Comprehensive Guide to New Holland 7090 Baler Parts Diagram

In the world of agricultural equipment, the ability to comprehend the intricate assembly of machinery is essential for maintaining efficiency and productivity. Each machine consists of numerous elements that work together seamlessly, and understanding these components can significantly enhance operational effectiveness.

Identifying individual elements within the machinery not only aids in troubleshooting but also facilitates timely maintenance. A comprehensive exploration of these components can help operators recognize potential issues before they escalate, ensuring the longevity of the equipment and optimizing performance.

Moreover, having access to visual aids that outline the arrangement of these elements is invaluable. Such resources provide a clear representation of how each part interacts within the system, offering insights that are crucial for both seasoned professionals and newcomers in the field. By familiarizing oneself with the structure and function of each component, one can confidently tackle repairs and maintenance, thereby fostering a deeper connection with the machinery at hand.

Overview of New Holland 7090 Baler

This section provides a comprehensive insight into a specific model of agricultural machinery designed for effective hay and straw processing. Recognized for its efficiency and reliability, this equipment is an essential tool for modern farming operations.

Key features include:

- Robust construction ensuring longevity and durability.

- Advanced technology for optimal performance and ease of use.

- Versatile functionality suitable for various crop types.

Maintenance and support play a crucial role in maximizing productivity. Proper care and timely servicing contribute to:

- Enhanced operational efficiency.

- Reduced downtime during critical harvest periods.

- Extended lifespan of the machinery.

Farmers appreciate the intuitive design and user-friendly features, making it easier to adapt to various field conditions. Overall, this model represents a valuable investment for those seeking to improve their harvesting capabilities.

Importance of Proper Maintenance

Regular upkeep of agricultural machinery is crucial for ensuring optimal performance and longevity. Neglecting maintenance can lead to unforeseen breakdowns, decreased efficiency, and increased operational costs. By prioritizing maintenance, operators can prevent issues before they arise and maintain high productivity levels.

Benefits of Routine Care

Implementing a systematic maintenance schedule offers numerous advantages. First, it enhances reliability, allowing machinery to perform consistently under varying conditions. Additionally, well-maintained equipment can operate at peak efficiency, reducing fuel consumption and minimizing wear on components. This proactive approach not only extends the life of the machinery but also safeguards the investment made in these essential tools.

Cost-Effectiveness

Investing time and resources into regular maintenance can lead to significant cost savings over time. By addressing minor repairs early, operators can avoid more extensive and costly repairs that may arise from neglect. Moreover, efficient machinery contributes to higher output levels, ultimately boosting overall profitability. Prioritizing maintenance is a strategic decision that pays dividends in the long run.

Common Issues with Baler Parts

Equipment used for hay and straw collection often encounters various challenges that can affect performance and efficiency. Understanding these common issues is essential for proper maintenance and ensuring optimal functionality.

- Worn Components: Over time, moving elements may experience wear, leading to decreased efficiency and potential breakdowns.

- Misalignment: Improper alignment of mechanical parts can cause uneven operation, resulting in increased strain and potential failure.

- Blockages: Accumulation of debris or material can obstruct flow, causing interruptions and necessitating frequent cleanups.

- Hydraulic Failures: Issues with hydraulic systems can lead to inadequate pressure, affecting the performance of crucial functions.

- Electrical Malfunctions: Faulty wiring or connections can disrupt control mechanisms, impacting overall operation.

Regular inspections and maintenance can help identify these issues early, allowing for timely repairs and ensuring longevity of the machinery.

