Kubota KX040 4 Parts Diagram Overview

In the world of compact machinery, having a clear understanding of your equipment is crucial for optimal performance and maintenance. This section aims to provide an in-depth exploration of the various components that make up a specific model of mini excavator, highlighting their functions and interrelationships.

By examining the individual elements, operators can gain insights into the design and engineering that contribute to the overall efficiency of the machine. Each section will detail key components, offering valuable information that can assist in troubleshooting and routine care.

Whether you are a seasoned operator or new to the field, familiarizing yourself with the intricate layout of your machinery will enhance your ability to manage tasks effectively. This guide serves as a resource to help you navigate the complexities of your equipment, ensuring it operates at peak capacity.

Kubota KX040 Overview

This machine is designed for efficiency and versatility, making it a reliable choice for various construction and landscaping tasks. Its robust construction ensures durability while providing the operator with a high level of control and precision.

Engine performance is a key feature, offering ample power for demanding jobs. The compact size allows for maneuverability in tight spaces, which is essential for urban projects. Additionally, the hydraulic system is engineered to enhance lifting capabilities, contributing to overall productivity.

Operators will appreciate the ergonomic design of the cabin, which focuses on comfort and ease of use. Intuitive controls and excellent visibility enhance operational efficiency, allowing for quick adaptations to changing worksite conditions. Overall, this model stands out for its balance of strength and agility, making it a preferred choice among professionals in the field.

Key Features of KX040

This compact excavator is designed for efficiency and versatility, making it an ideal choice for various construction tasks. Its powerful engine and advanced hydraulics enable operators to tackle challenging projects with ease, while its compact size ensures maneuverability in tight spaces.

Performance and Power

Equipped with a robust engine, this machine delivers impressive torque and horsepower, facilitating rapid digging and lifting operations. The hydraulic system enhances performance, allowing for smooth operation and precise control, even under heavy loads.

Operator Comfort and Control

The cab is ergonomically designed to provide maximum comfort, featuring intuitive controls that improve usability. With ample visibility and reduced noise levels, operators can work efficiently for extended periods without fatigue.

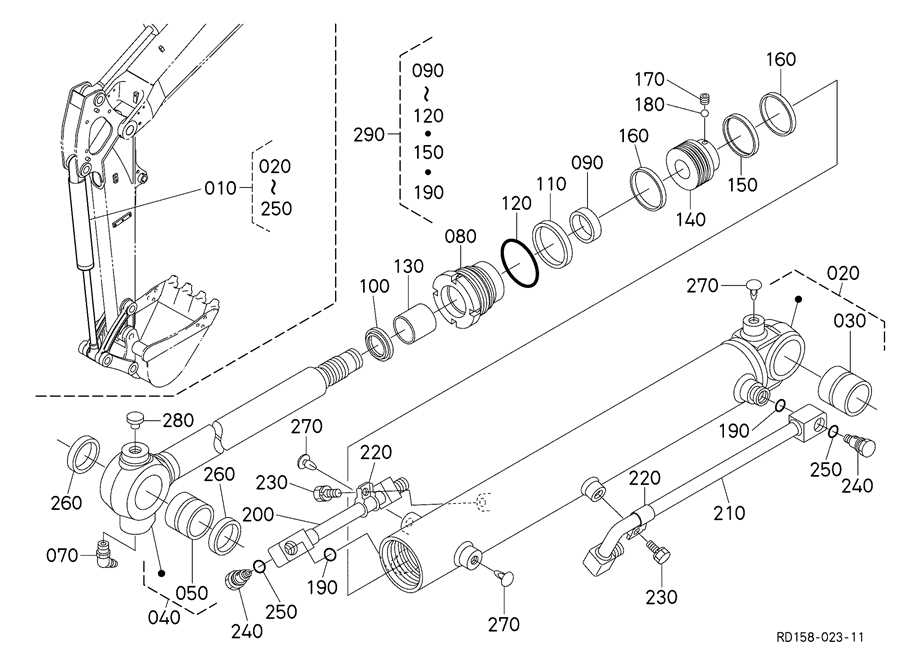

Understanding the Parts Diagram

Comprehending the schematic representation of machinery components is essential for effective maintenance and repair. Such illustrations serve as vital resources, offering a clear overview of the various elements that contribute to the overall functionality of the equipment.

