Understanding the Br 600 Parts Diagram for Efficient Maintenance

In the world of outdoor equipment, knowledge of each element is crucial for optimal performance and maintenance. A thorough comprehension of the individual components not only enhances functionality but also extends the lifespan of the machinery. By delving into the intricate relationships between these elements, users can ensure their tools operate smoothly and efficiently.

For enthusiasts and professionals alike, having access to a comprehensive visual reference can be invaluable. This reference serves as a guide, illuminating the specifics of how each section fits together and contributes to the overall operation. Understanding these connections allows for better troubleshooting and repairs, empowering users to take full control of their equipment.

As we explore the intricacies of this particular model, we will uncover the significance of each individual component. With a clear visual representation, users can identify, assess, and address any issues that may arise, ensuring their machinery remains in peak condition for any task at hand.

Understanding the BR 600 Parts Diagram

When working with intricate machinery, visual aids play a crucial role in comprehending the individual components and their interconnections. This section delves into the significance of such visual representations, which serve as valuable tools for both troubleshooting and maintenance. By familiarizing oneself with these illustrations, users can enhance their understanding of how each element functions within the overall system.

Importance of Visual Representation

Visual representations provide clarity in identifying components and their roles. Here are some key benefits:

- Enhanced Understanding: Simplifies complex structures.

- Efficient Repairs: Aids in pinpointing issues quickly.

- Better Maintenance: Facilitates regular upkeep and inspection.

Common Components Illustrated

Familiarity with the various elements depicted is essential for effective operation. Common features include:

- Engine assembly

- Fuel system

- Air intake system

- Control mechanisms

Understanding these components will empower users to manage their equipment more effectively and ensure optimal performance.

