventory management by clearly showing required components for specific repairs.

- Serving as a training tool for new technicians, providing a visual guide to complex systems.

In summary, these visual aids are invaluable for anyone involved in the upkeep of machinery, ensuring efficient and accurate work while promoting a deeper understanding of mechanical systems.

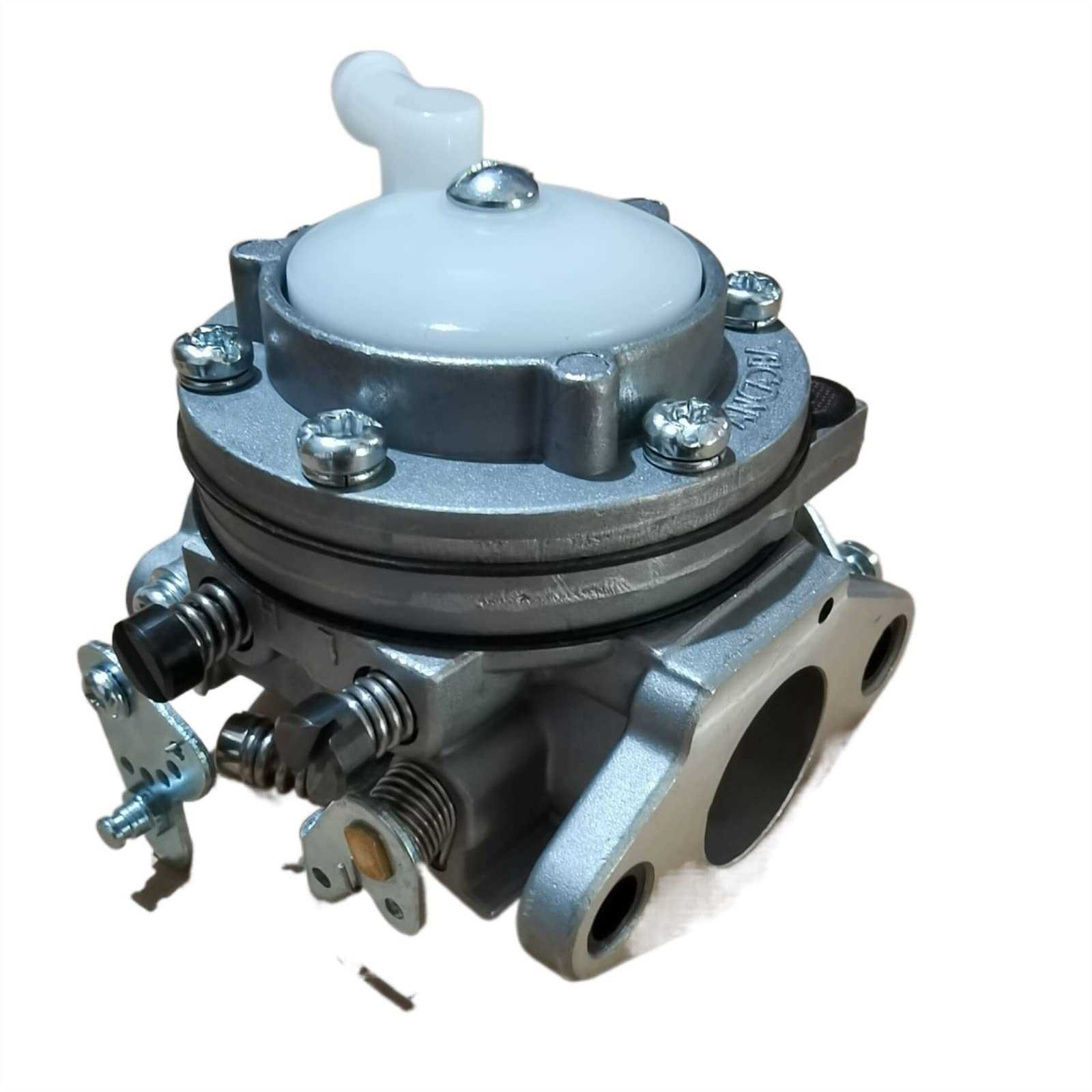

Key Components of the TS350

This section explores the essential elements that contribute to the functionality and efficiency of the cutting tool. Understanding these components is crucial for both maintenance and optimal performance, ensuring that users can tackle their tasks effectively.

Engine and Power System

The engine serves as the heart of the device, providing the necessary power to operate. Its design emphasizes reliability and efficiency, allowing for prolonged use without overheating. A well-maintained engine translates to better performance and extended lifespan.

Cutting Mechanism

The cutting system is pivotal for achieving precise results. Featuring durable blades and an efficient drive, this mechanism enables users to handle various materials with ease. Regular inspection and upkeep of this system are vital to maintaining cutting accuracy and safety.

Common Issues with Stihl TS350

Every tool may encounter problems over time, leading to inefficiencies and frustration for users. Understanding the typical challenges can enhance maintenance practices and ensure optimal performance.

