Complete Guide to International 354 Tractor Parts Diagram

The intricate workings of agricultural machinery play a crucial role in enhancing productivity on farms. These robust machines are designed to withstand various conditions while delivering optimal performance. A comprehensive exploration of their components can provide valuable insights into maintenance and functionality.

When analyzing the essential elements of such equipment, it becomes evident that each part serves a unique purpose. Understanding how these components interact can lead to improved efficiency and longevity of the machinery. This knowledge empowers operators to make informed decisions regarding repairs and upgrades.

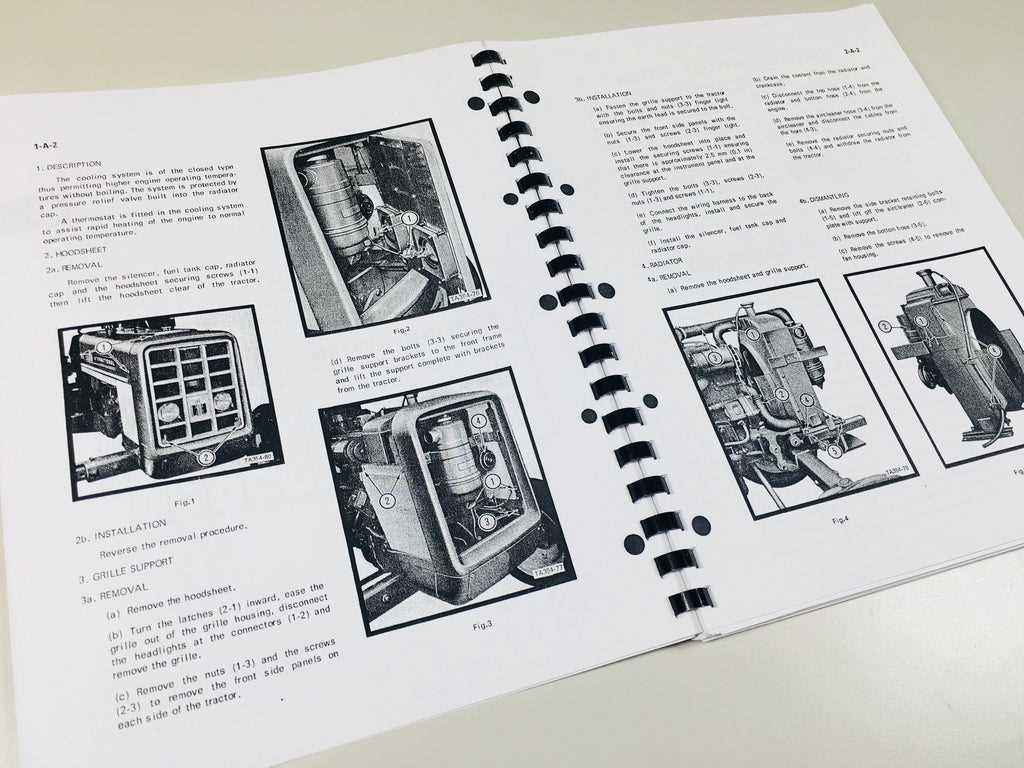

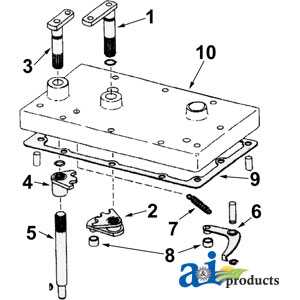

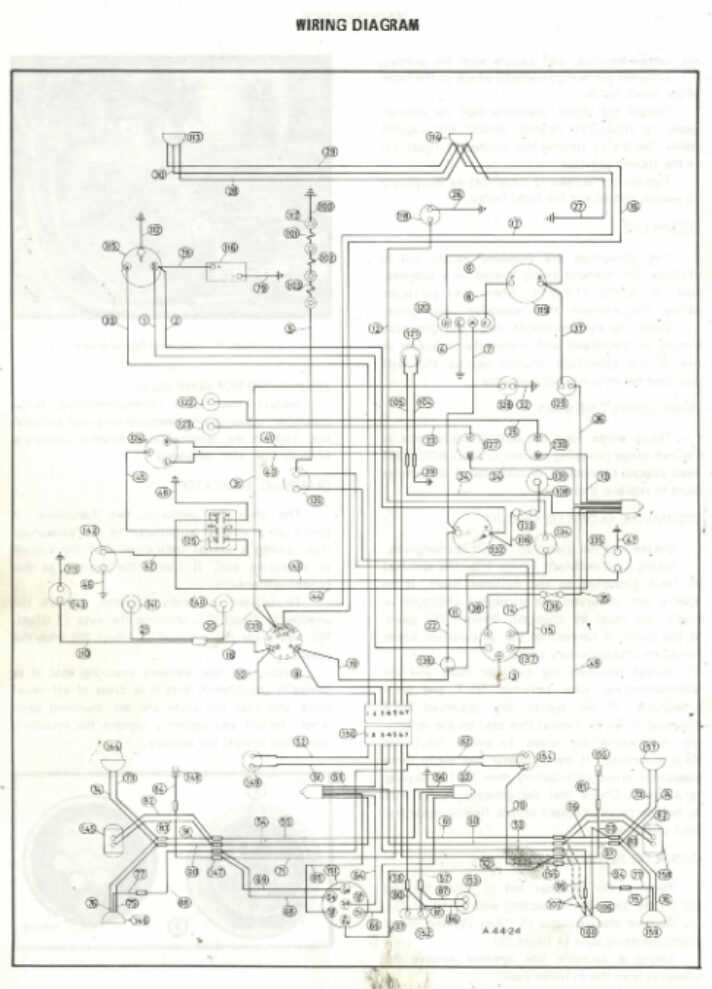

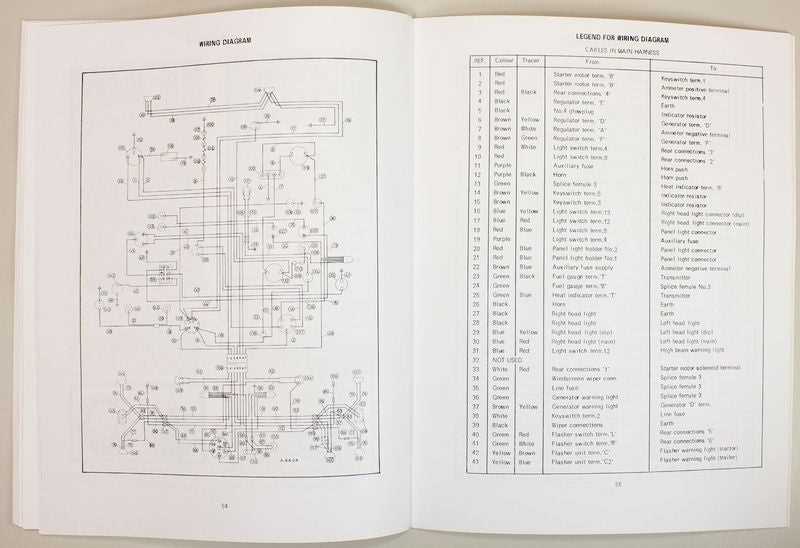

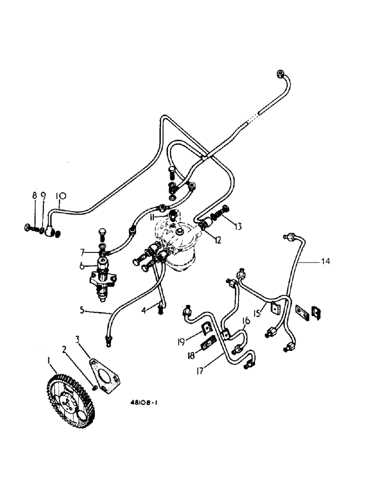

Additionally, a visual representation of these components can serve as a beneficial guide for both novice and experienced users. By delving into detailed illustrations, individuals can identify specific elements, facilitating a deeper appreciation of the machine’s overall design and capabilities. Ultimately, this understanding enhances operational effectiveness and fosters a culture of proactive maintenance.

Understanding the International 354 Tractor

Exploring the complexities of a specific agricultural vehicle reveals its significance in enhancing productivity and efficiency in farming practices. Recognizing the key components and their functions is essential for proper maintenance and operation, ensuring longevity and optimal performance.

Key Features

- Robust engine design that delivers reliable power.

- Efficient hydraulic system for improved performance.

- Comfortable operator platform for enhanced usability.

- Versatile attachment options for diverse agricultural tasks.

Maintenance Considerations

- Regular oil changes to ensure engine health.

- Routine inspection of hydraulic fluid levels.

- Monitoring tire pressure for stability and traction.

- Cleaning and replacing air filters to maintain air quality.

