Understanding the Ridgid Tile Saw Parts Diagram for Optimal Repairs

When tackling projects that require precision cutting, it’s essential to familiarize yourself with the essential elements that contribute to the overall functionality of your equipment. Knowing the intricate details of these elements can significantly enhance your experience and efficiency in various tasks.

In this section, we will explore the various components that make up your cutting instrument. Each part plays a crucial role in ensuring optimal performance and longevity, so understanding their functions will allow you to maintain and troubleshoot effectively.

Additionally, we will delve into the significance of recognizing how these elements interact with one another. This knowledge can empower you to make informed decisions regarding repairs, upgrades, and replacements, ultimately leading to a more productive workflow.

Understanding Ridgid Tile Saws

This section explores essential machinery designed for precision cutting in construction and remodeling projects. Users benefit from understanding the components and their functions to enhance performance and durability. With the right insights, operators can achieve optimal results in their tasks.

Key Components

Familiarity with various elements of the equipment is crucial for effective operation. Each part plays a significant role in the overall functionality, contributing to the efficiency of the cutting process.

| Component | Function |

|---|---|

| Motor | Powers the cutting action, providing necessary torque. |

| Blade | Responsible for executing precise cuts through materials. |

| Table | Stabilizes the material during the cutting process. |

| Water Tray | Minimizes dust and cools the blade for extended use. |

Maintenance Tips

Regular upkeep ensures longevity and optimal performance. Key practices include checking components for wear, cleaning debris, and ensuring proper lubrication. By adhering to maintenance schedules, users can prevent unexpected failures and prolong the lifespan of the machinery.

Key Components of Tile Saws

Understanding the essential elements of cutting machines is crucial for both effective usage and maintenance. Each component plays a significant role in the overall functionality, ensuring precise and efficient performance during various projects. Familiarity with these parts not only aids in optimal operation but also assists in troubleshooting and repairs when necessary.

Main Elements

Among the vital components, the blade holder, motor, and water reservoir stand out as integral to the cutting process. The blade holder secures the cutting instrument in place, allowing for stability during operation. The motor powers the cutting action, while the water reservoir provides lubrication and cooling, minimizing dust and heat generation.

| Component | Function |

|---|---|

| Blade Holder | Secures the cutting blade for stability and accuracy. |

| Motor | Powers the cutting mechanism for effective operation. |

| Water Reservoir | Supplies water for cooling and dust reduction. |

| Base | Provides support and stability during cutting tasks. |

| Fence | Guides materials for straight and accurate cuts. |

By comprehending these key components, users can ensure a smoother cutting experience and prolong the life of their equipment.