Key Components of the BR 600

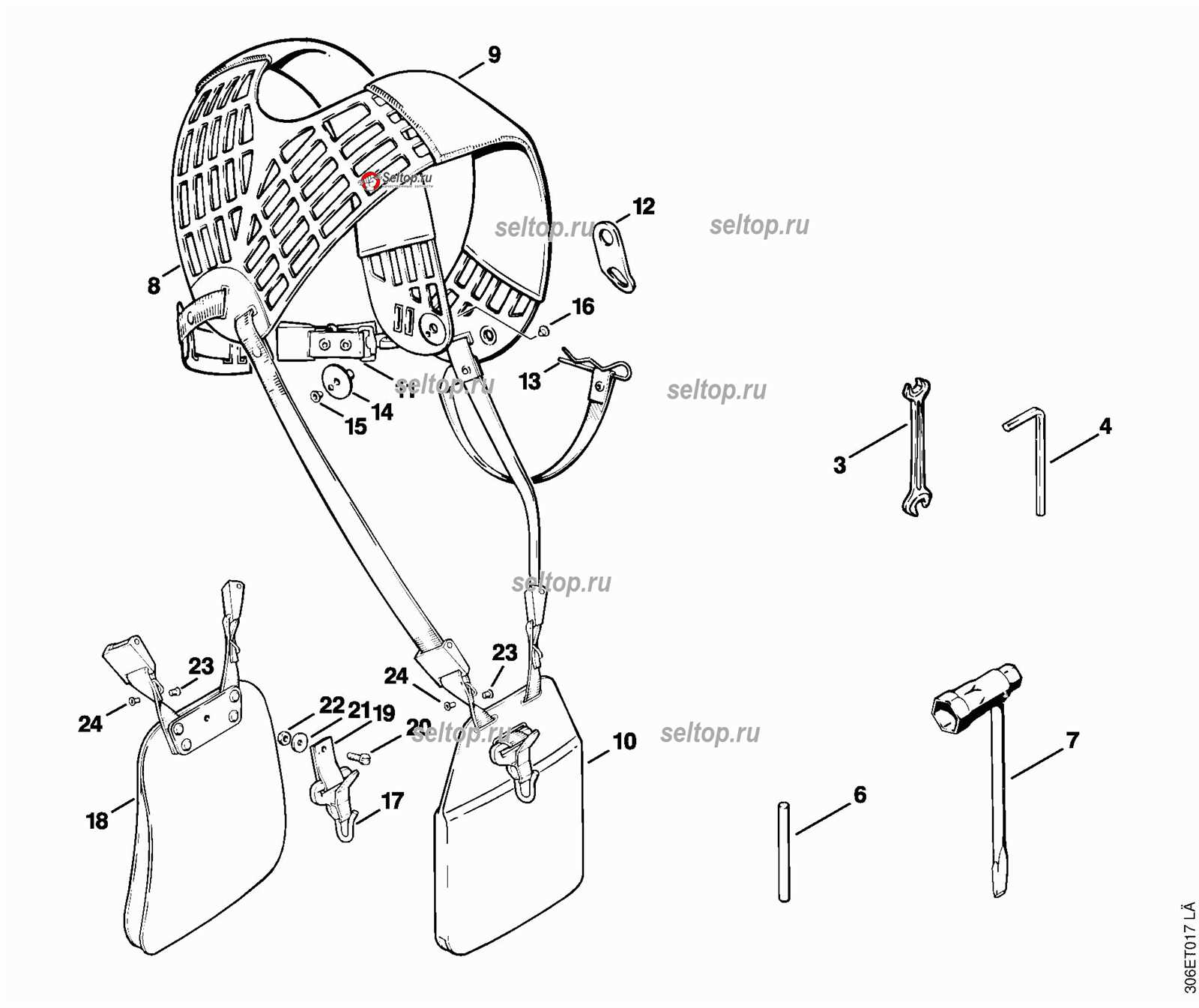

The BR 600 is a sophisticated tool designed for efficient outdoor maintenance. Understanding its main elements is essential for proper usage and maintenance. Each component plays a vital role in ensuring optimal performance and durability, allowing users to tackle various tasks with ease.