Understanding these aspects not only aids in effective utilization but also fosters a deeper appreciation for the engineering behind agricultural machinery.

Key Features of the International 354

This section explores the distinctive characteristics that set this machine apart in its field. Its design integrates functionality and efficiency, making it a favored choice among users.

- Powerful Engine: The robust engine ensures optimal performance, delivering substantial horsepower for various tasks.

- Versatile Attachments: Compatibility with a range of tools enhances its utility across different applications.

- Compact Size: The compact dimensions allow for maneuverability in tight spaces, ideal for smaller operations.

- User-Friendly Controls: Intuitive controls facilitate ease of operation, reducing the learning curve for new users.

- Durable Build: Constructed with high-quality materials, it offers longevity and resistance to wear and tear.

These features collectively contribute to its reputation as a reliable and efficient machine for various agricultural and industrial tasks.

Common Uses in Agriculture

In the agricultural sector, powerful machines play a crucial role in enhancing productivity and efficiency. These vehicles are versatile tools that enable farmers to carry out various tasks essential for crop cultivation and livestock management.

Field Preparation: One of the primary applications of these machines is in preparing land for planting. They are equipped to plow, till, and cultivate soil, ensuring optimal conditions for seed growth.

Harvesting: During harvest season, these machines streamline the process by efficiently gathering crops, significantly reducing labor costs and time. Their design allows for effective transportation of harvested materials from fields to storage areas.

Transportation: Additionally, they are invaluable for transporting heavy loads around the farm, whether it’s feed, fertilizers, or harvested goods. This mobility contributes to smoother operations and overall farm management.

Pest Control: Many farmers utilize these vehicles for spraying pesticides and fertilizers, ensuring that crops receive necessary treatments in a timely manner. This capability aids in maintaining plant health and maximizing yields.

Overall, these machines are indispensable assets that enable agricultural practices to evolve, adapt, and thrive in a constantly changing environment.

