Husqvarna 550XP Parts Breakdown

Maintaining a powerful chainsaw requires a clear understanding of its essential components. Each element plays a crucial role in ensuring the tool operates efficiently and reliably, providing precision and longevity in tough environments. Knowing how these parts work together can help in troubleshooting issues, replacing worn-out elements, and ensuring peak performance over time.

This guide will take you through the key mechanisms and their functions, highlighting their importance in keeping your machine in top condition. Whether you’re performing regular maintenance or addressing specific concerns, having a detailed view of the system’s structure is essential for effective care and repair.

Husqvarna 550XP Parts Overview

This section provides a comprehensive look at the key components essential for the efficient operation of this chainsaw model. Each element plays a crucial role in ensuring the overall functionality and durability of the equipment. Understanding how these various mechanisms work together can help with maintenance and performance optimization.

| Component | Function |

|---|---|

| Engine | Powers the tool, converting fuel into mechanical motion. |

| Air Filter | Prevents dust and debris from entering the engine, ensuring smooth operation. |

| Guide Bar | Supports the cutting chain, providing precise control during use. |

| Cutting Chain | Responsible for the actual cutting action, moving at high speed to slice through wood. |

| Clutch | Engages and disengages the chain from the engine’s power, allowing for controlled operation. |

| Fuel Tank | Stores the fuel mixture needed to run the engine. |

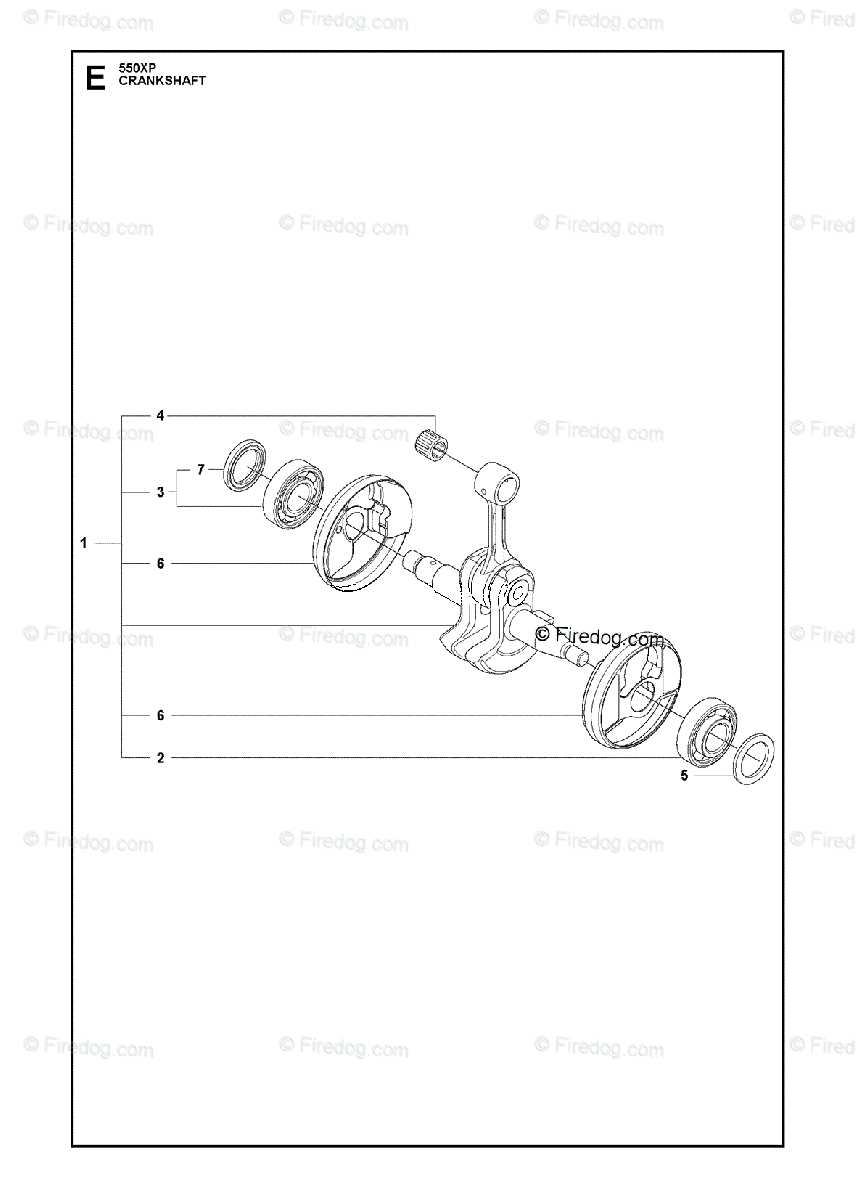

Engine Components and Specifications

The engine is designed for high efficiency and durability, utilizing advanced technology to ensure optimal performance. With key components working in harmony, this type of motor ensures smooth operation, even under demanding conditions.

