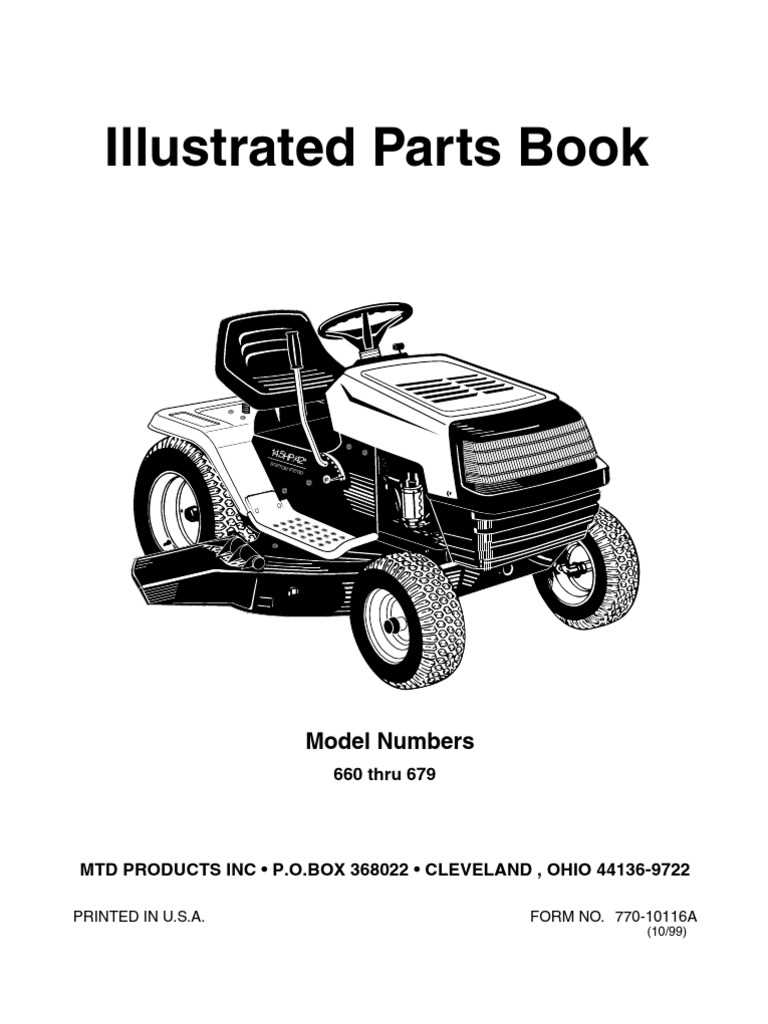

Ultimate Guide to Yard Machine Lawn Tractor Parts Diagram

In the realm of outdoor maintenance, familiarity with the components of your machinery is essential for effective operation and longevity. Knowing the various elements that make up these powerful tools can significantly enhance your efficiency in managing your green spaces.

Visualization plays a crucial role in grasping how each element interacts within the overall structure. By examining a comprehensive layout, users can better appreciate the functionality and importance of each segment, ensuring a smoother experience during usage.

Additionally, when challenges arise, having a clear reference can be the ultimate asset in troubleshooting issues. This knowledge empowers users to perform repairs and maintenance confidently, preserving the performance of their equipment over time.