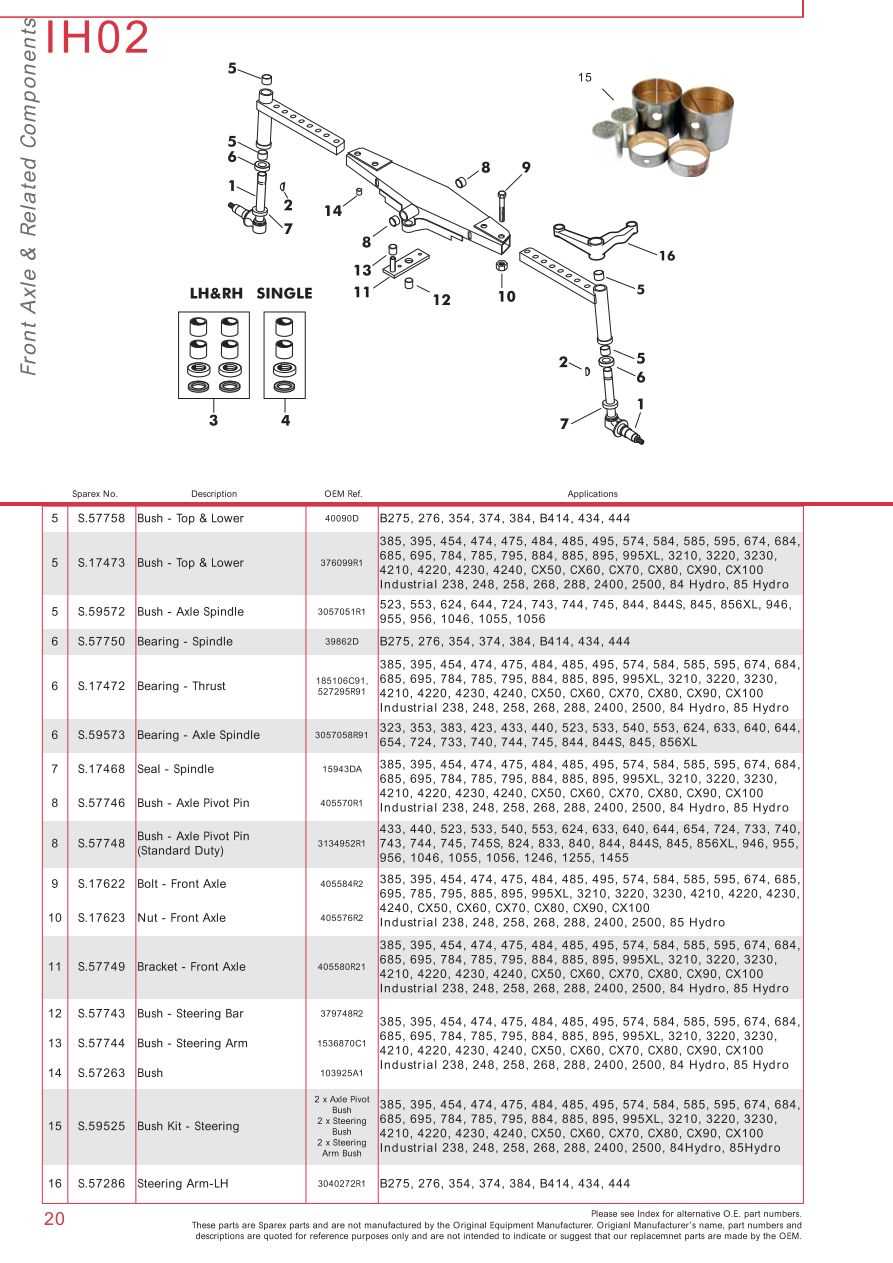

Importance of Parts Diagrams

Understanding the layout and functionality of various components is crucial for efficient maintenance and repair. Visual representations provide clarity, enabling users to identify, troubleshoot, and replace essential elements effectively.

- Enhances comprehension of complex machinery.

- Facilitates quick identification of needed components.

- Streamlines repair processes by offering a clear reference.

- Reduces errors in reassembly and maintenance tasks.

Ultimately, these illustrations serve as invaluable resources, empowering operators and technicians to ensure optimal performance and longevity of their equipment.

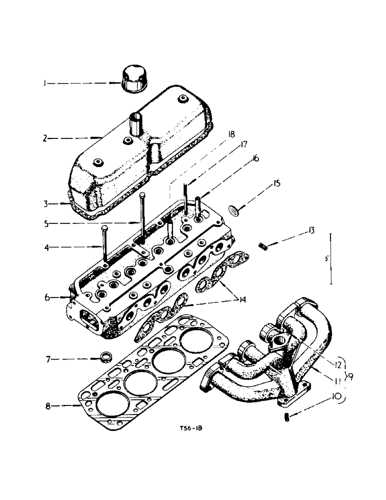

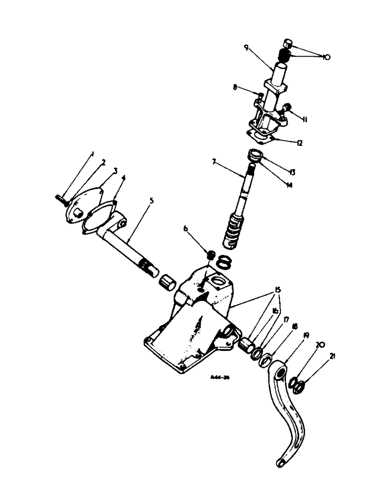

Identifying Major Components

Understanding the key elements of agricultural machinery is essential for effective maintenance and operation. Each unit comprises various sections that contribute to its overall functionality. Familiarity with these components not only aids in troubleshooting but also enhances performance through informed repairs and replacements.

Essential Elements Overview

Several primary sections play crucial roles in ensuring optimal operation. Recognizing these parts will empower users to make informed decisions about maintenance and upgrades.

| Component | Description |

|---|---|

| Engine | The powerhouse, providing the necessary energy for movement and operation. |

| Transmission | Facilitates the transfer of power from the engine to the wheels. |

| Hydraulics | Controls various functions, including lifting and steering mechanisms. |

| Chassis | The structural framework supporting all other components. |

| Electrical System | Enables ignition, lighting, and other electronic functionalities. |

Importance of Component Awareness

Recognizing and understanding these significant elements ensures proper functionality and longevity of the machinery. This knowledge is the foundation for efficient agricultural practices and maximizes productivity in the field.

Maintenance Tips for Longevity

Ensuring the durability and efficient operation of machinery requires regular upkeep and attention. Proper maintenance not only extends the lifespan of equipment but also enhances performance, leading to greater productivity. Implementing a systematic approach to care can prevent costly repairs and downtime.