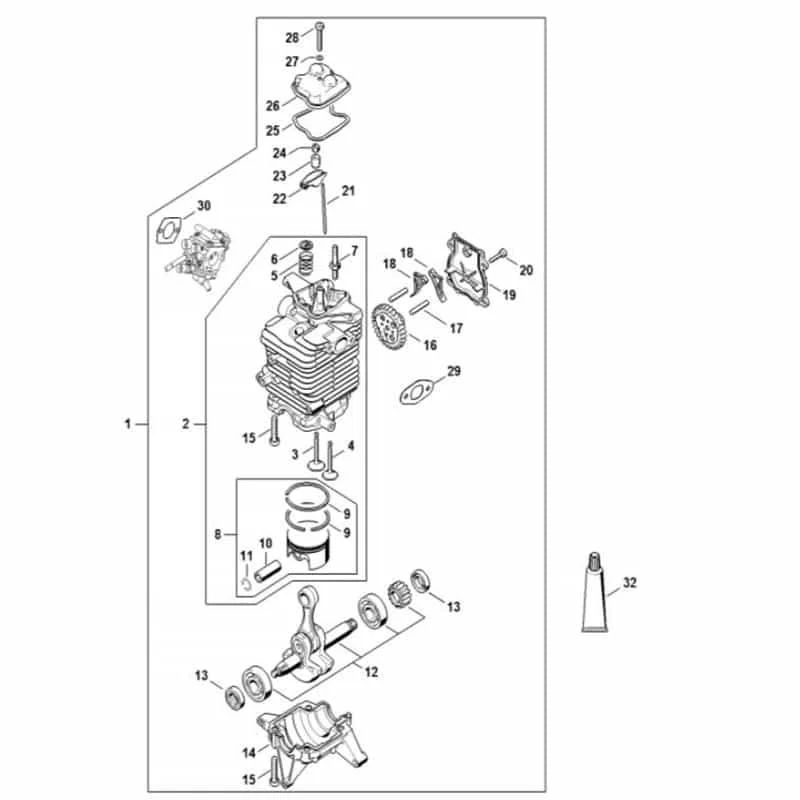

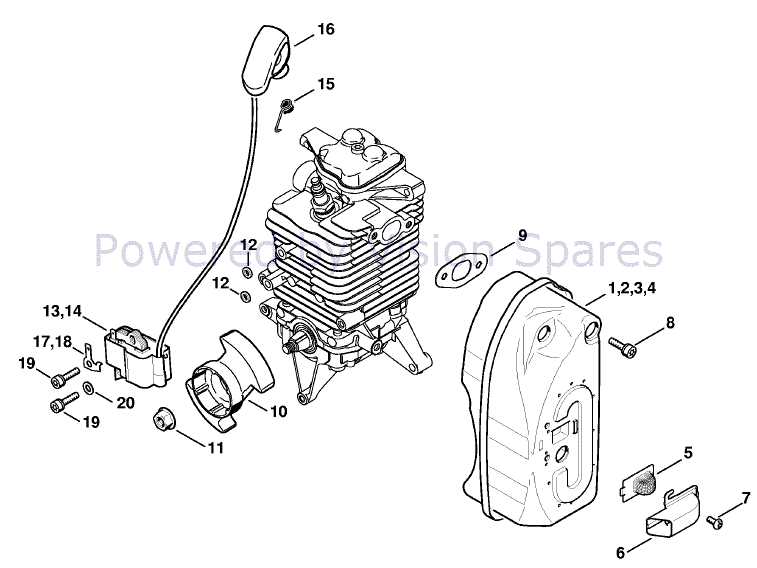

Engine Assembly

The heart of the machine lies in its powerful engine assembly. This unit provides the necessary power to drive the entire system, allowing for effective operation across diverse conditions. The engine is engineered for fuel efficiency and reliability, ensuring extended usage without frequent refueling.