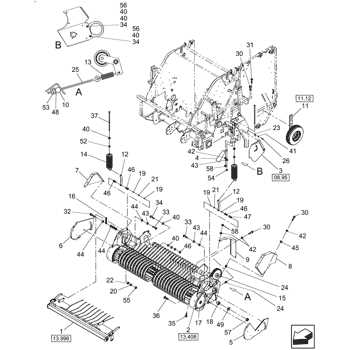

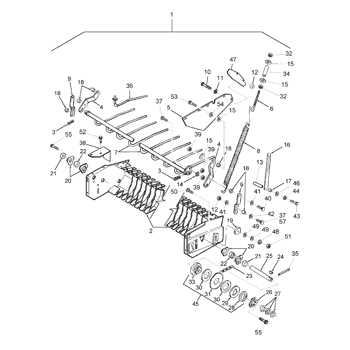

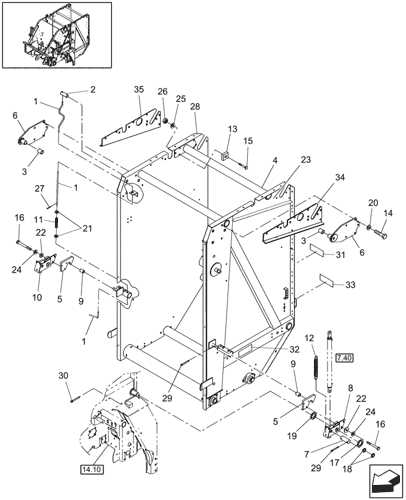

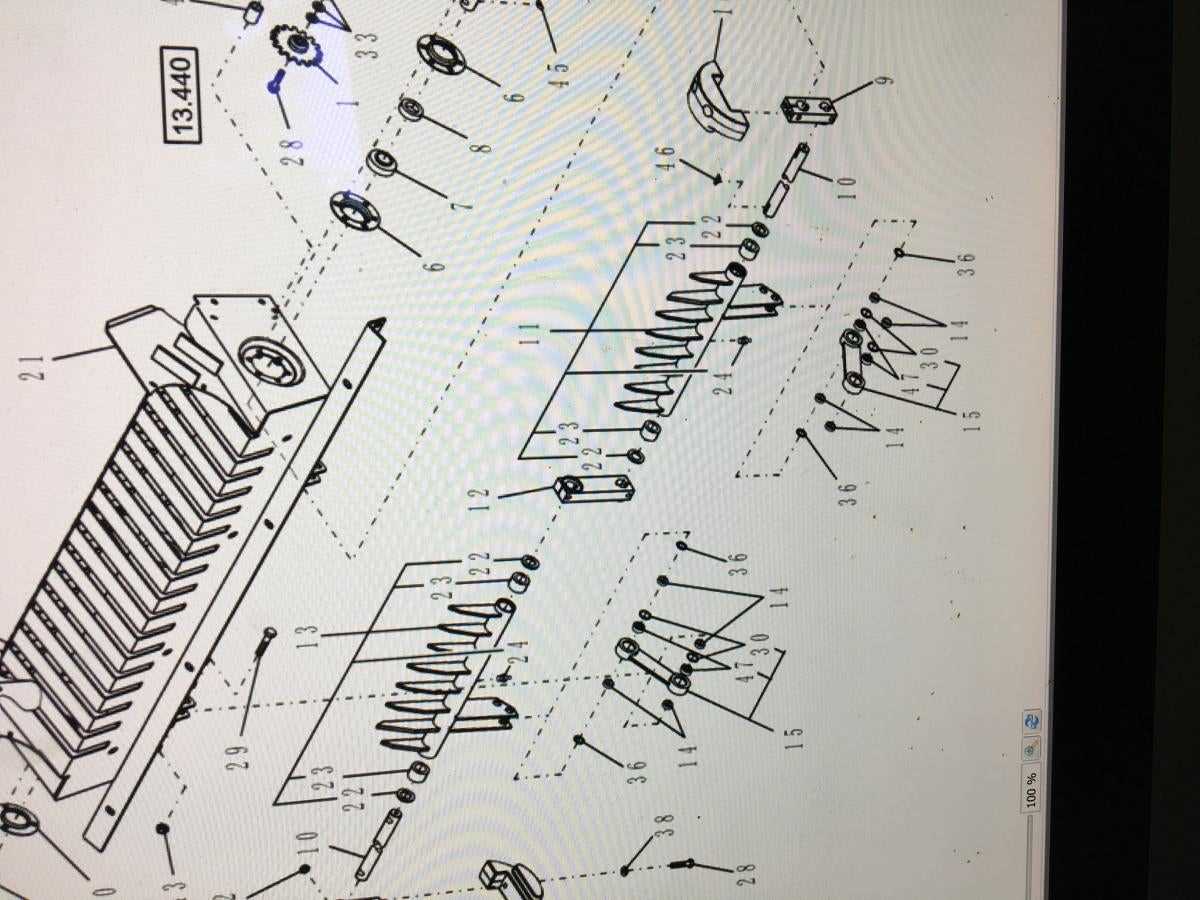

Parts Diagram Explained in Detail

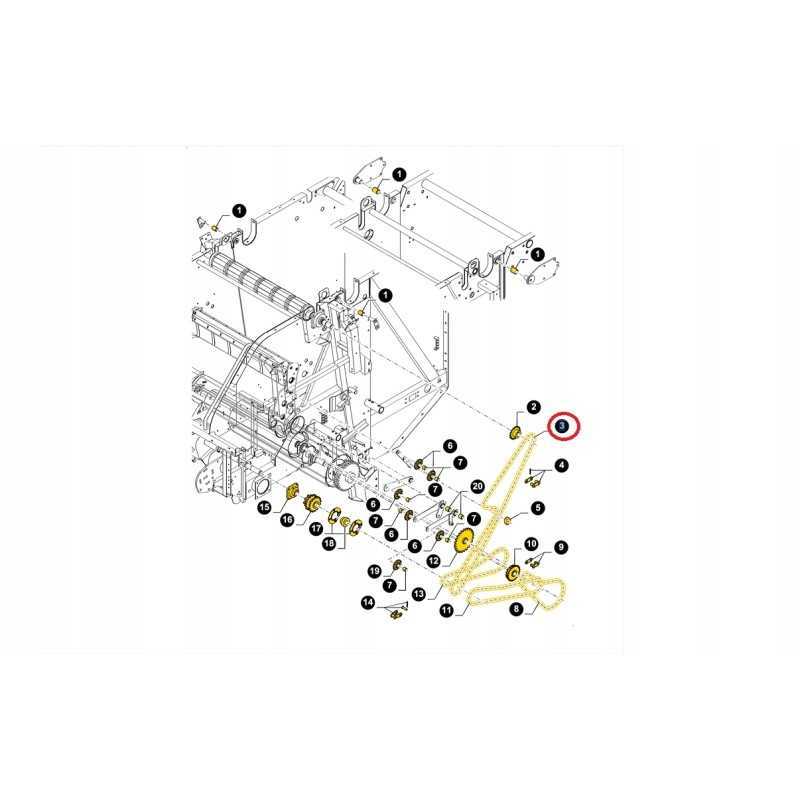

Understanding the intricate components of agricultural machinery is essential for efficient operation and maintenance. This section delves into the visual representation of essential elements, allowing operators and technicians to familiarize themselves with each part’s role and placement.

Such visual guides serve several important functions:

- Facilitating quick identification of components.

- Enhancing troubleshooting processes by clearly showing connections.

- Assisting in the assembly and disassembly of machinery.

The detailed visual representation typically includes:

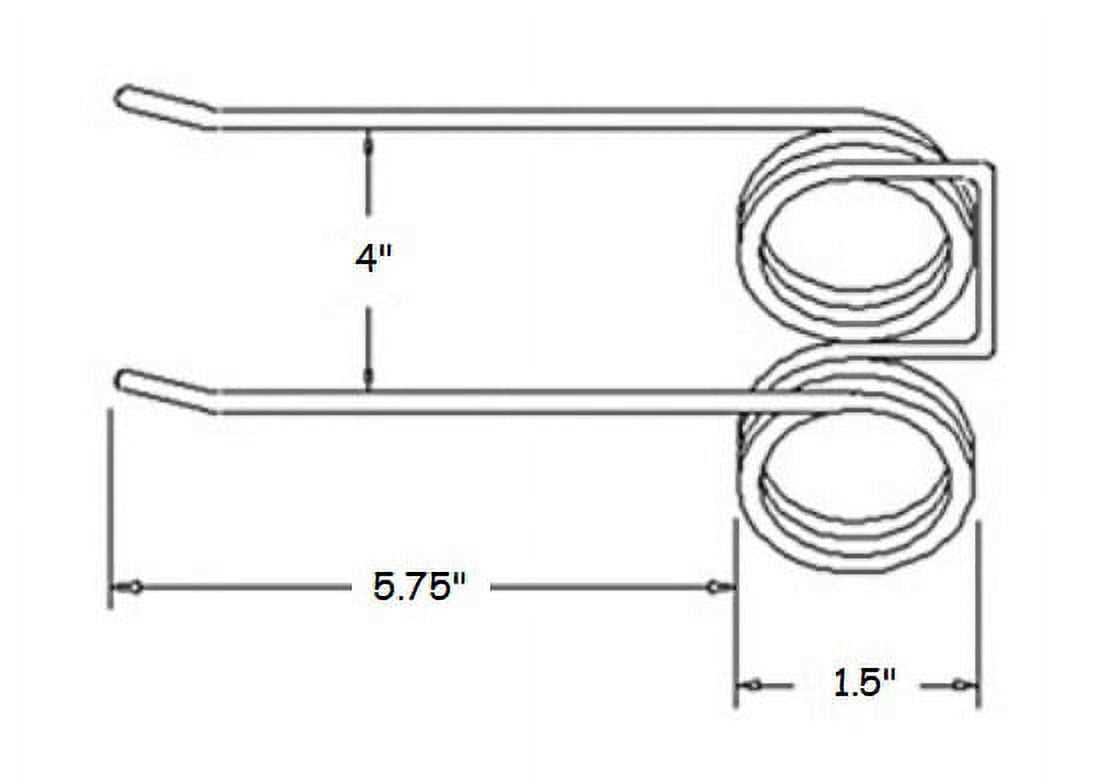

- Component Labels: Each part is labeled for easy reference, ensuring clarity.

- Exploded Views: These views offer a three-dimensional perspective, making it easier to see how components fit together.

- Reference Numbers: Many illustrations include numbers corresponding to parts lists, simplifying the ordering process.

- Material Specifications: Information regarding the materials used for each component can be included to guide replacements.

Incorporating such visual aids into maintenance practices leads to increased efficiency and reduced downtime, ultimately enhancing productivity in agricultural operations.

Identifying Key Components

Understanding the essential elements of any agricultural machinery is crucial for effective operation and maintenance. Familiarity with these components can enhance productivity and prolong the lifespan of the equipment. This section will delve into the primary features that are integral to the functionality of such machinery.

Main Features

- Feeding System: Responsible for drawing in material efficiently.

- Compression Chamber: Where the material is compacted into manageable units.

- Discharge Mechanism: Facilitates the expulsion of finished products.

- Power Transmission: Transfers energy from the engine to the working parts.

- Control Panel: Allows the operator to monitor and adjust settings.

Auxiliary Components

- Hydraulic System: Aids in the movement of parts and enhances efficiency.

- Chassis: Provides structural support and stability during operation.

- Wheels and Axles: Enable mobility and maneuverability across fields.

- Safety Features: Essential for protecting the operator and equipment.

By recognizing these vital components, operators can ensure their machinery runs smoothly and is well-maintained, ultimately leading to better agricultural outcomes.

Where to Find Replacement Parts

Locating suitable components for agricultural machinery can be crucial for maintaining efficiency and productivity. A variety of sources are available to ensure you can find the necessary items to keep your equipment running smoothly.

Online Retailers: Numerous websites specialize in agricultural machinery components. These platforms often provide detailed catalogs, allowing you to search by model and specifications, making it easier to find what you need.

Local Dealers: Visiting a local dealership can offer personalized service and immediate access to genuine components. Staff members are usually knowledgeable and can assist you in identifying the right parts for your machine.

Salvage Yards: For those looking for cost-effective solutions, salvage yards can be a valuable resource. They often have a variety of used components that are still in good condition, providing an economical alternative to brand-new items.

Manufacturer’s Website: The official website of the equipment manufacturer is an excellent starting point. Here, you can find technical specifications, recommendations, and sometimes even direct purchasing options for the necessary components.

Online Marketplaces: Platforms such as eBay and Amazon also feature listings from various sellers, offering a wide selection of components. Be sure to check seller ratings and reviews to ensure quality and reliability.

By exploring these options, you can find the right components to maintain your machinery effectively, ensuring its longevity and performance.

Understanding Baler Operation Mechanics

The mechanics behind compression equipment play a vital role in agricultural processes, enabling the efficient collection and bundling of various materials. Grasping how these machines function can significantly enhance operational efficacy and prolong equipment lifespan.