Here are some essential practices to consider:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 100 hours of use | Replace old oil to ensure smooth engine operation and prevent wear. |

| Filter Replacement | Every 200 hours of use | Change air and fuel filters to maintain optimal performance and efficiency. |

| Tire Inspection | Monthly | Check for wear and proper inflation to ensure safety and performance. |

| Battery Maintenance | Every 6 months | Inspect connections and clean terminals to prevent electrical issues. |

| Greasing | Weekly | Apply grease to all moving parts to reduce friction and wear. |

Following these guidelines will help maintain optimal functionality and prolong the life of your equipment, allowing you to achieve your operational goals efficiently.

Where to Find Replacement Parts

Locating suitable components for your machinery can be a straightforward process when you know where to look. Numerous resources are available, ranging from specialized retailers to online marketplaces. Each option offers unique benefits, ensuring you can find what you need efficiently and effectively.

Here are some reliable sources to consider:

| Source | Description |

|---|---|

| Authorized Dealers | Official distributors provide genuine components, often ensuring compatibility and quality. |

| Online Marketplaces | Platforms like eBay and Amazon offer a wide range of options from various sellers, often at competitive prices. |

| Local Salvage Yards | Used parts can be sourced from salvage yards, which can save money while still providing usable items. |

| Manufacturers’ Websites | Visiting the manufacturer’s site can provide information on available replacements and sometimes direct purchase options. |

| Forums and Community Groups | Online communities can be a treasure trove of information, often sharing sources and recommendations for quality suppliers. |

By exploring these avenues, you can ensure that your equipment remains in optimal condition without unnecessary delays or expenses.

Common Issues and Troubleshooting

When dealing with agricultural machinery, various challenges can arise that impact performance and efficiency. Identifying these common problems early can save time and resources, ensuring smooth operation. Here, we explore frequent issues and practical solutions to keep your equipment running optimally.

Frequent Problems

| Issue | Description | Possible Solution |

|---|---|---|

| Overheating | Engine temperature rises excessively during operation. | Check coolant levels and inspect radiator for blockages. |

| Poor Starting | Engine struggles to start or does not start at all. | Examine the battery and ignition system for faults. |

| Unusual Noises | Strange sounds coming from the engine or machinery. | Inspect belts, gears, and lubricants for wear or damage. |

Preventive Measures

Regular maintenance is crucial for preventing issues. Keep a consistent schedule for oil changes, filter replacements, and inspections to extend the life of your machinery. Additionally, always consult the manufacturer’s guidelines for specific recommendations.

Benefits of Original Equipment Parts

Utilizing genuine components ensures optimal performance and longevity for your machinery. These products are designed to meet the exact specifications of the equipment, providing reliability and efficiency that generic alternatives often lack.

One significant advantage of original components is the assurance of quality. When you choose authentic products, you are investing in durability and performance, which can lead to cost savings in the long run. Below is a comparison of benefits:

| Benefit | Original Components | Aftermarket Alternatives |

|---|---|---|

| Quality Assurance | High | Variable |

| Performance | Optimal | Often Compromised |

| Longevity | Extended | Shorter Lifespan |

| Warranty | Comprehensive | Limited |

In conclusion, choosing genuine components ultimately enhances the functionality and reliability of your equipment, ensuring it operates at peak efficiency for years to come.

Aftermarket Options Overview

When seeking enhancements for agricultural machinery, the aftermarket sector offers a variety of alternatives that can improve performance and extend the lifespan of your equipment. These options cater to various needs, from routine maintenance to specialized upgrades.

Benefits of Aftermarket Solutions

- Cost-effectiveness: Often more affordable than original manufacturer products.

- Variety: A broader selection allows for tailored solutions to specific requirements.

- Availability: Easier access and quicker delivery times.

Types of Aftermarket Offerings

- Maintenance items: Filters, belts, and oils.

- Performance upgrades: Enhanced engines, transmissions, and hydraulic systems.

- Accessories: Cab enhancements, lighting options, and more.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repairs. These illustrations provide a comprehensive overview of each element, showcasing how they interconnect and function within a larger system. Familiarity with these visuals can greatly enhance your ability to identify, source, and replace necessary items.

When examining a visual representation, focus on the following aspects:

| Aspect | Description |

|---|---|

| Symbols | Different shapes and icons represent various components, such as bolts, gears, and hoses. |

| Labels | Each item is usually annotated with a reference number or name, aiding in identification. |

| Connections | Lines or arrows may indicate how elements interact, showing assembly order or flow of operation. |

| Scale | Pay attention to the size ratio; some visuals may not be to scale, impacting perception of dimensions. |

| Exploded Views | These provide a 3D perspective, illustrating how components fit together, which is helpful for assembly or disassembly. |

By becoming proficient in interpreting these illustrations, you can streamline your repair processes and ensure that you acquire the correct components for your machinery. This skill not only saves time but also reduces the likelihood of errors in sourcing and installation.