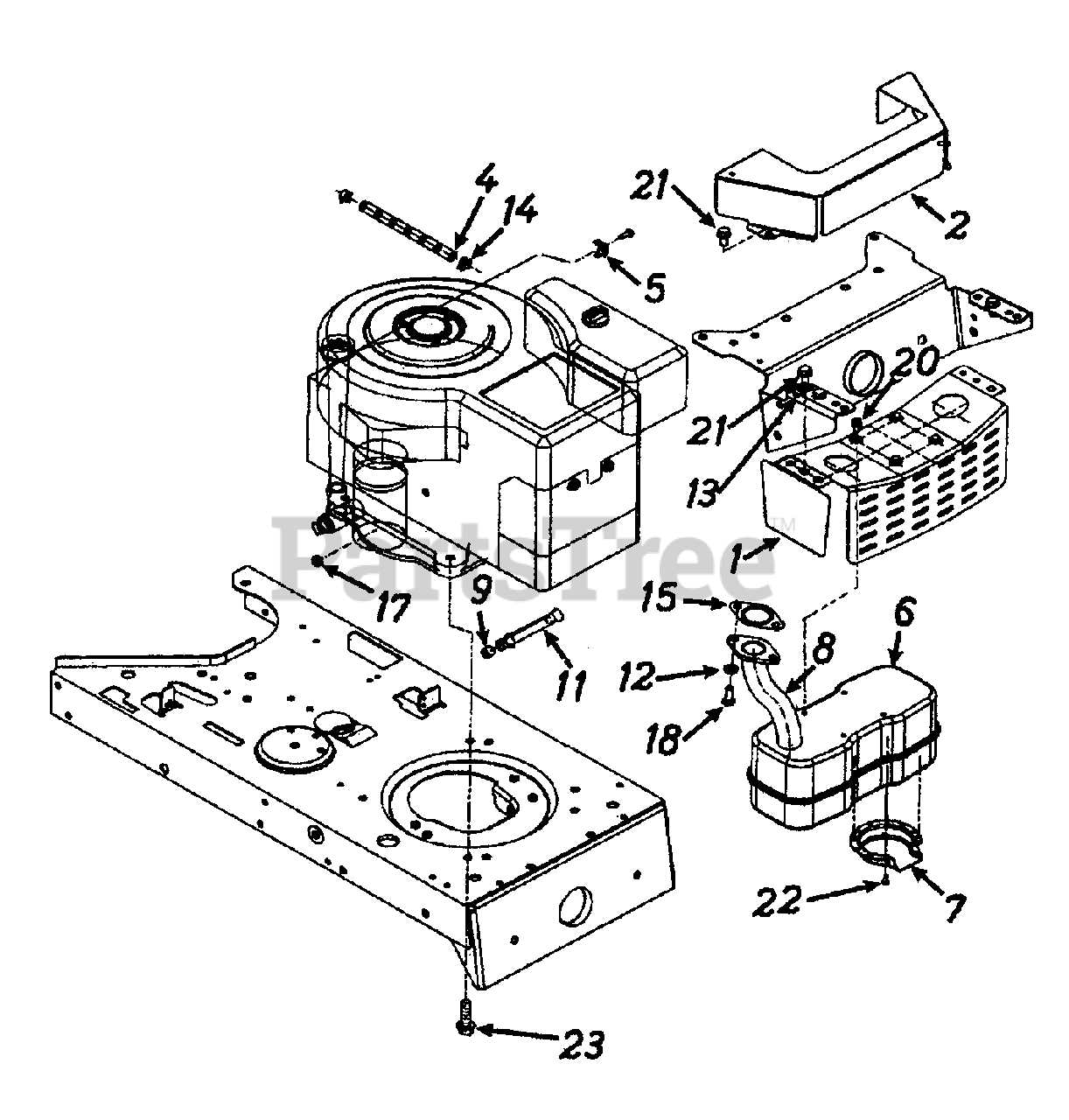

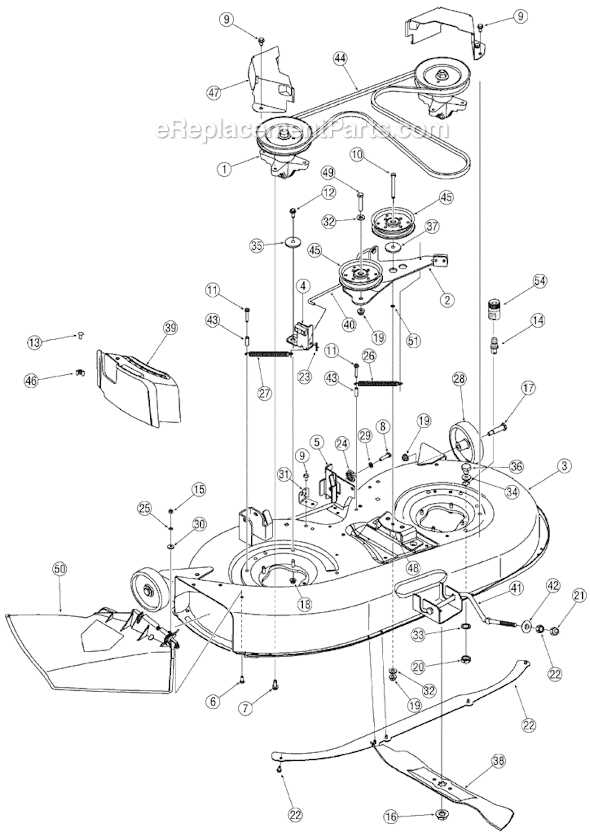

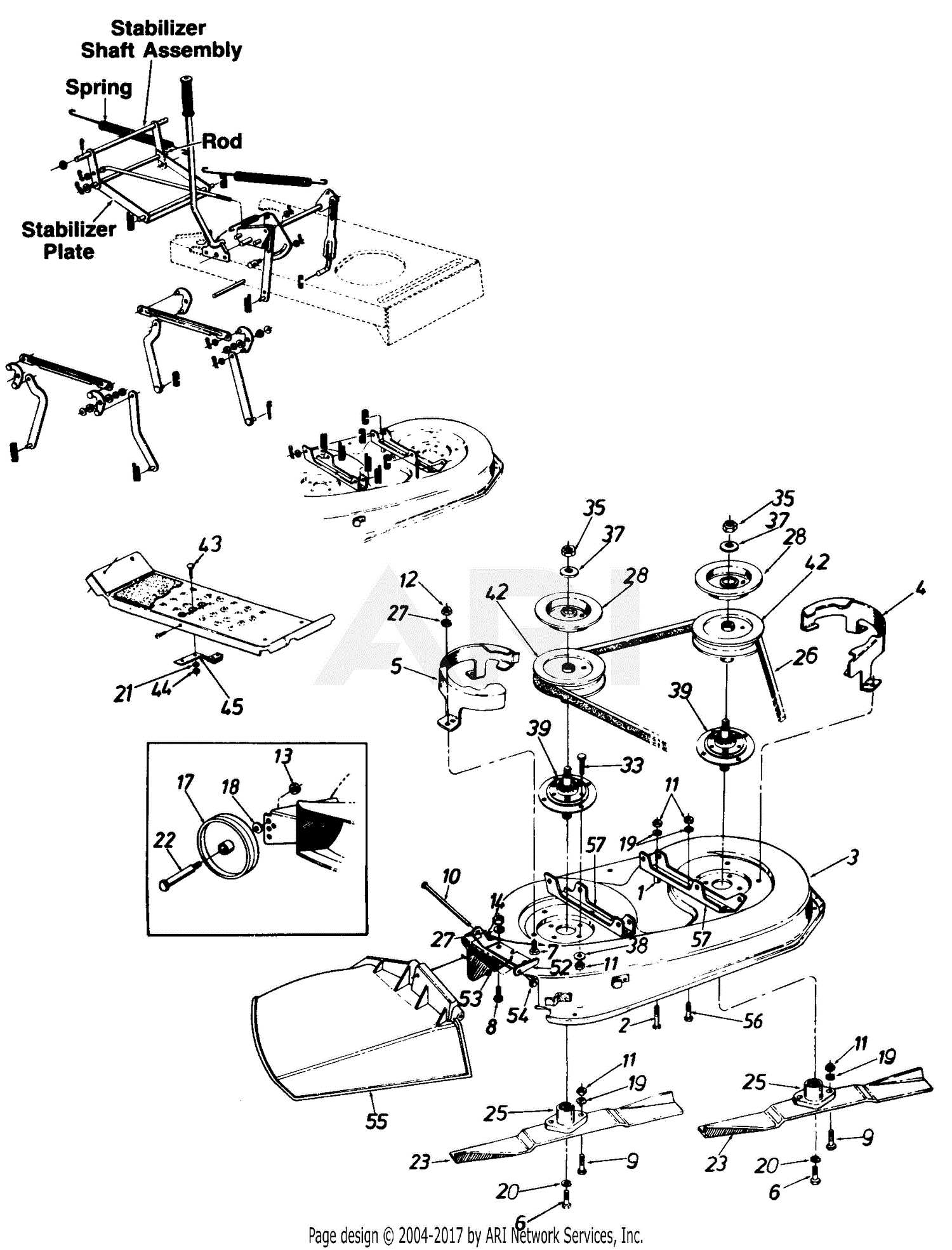

Understanding Lawn Tractor Components

Gaining insight into the various elements of a riding mower is essential for effective maintenance and repair. Each component plays a critical role in the overall functionality, contributing to a seamless mowing experience. Recognizing these features empowers users to make informed decisions regarding upkeep and troubleshooting.

Main Elements

The core features include the engine, transmission, and cutting mechanism. The engine provides the necessary power, while the transmission regulates speed and movement. The cutting mechanism, often equipped with blades, ensures an even and efficient trimming process.

Understanding these components aids in diagnosing issues and performing routine maintenance. Regular checks on belts, filters, and fluids can prevent potential breakdowns, ensuring longevity and reliability. Familiarity with these aspects ultimately enhances the performance of the equipment.

Common Issues with Yard Machines

Many outdoor equipment users encounter a variety of challenges that can hinder performance and reliability. Understanding these frequent problems can help in diagnosing and resolving issues more effectively, ensuring a smoother operation and prolonging the lifespan of the equipment.

Engine Troubles

One of the most prevalent difficulties involves engine performance. Symptoms such as difficulty starting, stalling, or uneven running can be attributed to fuel quality, spark plug wear, or air filter blockages. Regular maintenance and timely replacements are essential to prevent these complications.

Transmission Failures

Another common concern is related to the transmission system. Users may experience issues like slipping gears or unresponsiveness when shifting. These problems often stem from inadequate lubrication, worn components, or misalignment. Addressing these factors promptly can enhance efficiency and reduce repair costs.