| Component | Material | Function |

|---|---|---|

| Cylinder | Aluminum Alloy | Facilitates fuel combustion and controls pressure |

| Piston | Forged Steel | Transfers energy from combustion to the crankshaft |

| Crankshaft | High-strength Steel | Converts reciprocating motion to rotational power |

| Cooling Fins | Aluminum | Dissipates heat to maintain engine temperature |

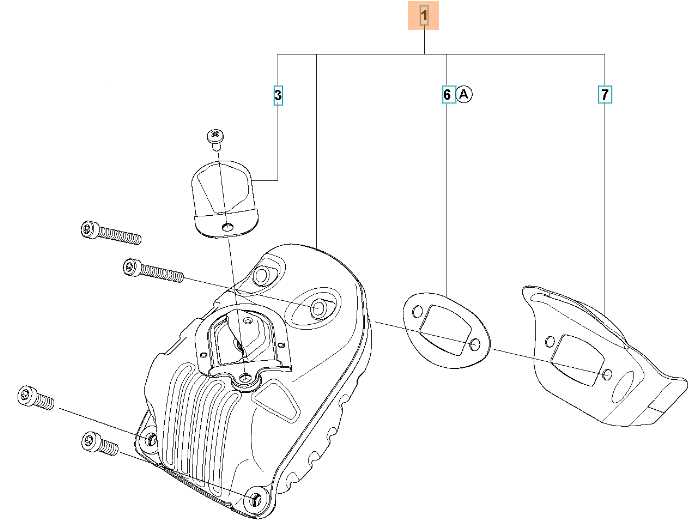

Air Filter and Maintenance Tips

Maintaining the cleanliness of the air filter is crucial for ensuring efficient engine performance and longevity. A well-maintained filter helps prevent debris from entering the engine, reducing the risk of damage and improving overall function. Regular checks and cleaning of this component are essential for keeping the system running smoothly.

Cleaning the Filter

To clean the air filter, first remove it carefully to avoid spreading dust or particles. Use compressed air or a soft brush to eliminate dirt from the surface. If the filter is too clogged, it may need to be replaced entirely. Always ensure the component is completely dry before reinserting it into the machine.

Regular Inspections

Regularly inspect the filter for signs of wear or damage, as these can compromise its effectiveness. Look for tears, holes, or excessive dirt buildup. Keeping a spare filter on hand is a good practice, allowing for quick replacements when necessary.

Chain and Bar Assembly Details

The chain and bar are essential components that work together to ensure smooth cutting performance. Their proper assembly and maintenance are crucial for optimal functioning. A well-tensioned chain and securely fitted bar allow for efficient operation and reduced wear on the machine.

Chain Tensioning

Adjusting the chain tension is a key step in the assembly process. The chain should be tight enough to stay in place on the bar but loose enough to move freely. Regularly check the tension before each use to prevent accidents or unnecessary strain on the motor.