Integrating Diagrams into Repairs

Incorporating visual representations into repair processes enhances efficiency and accuracy. These illustrations serve as invaluable tools, guiding technicians through complex tasks while ensuring that every component is properly addressed. Utilizing such resources can significantly reduce the likelihood of errors and streamline maintenance procedures.

Benefits of Visual Aids

Visual aids provide clarity, enabling users to quickly identify components and their functions. They also facilitate better understanding of assembly and disassembly processes, ultimately leading to more effective repairs.

Practical Application

| Task | Visual Aid | Outcome |

|---|---|---|

| Identifying Components | Illustration of Layout | Increased Accuracy |

| Assembly Guidance | Step-by-Step Diagram | Time Efficiency |

| Maintenance Check | Component Breakdown | Improved Inspection |

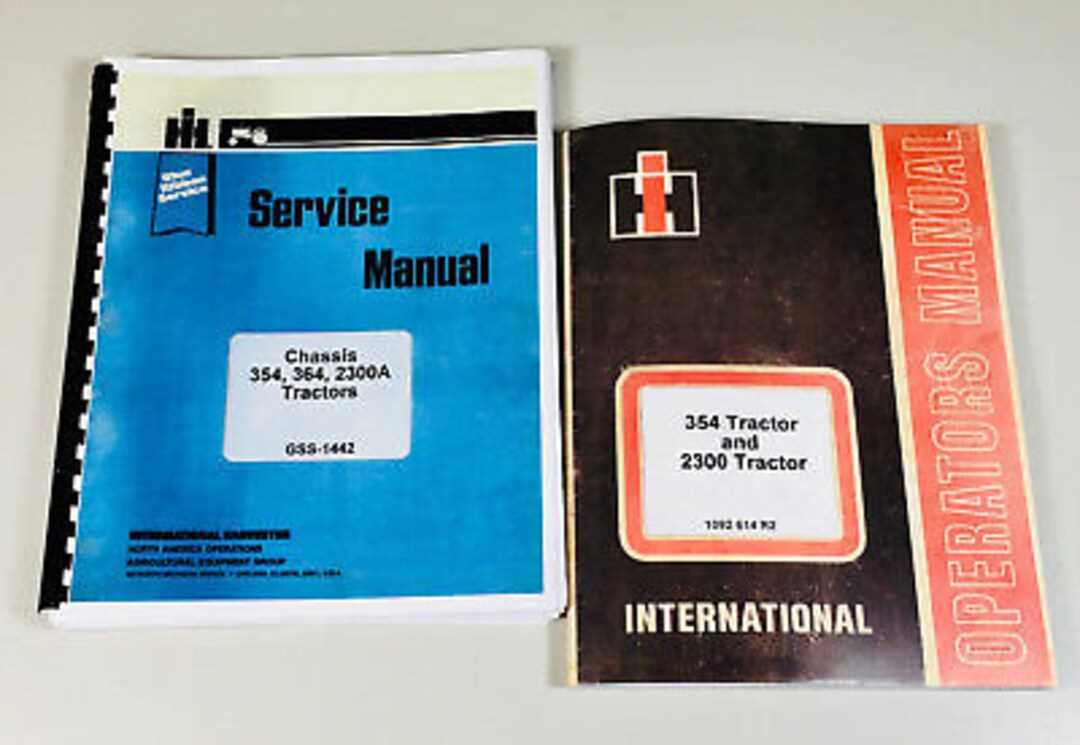

Resources for Further Learning

Expanding your knowledge about machinery maintenance and repair can significantly enhance your skills and understanding. Various materials are available to support enthusiasts and professionals alike in their journey towards mastering mechanical systems. Engaging with these resources will provide valuable insights and practical knowledge.

Books and Manuals

Technical manuals and specialized literature offer comprehensive information on machinery operation and servicing. Look for titles that focus on mechanical systems to get detailed instructions and illustrations, ensuring a solid grasp of the components and their functions.

Online Communities and Courses

Participating in forums and online platforms dedicated to machinery enthusiasts can foster learning through shared experiences. Additionally, consider enrolling in online courses that cover various aspects of machinery repair and maintenance, helping you delve deeper into the subject matter.