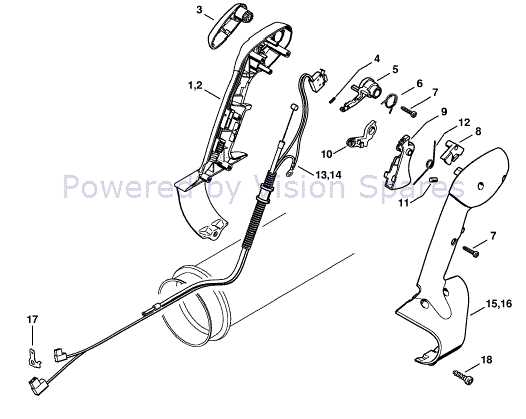

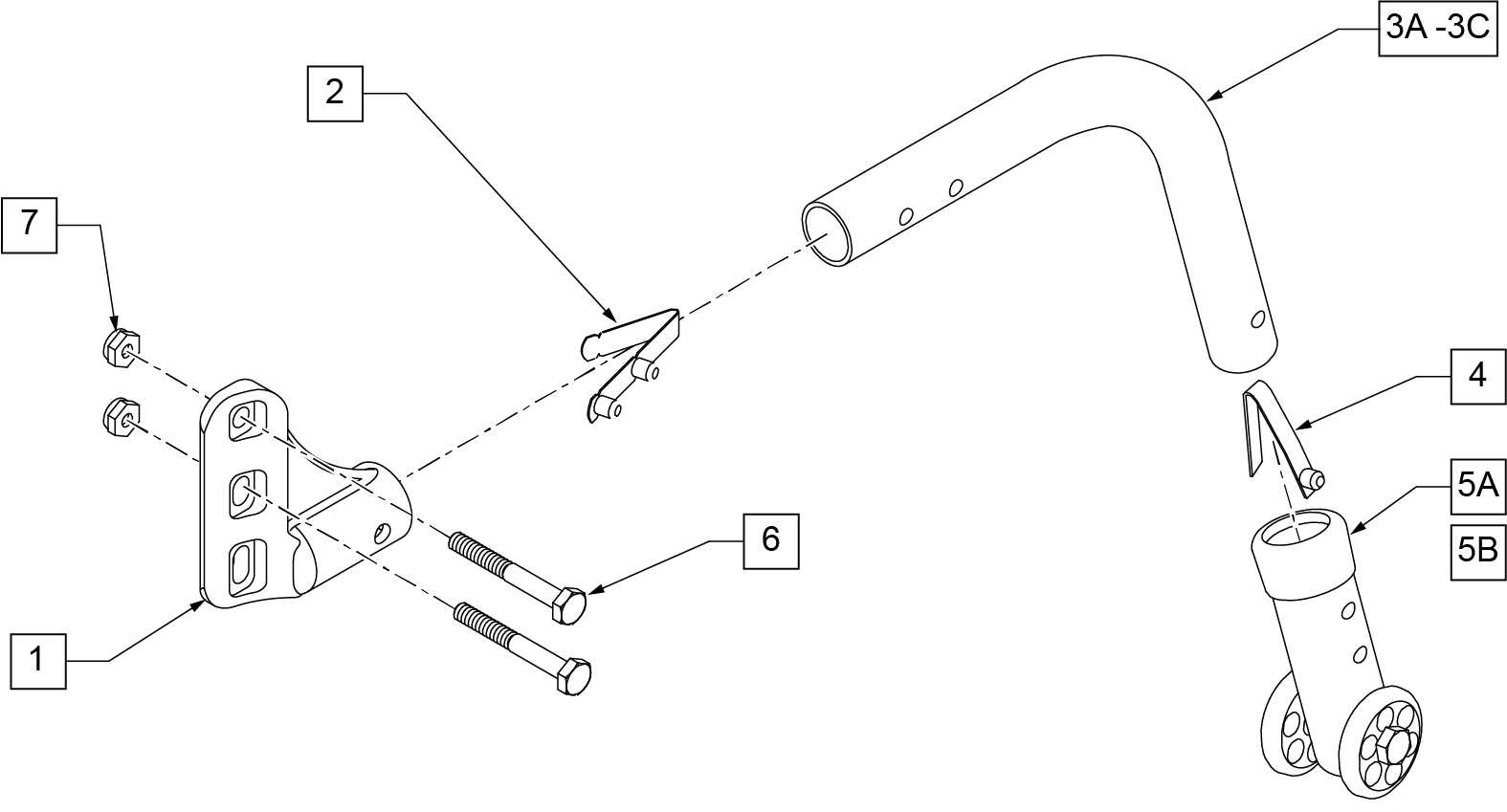

Blower Tube

The blower tube is a crucial element that directs airflow, enabling the efficient clearing of leaves and debris. Its design maximizes air velocity, making it easier to handle stubborn materials. The adjustable features allow users to customize the output according to specific needs, enhancing versatility and performance.

Importance of Accurate Diagrams

Clear and precise visual representations play a crucial role in understanding complex systems and components. They serve as essential tools for both professionals and enthusiasts, ensuring that everyone involved can comprehend intricate details effortlessly. The effectiveness of these illustrations directly impacts efficiency, safety, and performance in various tasks.

Enhancing Communication

When it comes to collaborative projects, well-crafted visuals facilitate communication among team members. They help bridge gaps in understanding, allowing individuals from different backgrounds to align their efforts. Accurate visuals not only minimize confusion but also foster a shared knowledge base, enabling smoother workflows.

Facilitating Maintenance and Repair

In the realm of upkeep and troubleshooting, having reliable illustrations is invaluable. They guide technicians in identifying issues and executing repairs correctly. Detailed representations reduce the risk of errors, ensuring that tasks are performed efficiently and effectively. This ultimately leads to increased longevity and reliability of the equipment in question.