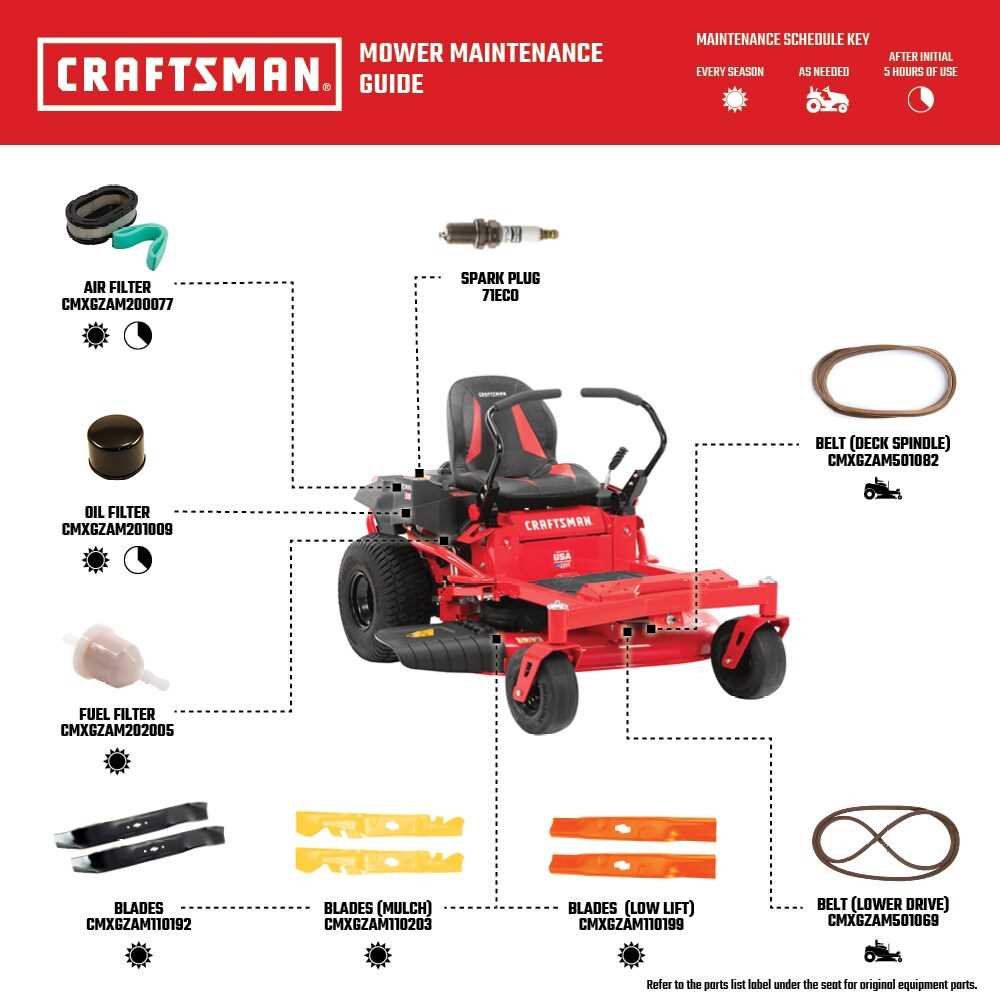

Importance of Maintenance for Longevity

Regular upkeep is essential for ensuring the durability and efficiency of any mechanical equipment. By adhering to a systematic maintenance routine, users can prevent unexpected breakdowns, enhance performance, and extend the operational lifespan of their devices. Consistent care not only minimizes wear and tear but also promotes optimal functionality, ultimately saving time and resources in the long run.

Preventing Wear and Tear

One of the primary benefits of maintenance is the reduction of wear and tear. Components that are routinely checked and serviced are less likely to suffer from significant damage. Regular inspections allow for the early detection of potential issues, enabling users to address them before they escalate into major problems. This proactive approach ensures that all parts operate smoothly, maintaining the integrity of the entire system.

Enhancing Efficiency and Performance

Another key aspect of consistent maintenance is its impact on overall efficiency and performance. Well-maintained equipment operates more effectively, which can lead to improved productivity. When all elements are functioning at their best, users experience fewer interruptions and greater reliability. This not only boosts satisfaction but also translates into better results in various tasks, underscoring the importance of a diligent maintenance schedule.