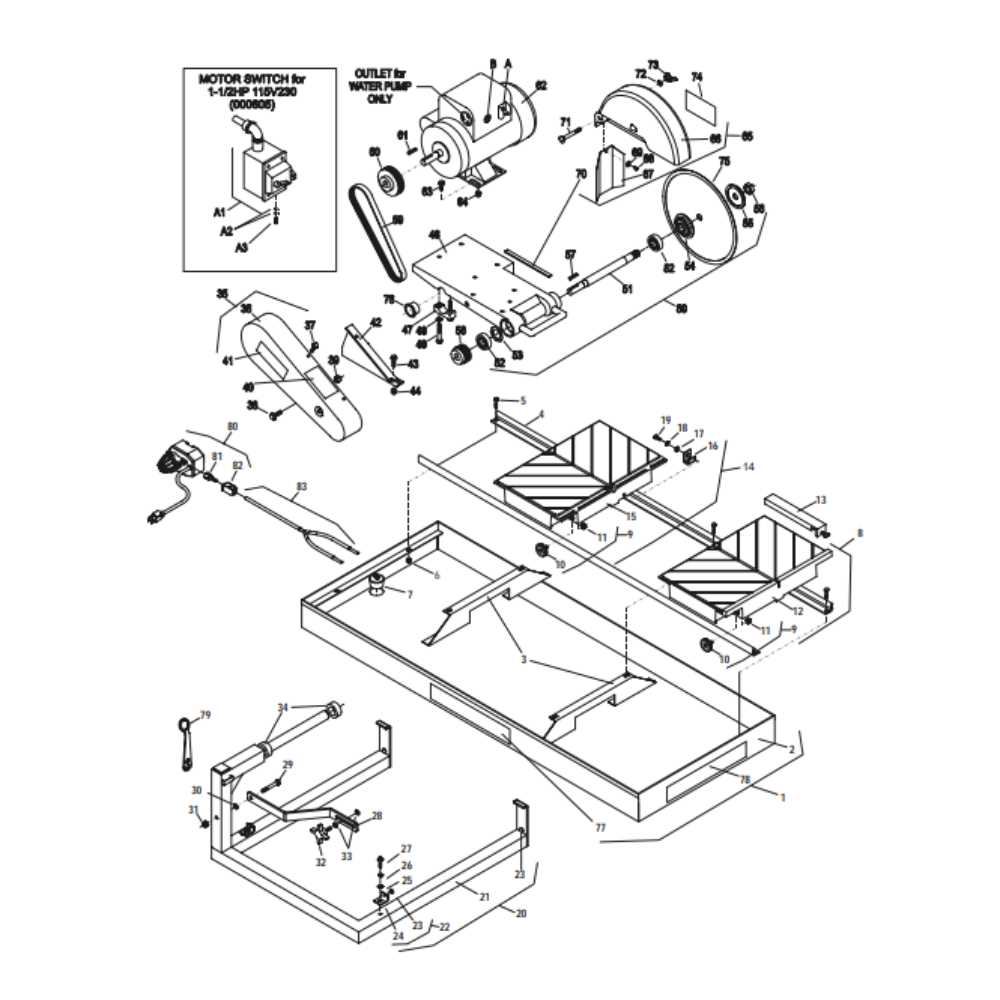

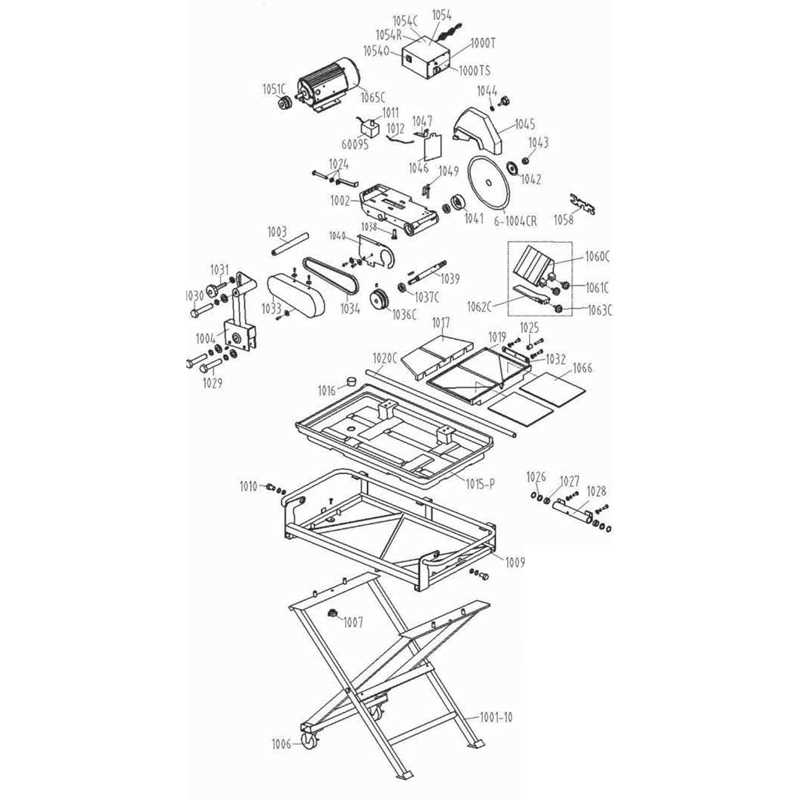

Importance of Accurate Parts Diagrams

Having precise illustrations of components is crucial for effective maintenance and repair processes. These visual guides enable users to identify individual pieces, facilitating a smoother workflow and minimizing errors during assembly or disassembly.