These visual aids allow operators and technicians to quickly identify specific sections and their roles, facilitating efficient troubleshooting and replacement processes. Familiarity with the layout empowers users to delve into repairs with confidence, ultimately enhancing the longevity and performance of the machine.

Moreover, recognizing the interconnections between different components helps in understanding the mechanics at play. This insight can lead to more informed decisions during service and maintenance, ensuring that all elements function harmoniously for optimal results.

Main Components of the Excavator

Understanding the essential elements of an excavator is crucial for efficient operation and maintenance. Each component plays a significant role in the overall functionality, contributing to the machine’s versatility and power. Below are the primary parts that comprise this heavy equipment.

- Chassis: The sturdy frame that supports the entire structure, providing stability during operations.

- Boom: The long arm that extends outward, allowing for reaching and lifting materials at a distance.

- Stick: Also known as the arm, it connects the boom to the bucket, offering additional reach and maneuverability.

- Bucket: The attachment at the end of the stick, designed for digging, scooping, and moving various materials.

- Tracks: The undercarriage that provides mobility, allowing the machine to navigate different terrains with ease.

- Cab: The operator’s compartment, equipped with controls and visibility features for safe operation.

- Hydraulic System: A critical system that powers the movements of the boom, stick, and bucket, enabling precise operations.

These components work in unison to facilitate a range of tasks, from excavation to demolition. Understanding their functions helps in optimizing the use and care of the equipment.

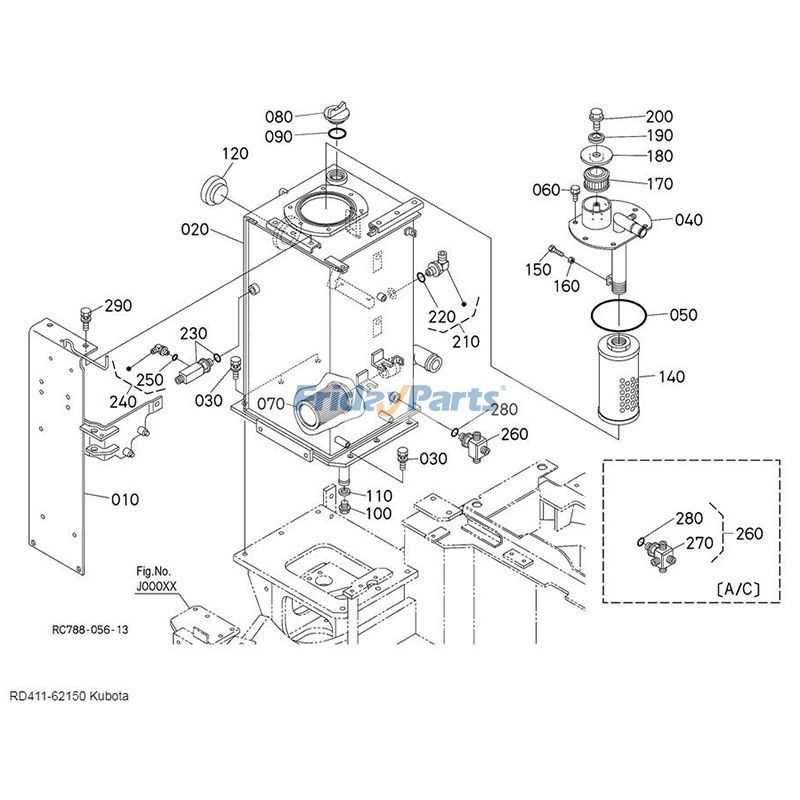

Hydraulic System Explained

The hydraulic system is a vital component in various machinery, utilizing fluid power to perform a multitude of tasks efficiently. By harnessing the properties of incompressible fluids, this system enables heavy lifting and precise control, making it essential for numerous applications in construction and agriculture.

How It Works

At its core, the hydraulic mechanism operates through a series of interconnected components, including pumps, cylinders, and valves. When fluid is pressurized by the pump, it is directed to the cylinders, which then translate this pressure into linear motion. This principle allows for the amplification of force, enabling operators to manipulate significant loads with relative ease.