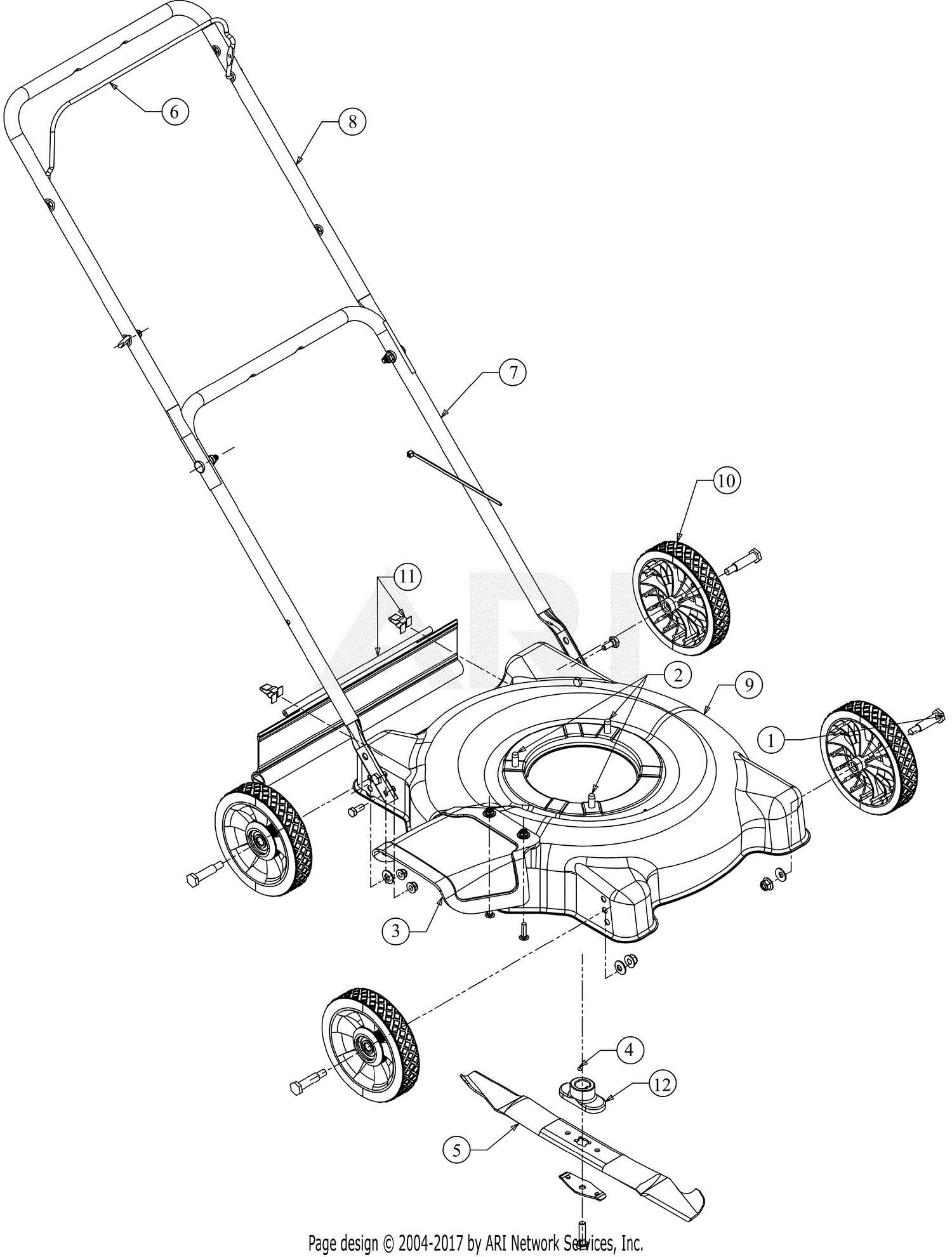

Identifying Essential Spare Parts

Understanding the key components of outdoor equipment is crucial for maintaining optimal performance and longevity. Each element plays a significant role, and recognizing which ones are essential can help in effective troubleshooting and repairs.

To aid in the identification of critical components, consider the following categories:

- Power System: This includes elements responsible for generating and delivering energy.

- Drive Mechanism: Essential for the movement and operation of the equipment.

- Cutting Assembly: Integral for achieving precise results in various tasks.

- Control Systems: These components enable user interaction and adjustments during operation.

- Safety Features: Important for protecting the operator and ensuring safe use.

By familiarizing yourself with these categories, you can more easily identify which components may need replacement or repair, ultimately enhancing the reliability and efficiency of your equipment.