Enhancing Understanding

Clear representations of each component significantly enhance comprehension. Users can quickly locate necessary elements and understand how they interact within the entire system, leading to more efficient troubleshooting and repair.

Reducing Downtime

When users can easily reference accurate illustrations, the time spent searching for or identifying components decreases. This efficiency ultimately leads to reduced downtime, allowing for faster project completion and improved productivity.

| Benefits | Impact |

|---|---|

| Clarity | Improved identification of components |

| Efficiency | Quicker repairs and assembly |

| Accuracy | Minimized risk of errors |

Common Issues with Ridgid Saws

When working with cutting tools, various challenges may arise that can hinder performance and efficiency. Understanding these common problems can help users troubleshoot effectively and maintain optimal functionality.

1. Overheating: A frequent issue is excessive heat buildup during operation. This can lead to decreased performance and may damage components. To prevent overheating, ensure proper ventilation and avoid prolonged use without breaks.

2. Blade Dullness: Another prevalent concern is the dulling of blades. A worn-out cutting edge can cause uneven cuts and require more effort. Regular inspection and timely replacement are essential to maintain precision.

3. Misalignment: Tools can sometimes become misaligned, resulting in inaccurate cuts. Regularly checking and adjusting alignment can significantly enhance cutting accuracy and extend the lifespan of the equipment.

4. Electrical Issues: Electrical failures may occur, manifesting as power loss or erratic functioning. Checking connections, ensuring proper voltage, and routine maintenance of the electrical system can help mitigate these problems.

5. Vibration: Excessive vibration during operation can indicate mechanical issues or improper setup. Ensuring the tool is securely mounted and balanced can reduce vibration and improve overall user experience.

By being aware of these common issues, users can take proactive measures to ensure their tools remain in top condition, facilitating efficient and effective cutting tasks.

How to Read Parts Diagrams

Understanding technical illustrations can significantly enhance your ability to identify and replace components in various equipment. These visual aids offer a structured representation of different elements, facilitating easier maintenance and repair. Knowing how to interpret these images is essential for efficient troubleshooting.

When approaching these illustrations, follow these key steps:

| Step | Description |

|---|---|

| 1 | Identify the sections of the image, often organized into categories. |

| 2 | Locate the reference numbers or letters that correspond to specific components. |

| 3 | Cross-reference these identifiers with the accompanying list for detailed information. |

| 4 | Take note of any symbols that indicate functionality or assembly direction. |

By mastering these techniques, you can delve deeper into the workings of your equipment, ultimately streamlining repairs and enhancing performance.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular attention and care. Proper maintenance practices not only enhance performance but also extend the lifespan of the machinery, allowing it to operate at its best for years to come.

Regular Cleaning

Keeping your tools clean is essential for optimal performance. Dust and debris can accumulate and affect functionality. Follow these cleaning tips:

- Wipe down surfaces after each use to remove any residue.

- Use a soft brush or cloth to clean hard-to-reach areas.

- Inspect for any buildup around moving parts and remove it promptly.

Periodic Inspections

Routine checks can help identify potential issues before they become significant problems. Consider the following:

- Examine all components for wear and tear regularly.

- Check electrical connections for fraying or damage.

- Look for signs of rust or corrosion and address them immediately.

Replacing Worn-Out Parts

Maintaining the efficiency of your cutting tool requires regular attention to its components. Over time, various elements can become worn or damaged, leading to decreased performance. Understanding when and how to replace these elements is crucial for optimal functionality and safety.

| Component | Signs of Wear | Replacement Tips |

|---|---|---|

| Blade | Dullness, chipping | Ensure proper size and compatibility |

| Motor | Unusual noises, overheating | Check specifications before purchasing |

| Base | Cracks, instability | Use original manufacturer replacements |

| Water System | Leaks, poor flow | Inspect hoses and seals regularly |

By identifying and replacing worn components promptly, you can ensure that your equipment operates at its ultimate efficiency, prolonging its lifespan and enhancing your projects.