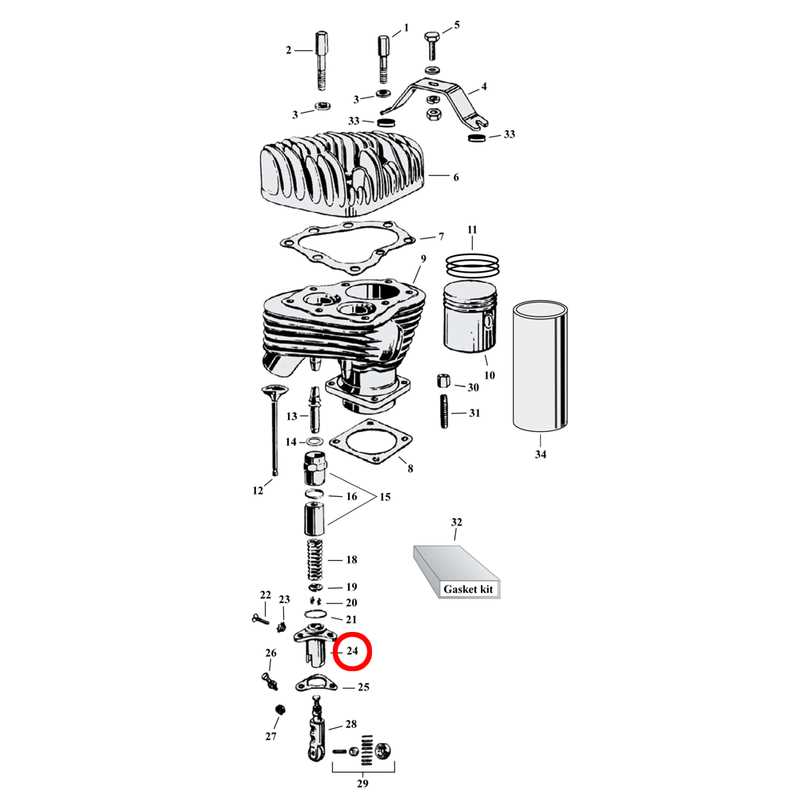

How to Read Parts Diagrams

Understanding the visual representation of components is essential for effective maintenance and repairs. These illustrations provide an overview of the assembly, highlighting various elements and their relationships. By mastering this skill, users can navigate complex structures with greater ease, ensuring they identify the necessary items accurately.

Familiarize Yourself with Symbols and Labels

Each illustration utilizes specific icons and markings to convey information about the components. Take time to familiarize yourself with these symbols, as they indicate functions, sizes, and materials. Often, there will be a legend included that explains each symbol clearly, aiding in a better understanding of the layout.

Follow the Flow of Assembly

Pay attention to the arrangement of components as depicted in the illustration. Typically, these visuals are organized in a logical sequence, guiding you through the assembly process. Observing how elements connect or fit together can clarify the installation or disassembly procedures, reducing the likelihood of errors.

Common Issues with the BR 600

When utilizing powerful outdoor equipment, users often encounter various challenges that can hinder performance and efficiency. Identifying and understanding these common problems is essential for maintaining optimal functionality and extending the lifespan of the device.

One prevalent issue is starting difficulties. Users may find that their machine fails to start or requires multiple attempts. This can often be attributed to fuel quality, spark plug conditions, or air filter blockages. Regular maintenance of these components can mitigate such frustrations.

Another frequent concern involves engine performance. Users might experience reduced power or inconsistent operation, often resulting from clogged fuel lines or improper carburetor settings. Ensuring that fuel systems are clean and properly adjusted can significantly improve performance.

Furthermore, vibration problems can arise, leading to discomfort during use and potential mechanical issues. This may be linked to loose screws or worn-out components. Regular inspections and tightening of parts can help maintain a smoother operation.