Benefits of Hydraulic Systems

One of the ultimate advantages of hydraulic systems is their ability to generate substantial power in a compact form. This efficiency is complemented by their smooth operation and adaptability, allowing for precise control in various environments. Additionally, maintenance is often straightforward, contributing to the longevity and reliability of the equipment.

Engine Specifications and Details

This section focuses on the vital characteristics and performance metrics of the power unit in compact machinery. Understanding these specifications is essential for optimizing operation and maintenance, ensuring that the equipment performs at its best.

Key Engine Features

The engine is designed for efficiency and reliability, providing the necessary power for various applications. Key attributes include displacement, horsepower, torque, and fuel type, all of which contribute to the overall functionality of the machine.

| Specification | Details |

|---|---|

| Displacement | 1.8 L |

| Power Output | 40 HP |

| Torque | 100 Nm |

| Fuel Type | Diesel |

Performance Metrics

The operational efficiency and environmental impact of the engine are paramount. These metrics help in assessing fuel consumption rates and emissions, providing insights into sustainable practices while maintaining performance.

Operator’s Cabin Layout

The design of the operator’s cabin plays a crucial role in enhancing productivity and comfort during operation. An efficient arrangement ensures that the operator has easy access to controls and displays, creating an intuitive working environment. Ergonomics, visibility, and accessibility are key factors that contribute to an effective workspace.

Control Panel: Positioned within easy reach, the control panel typically houses various levers and buttons that govern the machine’s functions. An optimal layout minimizes unnecessary movement, allowing the operator to respond quickly to changing conditions.

Seating: The operator’s seat is designed for comfort and support, often featuring adjustable settings to accommodate different body types. Proper seating height and angle contribute to improved visibility and reduce fatigue during prolonged use.

Visibility: Large windows and strategically placed mirrors enhance visibility, allowing the operator to monitor surroundings effectively. A clear line of sight is vital for safe operation, especially in tight or crowded spaces.

Storage Solutions: Integrated storage compartments provide convenient access to tools and personal items. Well-organized storage helps maintain a tidy workspace, which is essential for safety and efficiency.

Climate Control: Many cabins are equipped with climate control features to ensure a comfortable working temperature, regardless of external weather conditions. This aspect is essential for maintaining focus and productivity throughout the day.

Overall, a thoughtfully designed operator’s cabin enhances the user experience, allowing for more efficient and safer operation of the equipment.

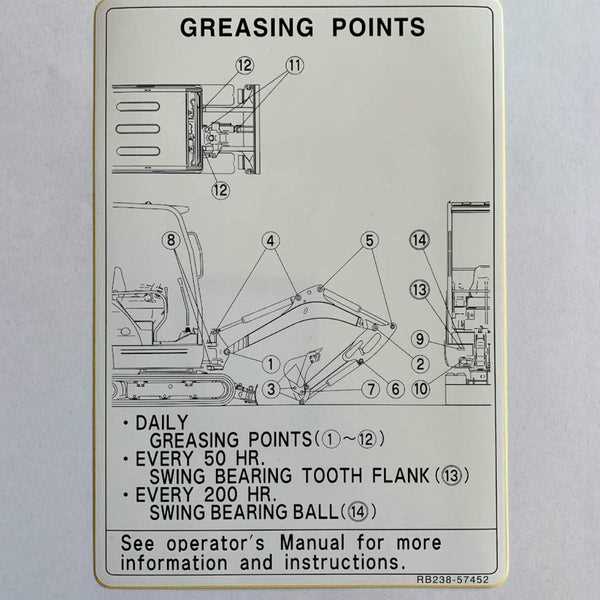

Maintenance Tips for KX040

Proper upkeep is essential for ensuring the longevity and efficiency of your machinery. Regular maintenance not only enhances performance but also minimizes the risk of unexpected breakdowns. Here are some crucial practices to keep in mind.

Routine Checks

- Inspect fluid levels regularly, including oil and coolant.

- Check filters for cleanliness and replace them as necessary.

- Examine the track and undercarriage for wear and tear.

Seasonal Maintenance

- In winter, ensure the battery is charged and connections are secure.

- In summer, keep an eye on engine temperatures to avoid overheating.

- Clean the air intake to prevent dust accumulation.

Implementing these tips will ultimately help maintain peak performance and extend the lifespan of your equipment.