Where to Buy Replacement Components

Finding suitable components for your tools is essential to maintain their efficiency and longevity. Several reliable sources can provide high-quality replacements, ensuring you keep your equipment in optimal condition.

- Official Manufacturers: Always a trustworthy option, as they offer components specifically designed for your tools.

- Online Retailers: Websites like Amazon or eBay often have a vast selection of components at competitive prices.

- Local Hardware Stores: Check your nearby shops, as they may stock essential parts or can order them for you.

- Specialized Tool Suppliers: Consider retailers that focus solely on tools and their components for a wider range of options.

By exploring these avenues, you can ensure you find the ultimate replacements for your needs.

DIY Repairs for Tile Saws

Maintaining your cutting tool can significantly extend its lifespan and enhance performance. By understanding common issues and their solutions, you can tackle repairs yourself, saving time and money. This section explores various methods to diagnose and fix common malfunctions, empowering you to get back to your projects swiftly.

Identifying Common Issues

First, recognize the symptoms of wear or malfunction. Unusual noises, vibrations, or inconsistent cutting may indicate that something is amiss. Regular inspection can help pinpoint problems before they escalate.

Essential Tools

Gather a basic toolkit for repairs. Screwdrivers, wrenches, and replacement components will be essential for addressing most issues. Always have safety gear on hand to protect yourself during repairs.

Replacing Worn Components

Common replacements include blades, bearings, and belts. Consult your manual for specifications, and ensure that you purchase compatible items for seamless installation. Following manufacturer guidelines will help avoid potential complications.

Routine Maintenance Tips

Regular cleaning and lubrication can prevent many issues. Keep the cutting area free from debris, and check for any signs of rust or wear. A proactive approach will ensure your equipment remains in optimal condition.

By taking the initiative for DIY repairs, you not only save on service costs but also gain valuable skills that enhance your overall project experience.

Comparing Ridgid to Other Brands

When evaluating different tools for cutting and shaping materials, it’s essential to consider the unique features and advantages offered by each manufacturer. While some brands may excel in durability, others may shine in precision or ease of use. This comparison provides insights into the strengths and weaknesses of various options available on the market.

One notable brand stands out for its innovative technology and user-friendly design, appealing to both professionals and DIY enthusiasts. Users often appreciate its intuitive controls and reliable performance, making it a popular choice for a wide range of projects. In contrast, another manufacturer is renowned for its robust construction, ensuring longevity even under heavy usage. However, this brand may sacrifice some portability, making it less ideal for those who frequently move their equipment.

Price is also a significant factor when comparing these tools. While one option may offer a more budget-friendly solution, it might compromise on certain features that are critical for professional use. On the other hand, premium brands often justify their higher price points with advanced features and exceptional build quality, catering to those who require top-tier performance.

Ultimately, the best choice depends on the specific needs of the user, whether they prioritize cost, performance, or additional features. By carefully assessing the offerings from different manufacturers, individuals can make informed decisions that align with their project requirements.

Ultimate Guide to Tool Safety

Ensuring safety while using power equipment is crucial for both novice and experienced users. This guide aims to highlight essential precautions and practices that can significantly reduce the risk of accidents and injuries in the workshop. By understanding the common hazards and implementing safety measures, operators can maintain a secure working environment.

Essential Safety Gear

Wearing appropriate personal protective equipment (PPE) is a fundamental aspect of safe operation. Always use safety glasses to shield your eyes from debris and dust. A dust mask can prevent inhalation of harmful particles, while ear protection is advisable when working with loud machinery. Additionally, sturdy gloves and non-slip footwear enhance grip and protect against cuts.

Best Practices During Operation

Before starting any equipment, it is vital to read the manufacturer’s instructions thoroughly. Always inspect the machine for any signs of damage or wear. Ensure that all safety features are functioning properly. When in use, maintain a clear workspace to avoid tripping hazards, and never bypass safety guards. Stay focused and avoid distractions to ensure optimal control over the equipment. Following these guidelines will help create a safer working environment.