Bar Installation

Installing the bar requires aligning it correctly with the engine unit and securing it with appropriate fasteners. Make sure that the bar is straight and properly aligned to ensure an even cut and reduce the risk of kickback. Proper lubrication also helps extend the life of both the chain and bar.

Ignition System Parts Breakdown

The ignition system is critical for ensuring the proper operation of the engine by providing the necessary spark at the right moment. This section offers an overview of the components involved, each playing a vital role in delivering reliable ignition performance.

Main Components

- Flywheel – Creates the magnetic field needed to generate electricity for the spark.

- Coil – Converts the generated electrical charge into a high voltage that fires the spark plug.

- Spark Plug – Receives the voltage from the coil and produces the spark to ignite the air-fuel mixture.

- Ignition Switch – Controls the flow of electricity to the ignition system, enabling engine start and stop functions.

Supporting Elements

- Wiring – Connects the components, ensuring a steady flow of electricity.

- Grounding – Ensures proper electrical grounding to prevent malfunctions.

- Timing Mechanism – Synchronizes the spark with engine operation for optimal performance.

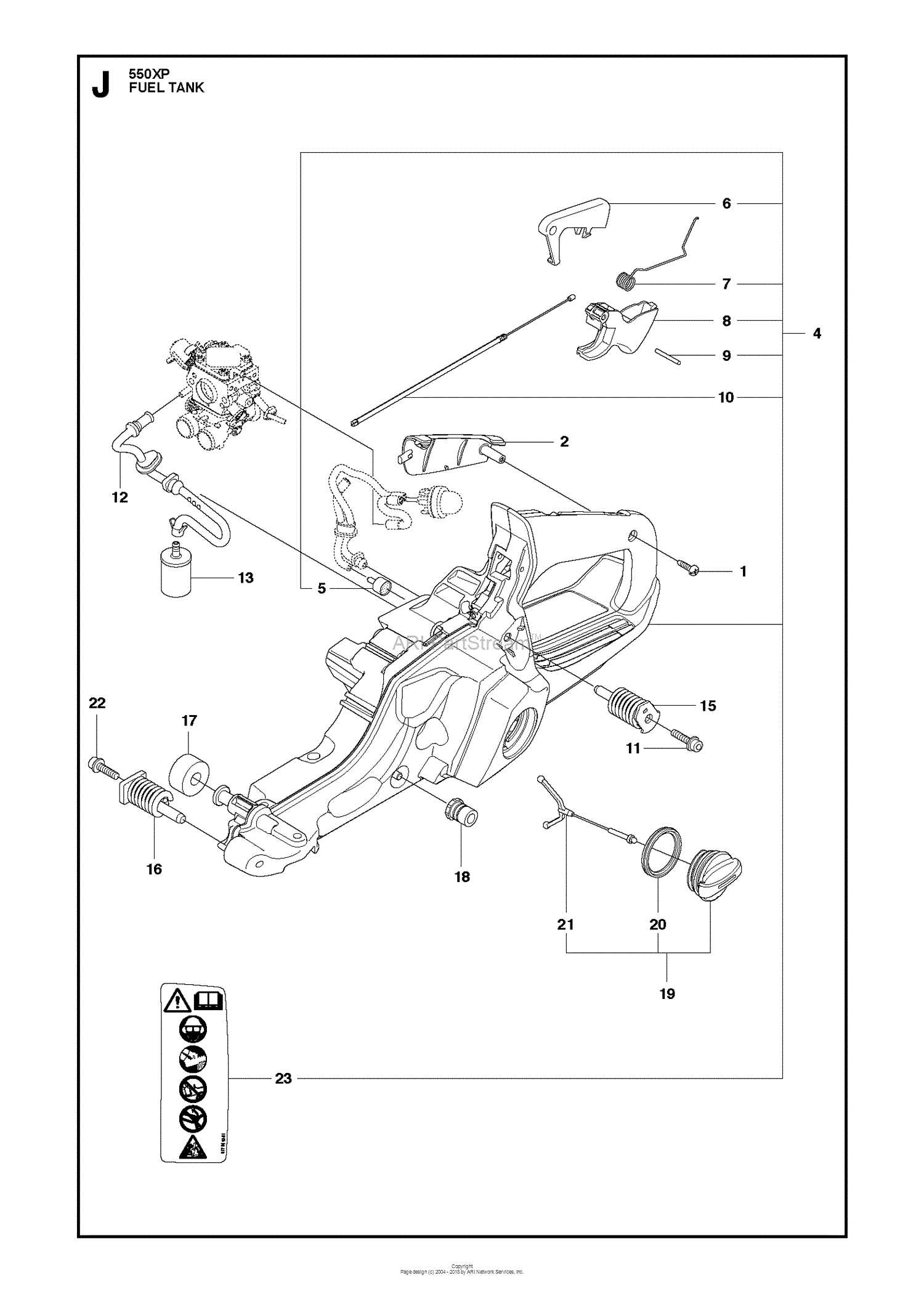

Fuel System and Carburetor Parts

The fuel system plays a crucial role in ensuring optimal performance and efficiency of the engine. It is responsible for delivering the correct mixture of air and fuel to the combustion chamber. A well-functioning system includes several components that work together to regulate fuel flow and maintain engine operation.

The carburetor is a key element within this system, responsible for mixing air with fuel in the right proportions. It typically consists of various parts, including the float chamber, throttle valve, and jet assemblies, each contributing to the overall functionality. Proper maintenance of these components is essential for smooth engine performance, as any malfunction can lead to issues such as stalling or inefficient fuel consumption.