Common Repairs and Troubleshooting

Understanding common issues and repairs can greatly enhance the longevity and performance of your machinery. Regular maintenance and timely interventions are key to avoiding costly breakdowns and ensuring efficient operation.

Frequent Issues

Some typical problems include hydraulic fluid leaks, engine overheating, and electrical system failures. Identifying these issues early can prevent further damage and save time and money. Regular inspections and monitoring of fluid levels are essential practices for any operator.

Troubleshooting Techniques

When facing a malfunction, start by checking the basic systems: fluid levels, filters, and electrical connections. Documentation is crucial; refer to the user manual for specific error codes and recommended solutions. If a problem persists, consider consulting a professional for a detailed analysis.

Aftermarket Parts and Accessories

Exploring the world of alternative components and enhancements offers users a chance to optimize their machinery’s performance and expand its capabilities. These products often present a cost-effective solution while maintaining quality and reliability, making them an attractive option for many operators.

Benefits of Alternative Components

Utilizing aftermarket offerings can lead to improved efficiency and increased durability. Many of these options are designed to meet or exceed original specifications, ensuring compatibility and performance that suits individual needs. Furthermore, operators may discover unique features that enhance functionality beyond standard offerings.

Choosing the Right Accessories

When selecting enhancements, it is crucial to consider factors such as compatibility, quality, and the specific requirements of your machine. Research and consultation with industry experts can help in identifying the most suitable additions to maximize productivity and extend the life of your equipment.

Safety Features and Guidelines

Ensuring safety during operation is crucial in any machinery usage. Implementing robust safety measures and following established guidelines can significantly reduce the risk of accidents and injuries. This section focuses on essential safety elements that should be adhered to while operating heavy equipment.

Key Safety Features

- Operator Presence Systems: These mechanisms ensure that the machine operates only when the operator is securely positioned within the designated area.

- Stability Control: Systems designed to monitor the machine’s balance, preventing tipping or rolling over during operation.

- Emergency Stop Mechanisms: Easily accessible controls that immediately halt all operations in case of an emergency.

- Protective Guards: Physical barriers that shield the operator from moving parts, reducing the risk of injury.

Guidelines for Safe Operation

- Always read and understand the operator’s manual before using the machinery.

- Conduct a thorough pre-operation inspection to identify any potential issues.

- Wear appropriate personal protective equipment (PPE), including helmets, gloves, and safety glasses.

- Maintain a clear work area free of obstacles and hazards.

- Ensure all bystanders are at a safe distance during operation.

- Be aware of your surroundings and any overhead hazards.

By adhering to these safety features and guidelines, operators can help create a safer working environment, minimizing risks associated with heavy machinery operation.

Comparing KX040 to Similar Models

In the competitive landscape of compact excavators, understanding the distinctions between various models can greatly assist in making an informed decision. This segment explores how one particular machine stands out in comparison to its counterparts, highlighting both strengths and weaknesses.

When examining this excavator alongside similar units, several key aspects come into focus:

- Performance: Look at engine power, digging depth, and lift capacity.

- Fuel Efficiency: Assess how well each machine manages fuel consumption during operations.

- Size and Maneuverability: Evaluate the dimensions and weight, which influence mobility in tight spaces.

- Operator Comfort: Consider cabin design, control accessibility, and overall ergonomics.

Here are some models for comparison:

- Model A: Known for its compact size and exceptional fuel efficiency.

- Model B: Offers superior digging capabilities but at a higher operational cost.

- Model C: Balances performance and comfort, appealing to operators seeking a versatile machine.

Ultimately, choosing the right equipment requires evaluating specific needs and operational demands, making side-by-side comparisons essential in the selection process.

User Reviews and Feedback

Gathering insights from users provides a comprehensive understanding of equipment performance and satisfaction. This section highlights the experiences of operators, revealing both strengths and areas for improvement.

Positive Experiences: Many users praise the reliability and efficiency of their machinery, noting its ability to handle various tasks with ease. The comfort of operation and intuitive controls often receive commendation, enhancing productivity on the job site.

Areas for Improvement: Some feedback points to the need for better support and availability of accessories. Users have expressed a desire for enhanced documentation and clearer maintenance guidelines to optimize their experience further.

Overall, user reviews serve as a valuable resource for potential buyers, offering insights that can guide informed decisions and foster a better understanding of the equipment’s capabilities.