Lastly, excessive noise is a common complaint among users. This may indicate that the exhaust system is not functioning as intended, potentially due to blockages or leaks. Addressing these concerns promptly can enhance both the user experience and the machine’s efficiency.

Maintenance Tips for Longevity

Ensuring the durability and efficient performance of your equipment requires consistent care and attention. Regular upkeep not only prolongs the life of your machinery but also enhances its overall functionality. By adopting a systematic approach to maintenance, you can prevent potential issues and optimize performance.

Regular Cleaning: Keeping the exterior and interior components clean is essential. Dust and debris can lead to wear and tear, so routine cleaning helps maintain optimal performance.

Inspection and Lubrication: Periodically examine moving parts for signs of wear. Applying the appropriate lubricants reduces friction and prevents overheating, contributing to smoother operation.

Timely Replacements: Identify and replace worn-out components as soon as possible. Delaying replacements can lead to further damage and costly repairs down the line.

Follow Manufacturer Guidelines: Adhering to the recommended maintenance schedule outlined in the user manual is crucial. This ensures that all necessary tasks are performed at the right intervals, keeping your equipment in peak condition.

Store Properly: When not in use, store your machinery in a dry, cool environment. Proper storage protects it from environmental factors that could cause deterioration.

By implementing these practices, you can significantly extend the lifespan of your equipment while ensuring it operates efficiently when you need it the most.

Identifying Replacement Parts Easily

Recognizing components for machinery maintenance can often feel daunting. However, with the right approach and tools, the process can become straightforward and efficient. Understanding how to navigate the available resources not only saves time but also ensures that you select the correct items for your specific needs.

Utilizing Reference Manuals

One of the most effective methods for identifying the necessary components is through reference manuals. These documents typically include detailed illustrations and descriptions, making it easier to locate the specific items you require. Always consult the manual that corresponds to your model, as different variations may have unique specifications.

Online Resources and Communities

The internet provides a wealth of information for those seeking assistance. Websites dedicated to machinery often feature user forums where enthusiasts and professionals exchange knowledge. Engaging with these communities can lead to valuable insights and recommendations, enhancing your ability to identify and acquire the right components swiftly.

Where to Find Genuine Parts

Acquiring authentic components for your equipment is essential for maintaining optimal performance and longevity. Reliable sources ensure that the items you purchase meet quality standards, providing peace of mind and reliability in your work. Here are some avenues to explore when seeking these crucial elements.

Authorized Dealers

One of the most dependable options for sourcing original components is through authorized dealers. These distributors have direct access to the manufacturer’s inventory, ensuring that you receive genuine items specifically designed for your model. Moreover, they often provide expert guidance and support to help you make informed decisions.

Online Retailers

The digital marketplace offers a plethora of options for finding authentic components. Reputable online retailers often have a wide selection of items and provide detailed descriptions to help you choose the right one. Look for platforms with positive reviews and a solid return policy to ensure a satisfactory purchasing experience.

| Source | Advantages | Considerations |

|---|---|---|

| Authorized Dealers | Guaranteed authenticity, expert advice | May have higher prices |

| Online Retailers | Convenience, wide selection | Varied quality, ensure trustworthiness |

| Manufacturer’s Website | Direct purchase from the source | Limited availability |

Comparing BR 600 Models and Diagrams

When exploring the different versions of the BR series, it becomes essential to analyze their unique features and internal layouts. Understanding these distinctions can enhance user experience and maintenance efficiency. This section aims to break down the variations across models, highlighting their specific attributes and functionalities.

Key factors to consider when comparing models include:

- Performance: Each version may offer varying power outputs and efficiency levels, catering to different user needs.

- Design Variations: Structural changes can affect weight distribution and ergonomics, impacting ease of use.

- Maintenance Requirements: Some models might necessitate more frequent upkeep due to their design or components.

- Compatibility: Identifying which components are interchangeable across models can simplify repairs and upgrades.