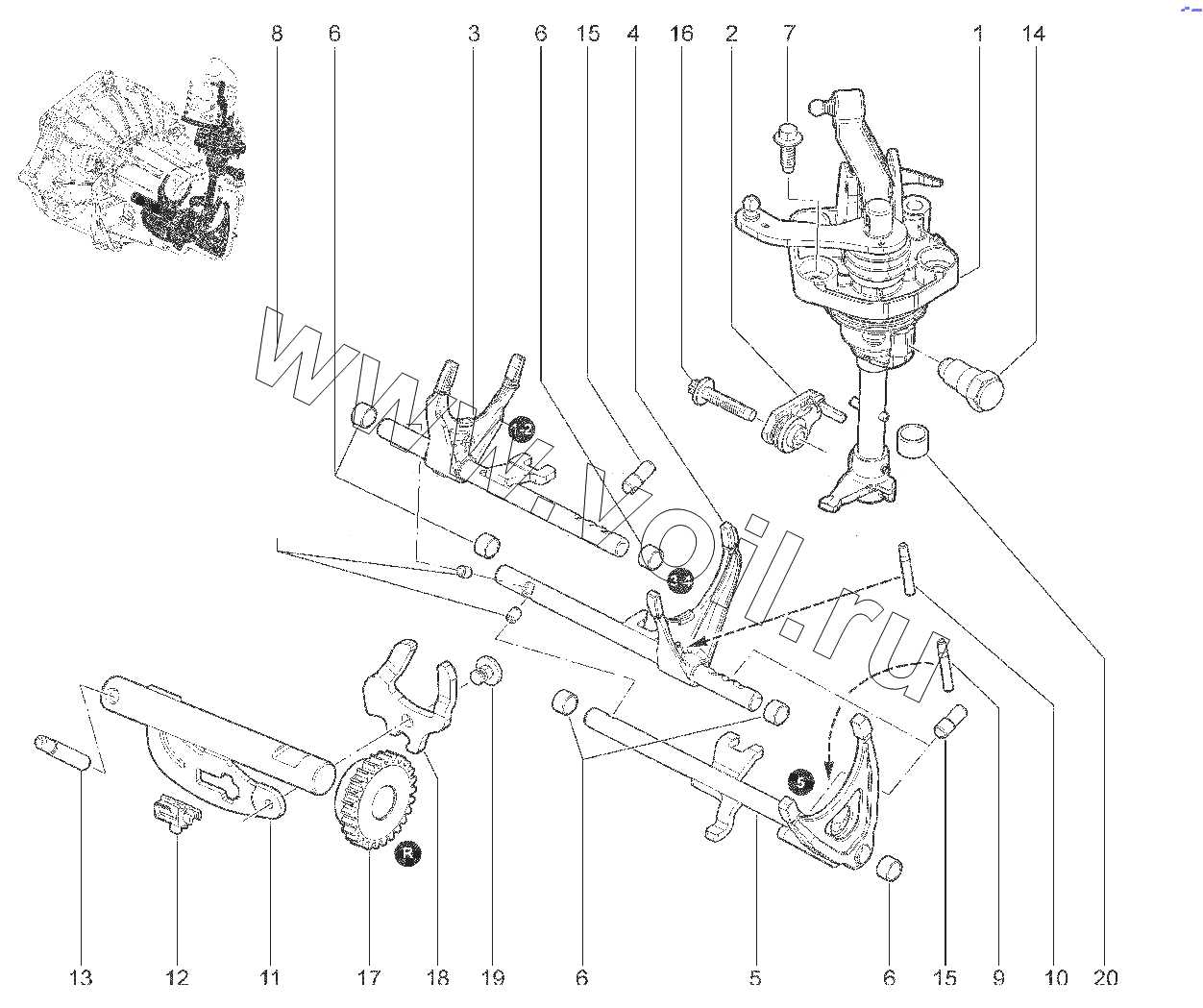

Clutch Assembly and Operation

The clutch assembly is a crucial component in the functioning of many motorized tools, enabling efficient power transfer from the engine to the cutting apparatus. Its design allows for the engagement and disengagement of the power source, facilitating smoother operation and enhancing safety during use.

Components of the Clutch Assembly

The assembly typically consists of several key parts, including the clutch drum, springs, and shoes. Each of these elements plays a vital role in ensuring that the clutch engages at the appropriate engine speed, providing optimal performance while preventing unnecessary wear.

Operation Mechanism

When the engine reaches a predetermined RPM, the centrifugal force causes the shoes to expand outward, engaging with the clutch drum. This action transmits power to the cutting tool. Conversely, as the engine speed decreases, the springs pull the shoes back, disengaging the clutch and stopping power transmission. This mechanism ensures efficient operation while safeguarding against stalling or engine overload.

Handle and Vibration Control Features

Effective grip and vibration management are essential for maintaining comfort and safety during operation. The design of the handle not only facilitates a secure hold but also plays a crucial role in minimizing the impact of vibrations that can occur during use. By enhancing user experience, these features contribute to longer working periods without fatigue.

Ergonomic Design: The handle is engineered to fit comfortably in the user’s hand, promoting a natural wrist position. This reduces strain and allows for extended use without discomfort.

Vibration Dampening: Advanced technologies are employed to absorb and dissipate vibrations, significantly lowering the amount felt by the operator. This system is crucial for reducing the risk of vibration-related injuries over time.

Adjustable Features: Certain models may offer adjustable settings for handle positioning, allowing users to customize their grip based on personal preferences. This adaptability further enhances control and comfort during operation.

Safety Mechanisms: Integrated safety features are designed to prevent excessive vibration exposure, ensuring that users can operate the equipment with confidence. These elements contribute to overall operational efficiency while safeguarding the health of the operator.

Guide to Husqvarna 550XP Safety Features

This section explores essential safety mechanisms integrated into high-performance outdoor tools. These features are designed to enhance user protection while ensuring efficient operation. Understanding these safety aspects is crucial for both novice and experienced users to prevent accidents and ensure optimal usage.

Key Safety Mechanisms

Several vital safety components contribute to the reliable operation of these tools. The first notable feature is the chain brake, which activates instantly in case of kickback. This mechanism significantly reduces the risk of injury by stopping the chain’s movement swiftly. Additionally, the throttle lockout prevents accidental acceleration, allowing users to maintain better control during operation.