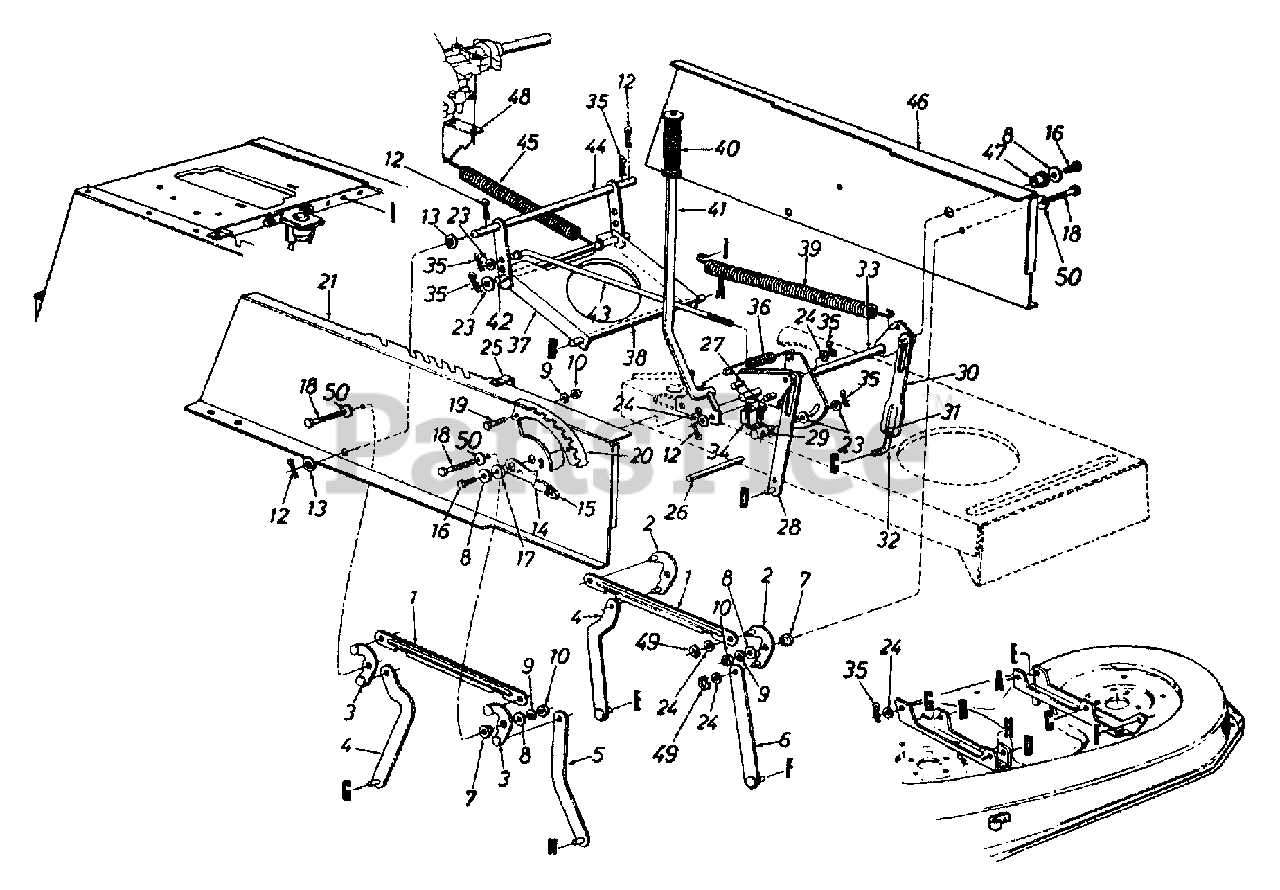

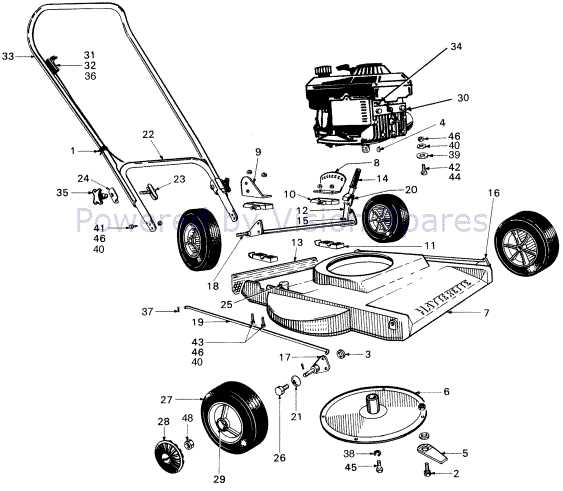

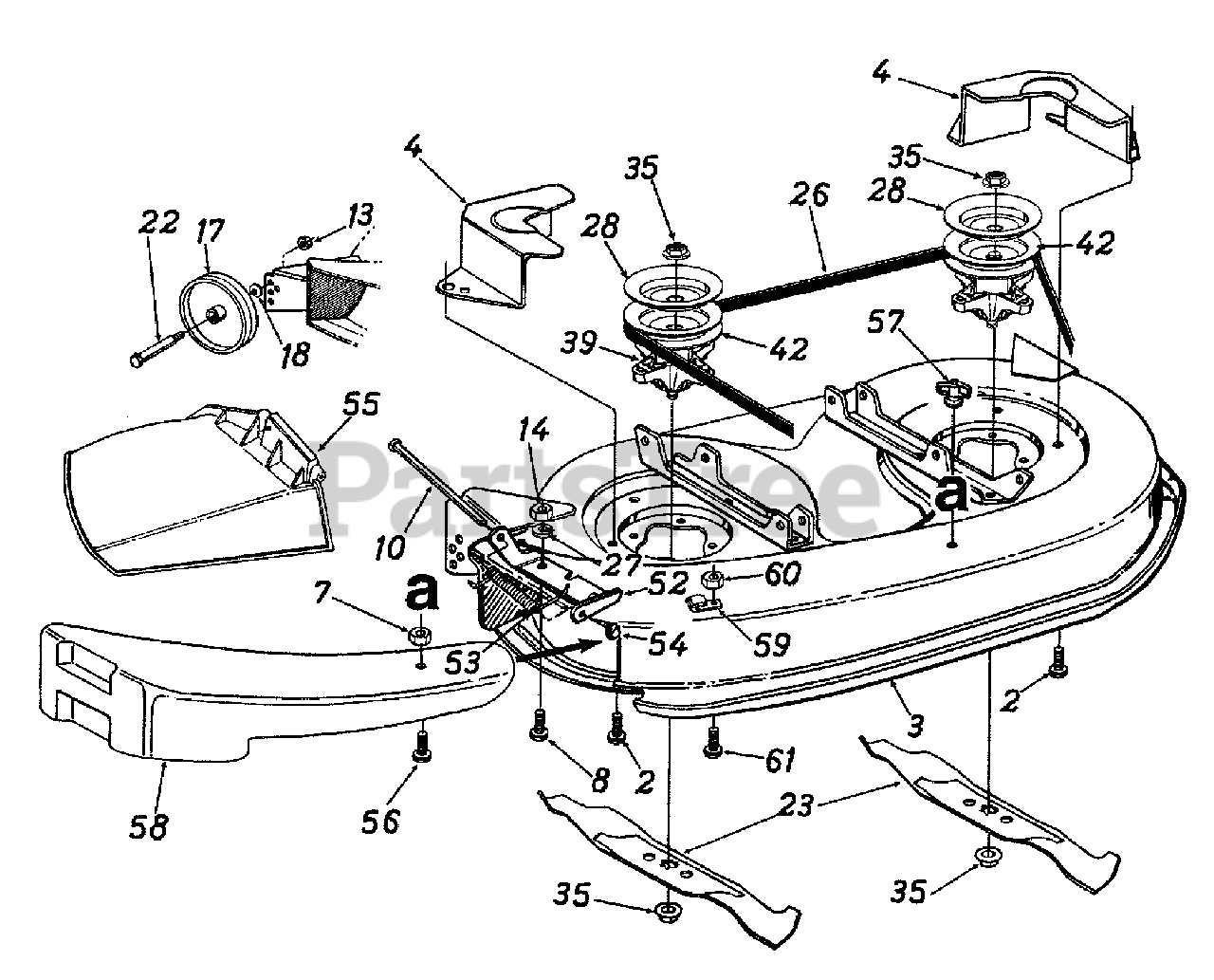

How to Read Parts Diagrams

Understanding schematic representations is essential for anyone involved in repair or maintenance. These visual aids provide a clear outline of components and their relationships, making it easier to identify what is needed for any task. Here are some key points to consider when interpreting these illustrations:

- Familiarize Yourself with Symbols: Each graphic uses specific symbols to represent different elements. Knowing what these symbols mean will help you decode the information quickly.

- Follow the Flow: Often, the layout is designed to show the sequence of assembly or functionality. Observing how parts connect can guide you through the repair process.

- Note the Labels: Descriptions or part numbers accompany most images. These notations are vital for identifying the exact components needed for replacement.

- Check for Variations: Some representations may include multiple versions of a component. Be sure to verify which version applies to your specific model.

- Consult the Manual: Whenever possible, refer to the accompanying guide for additional context and instructions related to the schematic.

By mastering the art of reading these visual representations, you can significantly enhance your repair skills and ensure successful maintenance of your equipment.

Tools Required for Repairs

When undertaking maintenance tasks on your equipment, having the right tools is essential for efficient and effective repairs. This section outlines the necessary instruments that can facilitate a smoother workflow, ensuring that you are well-prepared to tackle any issue that may arise.