When examining internal structures, consider the following:

- Assembly Layout: Variations in assembly can influence accessibility for repairs.

- Component Locations: The placement of essential elements may differ, affecting serviceability.

- Innovation Features: Newer iterations often incorporate technological advancements that enhance functionality.

By understanding these elements, users can make informed decisions when selecting or maintaining their equipment, ensuring optimal performance and longevity.

Tools Needed for Repairs

Having the right tools at your disposal is essential for effective maintenance and restoration tasks. This section highlights the necessary implements that can make your repair work smoother and more efficient. Whether you’re a seasoned professional or a weekend enthusiast, equipping yourself with the appropriate devices ensures that you can tackle any challenge that comes your way.

Basic Tools

To begin with, a solid foundation of basic implements is crucial. Items such as screwdrivers, wrenches, and pliers should always be part of your toolkit. These essentials enable you to handle a variety of common issues with ease. Additionally, having a reliable set of measuring tools can aid in ensuring precision during your repairs.

Specialized Equipment

In some cases, specific tasks may require more specialized equipment. For instance, torque wrenches and diagnostic tools can be invaluable when addressing more complex problems. Investing in quality gear tailored for particular functions can save you time and improve the overall effectiveness of your repair efforts.

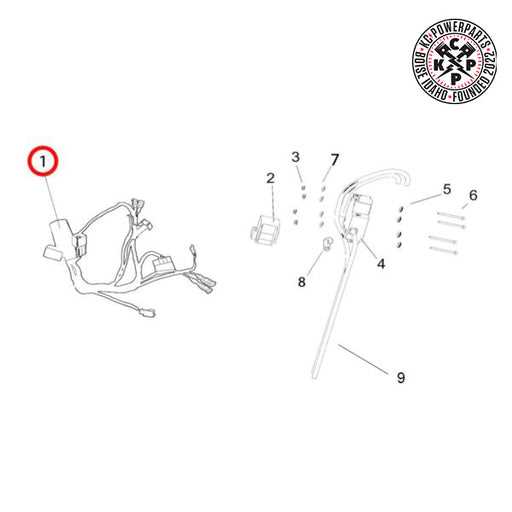

Step-by-Step Assembly Instructions

Proper assembly is crucial for optimal functionality and longevity of your equipment. This section provides a clear, methodical approach to putting together the various components, ensuring everything is correctly aligned and secured.

Required Tools

- Screwdriver (Phillips and flathead)

- Wrench set

- Pliers

- Measuring tape

- Safety goggles

Assembly Process

- Begin by laying out all components on a clean, flat surface.

- Identify each piece using the provided reference guide.

- Start with the base unit and secure the mounting brackets using screws.

- Attach the motor to the designated area, ensuring all connectors are aligned.

- Install the protective casing, checking that it fits snugly around the components.

- Connect all necessary wiring, making sure each connection is tight.

- Double-check the assembly for any loose parts or misalignments.

- Finally, conduct a test run to verify everything operates smoothly.

Customer Experiences and Feedback

Understanding user insights and evaluations is essential for enhancing product offerings and fostering customer loyalty. Feedback from individuals who have interacted with a particular model provides invaluable information that can guide future improvements and innovations. This section explores various perspectives from users, highlighting both positive experiences and areas needing attention.

Positive Testimonials

Many users express satisfaction with the overall performance and reliability of the equipment. Durability and efficiency are often praised, with customers noting that their experiences have exceeded expectations. For instance, several reviews highlight how the device has seamlessly handled demanding tasks, making it a trusted companion for professionals in various fields.

Areas for Improvement

While the majority of feedback is favorable, some users have pointed out potential enhancements. Ease of maintenance is a recurring theme, with suggestions for clearer instructions and improved accessibility to certain components. Addressing these concerns could significantly elevate the user experience, ensuring that all customers feel supported throughout their ownership journey.