Importance of Regular Maintenance

Regular maintenance plays a critical role in ensuring that safety features function correctly. Users should routinely check and clean the chain brake and throttle components, as dirt and debris can hinder their performance. Adhering to the manufacturer’s guidelines for maintenance will help maintain safety standards and prolong the life of the equipment.

Exhaust System and Muffler Parts

The exhaust mechanism plays a crucial role in the operation of outdoor power equipment, ensuring efficient expulsion of combustion gases. This section delves into the various components associated with the exhaust assembly, focusing on their functions and significance in maintaining optimal performance.

Key Components of the Exhaust Assembly

Essential elements of the exhaust structure include the muffler, exhaust pipe, and gaskets. The muffler is designed to minimize noise generated by the engine while controlling the outflow of gases. The exhaust pipe directs emissions away from the machine, ensuring safety and efficiency. Gaskets are vital in providing a secure seal between different parts, preventing leaks and enhancing overall effectiveness.

Importance of Regular Maintenance

Routine inspection and maintenance of the exhaust system are imperative for longevity and performance. Keeping the muffler and associated components free from debris and damage not only optimizes operation but also contributes to environmental compliance. Ensuring that all parts are in good condition will lead to improved fuel efficiency and a reduction in harmful emissions.

Starter Mechanism Components

The starter mechanism is essential for the smooth operation of any chainsaw. It consists of various parts that work together to initiate the engine’s ignition process. Understanding these components can help in troubleshooting and maintaining optimal performance.

| Component | Description |

|---|---|

| Starter Rope | A durable cord that is pulled to engage the starting mechanism. |

| Recoil Spring | This component allows the starter rope to retract after being pulled. |

| Starter Pulley | A circular part that houses the starter rope and connects to the recoil spring. |

| Flywheel | Connected to the engine, it provides momentum to start the ignition process. |

| Starter Handle | The grip that the user pulls to initiate the starting process. |

Lubrication System and Oil Pump

The lubrication mechanism is essential for ensuring the optimal performance of a chainsaw. It minimizes friction between moving components, enhancing durability and efficiency. This system is designed to deliver a specific amount of oil to vital parts, ensuring smooth operation and preventing overheating.

Functionality of the Lubrication Mechanism

The lubrication system works by transferring oil from the reservoir to the chain and bar during operation. As the engine runs, an oil pump activates, creating a flow that distributes lubricant to areas where friction occurs. This continuous flow not only protects the equipment but also helps maintain the chainsaw’s performance over time.

Importance of Regular Maintenance

Regular inspection and maintenance of the lubrication system are crucial. Ensuring that the oil reservoir is filled and that the pump functions correctly can prevent damage to the engine and extend the lifespan of the tool. Additionally, using the appropriate type of oil is vital for achieving optimal results and maintaining efficiency.

Troubleshooting Common Part Failures

When operating outdoor power equipment, users may encounter issues related to component malfunctions. Understanding the typical problems that can arise with these parts is essential for effective maintenance and repair.

Identifying Symptoms: The first step in resolving part failures is to recognize the signs that indicate a malfunction. Common symptoms include unusual noises, decreased performance, or visible damage. Noticing these early warning signs can prevent further complications.

Checking Connections: Loose or corroded connections often lead to operational issues. Inspect all wiring and connectors to ensure a secure fit. Cleaning corrosion with appropriate tools can enhance conductivity and restore functionality.

Examining Components: Various elements may wear out over time due to regular use. It is crucial to examine components for signs of wear such as cracks, fraying, or discoloration. Replacing worn parts promptly can improve performance and prolong the equipment’s lifespan.

Consulting Manuals: Referencing technical manuals can provide valuable guidance for troubleshooting specific issues. These documents often include diagrams and instructions that facilitate a better understanding of the equipment’s components.

Seeking Professional Help: If troubleshooting efforts do not resolve the problem, consider consulting a professional technician. Their expertise can be invaluable in diagnosing and repairing complex issues that may not be easily identifiable.