Essential Tools

To get started, a variety of tools will be needed. Below is a list of fundamental instruments that will assist you in making the necessary adjustments and fixes.

| Tool | Purpose |

|---|---|

| Socket Wrench Set | For loosening and tightening bolts and nuts. |

| Screwdriver Set | For fastening and removing screws in various sizes. |

| Pliers | For gripping and twisting wires and other components. |

| Torque Wrench | To ensure bolts are tightened to the correct specifications. |

| Multimeter | For checking electrical systems and troubleshooting. |

Safety Equipment

In addition to standard tools, safety should be a priority. Always equip yourself with protective gear to ensure a safe working environment while performing repairs.

| Safety Gear | Purpose |

|---|---|

| Safety Glasses | To protect your eyes from debris and dust. |

| Gloves | For hand protection against sharp edges and chemicals. |

| Ear Protection | To safeguard against loud machinery noises. |

Safety Tips for Lawn Tractor Use

Operating outdoor equipment requires diligence to ensure a safe experience. Familiarizing oneself with essential safety practices can prevent accidents and enhance overall efficiency during tasks.

Here are key precautions to consider:

| Tip | Description |

|---|---|

| Read the Manual | Understand the equipment’s functions and safety features by thoroughly reviewing the user guide. |

| Wear Protective Gear | Use appropriate clothing, gloves, and eyewear to shield yourself from debris and hazards. |

| Check the Area | Inspect the surroundings for obstacles or hazards before starting operation to ensure a clear path. |

| Maintain Visibility | Always ensure clear sightlines and be aware of your environment to avoid potential accidents. |

| Follow Manufacturer Guidelines | Adhere to specified operational limits and maintenance schedules for optimal safety. |

Where to Buy Replacement Parts

Finding quality components for your outdoor equipment can enhance its longevity and performance. There are various sources to consider when seeking these essential elements, from specialized retailers to online marketplaces.

Local hardware stores often stock a range of necessary items and can provide immediate assistance. Additionally, authorized dealers offer original equipment, ensuring compatibility and reliability. For those preferring convenience, e-commerce platforms present a vast selection with the possibility of comparing prices and reading reviews.

Furthermore, consider checking forums and community groups where enthusiasts share recommendations and may offer used or hard-to-find items. Engaging with fellow users can lead to valuable insights and potential savings.

By exploring these options, you can ensure that your equipment remains in optimal condition for years to come.

Step-by-Step Repair Process

This section outlines a comprehensive approach to troubleshooting and fixing mechanical equipment. By following a structured methodology, users can efficiently identify issues and implement effective solutions.

Preparation Phase

- Gather all necessary tools and materials.

- Ensure you have the correct replacement components ready.

- Read the user manual for specific guidance related to your model.

Execution Steps

- Begin by disconnecting the power source to avoid accidents.

- Carefully remove any coverings or components obstructing access.

- Inspect each element for signs of wear or damage.

- Replace faulty items as identified during your inspection.

- Reassemble the equipment, ensuring all connections are secure.

- Reconnect the power source and conduct a test run to verify functionality.

Following these steps can lead to successful repairs and extend the lifespan of your equipment.

Upgrading Your Lawn Tractor Performance

Enhancing the efficiency of your outdoor equipment can significantly improve its functionality and longevity. With the right modifications, you can achieve superior results in your tasks, making your investment more worthwhile.

- Consider upgrading the engine for increased power and efficiency.

- Install high-quality blades for a cleaner cut and better overall performance.

- Explore advanced tire options for improved traction and handling.

- Evaluate the battery system for longer run times and reliability.

- Implement regular maintenance routines to keep all components in optimal condition.

By focusing on these areas, you can delve into a comprehensive upgrade process that ultimately transforms your equipment into a more capable ally for your outdoor projects.

Frequently Asked Questions on Repairs

This section addresses common inquiries related to maintenance and troubleshooting. Understanding the nuances of repair can enhance your efficiency and prolong the lifespan of your equipment. Below are some frequently asked questions that cover essential aspects of repairs and upkeep.

| Question | Answer |

|---|---|

| What should I do if the engine won’t start? | Check the fuel level, inspect the battery connections, and ensure the ignition switch is in the correct position. If the problem persists, consult the manual for further troubleshooting steps. |

| How can I tell if the blades need sharpening? | If you notice uneven cuts or a tearing of the grass instead of a clean cut, it may be time to sharpen the blades. |

| What maintenance is required for the transmission? | Regularly check the fluid levels and look for any signs of leaks. Following the manufacturer’s recommendations for servicing is also crucial. |

| How often should I change the oil? | Typically, it is recommended to change the oil every 50 hours of operation or at least once per season, depending on usage. |

| What can I do about excessive vibration during operation? | Inspect the wheels and blades for any damage or wear. Loose components may also cause vibrations, so tightening any loose screws or bolts can help. |