At the core of these devices are several key components that work together seamlessly. A basic understanding of their functions is essential for optimal usage:

- Feeding System: This section draws in loose materials, preparing them for processing.

- Compression Chamber: Here, the gathered materials are compacted into defined shapes, which is crucial for ease of handling and storage.

- Binding Mechanism: This component secures the compacted bundles, often using twine or netting to maintain shape during transport.

- Power Transmission: A series of belts and gears ensure that motion is effectively transferred from the engine to the various parts of the machine.

Understanding these elements provides insights into troubleshooting and maintenance, fostering better operational practices. Regular inspections of each component can prevent costly downtime and enhance productivity.

By familiarizing oneself with these mechanical principles, operators can ensure they are making the most of their equipment, adapting to various agricultural needs with confidence.

Tips for Effective Troubleshooting

When dealing with machinery issues, a systematic approach can significantly enhance the problem-solving process. By employing effective strategies, you can identify the root cause of the problem and implement the necessary solutions with greater confidence.

Here are some essential tips to guide you through the troubleshooting journey:

- Understand the System: Familiarize yourself with the machinery’s components and their functions. Knowing how each part interacts can help pinpoint the source of the issue.

- Refer to Manuals: Always consult the operation and maintenance manuals. These documents often contain valuable insights and troubleshooting steps specific to the equipment.

- Keep a Log: Document any issues encountered, along with the conditions under which they occurred. A detailed log can reveal patterns that may indicate underlying problems.

In addition to these foundational tips, consider the following techniques:

- Visual Inspection: Perform a thorough examination of the machine. Look for visible signs of wear, damage, or disconnection.

- Test Components: Use diagnostic tools to test individual parts. This can help isolate the malfunctioning component effectively.

- Seek Expertise: If the problem persists, do not hesitate to consult with professionals or experienced operators. Their insights can provide clarity and direction.

By following these strategies, you can enhance your troubleshooting skills, leading to quicker resolutions and reduced downtime.

Upgrading Your Baler Equipment

Enhancing your machinery can significantly improve efficiency and productivity in agricultural operations. By investing in modern components and technology, you can streamline processes, reduce downtime, and ultimately increase output. This section will explore various aspects of upgrading your equipment to ensure optimal performance.

Benefits of Modernization

Upgrading machinery offers numerous advantages, including better fuel efficiency, advanced automation features, and improved reliability. Modern equipment often incorporates innovative technology that can help in monitoring performance, reducing maintenance costs, and increasing overall effectiveness. These enhancements not only boost productivity but also contribute to sustainability efforts in farming practices.

Choosing the Right Components

Selecting the appropriate upgrades is crucial for maximizing the benefits of your machinery. Focus on components that align with your specific needs and operational goals. Research various manufacturers and options available in the market, considering factors such as compatibility, warranty, and user reviews. Investing in high-quality upgrades can lead to significant long-term savings and enhanced performance.

Safety Precautions During Repairs

When undertaking maintenance or repairs on machinery, prioritizing safety is essential. Proper precautions can prevent accidents and ensure a secure working environment. It is crucial to adhere to guidelines that promote well-being while working with mechanical equipment.

Essential Safety Guidelines

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and steel-toed boots.

- Ensure the machine is turned off and disconnected from any power source before starting repairs.

- Use tools that are in good condition and suitable for the task at hand.

- Keep the workspace clean and free of clutter to minimize hazards.

- Follow the manufacturer’s instructions and safety warnings when handling components.

Additional Precautions

- Inspect the area for potential hazards, such as loose objects or spills.

- Utilize lockout/tagout procedures to prevent accidental machine activation.

- Work with a partner when lifting heavy parts or performing complicated repairs.

- Be aware of your surroundings and communicate effectively with coworkers.

- Store tools and spare parts in designated locations to avoid confusion.

Cost Considerations for Baler Parts

When maintaining and operating agricultural machinery, understanding the financial aspects of component acquisition is crucial. The overall expense can vary significantly based on several factors, including brand, quality, and availability. This section delves into the key elements that influence the pricing of essential machine components.

Quality vs. Price

Investing in high-quality components often leads to enhanced durability and performance. While the initial outlay may be higher, the long-term savings from reduced maintenance and replacement frequency can justify the expense. Conversely, opting for lower-cost alternatives might appear appealing initially, but could result in increased operational costs over time.