Performance Fluctuations

Engines may exhibit irregular behavior, such as stalling or difficulty starting. This can often be attributed to fuel quality, air filter obstructions, or ignition system failures. Regular checks and replacements can mitigate these issues.

Wear and Tear on Components

As with any mechanical device, components can experience degradation. Common signs include excessive vibrations or unusual noises, often signaling the need for replacement parts. Routine inspections can help in identifying problems early.

How to Read Parts Diagrams

Understanding visual representations of components is essential for efficient assembly, maintenance, and repairs. These illustrations serve as guides, simplifying the identification of individual elements and their relationships within a complex system.

Key Components of Visual Representations

- Labels: Each part is usually accompanied by a label or number for easy reference.

- Grouping: Similar items are often clustered together, indicating their interconnections.

- Legend: A legend may provide additional information, such as part specifications or notes.

Tips for Effective Interpretation

- Familiarize yourself with the layout and symbols used in the illustration.

- Cross-reference with manuals or online resources for clarification.

- Take your time to trace each connection to understand how components work together.

Finding Replacement Parts for TS350

Locating suitable components for your equipment can be a straightforward process with the right approach. Understanding where to look and what to consider will enhance your chances of success.

- Identify the specific component needed.

- Research reliable suppliers, both online and locally.

- Check for compatibility with your model.

- Read reviews and ratings of the suppliers.

To delve deeper into this process, consider the following resources:

- Official manufacturer websites for authenticity.

- Specialized retailers focusing on outdoor equipment.

- Online marketplaces that offer a wide range of choices.

- Local repair shops for expert advice and recommendations.

Ultimately, a well-informed search can save time and ensure you find the right items for your maintenance needs.

Maintenance Tips for Your TS350

Proper upkeep is essential for ensuring the longevity and efficiency of your cutting tool. Regular maintenance not only enhances performance but also prevents unexpected breakdowns, allowing you to work seamlessly.

Start by checking the air filter regularly. A clean filter ensures optimal airflow and engine performance. Replace it as needed to avoid blockages that can hinder operation.

Next, inspect the blade frequently for signs of wear or damage. A sharp, well-maintained blade reduces strain on the machine and improves cutting accuracy.

Keep the fuel system clean. Use fresh fuel and inspect fuel lines for leaks or cracks. This practice ensures reliable starts and consistent performance.

Lastly, don’t forget to lubricate moving parts. Regular lubrication minimizes friction, prolonging the life of components and maintaining smooth operation.

Compatibility with Other Models

Understanding the interchangeability of components across various equipment can significantly enhance maintenance efficiency and reduce costs. Many tools share similar designs, which can facilitate the use of certain elements between different models. This section delves into the compatibility of a specific unit with other devices from the same brand, highlighting potential benefits and considerations.

Shared Components

Several models feature interchangeable parts that can be utilized across different units. This compatibility not only streamlines repairs but also allows users to maximize their existing inventory of spare components. By identifying shared elements, operators can ensure that they have the necessary supplies on hand, ultimately improving operational efficiency.

Considerations for Compatibility

While many devices may share components, it is crucial to consider specifications such as size, performance, and design. Using incompatible parts can lead to suboptimal performance or even damage. It is advisable to consult the manufacturer’s guidelines to confirm compatibility and ensure the safe operation of the equipment.

Resources for Stihl TS350 Owners

Owning a powerful cutting tool requires access to reliable information and resources. Whether you need maintenance guides, troubleshooting tips, or replacement components, having the right materials can significantly enhance your experience. This section aims to provide valuable insights and links to help you effectively manage and operate your equipment.

Maintenance Guides

Regular upkeep is essential for optimal performance. Various online platforms offer comprehensive manuals that detail maintenance procedures, ensuring your machine remains in top condition. Look for guides that include step-by-step instructions, safety tips, and recommended schedules for routine checks.

Community Forums and Support

Joining forums dedicated to equipment enthusiasts can be invaluable. These communities often share personal experiences, tips, and advice on specific issues. Engaging with fellow users can provide answers to common problems and foster a supportive environment for troubleshooting.

In addition, consider visiting authorized dealers or service centers for professional assistance. They can offer expert guidance and access to genuine components, ensuring that your equipment operates safely and efficiently.

DIY Repairs and Troubleshooting

Taking on repairs and maintenance tasks yourself can be a rewarding experience, enabling you to save money and deepen your understanding of your equipment. By familiarizing yourself with common issues and solutions, you can effectively enhance the performance and longevity of your machinery.

Common Issues and Solutions

Many users encounter problems such as starting difficulties or decreased power. These issues often stem from fuel contamination or clogged air filters. To address these, regularly check and replace fuel and filters, ensuring that your machine runs smoothly. Additionally, inspect spark plugs for wear; replacing them can significantly improve performance.

Preventative Maintenance Tips

Routine checks are crucial for optimal functionality. Cleaning components, tightening bolts, and regularly inspecting belts can prevent larger issues. Keep an eye on wear and tear, and don’t hesitate to consult manuals for guidance on specific parts and their upkeep.