Source and Availability

The supplier chosen for component procurement can greatly affect pricing. Authorized dealers might offer warranties and assurances of compatibility, but their prices may be elevated. Independent suppliers can provide more competitive rates, yet the risk of encountering subpar quality or incompatible items increases. Additionally, regional availability plays a role; in areas with limited suppliers, prices may rise due to demand and shipping costs.

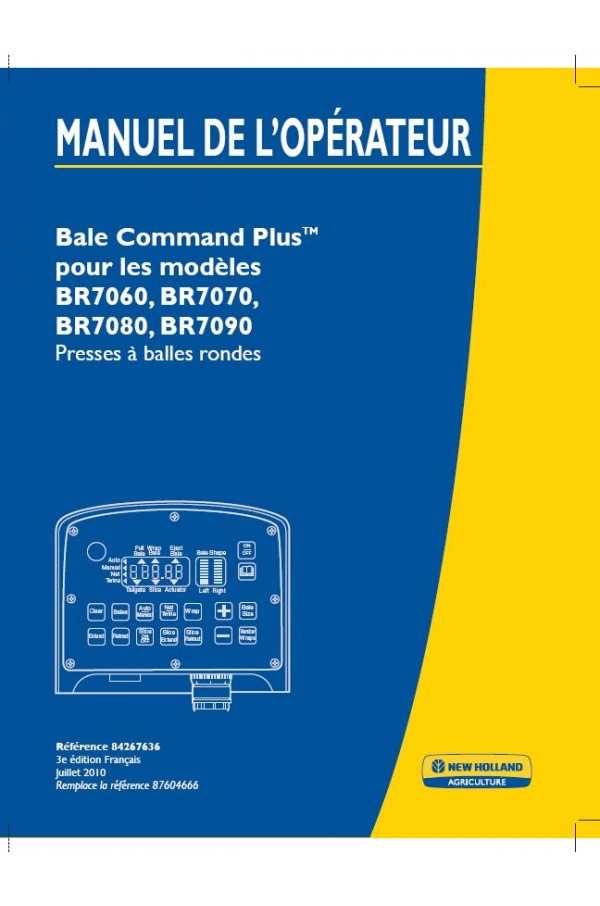

Comparing New Holland Models

When evaluating various agricultural machinery options, it’s essential to consider the distinct features and capabilities each model offers. Different iterations of equipment serve specific purposes, which can greatly influence productivity and efficiency in farming operations. By examining the attributes and functionalities of these models, operators can make informed choices that best suit their needs.

One popular model is renowned for its innovative technology that enhances user experience and operational performance. This variant boasts advanced automation systems, making it easier for farmers to achieve optimal results with minimal effort. Another version, while slightly older, is celebrated for its durability and straightforward mechanics, appealing to those who prioritize reliability over complex features.

Additionally, there are models designed with specialized applications in mind. For instance, certain versions are optimized for handling diverse crop types, allowing for versatility across different farming practices. Others focus on maximizing output efficiency, ensuring that operators can handle larger volumes of material without sacrificing quality.

Ultimately, the decision between these different machinery types should be guided by specific operational requirements, budget constraints, and personal preferences. Understanding the unique strengths of each model empowers farmers to choose the right equipment, enhancing their overall agricultural productivity.

Resources for Technical Support

Accessing reliable assistance is crucial for maintaining equipment efficiency and longevity. Various channels are available to provide the necessary guidance and resources for troubleshooting and repair needs. These resources can help users address common issues and enhance their understanding of machinery operation.

Here are some valuable resources for technical support:

| Resource Type | Description | Access Method |

|---|---|---|

| Manufacturer Website | Official site offering manuals, FAQs, and troubleshooting guides. | Online |

| User Forums | Community-driven platforms where users share experiences and solutions. | Online |

| Technical Helpline | Direct access to professionals for real-time assistance. | Phone |

| Service Centers | Authorized locations for in-person repairs and maintenance. | Physical Locations |

| Instructional Videos | Visual guides demonstrating repair techniques and operational tips. | Online Platforms |

Utilizing these resources can significantly improve problem-solving efficiency and ensure optimal performance of your machinery.